| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2458

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: My problem for you to participate in if chosen: Topic: My problem for you to participate in if chosen:

Posted: 11 Mar 2024 at 9:32am |

My 11B keeps siphoning the transmission oil into the torque converter/flywheel housing exiting the tractor through the starter penetration once the oil level reaches that mark. This is when the engine is not running. When the engine is started, the rotating members violently eject this oil out through the starter nose onto the ground. The venturi pump which acts as a scavenge pump for this housing is working as the level will decrease to normal, but if the tractor has set for a few days, the transmission sump is too low to pickup oil and needs refilled. No external leaks anyplace I've found with floor, and belly pans removed and engine running at any rpm. The oil trace when the tractor has set for several days is evident around the starter nose as is the slick underneath. Not a problem if the tractor is started daily and the venturi pump reduces the oil level, but two days and it returns.

Here are a few snips from the manuals:

|

|

That's All Folks!

|

|

|

Sponsored Links

|

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34349

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2024 at 4:45pm Posted: 11 Mar 2024 at 4:45pm |

|

Check ALL the Vent Mushrooms for Choke up on the Main Trans Case. My 7G had one on each Brake Control housing, One for Each Final housing and One MAIN Vent on the Trans itself. Converter overflows to the Trans Main Case where a Volume of pressure in the Trans could cause as you see.

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2458

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2024 at 5:42pm Posted: 11 Mar 2024 at 5:42pm |

|

Thanks Dave. That was part of the first track I was on thinking the transmission was pressurizing above ambient. I cleaned all three vents found in the solvent tank and blown dry. All free flow air through them easily.

|

|

That's All Folks!

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34349

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2024 at 6:10pm Posted: 11 Mar 2024 at 6:10pm |

|

One down, now on the scavenge system recovery. Should be a line off the converter housing that diverts excess back to the trans, small line likely has a screen Filter unit in it. Small Syphon System Top Left of System diagram is that. Also has a Mechanical Link to trigger that, not ever seen one to know.

Edited by DMiller - 11 Mar 2024 at 6:13pm

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2458

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2024 at 6:56pm Posted: 11 Mar 2024 at 6:56pm |

|

Scavenge system does appear to be functional but requires oil flow from main charge pump to operate the venturi pump. The scavenge lines are steel tubing and I didn't notice any filter but I've not had anything broken open to ascertain if an insert filter exists. Nothing shown in parts manual for tractor. Once housing is evacuated it doesn't refill till the engine is shut down. Only valves I see in the system are the pressure regulating, and oil filter bypass. Again nothing broken open yet but not line checks or anything like that incorporated. All pressures appear to be normal. All pressures reduce with engine speed decay, or oil heating which are both normal.

|

|

That's All Folks!

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2458

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2024 at 7:25am Posted: 12 Mar 2024 at 7:25am |

Given the flywheel/torque converter housing is the low point in the system, if a valve is leaking someplace it would make sense for the oil to accumulate here. However, to siphon the oil would require a tube on the return to sump path that is submerged in the sump rather than just dumping into the transmission case. The only return path I see is the discharge of the pressure relief valve block. Running with this analogy, it is possible there is a stuck spool in the pressure relief valve block that is not closing it's port allowing a gateway for the oil to siphon from the transmission sump. Remember this tractor set several years and I'd be doubtful the transmission oil maintained a steady state after those years.

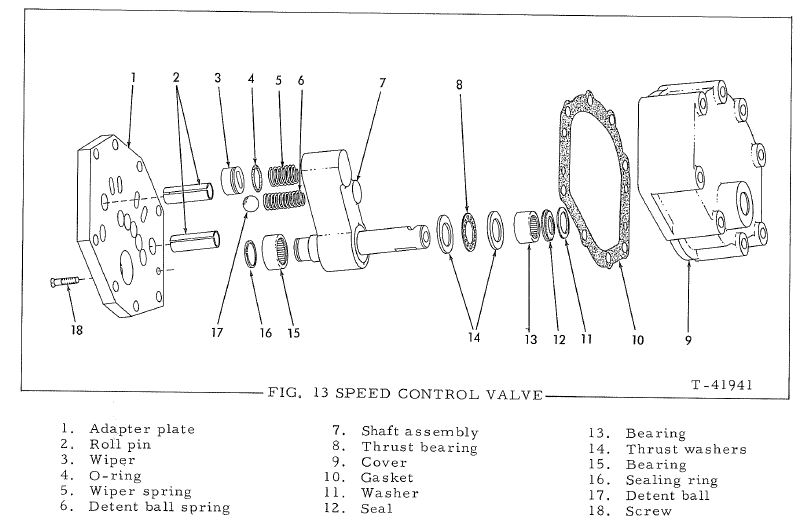

I may pull this block apart and evaluate it's interior as it's a rather simple affair. Another scenario is the leaking/seeping speed control valve which could allow an air break into the system doing much the same as referenced earlier.

Once I break into the system I'm certain things with wear will be found and repaired. Kinda nice to evaluate and chart prior to actually getting the hands dirty so to speak.

|

|

That's All Folks!

|

|

JD60

Bronze Level

Joined: 09 Mar 2024

Location: Michigan

Points: 2

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2024 at 11:01am Posted: 12 Mar 2024 at 11:01am |

Hello, I currently own a fiatallis745-C that will be needing a new engine soon. I read somewhere on the internet where you and Blazefork figured out what engine to use. If you could please let me know what engine you put in it and how it is done I would really appreciate it. If you are willing to call me my number is 616-293-2984. Thank you.

