| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D19 Diesel engine work Topic: D19 Diesel engine work

Posted: 19 Mar 2016 at 7:33pm |

Started removing the engine for a little engine rebuild, this one will be getting 6 NOS pistons and sleeves,gasket set, ex-manifold and a hand full of more NOS parts the owner has just for this tractor. It's nice installing NOS parts again just like it was back in the good old days. Like all jobs you have to start somewhere. lol

Edited by Don(MO) - 20 Mar 2016 at 9:30am

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

|

Sponsored Links

|

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7574

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Mar 2016 at 8:43pm Posted: 19 Mar 2016 at 8:43pm |

|

Nice looking tractor. I am sure it's in good hands now!

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2016 at 6:42pm Posted: 20 Mar 2016 at 6:42pm |

|

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Mar 2016 at 8:24am Posted: 21 Mar 2016 at 8:24am |

|

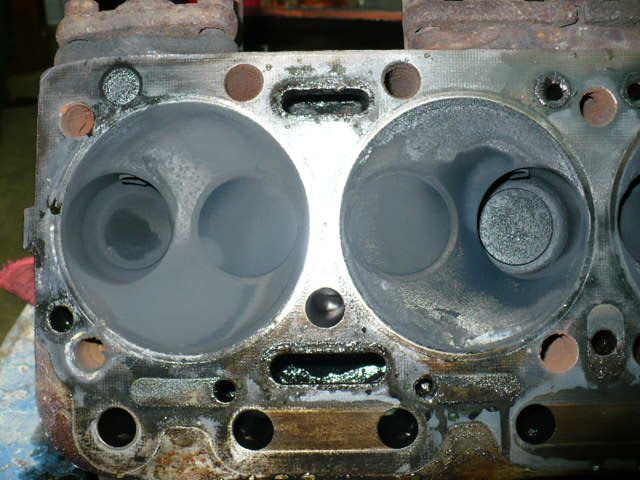

Don is that considered a PC head? Leon Cmo

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8744

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Mar 2016 at 9:59am Posted: 21 Mar 2016 at 9:59am |

