| Author |

Topic Search Topic Search  Topic Options Topic Options

|

GaryL

Orange Level

Joined: 18 Jan 2015

Location: Oklahoma

Points: 704

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: GaryL's Model B Build Thread - Take a Peek Topic: GaryL's Model B Build Thread - Take a Peek

Posted: 14 May 2017 at 11:45am |

wbecker wrote: wbecker wrote:

Gary, nice job, and you should have clearance on the back side, no problem. Also it doesn't matter how tight the pin fits,it cannot come out and even a loose siding fit will work.

Glad you did it yourself, so much more rewarding!

Bill B

|

Thanks. I did a test fit and the backside of the steering shaft hits the cover. Seems whoever touched the box before I did ground the backside to clear. I'll have to grind down the other side, where the pin makes contact. At least I have something for reference.

My next challenge is to find some replacement bearings and then make a gasket for the cover.

|

|

|

Sponsored Links

|

|

|

wbecker

Orange Level

Joined: 29 Oct 2009

Location: STL

Points: 837

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2017 at 6:57pm Posted: 07 May 2017 at 6:57pm |

|

Gary, nice job, and you should have clearance on the back side, no problem. Also it doesn't matter how tight the pin fits,it cannot come out and even a loose siding fit will work.

Glad you did it yourself, so much more rewarding!

Bill B

|

|

Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152

|

|

GaryL

Orange Level

Joined: 18 Jan 2015

Location: Oklahoma

Points: 704

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 May 2017 at 9:39am Posted: 07 May 2017 at 9:39am |

After much delay and procrastinating, plus a failed attempt at getting a professional machinist to replace the pin, I tackled the job myself. It took about half an hour of work, where I ground the existing pin smooth so I could hit the stub with a center punch. After that, I set it up in my drill press and progressively increased the drill bit size until I could insert the pin. As it stands, the current friction fit is tight.

Does this look OK? The pin stands slightly proud from the backside. I haven't test fit everything yet with the worm gear, et al.

|

|

BenGiBoy

Orange Level

Joined: 11 Nov 2015

Location: Ashville, NY

Points: 696

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Aug 2016 at 7:37am Posted: 30 Aug 2016 at 7:37am |

Dan73 wrote: Dan73 wrote:

You could weld any somewhat course screen to the bottom of the mushroom cap. As I recall it is typically a screen with holes about the size of your pinky. |

I think that the holes in mine are smaller, but I would have to go look to make sure. I could get a picture if you want one.

|

|

'39 Model B

Tractors are cheaper than girls, remember that!

|

|

Dan73

Orange Level

Joined: 04 Jun 2015

Location: United States

Points: 6054

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2016 at 5:54pm Posted: 28 Aug 2016 at 5:54pm |

|

You could weld any somewhat course screen to the bottom of the mushroom cap. As I recall it is typically a screen with holes about the size of your pinky.

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22810

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2016 at 3:15pm Posted: 28 Aug 2016 at 3:15pm |

wbecker wrote: wbecker wrote:

If it was flush, it may be too short after you put a 45 on it, so you may have to get one from a good hardware store.

Bill B

|

It may be easier to get a new one a bit longer, but beveling the leading edge of the thread will NOT change the length of this one.

|

|

|

|

GaryL

Orange Level

Joined: 18 Jan 2015

Location: Oklahoma

Points: 704

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2016 at 2:44pm Posted: 28 Aug 2016 at 2:44pm |

Ken in Texas wrote: Ken in Texas wrote:

Farmer fix. Put a piece of panty hose over the mushroom cap in dusty conditions. Tape it securely to the Air Cleaner Pipe. If keeping the

Dirt dauber wasps out becomes a problem leave the panty hose on all the time. |

Oh brother! Now I'll have to order pantyhose online so I don't get any odd looks

Meanwhile, I sourced the oil seal for the steering box (SKF 9838 - Steering Gear Pitman Shaft Seal) from Rock Auto for $5.50 versus $10+ from many other sources. I also have a replacement steering pin.

I was able to contact Midwest Steering as a source for parts. Unfortunately, the bearings and races cost $68/kit (2 kits needed) and some shims can be purchased used. I need to call Matt Scott to see if he happens to have parts (no response to e-mail). I was hoping to have all the parts I need by Labor Day.

