| Author |

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 7080 dual PTO install Topic: 7080 dual PTO install

Posted: 25 Oct 2015 at 9:01pm |

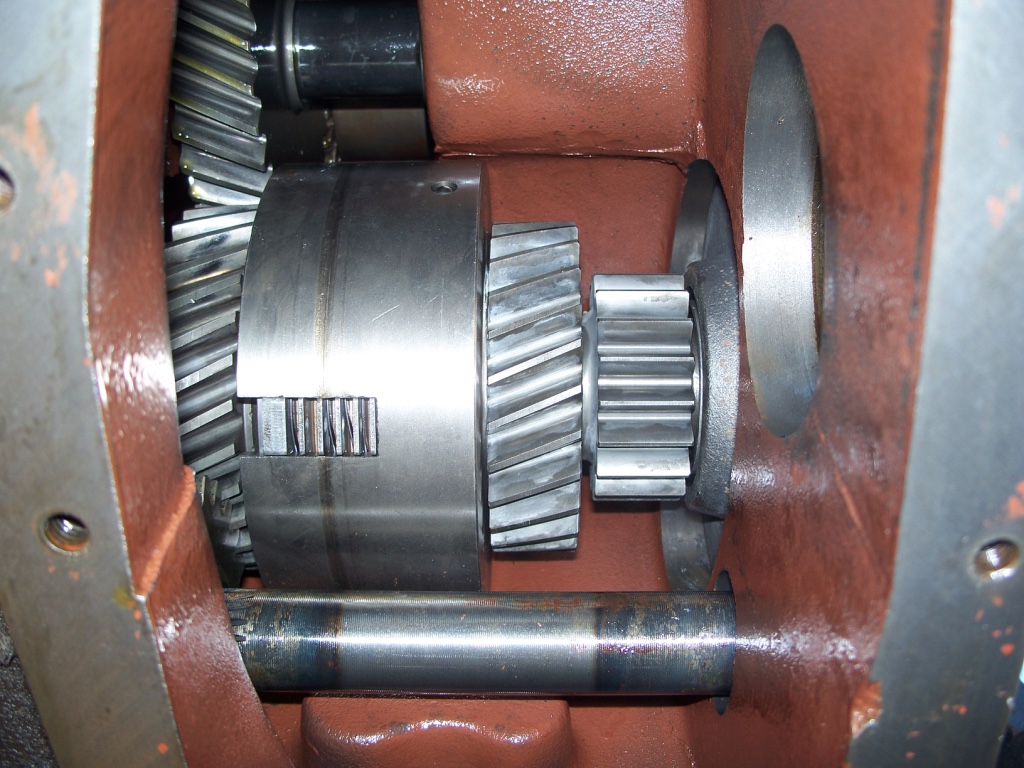

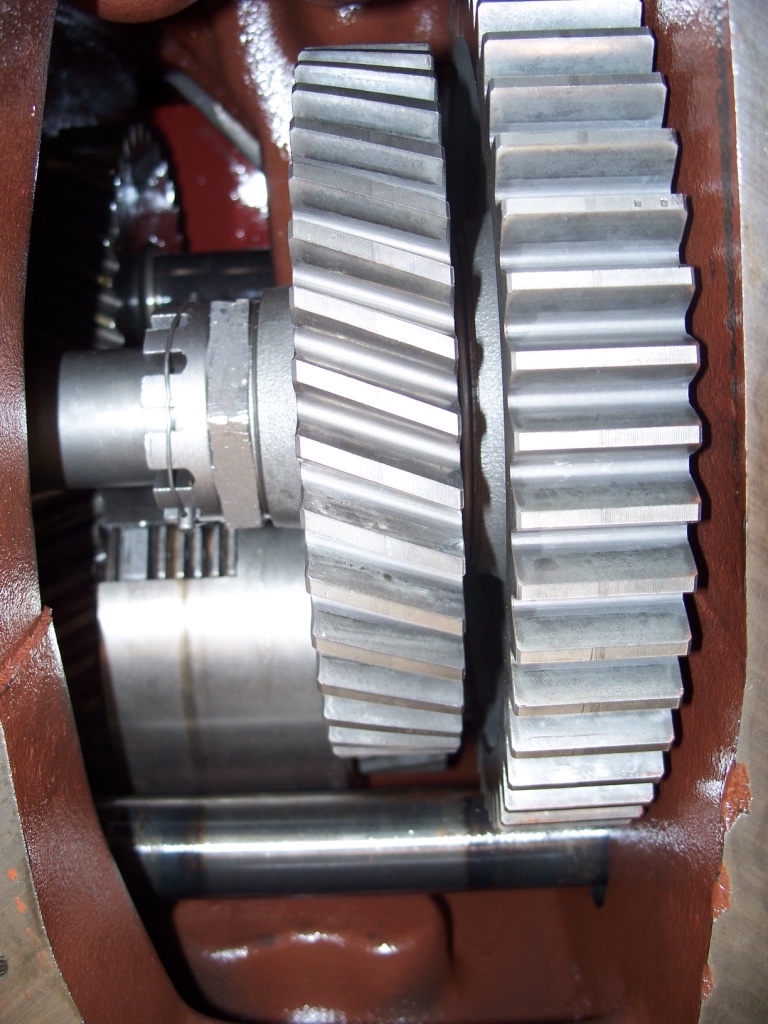

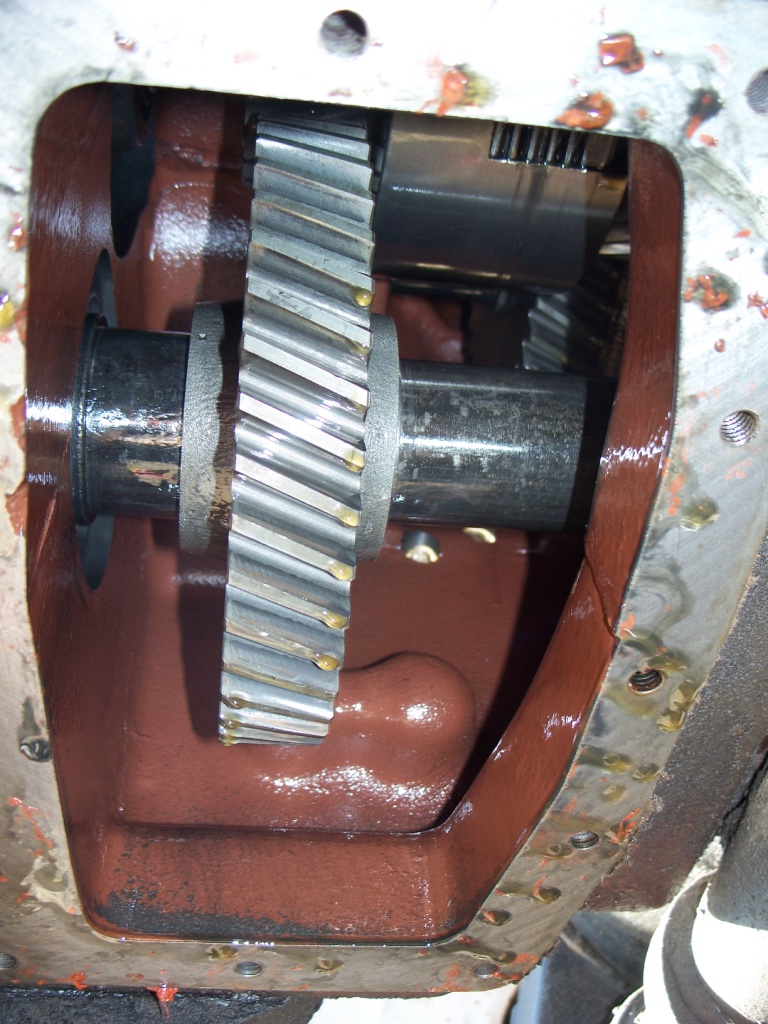

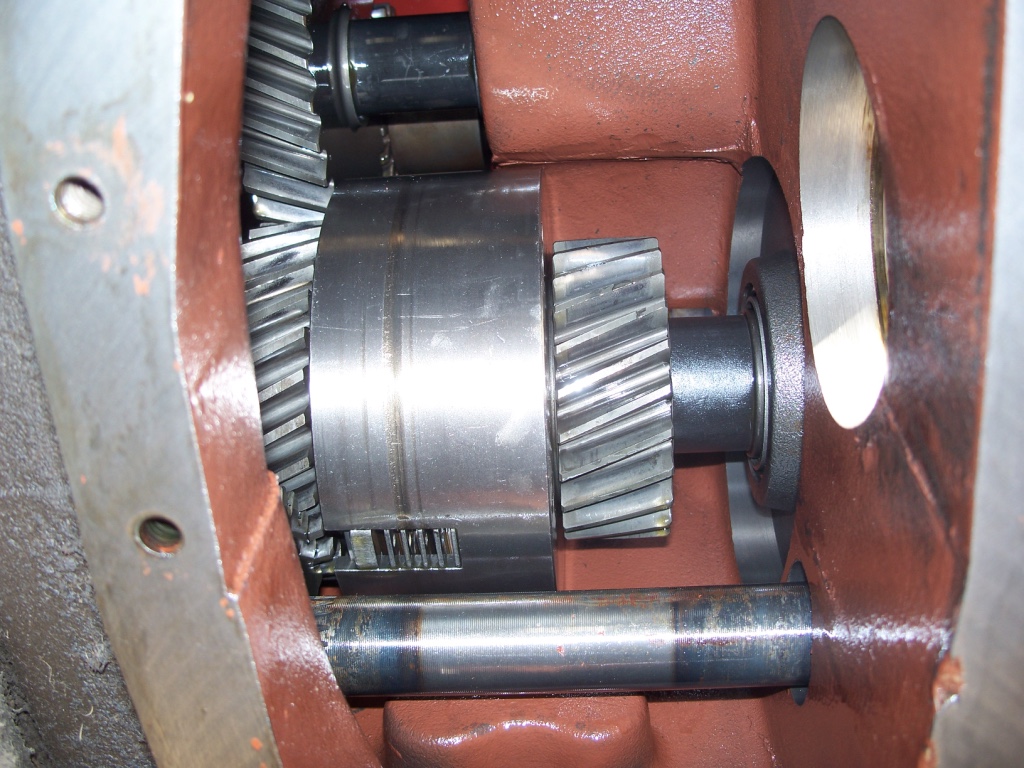

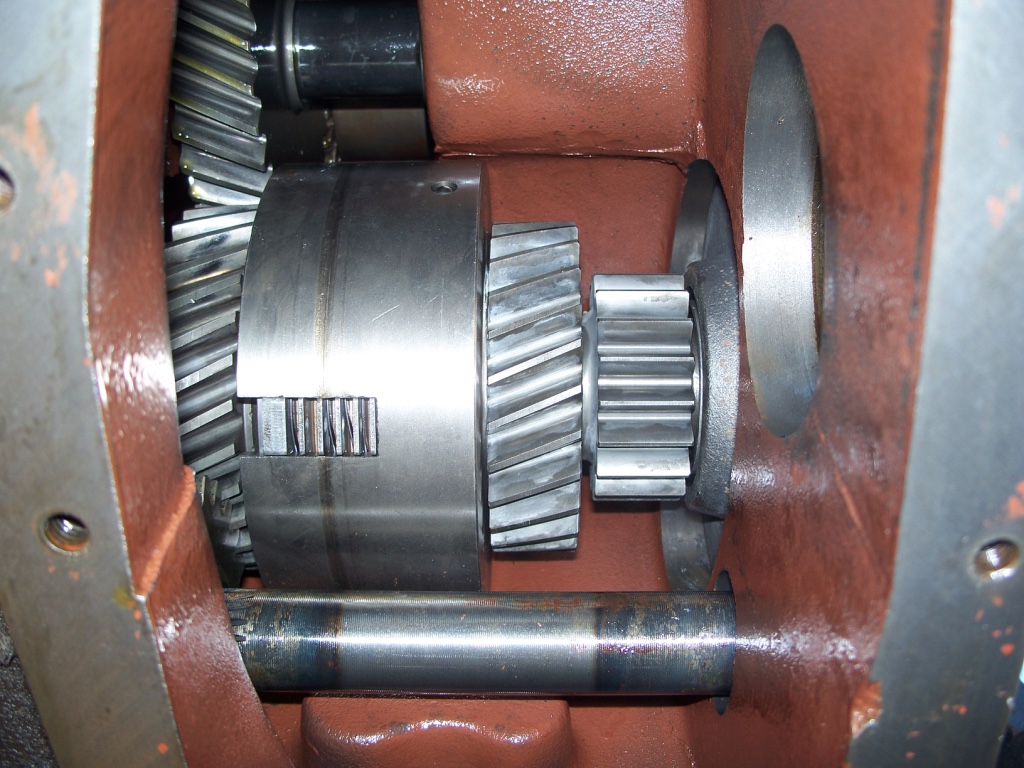

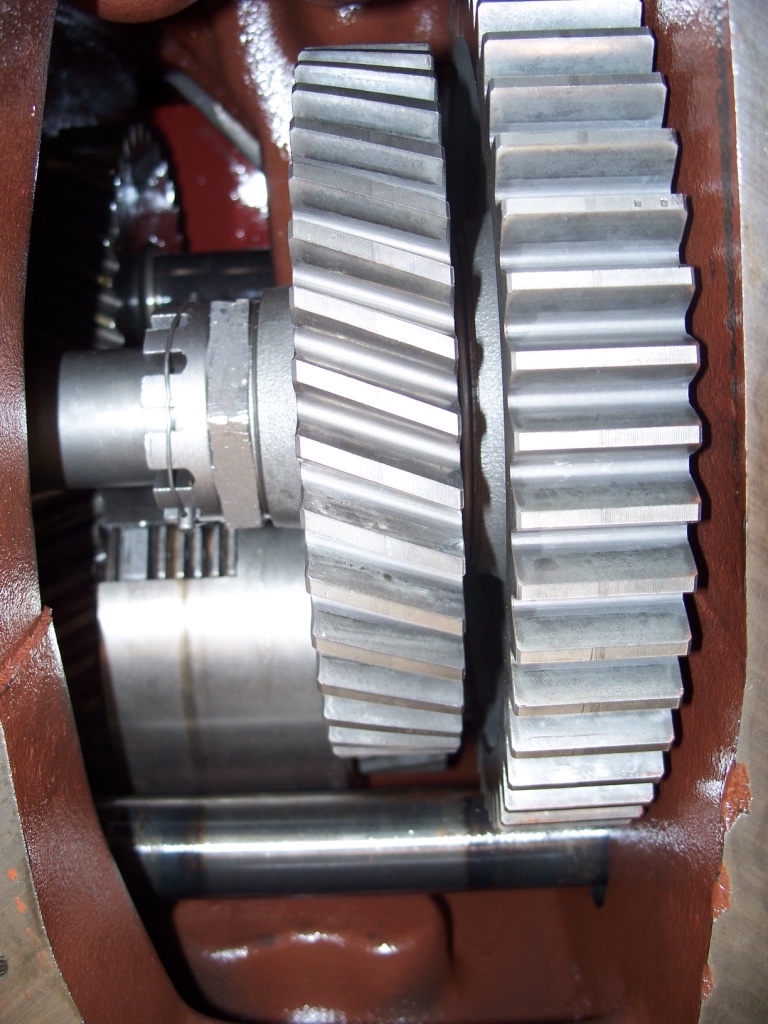

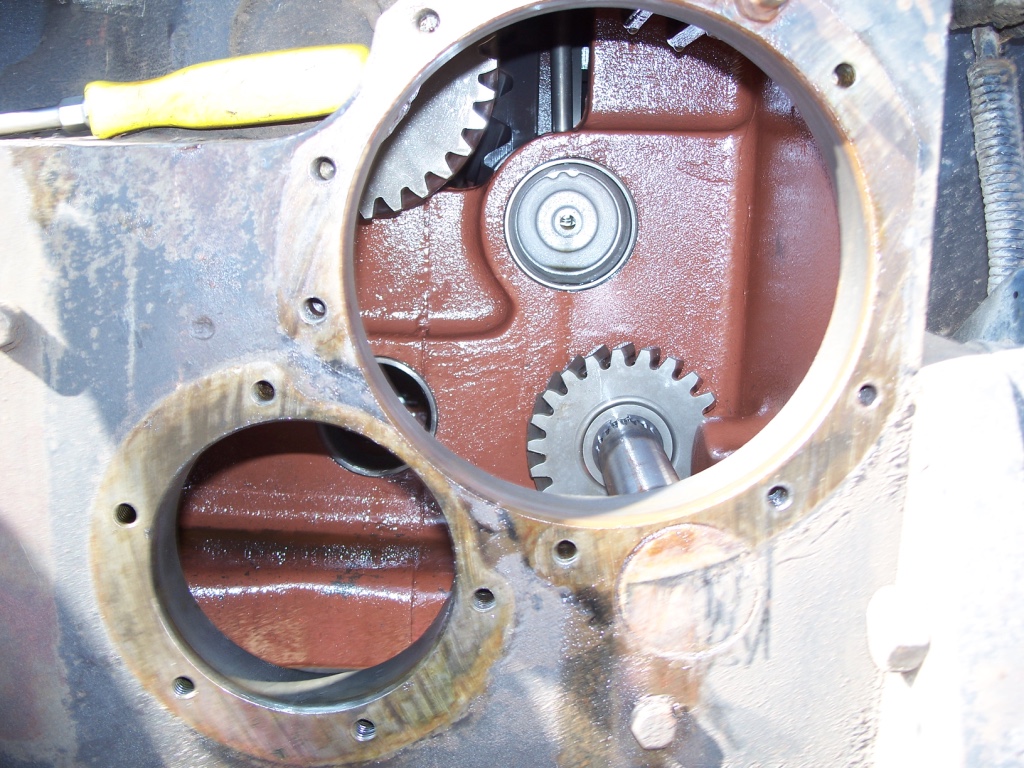

All the implements I have are 540 so I decided to convert my latest purchase, 7080, to dual 540/1000 PTO. This is