|

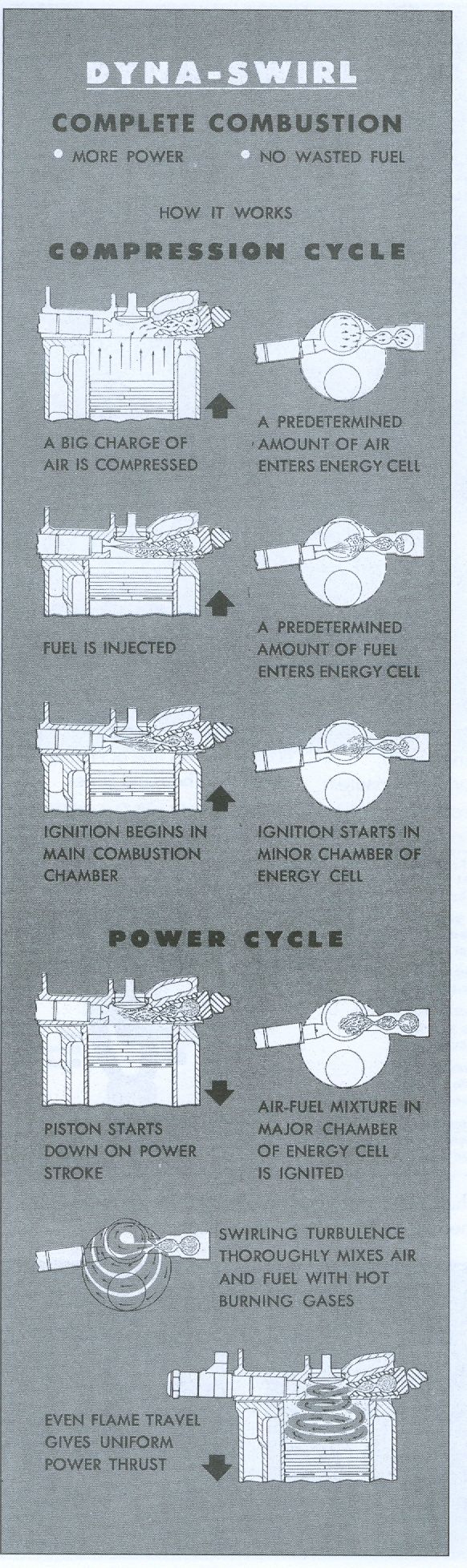

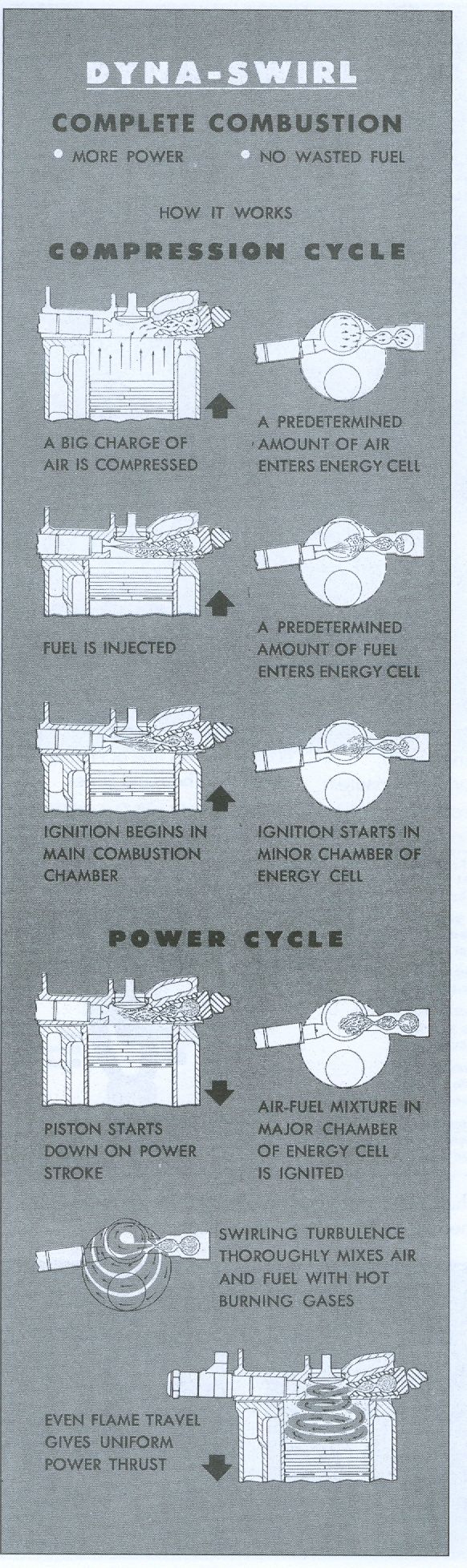

Sorta,,Lanova is diff than than other pre cup systems

|

|

FHOliver

Bronze Level

Joined: 11 Sep 2009

Location: Elgin Il

Points: 58

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Mar 2016 at 1:44pm Posted: 21 Mar 2016 at 1:44pm |

|

Don, Ive wanted to thank you for some time now for the great info and pics. It helps tons of guys. Also have a D19 story to share. 1978 I worked in a dealer and we did a lot of work for one farmer who was all allis. His d19 had 10,000 hrs on it and i mean they were hard hrs. he wasnt exactly gentle. It limped in on about 4 cylinders and I rebuilt it for the first time, eng never was touched before. The block was so bad cracked and low sleeves and everything you could think of was wrong. We just orderd a new block and it showed up in 3 days from batavia ill. dont remember cost. Dont ya wish we had a crystal ball and ordered extras ha ha. I Uncrated it, steam cleaned it, and carried block to shop area. later looked at shipping papers and block alone was between 280 and 300 lbs. I never could pick one up again !!!! More muscle than brain back then not a lot of either now !! all new injector tips and beautiful rebuild , cuople hrs on dyno and she was a sweetheart

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2016 at 12:09am Posted: 22 Mar 2016 at 12:09am |

|

Leon the short answer is yes it's a PC head and Steve is spot on it's a little bit diff, I will try to find the video of the Lanova head setup and post it.

Frank nice story about replacement engine and funny you posted about installing one in a D19, this D19 engine is a replacement two. I have not nor will I try to lift one of them up.lol

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2016 at 1:52am Posted: 22 Mar 2016 at 1:52am |

I didn't find the video I was looking for but this might help you understand better how the Allis Chalmers Buba Diesel head works. Lanova systems and most pre-cup Diesel systems are a little bit diff but this will give you some idea how it fires. I hope. https://www.youtube.com/watch?v=Ll3eK_EvsBE

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

FHOliver

Bronze Level

Joined: 11 Sep 2009

Location: Elgin Il

Points: 58

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2016 at 9:53am Posted: 22 Mar 2016 at 9:53am |

|

Don, in hindsight I didnt mean to hijack the thread. please keep pics coming, Also how can you tell its a replacement ? lack of serial # ?

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2016 at 10:42am Posted: 22 Mar 2016 at 10:42am |

FHOliver wrote: FHOliver wrote:

Don, in hindsight I didnt mean to hijack the thread. please keep pics coming, Also how can you tell its a replacement ? lack of serial # ? |

First off you didn't hijack.  Yes the lack of the ser # is one way to tell.