Edited by GaryL - 28 Aug 2016 at 2:47pm

|

|

Ken in Texas

Orange Level

Joined: 11 Sep 2009

Location: Henderson, TX

Points: 5919

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Aug 2016 at 5:02pm Posted: 27 Aug 2016 at 5:02pm |

|

Farmer fix. Put a piece of panty hose over the mushroom cap in dusty conditions. Tape it securely to the Air Cleaner Pipe. If keeping the

Dirt dauber wasps out becomes a problem leave the panty hose on all the time.

|

|

GaryL

Orange Level

Joined: 18 Jan 2015

Location: Oklahoma

Points: 704

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Aug 2016 at 1:19pm Posted: 27 Aug 2016 at 1:19pm |

Dan73 wrote: Dan73 wrote:

Mushroom caps normally have a corse screen to keep big bugs out. Typically the mess is held in by a metal thing that is spot welded to the container. But normally you can blow them out with air and soak them in diesel fuel and clean them without disassembly. If you have to take them apart the screens can be cleaned. As to oil just about anything will do I use 30 weight same stuff I use for motor oil just fill it to the fill line and check it once in a while if it looks bad water or dust dump it out and fill it up fresh.

|

|

|

Dan73

Orange Level

Joined: 04 Jun 2015

Location: United States

Points: 6054

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Aug 2016 at 10:42am Posted: 27 Aug 2016 at 10:42am |

|

Mushroom caps normally have a corse screen to keep big bugs out. Typically the mess is held in by a metal thing that is spot welded to the container. But normally you can blow them out with air and soak them in diesel fuel and clean them without disassembly. If you have to take them apart the screens can be cleaned. As to oil just about anything will do I use 30 weight same stuff I use for motor oil just fill it to the fill line and check it once in a while if it looks bad water or dust dump it out and fill it up fresh.

|

|

GaryL

Orange Level

Joined: 18 Jan 2015

Location: Oklahoma

Points: 704

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Aug 2016 at 10:02am Posted: 27 Aug 2016 at 10:02am |

I've searched the forum for how to replace the mesh material in the air cleaner and am a bit confused.

1) Are there a few spot-welds to be drilled? 2) What kind of oil is used? 3) Is there anything that should be inside the mushroom cap? The one on my tractor is empty.

|

|

GaryL

Orange Level

Joined: 18 Jan 2015

Location: Oklahoma

Points: 704

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2016 at 5:23pm Posted: 21 Aug 2016 at 5:23pm |

wbecker wrote: wbecker wrote:

If it was flush, it may be too short after you put a 45 on it, so you may have to get one from a good hardware store.

Bill B

|

That's what I figured. Normally, the adjusting screw should be proud of the lock nut by at least ¼" - 5/16" assuming the steering box has been properly maintained during its lifetime. Based on the photos I have posted, it's obvious to see mine hasn't.

Just another items on my list for my trip to ACE Hardware.

|

|

wbecker

Orange Level

Joined: 29 Oct 2009

Location: STL

Points: 837

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2016 at 4:27pm Posted: 21 Aug 2016 at 4:27pm |

|

If it was flush, it may be too short after you put a 45 on it, so you may have to get one from a good hardware store.

Bill B

|

|

Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22810

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2016 at 3:20pm Posted: 21 Aug 2016 at 3:20pm |

|

No need to replace it, just push the leading edge of the thread against a grinding wheel at a 45 degree angle, while you turn it a few times. Use a nut to check the threads before putting it back in.

|

|

|

|

GaryL

Orange Level

Joined: 18 Jan 2015

Location: Oklahoma

Points: 704

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2016 at 1:11pm Posted: 21 Aug 2016 at 1:11pm |

The adjusting screw Looks like it's been mashed quite a bit. It won't back out of the hole -- I had to screw it all the way in to remove it from the cover. I can't remember if that's normal or not. It was almost flush with the nut, so I'm wondering if I should replace it while I'm dismantling everything.

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22810

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Aug 2016 at 10:09pm Posted: 16 Aug 2016 at 10:09pm |

|

Well I put regular grease gun grease in my CA when I put a bearing in the pedestal and with the Woods mower hanging underneath, I could steer it with one finger, Grease in the pedestal and the gear box. Dad put the grease zerk in the gearbox probably over 50 years ago and it has never been rebuilt, it just wouldn't hold gear lube anymore.

|

|

|

|

Wdtractorman

Orange Level

Joined: 24 Sep 2013

Location: Kentucky

Points: 975

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Aug 2016 at 9:30pm Posted: 16 Aug 2016 at 9:30pm |

CTuckerNWIL wrote: CTuckerNWIL wrote:

Cornhead grease won't make a mess if you have no leaks and DON"T pump the box full with pressure. If cornhead grease gets out, gear oil will easier. |

