| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Jeff K

Silver Level

Joined: 15 Oct 2015

Location: Michigan

Points: 202

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D10 Series 3 Restoration Topic: D10 Series 3 Restoration

Posted: 11 Oct 2016 at 7:59pm |

|

Guys, I am restoring a D10 Series 3 and I started it up tonight after just under a year of starting the restoration so it was sitting for a long time but it started up pretty well. There are however some issues I am hoping I can get some help with. They are:

1. I have an oil leak in the oil pan gasket area, So I am going to remove the oil pan and put on a new gasket. Does anyone have any advice to help me get it sealed up with no leaks.

2. My oil pressure gauge was at the low end of normal. Its a brand new gauge. Is the oil pump accessible when the pan is removed and is it a big job to replace?

3. The temp went up into the red (barely) and then settled in at right about the red line. The water pump is brand new as is the thermostat. When I took the tractor apart it didn't even have a thermostat in it. Any advice?

4. I bought a brand new muffler that has slits in where it enters the manifold but the slits are visible (3/8") when the muffler is in position. This causes an exhaust leak. Has anyone else ever run into this?

Thanks

|

|

|

Sponsored Links

|

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10832

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2016 at 8:09pm Posted: 11 Oct 2016 at 8:09pm |

|

Did you rebuild engine or is it just like you got it? Tracy

|

|

No greater gift than healthy grandkids!

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54397

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Oct 2016 at 8:10pm Posted: 11 Oct 2016 at 8:10pm |

On the Oil pump, requires splitting the tractor, IIRR.

On the gasket, get a shop manual from agco, it will have the procedure, to use for best results...

Oil filter type can change pressure.

Temp gauge is notoriously off, on both my 10 and 12, it sits right next to the ex. manifold. Take an IR thermometer, and check. Mine reads +40ºF, on the tractor vs what the gun says...

On the muffler, you might have to cut/grind for a perfect fit... |

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6369

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Oct 2016 at 5:40am Posted: 12 Oct 2016 at 5:40am |

On the oil pan you can try and tightening the bolts a little. Don't over do it as you can warp the pan. Or maybe someone has done this in the past. You can take it off and try and fix it. Just don't cake silicon all over it....

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

Jeff K

Silver Level

Joined: 15 Oct 2015

Location: Michigan

Points: 202

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Oct 2016 at 5:56am Posted: 12 Oct 2016 at 5:56am |

|

I did not rebuild the engine. It ran well when I got it and I checked the compression and it was good so I decided not to rebuild the engine.

Jeff

|

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6369

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Oct 2016 at 6:11am Posted: 12 Oct 2016 at 6:11am |

where is the leak? sides or back/front?

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

Jeff K

Silver Level

Joined: 15 Oct 2015

Location: Michigan

Points: 202

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Oct 2016 at 7:00am Posted: 12 Oct 2016 at 7:00am |

|

The leak is in the front Charlie. I believe (hope) it is the oil pan gasket. I should have changed it when everything was apart but I was lazy.

Jeff

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88482

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Oct 2016 at 12:24pm Posted: 12 Oct 2016 at 12:24pm |

its not uncommon for the front crank shaft seal to leak if its OLD.......... clean the area and look ABOVE the pan to see if the leak is the seal prior to pulling the pan.... If you do remove the pan, get a new gasket and glue it to the pan and let it set overnight so it will not slide... then put sealer on the gasket and install pan to block.

-

Oil pump is not accessable from the pan. Have to break the motor to belllhousing flange to see the rear pump. Your pressure is not too bad. If you remove the pan, check the suction tube and screen prior to reinstalling the pan.

|

|

Like them all, but love the "B"s.

|

|

Jeff K

Silver Level

Joined: 15 Oct 2015

Location: Michigan

Points: 202

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Oct 2016 at 3:38pm Posted: 12 Oct 2016 at 3:38pm |

|

Thanks Steve. I will check carefully but it is hard to see. Worst Case scenario is I will replace the pan gasket and then if the leak doesn't stop I will get after the front crank seal. How much of a tear down is the front crank seal?

