| Author |

Topic Search Topic Search  Topic Options Topic Options

|

WIAllisFan

Bronze Level

Joined: 29 Sep 2021

Location: Wisconsin

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D19 Troubleshooting Topic: D19 Troubleshooting

Posted: 29 Sep 2021 at 5:23pm |

Hello All, We just recently picked up a D19 and found it to have a few problems we need to troubleshoot.

The problem we are trying to track down right now is that it starts and runs fine until it warms up and we start doing work with it. After a while(about 20 minutes) it starts to have trouble maintaining RPM and shuts down. It is very hard to get running again until it cools for a while. Once I get it running it will go for a much shorter time before it has problems again.

We suspected coolant level but that was fine, our next step this weekend to check if he water pump has failed. The water temp gauge doesn't work but that might be just a busted gauge, this tractor has not been well maintained. Any ideas from the experts on the forum?

|

|

|

Sponsored Links

|

|

|

WIAllisFan

Bronze Level

Joined: 29 Sep 2021

Location: Wisconsin

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Sep 2021 at 5:27pm Posted: 29 Sep 2021 at 5:27pm |

Also, where the heck is the S/N on this thing?

I found a plate on the engine block that looks like it my be a S/N but it doesn't match at all with the serial numbers in my operators manual.

I found- G-262(I'm assuming this is cubic inches since it is 262ci) G-50797 4515925

Edited by WIAllisFan - 29 Sep 2021 at 5:31pm

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54667

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Sep 2021 at 5:34pm Posted: 29 Sep 2021 at 5:34pm |

WIAllisFan wrote: WIAllisFan wrote:

Also, where the heck is the S/N on this thing?

I found a plate on the engine block that looks like it my be a S/N but it doesn't match at all with the serial numbers in my operators manual.

I found- G-262(I'm assuming this is cubic inches since it is 262ci) G-50797 4515925

|

That's an engine serial #, the tractor number should be about an inch to the rear of it. On the bell housing.

When it starts running bad, after 20 minutes or so, I would suspect a bad ignition coil. Check the spark...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

WIAllisFan

Bronze Level

Joined: 29 Sep 2021

Location: Wisconsin

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Sep 2021 at 5:47pm Posted: 29 Sep 2021 at 5:47pm |

DiyDave, thanks for the advice on the serial number I will take a look. It's funny you should say to check the coil. An hour after we picked it up it blew a coil and I found that it had a 6V coil on it. That was replaced with a 12V coil but the coil I got didn't have an internal resister and I don't see any resister inline so I was suspecting that as well. I assumed at the time there was a resister somewhere I couldn't see it, but after consulting the wiring diagram it doesn't look like there is one.

It has OEM wiring on it still which is brittle and cracking, I have been concerned about a short somewhere on the tractor.

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 964

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Sep 2021 at 7:11pm Posted: 29 Sep 2021 at 7:11pm |

|

The D19 tractor serial number is stamped in the flat spot on top of the differential housing, behind the seat mounting.

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34416

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Sep 2021 at 9:15pm Posted: 29 Sep 2021 at 9:15pm |

If you put a 12 volt coil on that does not have an internal resistor, put new points and condensor in, (Napa Blue Streak or better) with an inline resistor to coil. And when you have time, put a 4 post solenoid on and run a wire from 'I' post on solenoid to wire between resistor and coil. Winter time, they will start a lot better. I fought with a D17 that would run about that long and burn points and made you think that it was a gas issue, and clean the carb and file the points over and over, put new ignition parts in 3 times. It made you think you don't know how to fix the problem... I finally figured out that the two previous owners had gotten rid of the tractor for the same reason. I realized it was burning the points, so I put a GM car resistor in and it ran alllll day working it. Later updated it to the wiring of a later series D17. It starts anytime now.

Hope it is that simple for you.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

ACjack

Silver Level

Joined: 13 Sep 2014

Location: Peoria, Arizona

Points: 277

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Sep 2021 at 10:03am Posted: 30 Sep 2021 at 10:03am |

|

To expand on what DiyDave said. The "G" identifies it as a gas fueled engine. The G-50797 is the serial number of the engine and the 4515925 is the catalog number. The catalog number is used to determine the "build" of the engine. Every series of engine was used in different products and therefor each engine needed to be configured differently for the application that it was to be used for and the catalog number determined what individual parts that were used.

|

|

WIAllisFan

Bronze Level

Joined: 29 Sep 2021

Location: Wisconsin

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Sep 2021 at 12:10pm Posted: 30 Sep 2021 at 12:10pm |

Thanks ACJack and JCWI for the info that is very helpful.