Corn head grease is better that regular gun grease, but what I'm geting at is I think that gear oil is much better expecially if your going threw the trouble of rebuilding it frist. Iv tryed it both ways and it seams to me that oil steers easier. I may have over filled mine with grease too, I wasn't sure how much to use so I put I think 10 or 12 pumps. It work fairly well for a few months before it started leaking, but I use my b to mow with weekly too so that my have something to do with it too

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22810

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Aug 2016 at 9:13pm Posted: 16 Aug 2016 at 9:13pm |

|

Cornhead grease won't make a mess if you have no leaks and DON"T pump the box full with pressure. If cornhead grease gets out, gear oil will easier.

|

|

|

|

Wdtractorman

Orange Level

Joined: 24 Sep 2013

Location: Kentucky

Points: 975

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Aug 2016 at 7:25pm Posted: 16 Aug 2016 at 7:25pm |

This is the mess corn head grease makes

|

|

Wdtractorman

Orange Level

Joined: 24 Sep 2013

Location: Kentucky

Points: 975

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Aug 2016 at 7:20pm Posted: 16 Aug 2016 at 7:20pm |

|

Sorry about the double post I was trying to do to many things at once lol, Explains why I couldn't think of pin too lol. As far as the corn head grease it works OK but I have trouble with it working out of the steering box between the tube and the box, I'm going back with oil as sone as I get it where it will hold some.

|

|

wbecker

Orange Level

Joined: 29 Oct 2009

Location: STL

Points: 837

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Aug 2016 at 6:01pm Posted: 16 Aug 2016 at 6:01pm |

|

I think I got the bushing from MotionIndustrys.com you could get them from any bearing supply.

The Stud or Pin as it's sometimes called, I get from the John Deere dealer, it's for the Ross steering gear in the Model M, part number AM1515T. I have also gotten them from Tracy Martin.

Bill B

|

|

Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152

|

|

GaryL

Orange Level

Joined: 18 Jan 2015

Location: Oklahoma

Points: 704

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Aug 2016 at 5:56pm Posted: 16 Aug 2016 at 5:56pm |

wbecker wrote: wbecker wrote:

Gary, here is one I rebuilt some time ago. Hope it helps.

Also it is not recommended to use grease (I see the grease fitting).

Remove the grease fitting and install a 1/4" pipe plug, use heavy gear oil.

|

Thank you for both posts. That's exactly the information I am looking for.

As far as using oil or grease, I found a Jeep forum where someone details rebuilding a Ross steering box in a late-50s Jeep. He filled it with a mix of oil as was done in the era. A steering box discussion came up on an air-cooled VW forum I frequent, and one person who deals with various industrial chemicals stated John Deer Corn Head Grease is perfect for steering boxes. I'm planning to use the Corn Head grease and will do a write-up of my rebuild.

Thanks again.

|

|

Wdtractorman

Orange Level

Joined: 24 Sep 2013

Location: Kentucky

Points: 975

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Aug 2016 at 5:26pm Posted: 16 Aug 2016 at 5:26pm |

wbecker wrote: wbecker wrote:

Gary, here is one I rebuilt some time ago. Hope it helps.

Also it is not recommended to use grease (I see the grease fitting).

Remove the grease fitting and install a 1/4" pipe plug, use heavy gear oil.

I'm going to be noisy where can you get the bushings and that knob (idk the correct name) that on the end of the steering shaft from? I'm going to have to rebuild mine before long.

|

|

|

Wdtractorman

Orange Level

Joined: 24 Sep 2013

Location: Kentucky

Points: 975

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Aug 2016 at 5:26pm Posted: 16 Aug 2016 at 5:26pm |

wbecker wrote: wbecker wrote:

Gary, here is one I rebuilt some time ago. Hope it helps.

Also it is not recommended to use grease (I see the grease fitting).

Remove the grease fitting and install a 1/4" pipe plug, use heavy gear oil.