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

Skyhighballoon(MO)

Orange Level

Joined: 11 Sep 2009

Location: Pilot Grove, MO

Points: 3115

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2016 at 3:29pm Posted: 22 Mar 2016 at 3:29pm |

Don. That tractor will sure be one the owner can crow about when you get it done.  Mike

|

|

1981 Gleaner F2 Corn Plus w 13' flex

1968 Gleaner EIII w 10' & 330

1969 180 gas

1965 D17 S-IV gas

1963 D17 S-III gas

1956 WD45 gas NF PS

1956 All-Crop 66 Big Bin

303 wire baler, 716H, 712H mowers

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2016 at 5:02pm Posted: 22 Mar 2016 at 5:02pm |

Skyhighballoon(MO) wrote: Skyhighballoon(MO) wrote:

Don. That tractor will sure be one the owner can crow about when you get it done.  Mike Mike |

Mike the tractor owners like you and the nice guy that own this tractor's make my job a piece of cake. I can't name who my customers are in-less they let me, I'll bet he will let me sometime. lol

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

DonDittmar

Orange Level

Joined: 15 Sep 2009

Location: MIllersburg, MI

Points: 2516

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2016 at 5:35pm Posted: 22 Mar 2016 at 5:35pm |

|

I've been there

|

|

Experience is a fancy name for past mistakes. "Great moments are born from great opportunity"

1968 D15D,1962 D19D

Also 1965 Cub Loboy and 1958 JD 720 Diesel Pony Start

|

|

Michael Crowe

Orange Level

Joined: 11 Sep 2009

Location: Kansas City

Points: 1726

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2016 at 10:22pm Posted: 22 Mar 2016 at 10:22pm |

|

Don, no harm in disclosing its my tractor. I'm looking forward to using it with the new motor.

|

|

The 14th Annual Exclusive AC Swap Meet will be held in Boonville, MO, March 7-8, 2025. See the club website for details: http://www.moacclub.com/

|

|

ac45dave

Orange Level Access

Joined: 23 May 2015

Location: SE(IN)

Points: 1346

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2016 at 10:45pm Posted: 22 Mar 2016 at 10:45pm |

all i can say, it's in the best hands it could be in.

|

|

54 wd-45gas ; 56 wd-45d N/F w/fact p/s ; 63 d-17 sIII N/F gas ; 60 D14 N/F ; 67 d-17 sIV N/F gas ; 63D15 sII W/F; 39rc#667 ; 2021 massey 4710 fwa ; gravely 2 wheel tractors

|

|

darrel in ND

Orange Level

Joined: 22 Nov 2009

Location: Hebron, ND

Points: 8759

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Mar 2016 at 10:59pm Posted: 22 Mar 2016 at 10:59pm |

|

Hmmmmm. Is there some puns going on here that Michael "Crowe" should be able to "crow" about this tractor when it's done? I am envious "in a good way" of this project. BTW, nice talking to you this morning Don, and I will definitely be getting back to you soon. Darrel

|

|

OnlyAC

Bronze Level

Joined: 21 Apr 2016

Location: Ohio

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2016 at 10:26am Posted: 21 Apr 2016 at 10:26am |

|

Any update on this project or progress pictures. I have a D19 Diesel that runs really rough until it warms up and I feel like I will need to do a rebuild on it as well.

|

|

TomMN

Orange Level

Joined: 13 Sep 2009

Location: Elbow Lake, MN

Points: 858

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2016 at 11:37am Posted: 21 Apr 2016 at 11:37am |

Since the Lanova system is being discussed here I can post a picture we took of the cut-away WD45 diesel head and air-cell with an injector firing. The main portion of the fuel pulse is directed into the air-cell. Since the stream flows across the combustion chamber in the head some of the outer mist from the injector misses the air-cell hole and ignites there. The piston is still on its way up during the injection pulse so the beginning of the flame in the combustion chamber enters the air-cell igniting the fuel there. All that exploding pressure is metered out through the orifice of the air-cell. You can see that the WD45 air-cell has two spherical chambers with metered orifices, not sure if the D19 air-cells are the same. I put together what information I could find on the Lanova system back in 2006 when I was working on mine. Here is a link to that: http://www.allis01.com/fossto/Lanova_System.html

|

|

TomMN

Orange Level

Joined: 13 Sep 2009

Location: Elbow Lake, MN

Points: 858

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2016 at 11:44am Posted: 21 Apr 2016 at 11:44am |

One more fun picture of the Lanova cycle.