It seems that this is getting better by moment. Here is what we discovered today.

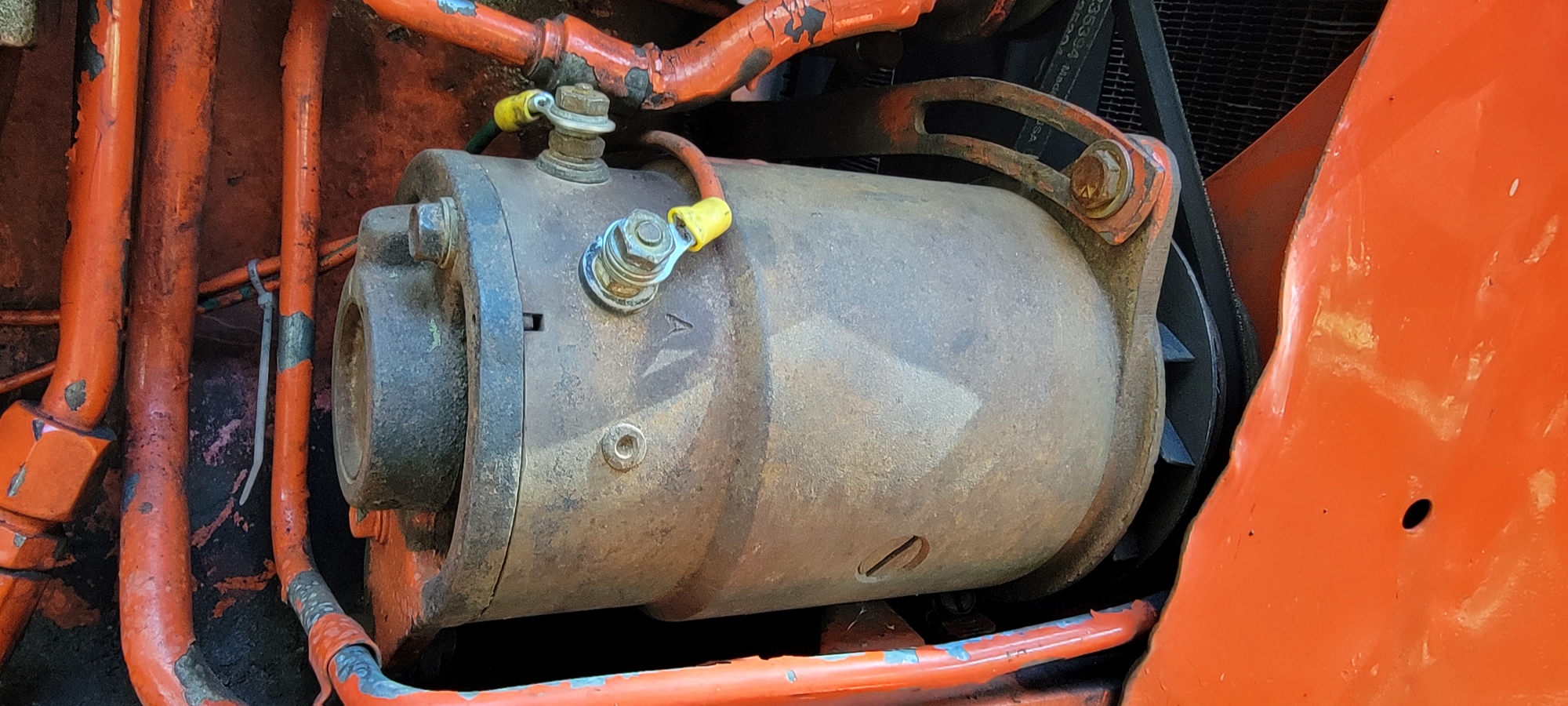

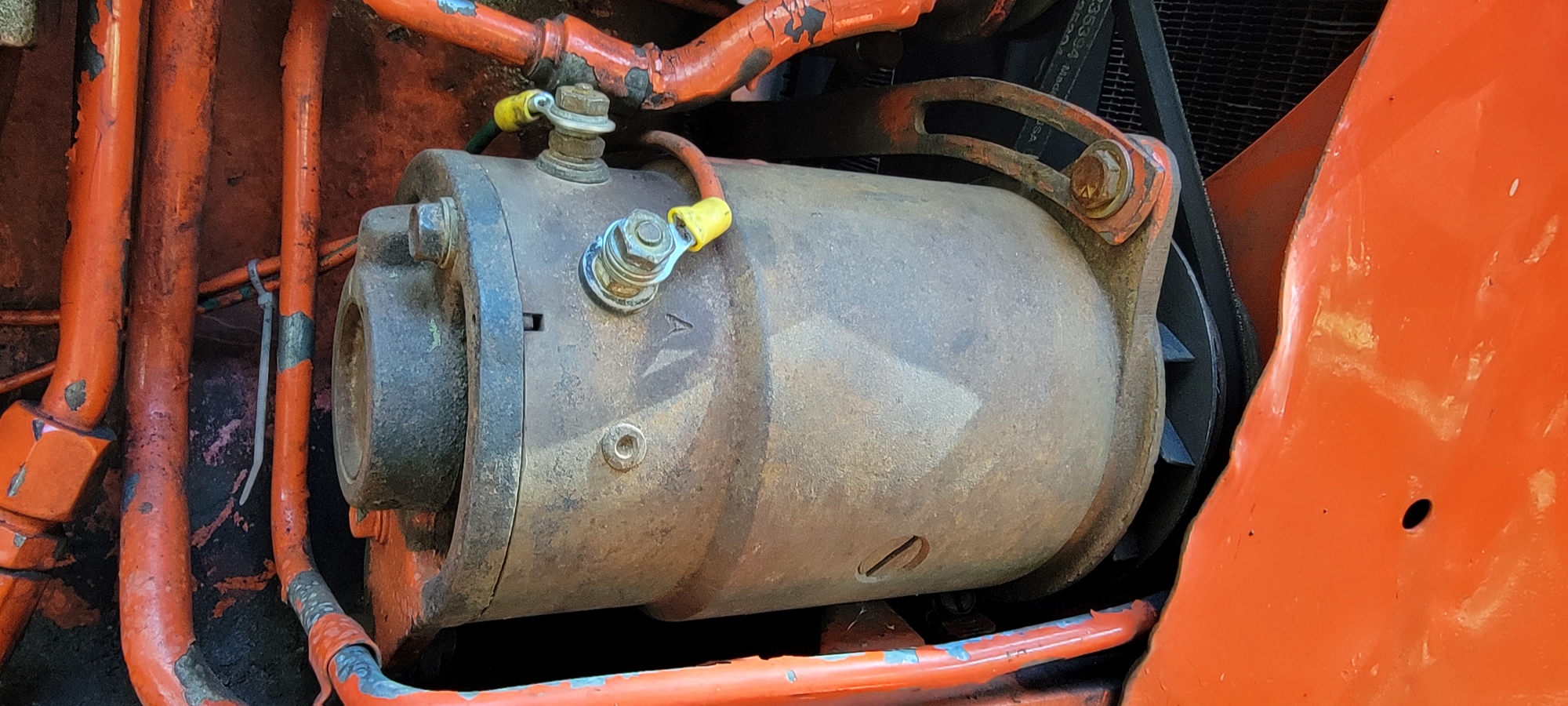

The battery is grounded on the negative side. However it appears that the original generator is still installed. And it appears that that coil that we blew was wired backwards. Meaning, the feed that comes from the ignition switch is attached to the positive side of the coil.

It "looks" like some one tried to convert this tractor to negative ground. Is that even possible while keeping the original generator installed?

I'll post a pic of the generator, or at least what I assume is the generator. I dunno if they make alternators that look like generators or not, but it sure looks like an old generator.

Edited by WIAllisFan - 30 Sep 2021 at 12:23pm

|

|

Alberta Phil

Orange Level

Joined: 13 Sep 2009

Location: Alberta, Canada

Points: 3950

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Sep 2021 at 12:29pm Posted: 30 Sep 2021 at 12:29pm |

|

That's a generator. It will work with negative or positive ground. Just have to polarize it correctly by briefly jumping a wire from the battery terminal to the armature terminal on the regulator. If everything is in working order, it should show a charge when running.

|

|

WIAllisFan

Bronze Level

Joined: 29 Sep 2021

Location: Wisconsin

Points: 18

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Sep 2021 at 1:09pm Posted: 30 Sep 2021 at 1:09pm |

Excellent! Thanks Phil!

I see some "how to guides" recommending I remove the belt and have the tractor running when I polarize the generator. Is that necessary?