what I got at the junkyard, I pulled it out of a 7045 rear end. They were nice enough to flip it upside down which made it awesome to pull out. This is what it looks like with the lower plate pulled, you can see this shaft is just made for the 1000 gear. This is a shot of the clutch pack just above the previous shaft asm. It has the spacer installed on the right of the picture instead of a 540 gear. I decided to dismantle everything to clean and reseal. This is the lower shaft asm. This is the clutch pack asm. This is where I ran into a little issue. I went to put the junkyard gear on the clutch pack and it was a no go. The original 1000 gear and spacer is on top, you can see it is about .250 wider than I can get on the shaft. So back to the junkyard I go, guess I should have looked at the parts book a little closer, remember in addition to the parts in the first picture you need the additional gear on the end of the clutch pack. The FSM says to set the preload on the clutch pack bearing set to 5-10 inch pounds, I tried to go with the lower end as they are used bearings, came out to 7 inch pounds.  This is the new clutch pack setup installed. That mark on the housing must have been from a previous repair(had red silicone on the lower plate) I didn't find any evidence as to where it came from. I took apart both the pistons, clutches, all looked good. I reseal the pistons as I like to make sure everything is good to go. The apply piston is teflon seals and the brake piston is cast rings. I have to say they looked perfect, but I figured it didn't cost much for seals.  This is the lower shaft asm installed. The FSM says to set it to 20 inch pounds more than the nominal turning torque. My dial type wrench only goes to 150in lbs and it maxed it out so the next bigger one I have is digital and that was difficult to get a correct turning torque, got it narrowed down to 185in lbs turning. I then tightened it up to an additional 20 in lbs. If I was going to do any more of these I would get a 250-300 in lb DIAL torque wrench. I changed the 2 axle filters filled it up, works perfect, nice and quiet. I know this is a long post, but everyone likes pictures and it does come up time to time about how to do this.