I'm going to be noisy where can you get the bushings and that knob (idk the correct name) that on the end of the steering shaft from? I'm going to have to rebuild mine before long.

|

|

|

wbecker

Orange Level

Joined: 29 Oct 2009

Location: STL

Points: 837

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 16 Aug 2016 at 12:26pm Posted: 16 Aug 2016 at 12:26pm |

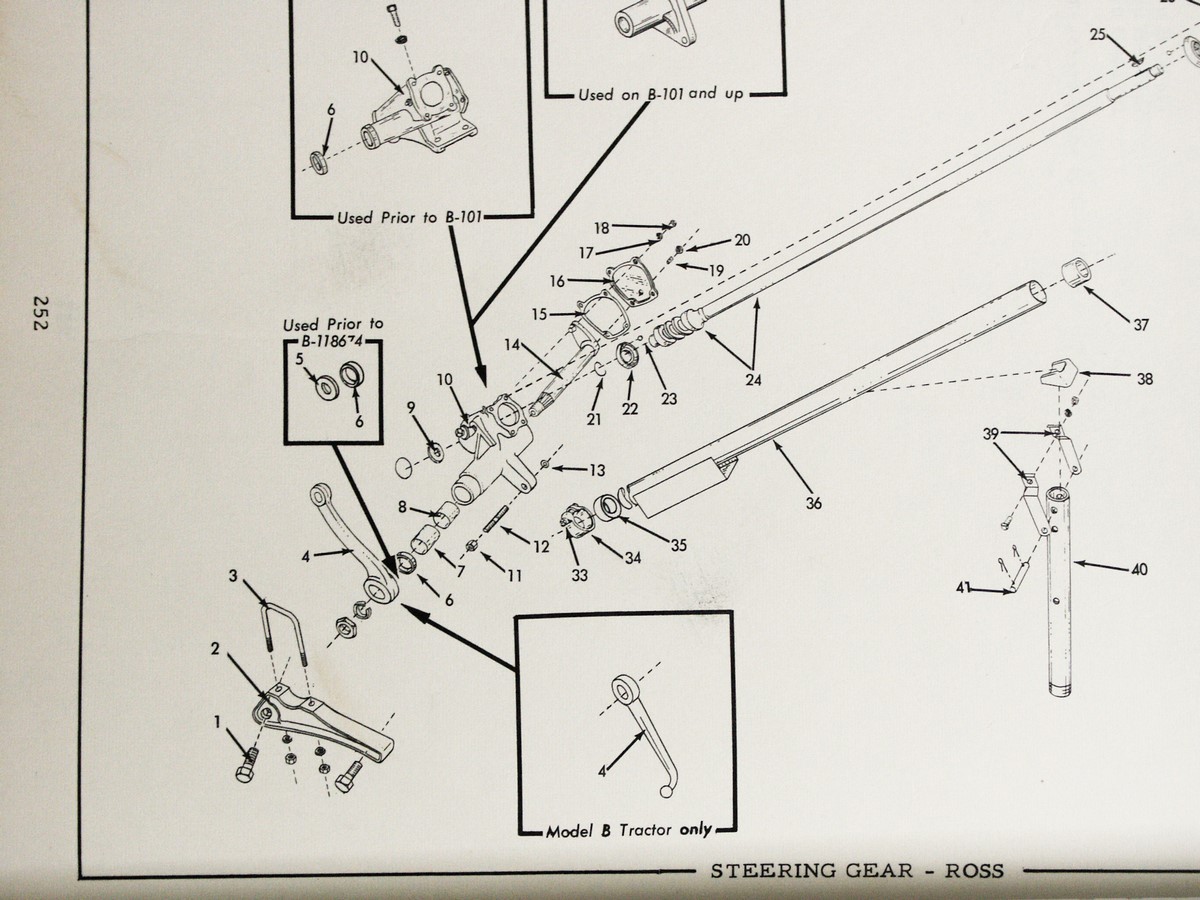

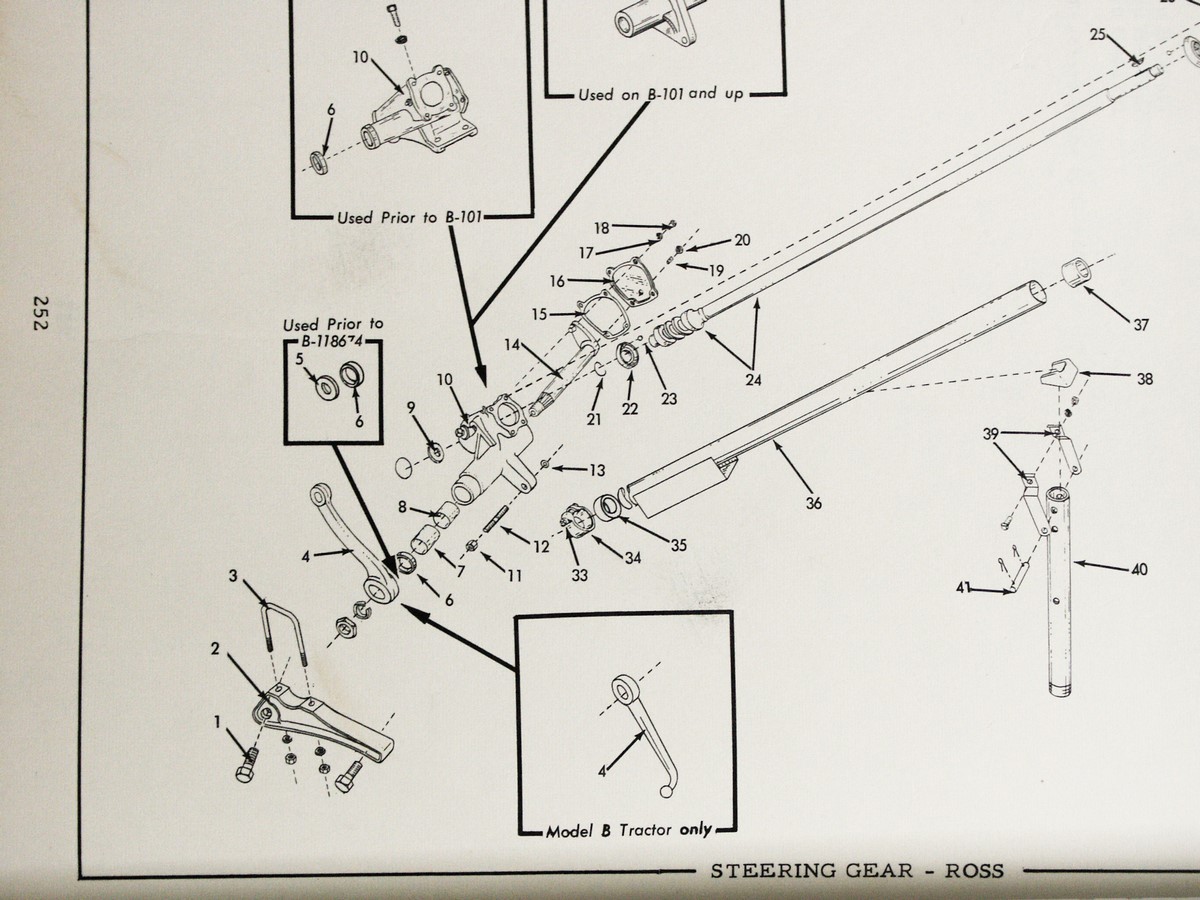

Gary, This diagram is for B&C disregard the parts on the lower left they are for a C.

|

|

Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152

|

|

wbecker

Orange Level

Joined: 29 Oct 2009

Location: STL

Points: 837

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 16 Aug 2016 at 12:03pm Posted: 16 Aug 2016 at 12:03pm |

Gary, here is one I rebuilt some time ago. Hope it helps. Also it is not recommended to use grease (I see the grease fitting). Remove the grease fitting and install a 1/4" pipe plug, use heavy gear oil.

|

|

Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152

|

|

GaryL

Orange Level

Joined: 18 Jan 2015

Location: Oklahoma

Points: 704

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Aug 2016 at 4:16pm Posted: 14 Aug 2016 at 4:16pm |

|

Does anyone have an exploded diagram of the Allis B steering box?

|

|

BenGiBoy

Orange Level

Joined: 11 Nov 2015

Location: Ashville, NY

Points: 696

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2016 at 8:44am Posted: 26 Jul 2016 at 8:44am |

|

I have an extra steering box, I don't know if it is good or not, it might not be, but it might still have the bearings or whatever else you might need. PM me if you are interested....

|

|

'39 Model B

Tractors are cheaper than girls, remember that!

|

|

Thad in AR.

Orange Level Access

Joined: 12 Sep 2009

Location: Arkansas

Points: 9291

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jul 2016 at 7:03pm Posted: 25 Jul 2016 at 7:03pm |

|

Gary I looked through all the B parts I could find and didn't see any steering box parts. I found a good complete box for a C but It won't fit your B. I'm still looking for pics.

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22810

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Jul 2016 at 10:48am Posted: 24 Jul 2016 at 10:48am |

GaryL wrote: GaryL wrote:

BTW: Is the ended being boogered up going to be an issue? It looks like a pressed-in retainer that can't be removed now due to the housing being distorted.

|

Stick a big screw driver or a pry bar in under that seal and pry it out. Then file any burrs out of the bore and make a slight chamfer on it. A die grinder with a light hand would be real handy for this.

|

|

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

wbecker wrote:

wbecker wrote: