| Author |

Topic Search Topic Search  Topic Options Topic Options

|

timmiso

Bronze Level

Joined: 11 Apr 2016

Location: iowa

Points: 35

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 7060 hydraulic issues Topic: 7060 hydraulic issues

Posted: 17 Mar 2019 at 5:13pm |

|

Have a 7060 that I picked up last fall to redo. Worked good on auger this fall - raised a 10x71 auger to bin. Changed fluids/filters ran on grain vac - worked fine to fold out the auger - went to fold up and hydraulics are very slow and low pressure. Pulled the cap by the pto and put guages on - at first startup it was 600 psi, hit lever (cold oil) and it went to 1800-2000 ish but went there slowly - as in open valve and a quick count to 1 to get to psi. After initial valve motion, standby pressure dropped to the 300 ish range, full output was still in the 1800-2000 psi range. Needle is steady, but its hard to read and run lever at same time. Where do I go from here? Oil looked clean coming out but did have a fair amount of water in it. Filters were clean as well.

|

|

|

Sponsored Links

|

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Mar 2019 at 9:05pm Posted: 17 Mar 2019 at 9:05pm |

|

when you changed left filter, did you take the screen from old filter and install it in new filter with screen going in first? How does steering work now?

MACK

|

|

timmiso

Bronze Level

Joined: 11 Apr 2016

Location: iowa

Points: 35

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Mar 2019 at 9:33pm Posted: 17 Mar 2019 at 9:33pm |

|

I’m pretty sure I did. Took one side out at a time, matched to correct filter and put back in the way it came out. I can double check them tomorrow.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22059

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Mar 2019 at 7:18am Posted: 18 Mar 2019 at 7:18am |

|

With the engine off, pull back on both remote levers. They should "detent" into the raise position. If they don't detent fully into raise, you have a linkage problem with those levers. Get that gauge so you can see it from the seat !! If both remote levers can fully engage, now check your pressures again with the hydraulic oil a little warmer to allow pressures to change more quickly. I assume you have the rear end FULL of hydraulic oil?? If standby pressure is still at 300 and full pressure at 2,000, I guess I'd start by inspecting and shimming the low pressure compensator spool and making sure the spring isn't broken. Re-check pressures and set standby at 600 psi. If you can get 600 standby and hi pressure is still too low, then I guess you need to shim it as well. I've never had one that BOTH pressures were low without it being an internal problem with the pump, so we'll see. Broken swash plate spring or a pump simply worn out at the rotating block to the end plate ?? I did have one Customer install the right side filter in backwards once and it caused all sorts of issues. Like Mack said, what is your power steering like????????????

|

|

timmiso

Bronze Level

Joined: 11 Apr 2016

Location: iowa

Points: 35

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Mar 2019 at 8:15am Posted: 18 Mar 2019 at 8:15am |

|

Steering seems to work ok - maybe a touch weak when it’s been sitting and froze to the ground- when driving or on loose ground it’s normal.

|

|

timmiso

Bronze Level

Joined: 11 Apr 2016

Location: iowa

Points: 35

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2019 at 9:53pm Posted: 19 Mar 2019 at 9:53pm |

|

Levers lock out when engine is off -so range seems good. Oil is full. Got better look at gauges today- 350 on the standby, 1900-2000 when activated. I did pull the spring in compensator valve for standby pressure - looks good. Found a very thin couple washers in the shop, I would jump from 350 to 1500 even using the factory shims to my thin washer. As in my washer by itself would be 350, add in the thinnest shim and it’d jump to 1500. Tractor steers good. How many shims are normally in the low side - mine had 4. Hour gauge is around 7500, but it’s spent the last 20 years as an acerage tractor with just hay, so they wouldn’t have noticed low hydraulic pressure. Should I order a shim kit and see what happens, or assume the pump is worn and go from there?

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2019 at 10:37pm Posted: 19 Mar 2019 at 10:37pm |

|

Last one I did I ordered a .005 and .008 shim. All it took was one .005 shim to get to 550 from 300psi. A little goes along way.

|

|

Ron(AB)

Orange Level

Joined: 27 Dec 2009

Location: Alberta

Points: 962

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2019 at 6:27pm Posted: 20 Mar 2019 at 6:27pm |

|

Is it possible for anyone to post a pic of the compensator.

It seems a very common adjustment problem as these tractors get older...

Do you have to remove anything to get to it on a 8000 series?