|

|

|

Sponsored Links

|

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Oct 2015 at 9:17pm Posted: 25 Oct 2015 at 9:17pm |

|

excellent post with pictures and descriptions. this should be made into a sticky for all to see what is necessary when converting 1000 only to dual pto

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Oct 2015 at 10:06pm Posted: 25 Oct 2015 at 10:06pm |

This is the parts list I used for this project. 70226012 Diff drain plug gaskets

70244461 PTO brake clutch end seal

70927925 PTO brake clutch inner cover oring

70923596 PTO brake clutch outer cover oring

70923663 PTO lines to outer clutch cover orings (2)

70925310 PTO shaft housing oring

70261957 PTO shaft large outer seal (dual 540/1000)

70928737 PTO shaft inner seal (dual 540/1000)

70923933 PTO clutch housing shaft orings

70253453 PTO clutch piston inner seal

70248064 PTO clutch piston outer seal

70267622 PTO brake clutch piston inner seal

70267623 PTO brake clutch piston outer seal

|

|

Ron(AB)

Orange Level

Joined: 27 Dec 2009

Location: Alberta

Points: 962

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Oct 2015 at 11:25pm Posted: 25 Oct 2015 at 11:25pm |

|

Very Helpful!

I have this on my "to do" list on a 8070.

Thanks again.

|

|

aras

Orange Level

Joined: 28 Jul 2011

Location: Weston, WI

Points: 665

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Oct 2015 at 9:26am Posted: 26 Oct 2015 at 9:26am |

|

Well done!!!

|

|

Kevin in WA

Orange Level Access

Joined: 08 Feb 2010

Location: Lynden, WA

Points: 612

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Oct 2015 at 10:47am Posted: 26 Oct 2015 at 10:47am |

|

Pretty sure the tooth count on that 7080 clutch pack gear is different also.

|

|

charlesbendal

Silver Level

Joined: 28 Nov 2015

Location: Fryburg, Pa

Points: 92

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Sep 2016 at 7:17pm Posted: 11 Sep 2016 at 7:17pm |

is their any way to get the pictures back up on this post i would love to see it

|

|

shameless (ne)

Orange Level

Joined: 08 Jul 2016

Location: nebraska

Points: 7463

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Sep 2016 at 10:53pm Posted: 11 Sep 2016 at 10:53pm |

|

me too...can't see the pics

|

|

Orange Blood

Orange Level

Joined: 29 Nov 2010

Location: ColoradoSprings

Points: 4053

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Sep 2016 at 11:01pm Posted: 11 Sep 2016 at 11:01pm |

|

The only way, would be for the original poster to upload them again, using the same file names. This happens anytime someone purges old pictures as there is a limit to how much we can have uploaded at any one time.

|

|

Still in use:

HD7 WC C CA WD 2-WD45 WD45LP WD45D D14 3-D17 D17LP 2-D19D D19LP 190XTD 190XTLP 720 D21 220 7020 7030 7040 7045 3-7060

Projects: 3-U UC 2-G 2-B 2-C CA 7-WC RC WDLP WF D14 D21 210 7045 N7

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Sep 2016 at 9:29am Posted: 12 Sep 2016 at 9:29am |

|

Like was said before you have to delete old photos before posting new ones. I understand their server space is limited for storage. I have them on the computer and will get them posted tonight.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Sep 2016 at 8:20pm Posted: 12 Sep 2016 at 8:20pm |

Well I re uploaded the pictures, looks like they are there. Of course I had to delete some others to do it, oh well. Here is one more I had that was not on the original post. Just the back half, empty.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Sep 2016 at 8:22pm Posted: 12 Sep 2016 at 8:22pm |

|

It is still working great, no leaks and quiet.

|

|

Tcmtech

Orange Level

Joined: 15 Apr 2015

Location: Minot ND

Points: 310

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Sep 2016 at 9:04pm Posted: 12 Sep 2016 at 9:04pm |

I did the same conversion to our 7050 by swapping the 7050's 1000 RPM single speed with the dual speed PTO and clutch from our 8030 that just does loader work.