Jeff

BTW - I am going to live with the oil pressure as is.

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1857

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Oct 2016 at 6:25pm Posted: 12 Oct 2016 at 6:25pm |

And also adding to what Steve (Ill) offered if you do separate the block from the bellhousing it would be reasonable to check to see if there is any wear on the cross pin that drives the oil pump. Have seen the pin wore nearly in half. This would be a good time to replace, or repair if needed.

If it wears through the engine will have no oil pressure. Good Luck...

Orangeman

|

|

Jeff K

Silver Level

Joined: 15 Oct 2015

Location: Michigan

Points: 202

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Oct 2016 at 8:14pm Posted: 12 Oct 2016 at 8:14pm |

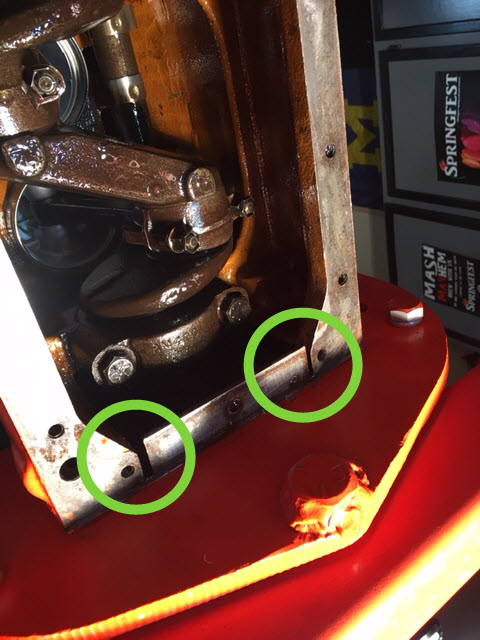

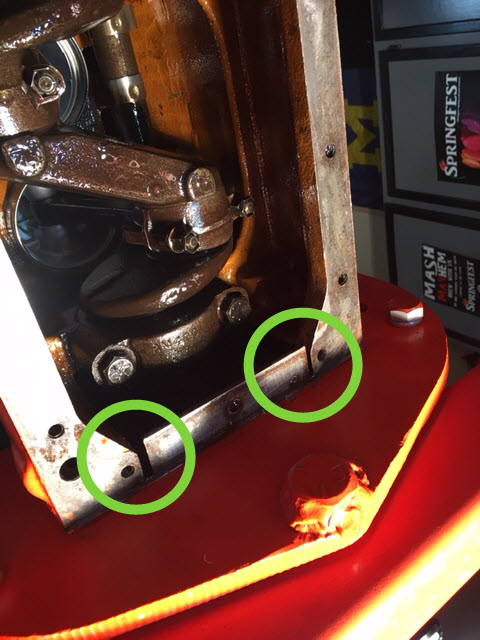

Guys, I have removed the oil pan and have a new gasket and I am going to clean it all up and re-install it. The pic below shows two areas that were gooped up with some type of flexible sealant. I took that stuff out when cleaning everything up and now I have to re-apply something in those areas because they are big gaps that will definitely leak oil. Questions are: 1. Is laying a really thick wad of sealant in those areas a correct method? 2. What type of sealant should I use for this? 3. When I put my new gasket (cork) on should I use that same sealant on both sides of the gasket? Thanks guys :) Jeff

|

|

mherndon

Bronze Level

Joined: 30 Apr 2012

Location: Tennessee

Points: 87

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Nov 2016 at 2:27pm Posted: 21 Nov 2016 at 2:27pm |

I'm getting ready to replace oil pan gasket on 1963 D-15. I want to see your replies to this same procedure. I saw one method of putting thin coat of silicon to hold gasket in place to block with bolts in to keep it from shifting while it firms up. Then use vaseline on the outside of the gasket for the pan to go against. Lightly tighten up bolts to around 5 lbs. torque. Not sure if this is correct way, but I do see some logic there.

Mark

Edited by mherndon - 21 Nov 2016 at 2:29pm

|

|

D-15, Old dealer in Smithville, TN

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)