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2016 at 9:15pm Posted: 21 Apr 2016 at 9:15pm |

TomMN wrote: TomMN wrote:

Since the Lanova system is being discussed here I can post a picture we took of the cut-away WD45 diesel head and air-cell with an injector firing. The main portion of the fuel pulse is directed into the air-cell. Since the stream flows across the combustion chamber in the head some of the outer mist from the injector misses the air-cell hole and ignites there. The piston is still on its way up during the injection pulse so the beginning of the flame in the combustion chamber enters the air-cell igniting the fuel there. All that exploding pressure is metered out through the orifice of the air-cell. You can see that the WD45 air-cell has two spherical chambers with metered orifices, not sure if the D19 air-cells are the same. I put together what information I could find on the Lanova system back in 2006 when I was working on mine. Here is a link to that:

http://www.allis01.com/fossto/Lanova_System.html

|

Tom that's a nice cut away and tells the story way better that I can, good job. Thanks for posting it.

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2016 at 9:31pm Posted: 21 Apr 2016 at 9:31pm |

|

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8627

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 8:22am Posted: 22 Apr 2016 at 8:22am |

|

Don,

Your right into it now! Great pictures of what to look for on these engines.

Thanks for posting the pictures. I love the before and after stuff and the inspection work needed to determine next moves.

What are the big items that folks cant get any more for these engines? Is there a list of things that you just cant get as remans?

Regards,

Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 8:39am Posted: 22 Apr 2016 at 8:39am |

|

Well Chris the list of part that can't be found new or rebuilt is long for the D19 engines, it's a hunt for parts for the 230/262's gas or Diesel. Right now it's a hunt for piston/sleeve kits, things like the cam just are not in-stock even from AGCO. That's what makes them so much fun to rebuilt and I like the parts hunt. lol

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

OnlyAC

Bronze Level

Joined: 21 Apr 2016

Location: Ohio

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 9:23am Posted: 22 Apr 2016 at 9:23am |

|

Well, I'm starting to get an uneasy feeling about mine now. My Dad had purchased my D19 and he is no longer with us. It has always misfired when cold but looking at all the problems they seem to have and the lack of parts, this is going to be an extremely tough restoration. Thank you for documenting all the problems with yours so I will know what to look for when I tear in to it.

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7574

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 9:48am Posted: 22 Apr 2016 at 9:48am |

OnlyAC wrote: OnlyAC wrote:

Any update on this project or progress pictures. I have a D19 Diesel that runs really rough until it warms up and I feel like I will need to do a rebuild on it as well. |

All 262 diesels run on the rough side when you start them up. No need to rebuild it because of that. Mine had 200 hours on a rebuild and was (still is) like that when I bought it. Put it to work after a few minutes and it runs great. Lots of power and very little smoke.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

OnlyAC

Bronze Level

Joined: 21 Apr 2016

Location: Ohio

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 10:42am Posted: 22 Apr 2016 at 10:42am |

|

Well I know at least 1 cylinder if not 2 have low compression and don't fire until it warms up. We have had the injectors tested and they are fine. Makes it a bear to start even in warm weather. Without removing The head, are there any symptoms that would indicate that the sleeves have dropped? I'm worried that its going to look like the one Don is working on now and I don't want to hurt the engine before I get a chance to fix it.

|

|

AC list: B-10 | B-112 | WC | WD45 | D12 | D14 high-crop | D17 gas | D17 Diesel | D19 gas | D19 Diesel | 185 |

|

|

Brian Jasper co. Ia

Orange Level

Joined: 11 Sep 2009

Location: Prairie City Ia

Points: 10508

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 11:37am Posted: 22 Apr 2016 at 11:37am |

|

I can say the only symptom mine gave from dropped sleeves is leaking head gasket. After seeing that other mess that was brought to Don to straighten out, makes me wish I had take pics of my 262 as I took it apart. It didn't have the bad rookie advice that Don's customer got, but it had some bad machine/assembly work.

|

|

"Any man who thinks he can be happy and prosperous by letting the government take care of him better take a closer look at the American Indian." Henry Ford

|

|

TramwayGuy

Orange Level Access

Joined: 19 Jan 2010

Location: Northern NY

Points: 11803

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 12:44pm Posted: 22 Apr 2016 at 12:44pm |

|

Has anyone ever tried to use shims under the sleeve flange to raise them up? Or maybe there's no such thing?

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 12:49pm Posted: 22 Apr 2016 at 12:49pm |

|

Don't let some of the stuff that I run into stop you from rebuilding yours, parts are still out there you just haft to look harder now.lol

Older engines just need more help, just like older men need more help than we did years ago. lmao

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8744

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2016 at 10:30pm Posted: 22 Apr 2016 at 10:30pm |

TramwayGuy wrote: TramwayGuy wrote:

Has anyone ever tried to use shims under the sleeve flange to raise them up? Or maybe there's no such thing? |

If you could see how narrow the flange is,you would understand that a shim is about out of question. Don,if you get a chance,could you post a pic of either the sleeve or the counterbore to show how minute it is?

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

FHOliver wrote:

FHOliver wrote: Yes the lack of the ser # is one way to tell.

Yes the lack of the ser # is one way to tell.

Mike

Mike