Worked great all winter until I got into baleing this summer and somehow that pin that holds the crown nut in place broke in half and came out so I had to go back in and replace it.

Back when I did my swap I drilled and tapped the bottom access plate so that I had a drain plug there.

That made the going in and replacing the two seals and pin (8 or 10ga cotter pin now) so much cleaner faster and easier to do!

|

|

charlesbendal

Silver Level

Joined: 28 Nov 2015

Location: Fryburg, Pa

Points: 92

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Sep 2016 at 11:28am Posted: 13 Sep 2016 at 11:28am |

|

This is a fantastic post does anyone have an estimate on what the parts would cost from a salvage yard?

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Sep 2016 at 4:48pm Posted: 13 Sep 2016 at 4:48pm |

|

It's been about a year since I did this. The salvage yard I got the parts from was getting ready to be sold and I knew the owner fairly well so he let me pull the parts myself and charged me $400. I'm pretty sure that was a better deal that normal. The seals/filters from agco were about $300 if I remember correctly.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2017 at 9:46am Posted: 20 Jun 2017 at 9:46am |

|

I had a request to repost these pictures. They had been deleted due to space limitations on the server. Last time I saved them in it's own folder so it was a little quicker. Is there any way to put this in the knowledge section? Just a thought as I have gotten quite a few questions on it from time to time.

|

|

chadn

Bronze Level

Joined: 17 Jun 2017

Location: WI

Points: 3

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2017 at 4:53pm Posted: 20 Jun 2017 at 4:53pm |

|

Thanks for posting the pics. Makes it easier to follow.

So what I am seeing is, you used your 7080 rear end. 7045 guts inside.

I see the 5 bolt pattern on the housing, correct.

Looks like I need to hunt down a clutch pack assembly and lower shaft assembly.

7020 thru 7050 would work ?

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2017 at 7:04pm Posted: 20 Jun 2017 at 7:04pm |

|

I believe you can use parts from 7010 thru 7060, and 8010 thru 8050. There are some good people here that should be able to confirm or correct that. It makes the tractor much more useful for my operation, had no problems with it since I changed it over.

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2439

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2017 at 10:14pm Posted: 20 Jun 2017 at 10:14pm |

|

I believe that the higher horsepower tractors used 5 friction and separator discs whereas the smaller tractors only used 4. I would be sure to use a clutch pack with the extra plates in it. They can be added to the pack by just moving the snap ring to a different groove.

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5319

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Mar 2018 at 7:30pm Posted: 01 Mar 2018 at 7:30pm |

|

Mmmm, sounds above my knowledge level and my equipment! Thank you so much for posting this thread. I have not had any luck with the search. I must not be doing something correct.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3603

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Mar 2018 at 10:44am Posted: 02 Mar 2018 at 10:44am |

|

Excellent post. Thank you.

I have a 77' 7040 that is leaking oil at its 540/1000 pto. I've purchased an AGCO seal kit for it. When our weather improves, I'll be tackling it. While I'm in it, is there anything else I should check?

Edited by AC7060IL - 02 Mar 2018 at 10:48am

|

|

Orangejbird

Bronze Level

Joined: 08 Mar 2016

Location: Dallas, WI

Points: 7

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2018 at 11:21am Posted: 20 Jun 2018 at 11:21am |

AC7060IL wrote: AC7060IL wrote:

Excellent post. Thank you.