Jim Nagel

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88528

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2024 at 11:43am Posted: 12 Mar 2024 at 11:43am |

|

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88528

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2024 at 11:45am Posted: 12 Mar 2024 at 11:45am |

|

|

|

Like them all, but love the "B"s.

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 994

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2024 at 11:31pm Posted: 12 Mar 2024 at 11:31pm |

|

That Van Natta Bros link brings up a #404 but is available via the Wayback Machine link

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2458

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Mar 2024 at 6:06am Posted: 13 Mar 2024 at 6:06am |

|

Pretty certain I'm gaining on this problem and most likely the transmission oil, and the setting duration with no use is a player, but siphoning seems to have slowed a bit.

|

|

That's All Folks!

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2458

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar 2024 at 7:55am Posted: 15 Mar 2024 at 7:55am |

Couldn't leave it alone so started the tractor and while at very low

idle, dropped the transmission into gear and just let it idle for 1/2

hour or so while I'd putz around with other things. While the machine

was warming, I kept an eye on it for leakage with none seen. Getting

bored I removed the shifting console lower cover to ascertain where the

speed control valve is leaking. The main shaft the linkage operates upon

is where the leak physically is but without taking it apart, can't tell

if just the seal, or roller bearings supporting the shaft are bad. Not

any discernible "rocking" of the actuator shaft so assuming just needs a

seal shown as #12 in the diagram. After wiping the area clean one could see a seepage around this shaft and subsequent run down the face after a couple of minutes. Sure was an oily mess behind that cover too....

No rebuild kit available for these so will replace all the sealing rings inside to preclude further leakage best I can. Local hydraulic shop and seal supplier is pretty good at coming up with things that will work so no worries there.

Learn as you go type of thing.

|

|

That's All Folks!

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2458

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2024 at 7:12am Posted: 16 Mar 2024 at 7:12am |

Problem appears to have self corrected with usage. Started the engine this morning without any leakage. I did however drop the machine right into gear upon engine start and allow it to warm this way.

Happy at this time for certain. Good clutch, and transmission lube oil pressure(s), well within book specifications.

|

|

That's All Folks!

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88528

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2024 at 1:32pm Posted: 16 Mar 2024 at 1:32pm |

|

not too many problems SOLVE THEMSELVES... unless it is a partly stuck valve from setting, that loosens up are some use ??

|

|

Like them all, but love the "B"s.

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2458

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2024 at 2:50pm Posted: 16 Mar 2024 at 2:50pm |

[QUOTE=steve(ill)]not too many problems SOLVE THEMSELVES... unless it is a partly stuck valve from setting, that loosens up are some use ??[/QUOTE

That is what I suspect happened. Tractor set for years, (shedded) and the transmission fluid additive package became "sticky" which heat and movement once broke free probably aided I surmise. No idea but the problem didn't exist in the past.

Not calling it good by any stretch at this time, but it will continue to be monitored, and addressed if needed.

Edited by Codger - 16 Mar 2024 at 2:54pm

|

|

That's All Folks!

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2458

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Mar 2024 at 8:15am Posted: 17 Mar 2024 at 8:15am |

Started the tractor again this morning and let it run a few minutes. I

didn't see any leakage but didn't rev the engine up high as didn't allow

long enough of a warm up. Trans and lube pressures are all very good

cold and warm.

Looking at this photo you can see a switch incorporated into the speed control pedestal.

This switch precludes engine start if the safety lever, (shown as #2) is not set which cannot happen if the transmission is not in neutral. However, I noticed the switch plunger remained "in" no matter the position of the safety lever effectively defeating the interlock. I always use the safety lever myself and after talking with the prior owner last evening, he never knew it existed as never used the safety lock, but always ran the tractor a few minutes in neutral to allow cool down before shutting down. He never tried to start it in anything but the neutral position.

Just after removing the pedestal cover to ascertain that speed control valve leak, I seen this switch and initially thought it to be the back up alarm switch. This alarm is unplugged under the tractor seat. Further evaluation clearly showed it to be a safety switch having nothing to do with the alarm. These must have been problematic as there was a modification and switch change a few tractors built after mine.

|

|

That's All Folks!

|

|

JD60

Bronze Level

Joined: 09 Mar 2024

Location: Michigan

Points: 2

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2024 at 9:08am Posted: 19 Mar 2024 at 9:08am |

|

Codger could you please contact me regarding a Fiat- Allis 745-C wheel loader engine swap, thanks JD60 1-616-293-2984

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2458

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2024 at 10:33pm Posted: 20 Mar 2024 at 10:33pm |

Hi there JD60. I was not involved in the actual engine swap for this loader but the owner was working with a Detroit 6-71 for the retrofit. My participation was questionary only and the owner did find a flywheel to adapt for the swap.

If I were doing an engine swap in one of these I would probably go with a Cummins C8.3ltr engine as they are robust enough to take the abuse these endure. If not the Cummins then probably a Detroit Diesel as this owner was looking to do.

I don't actually know if he was successful in the swap or not as haven't heard back from him since his questions were answered. Hopefully he had success with the swap and is blissfully utilizing the loader.

|

|

That's All Folks!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)