I think I see why converting to alternators is so popular, it seems to be more simple. |

|

Alberta Phil

Orange Level

Joined: 13 Sep 2009

Location: Alberta, Canada

Points: 3950

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Sep 2021 at 7:41pm Posted: 30 Sep 2021 at 7:41pm |

|

I've always done it with the tractor shut off and everything in place. I have nine Allis tractors here with 6 volt systems, all with generators and I very seldom ever have any electrical issues with any of them. They will all start any time I need them. I've had two generators rebuilt over the years, but they were non functional when I bought the tractors.

|

|

plummerscarin

Orange Level Access

Joined: 22 Jun 2015

Location: ia

Points: 4049

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Sep 2021 at 8:23pm Posted: 30 Sep 2021 at 8:23pm |

|

Agreed. The Cubs here had the generators polarized with a jumper wire and a quick touch of the two terminals

|

|

corbinstein

Orange Level

Joined: 31 Jul 2014

Location: Oklahoma

Points: 796

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Oct 2021 at 7:01am Posted: 01 Oct 2021 at 7:01am |

|

the one that drove me nuts, was one with a bad switch. Had power at the coil, until I started it. Then it just wouldn't stay running. Turned out the switch just wouldn't carry the current. as a test, I bypassed the switch and it ran good.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Oct 2021 at 6:16pm Posted: 01 Oct 2021 at 6:16pm |

12 v coils have an INTERNAL resistor and do NOT need an external resistor... If you have no INTERNAL resistor, you have a 6v coil... That is the difference.

You should be using a 12 v coil, with NO EXTERNAL resistor. With negative ground, the wire from the switch would be POSITIVE and go to the POSITIVE terminal on the coil.. NEG terminal goes to the point.

Edited by steve(ill) - 01 Oct 2021 at 6:17pm

|

|

Like them all, but love the "B"s.

|

|

Ed (Ont)

Orange Level

Joined: 08 Nov 2009

Location: New Lowell, Ont

Points: 1522

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Oct 2021 at 8:07am Posted: 02 Oct 2021 at 8:07am |

|

Steve the 12v automotive stuff had external resistor. GM and Ford used resistor wire. Chrysler used ceramic resistor. Start on 12v and then ran on 6-7 volts to save points.

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34416

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Oct 2021 at 5:58pm Posted: 02 Oct 2021 at 5:58pm |

Steve, Ever try and start stuff when it's -30 below with those internal resistor coils? There was a reason when Allis went from the resistor coil to the 4 post Solenoid and then feed full 12 volts to the coil on start up, and they changed the coil too. I know our old D17 needed a battery charger on the battery if we started it to clean barnat -30, and that was with a new battery... but we usually plugged in the tank heater when it was getting around zero for easier starts. That tractor was the three post solenoid. In the same below zero temperatures, the 170 would start because it had full voltage to coil despite the heavier draw on the battery to turn the hydraulic pump too. My uncle had a story of very near same problem back in the days when they had a cheap model of the Plymouth car, if it got down to 10 below, that car would refuse to start. He wondered why, and found that to make that Plymouth, they simply did not equip that car with full voltage on start up. He put on what would supply the full voltage and said it didn't matter after that what kind of weather they had, it started and went. That is the importance of having enough spark at the plugs when you need it. A poor spark don't cut it when it gets dam cold... Now they have hotter coils than what we had back then so... maybe you don't need full voltage now.  In my opinion and experience, that four post was needed and of a good design to get the job done. We had a 1954 Plymouth Belveder that could sit in the snow bank and when needed, just jump in and turn the key and it would start... while the dam ford falcon 4d sat in the garage and take a half hour of cranking before it thought about starting... And I will bet that it was lacking hot spark on the cold days... and that thing was the damdest cold car we ever road in. The plymouth and the dodge had far more comfort.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

Ed (Ont)

Orange Level

Joined: 08 Nov 2009

Location: New Lowell, Ont

Points: 1522

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Oct 2021 at 8:30pm Posted: 02 Oct 2021 at 8:30pm |

|

Interesting JC. We had a couple neighbours with mid 50’s Plymouth or Dodge. Never started on cold days when everyone else was going. I guess that’s why.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89114

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 02 Oct 2021 at 8:35pm Posted: 02 Oct 2021 at 8:35pm |

JC... Im on your side... all coils have some resistance.. A 12 volt coil is for a 12 volt system.. If you put an EXTERNAL resistor on a 6 v coil, you can cut the voltage so the 6v coil can be used on a 12 v tractor...... Im not for that.. If you have a 12 volt system, use a 12 volt coil.. ..I dont think a 12 v coil needs an external resistor.......... YES, autos did some odd things with 12 volt coils and external resistors as ED said..

A 6 volt coil should have 1.5 OHMS inside... a 12 volt coil should have 3.0 OHMS inside... since volts is OHMS x amps... they should both draw the same amps.

Edited by steve(ill) - 02 Oct 2021 at 8:48pm

|

|

Like them all, but love the "B"s.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

WIAllisFan wrote:

WIAllisFan wrote:

In my opinion and experience, that four post was needed and of a good design to get the job done.

In my opinion and experience, that four post was needed and of a good design to get the job done.