I have a 77' 7040 that is leaking oil at its 540/1000 pto. I've purchased an AGCO seal kit for it. When our weather improves, I'll be tackling it. While I'm in it, is there anything else I should check? |

Ours is a '76 and we need to do the same. BTT

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2018 at 9:56pm Posted: 20 Jun 2018 at 9:56pm |

If it is leaking out of that lower rear shaft area I think the biggest thing to worry about would be getting the correct turning torque on that lower assembly, the seal install is pretty basic. You certainly don't want it too loose. One of my sockets fit on the PTO shaft to put a torque wrench on. I guess you could check the large nut before you took it off and somehow put it on the same amount? I would probably get an inch pound torque wrench for an accurate measurement.

Possibly there is a shortcut some more knowledgeable people on here know?

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2018 at 9:59pm Posted: 20 Jun 2018 at 9:59pm |

|

Oh and I would use a good quality wire for that pin. Don't want that coming undone.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Oct 2019 at 9:19am Posted: 06 Oct 2019 at 9:19am |

|

Bump

|

|

tornado8070

Orange Level

Joined: 24 Mar 2013

Location: MI

Points: 1341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Feb 2020 at 4:09pm Posted: 10 Feb 2020 at 4:09pm |

|

Going through this process on and 8070. Have .025-.030 play on rear side of clutch between gears. Tighten nut and loose the free play in the drive gear. And ideas/help?

|

|

09’ DT205B, 08’ DT220A, 83' 8070 MFWD, 83’ 8070 85’ 8050 MFWD, 83' 8030, 82' 8010, 85’ 6080 MFWD, 84’ 6080, 79' 7020, 85' M3 RWD, 85' 920 diesel,AC C-50 forklift.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Feb 2020 at 6:36pm Posted: 10 Feb 2020 at 6:36pm |

|

Been a while since I had one apart, if I remember the 2 gears (540 & 1000) are splined to the shaft and they butt up against a lip in the center part, then you press the bearing on then a snap ring holds the bearing. Then on the clutch pack side, clutch pack goes on then the drive gear has 2 tapered bearings in it and the large staked nut holds it on and you tighten that nut down until you get 5-10 in lbs turning torque on that gear. 10 in lbs turning torque is fairly snug so it would be a good idea to have a tool to check it. If the 2 gears that are splined on are loose, possibly the bearing is not pressed on far enough? I can post some pages from the FSM later when I get home if needed, they might be more clear than me.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Feb 2020 at 6:49pm Posted: 10 Feb 2020 at 6:49pm |

|

Parts book is showing 2 different bearing numbers for each end of that shaft. Possibly 1 is slightly thicker allowing it to press on those gears more? I looked at my pictures and I could see I had 1 set with the staked nut but I don't remember if it looked similar to the other one. You're right I would sure want those splined gears to be on tight and not have a clearance.

|

|

tornado8070

Orange Level

Joined: 24 Mar 2013

Location: MI

Points: 1341

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Feb 2020 at 7:59pm Posted: 10 Feb 2020 at 7:59pm |

|

So the stake nut only tightens that side of the assembly/clutch pack? And the snap ring holds the gears on the opposite end? Tightening the stake nut will not remove play between the 540/1000 drive sprocket....

|

|

09’ DT205B, 08’ DT220A, 83' 8070 MFWD, 83’ 8070 85’ 8050 MFWD, 83' 8030, 82' 8010, 85’ 6080 MFWD, 84’ 6080, 79' 7020, 85' M3 RWD, 85' 920 diesel,AC C-50 forklift.

|

|

Unit3

Orange Level

Joined: 17 Oct 2009

Location: NC Iowa

Points: 5632

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Feb 2020 at 9:22pm Posted: 10 Feb 2020 at 9:22pm |

|

So why was there not a reversing PTO for a small 1000 and a BIG 1000?

|

|

2-8070FWA PS/8050PS/7080/7045PS/200/D15-II/2-WD45/WD/3-WC/UC/C

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

AC7060IL wrote:

AC7060IL wrote: