| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Dandan111

Bronze Level

Joined: 01 Mar 2015

Location: Indiana

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D15 brush cutters Topic: D15 brush cutters

Posted: 21 Apr 2020 at 9:07pm |

|

What mowers do you guys like behind these old tractors? I have a 5ft

3pt bush hog. It's never been very good. Wants to drift down and is a pain in tall grass. I've always thought a pull type with fixed height would be better. Maybe a 6ft ?

Father inlaw told me to cut th back skirt off. He might be right as it seems like grass doesn't exit good.

|

|

|

Sponsored Links

|

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7570

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2020 at 9:23pm Posted: 21 Apr 2020 at 9:23pm |

Drifting down? You just do not have the hydraulic lever in the "hold" position. There is a sweet spot in the middle of the quadrant where it keeps its position. I've never had a problem. I use a John Deere 5' 3 point. Use the hand clutch if it starts to struggle in tall grass. I do not believe in "torching" something off to make it work better. It was made that way for a reason.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2020 at 10:19pm Posted: 21 Apr 2020 at 10:19pm |

|

If it drifts up and down, traction booster linkage needs adjusted. MACK

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8459

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2020 at 10:29pm Posted: 21 Apr 2020 at 10:29pm |

|

On tractors with less than stellar hydraulics I’ve used limiter chains. Works quite well.

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54709

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 4:52am Posted: 22 Apr 2020 at 4:52am |

CrestonM wrote: CrestonM wrote:

On tractors with less than stellar hydraulics I’ve used limiter chains. Works quite well. |

Limiter chains are a close second to a AC 160, or 172 bush hog, with the "rooster comb" height adjuster. Best bush hog height control system ever built, bar none! It was a chain that connected each lower 3 point pin, to a bent bar, that was hung over a notched top link, to adjust height, you just pick up the BH, then reach back, adjust the bar, drop the BH, and go!

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

truckerfarmer

Orange Level Access

Joined: 26 Jan 2013

Location: Watertown, SD

Points: 3292

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 6:28am Posted: 22 Apr 2020 at 6:28am |

|

As for the struggling in tall grass. What shape are the blades in? May be time to sharpen or replace them. Sometimes in tall grass you have to take a smaller width of cut.

|

|

Looking at the past to see the future.

'53 WD, '53 WD45, WD snap coupler field cultivator, #53 plow,'53 HD5B dozer

Duct tape.... Can't fix stupidity. But will muffle the sound of it!

|

|

Dandan111

Bronze Level

Joined: 01 Mar 2015

Location: Indiana

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 6:53am Posted: 22 Apr 2020 at 6:53am |

|

Good question trucker. Iv never done anything with the blades. For reference it's a old bush hog squealer.father inlaw looked at it one time and said there's no place for the grass to go so it just swirls around bogging things down.

Mine has the steel triangle with a chain that runs to the back. Pain in the butt hitching.

|

|

Dandan111

Bronze Level

Joined: 01 Mar 2015

Location: Indiana

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 7:01am Posted: 22 Apr 2020 at 7:01am |

I found this picture on the internet. This is almost my exact set up with limit chains added.

|

|

Dandan111

Bronze Level

Joined: 01 Mar 2015

Location: Indiana

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 7:11am Posted: 22 Apr 2020 at 7:11am |

|

Another problem I have is the higher I lift the mower the more closer the pto gets to the deck. In fact the previous owner has the plastic pto cover rubbed in to. It's all ducked taped and looks like hell. I tried to shorten the chain that runs to the back last year, that's not the answer. I'd like to be able to cut taller.

|

|

Dandan111

Bronze Level

Joined: 01 Mar 2015

Location: Indiana

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 7:22am Posted: 22 Apr 2020 at 7:22am |

|

The more I look at this pitcture the more I'm thinking that top link is causing my frustration. If I get the back of the mower up it should be better I'd think. Should the mower be lever or with the back up higher like 6 or 8 inches?

Iv tried to shorten the chain a little but maybe I need to do more,like a foot.

|

|

Gary Burnett

Orange Level Access

Joined: 11 Sep 2009

Location: Virginia

Points: 3123

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 7:30am Posted: 22 Apr 2020 at 7:30am |

|

I'll take a pull type cutter over a 3pt 10 to 1.Easy to hook/unhook and ready to go when its hooked up no adjusting anything.