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2415

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2019 at 7:58pm Posted: 20 Mar 2019 at 7:58pm |

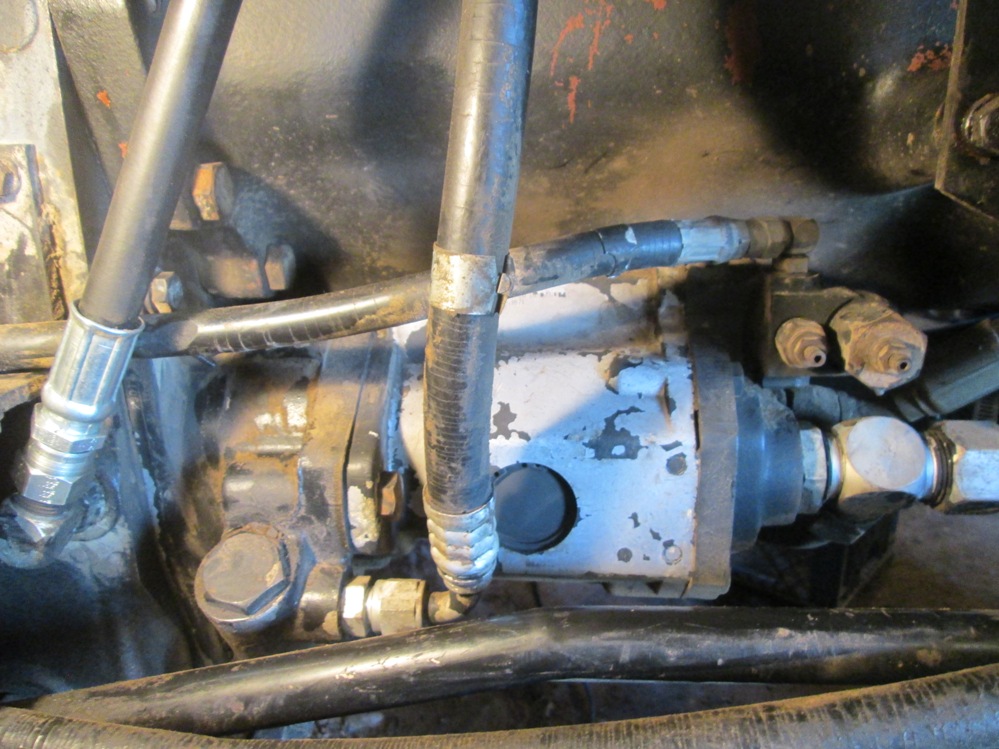

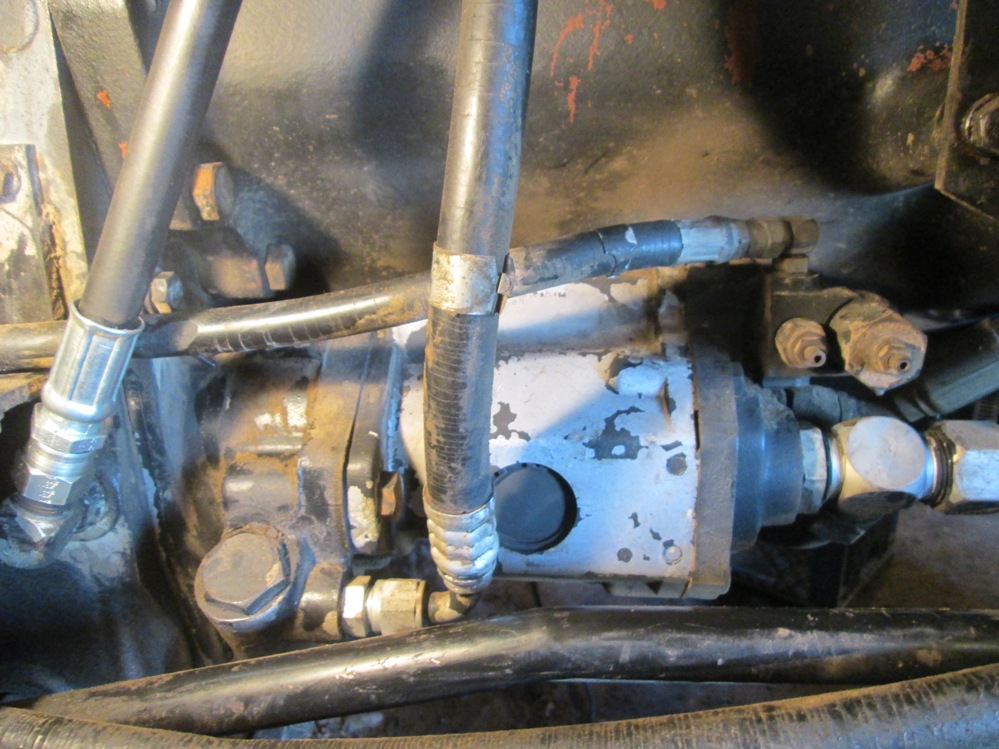

Compensator is on the front of the piston pump. This one is screw adjusted.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2019 at 8:17pm Posted: 20 Mar 2019 at 8:17pm |

Here is a picture of one that is adjusted with shims.

|

|

Ron(AB)

Orange Level

Joined: 27 Dec 2009

Location: Alberta

Points: 962

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2019 at 10:34pm Posted: 20 Mar 2019 at 10:34pm |

You guys are fantastic! Thank you from me and everyone else who looked at those pics.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)