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8459

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 11:25am Posted: 22 Apr 2020 at 11:25am |

Dandan111 wrote: Dandan111 wrote:

The more I look at this pitcture the more I'm thinking that top link is causing my frustration. If I get the back of the mower up it should be better I'd think. Should the mower be lever or with the back up higher like 6 or 8 inches?

Iv tried to shorten the chain a little but maybe I need to do more,like a foot. |

If you want a better chopping action, the rear should be lower than the front. Level is what it's "supposed" to be, but I generally adjust my top link so the rear is maybe 2-3" higher than the front. Supposed to use less power that way.

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 964

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 12:27pm Posted: 22 Apr 2020 at 12:27pm |

|

Does your cutter have the tail wheel on it? That should be set to carry the rear height a couple inches higher than the front level, which your limit chains can control, then grass should come out under the rear. How about posting a photo of your set up? Someone might see something to help, if we can look at it.

|

|

Dandan111

Bronze Level

Joined: 01 Mar 2015

Location: Indiana

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 2:47pm Posted: 22 Apr 2020 at 2:47pm |

My tractor isn’t here. Here’s the mower. Looks like I can adjust the rear wheel. That bar that goes across the 3 point is what the pto has hit in the past. Looks like previous owner just lived with it.

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 964

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 5:06pm Posted: 22 Apr 2020 at 5:06pm |

|

To me it looks to me like the cross bar might be upside down. Bow in the bar up and the PTO shaft under it might look better. If you can find any more of a model number to go with the Bush Hog Squealer You can likely get a book for it from Bush Hog.

|

|

Dandan111

Bronze Level

Joined: 01 Mar 2015

Location: Indiana

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 5:51pm Posted: 22 Apr 2020 at 5:51pm |

|

That's interesting jim.i see pictures with that cross bar both ways. That

might help the pto interference.

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 964

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 6:09pm Posted: 22 Apr 2020 at 6:09pm |

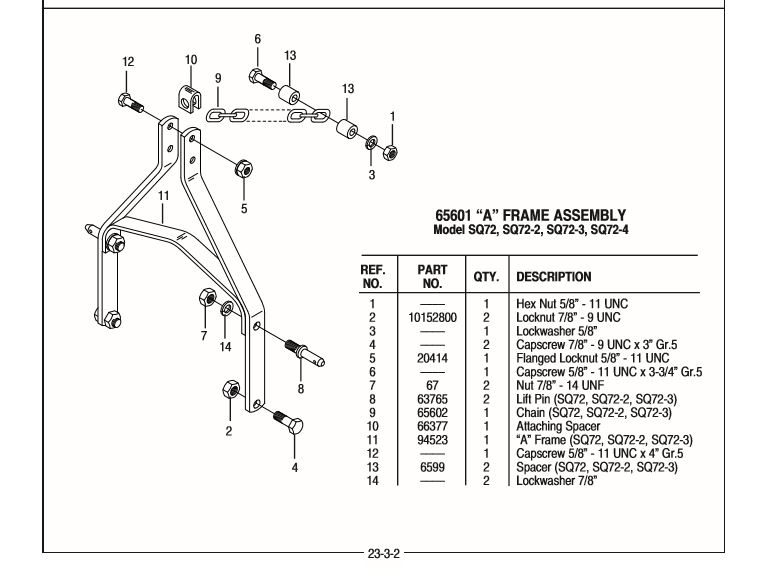

Besides a picture with the bar installed bow up, I found this in one of the Squealer parts manuals.

Edited by Jim.ME - 22 Apr 2020 at 6:09pm

|

|

Dandan111

Bronze Level

Joined: 01 Mar 2015

Location: Indiana

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 6:16pm Posted: 22 Apr 2020 at 6:16pm |

|

Thanks jim.

I think we'll run with that this summer. I plan to adjust the wheel higher on the back and buy a heavy duty S hook to adjust that

chain if needed also.

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54709

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 6:19pm Posted: 22 Apr 2020 at 6:19pm |

https://images.app.goo.gl/K4u3UYTQQxDHKZdq5

Look at the rooster comb piece, in place of the top-link...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

Dandan111

Bronze Level

Joined: 01 Mar 2015

Location: Indiana

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 6:28pm Posted: 22 Apr 2020 at 6:28pm |

|

Never seen that Dave. Looks like it's got a fast hitch or something. Is that a IH mower?

|

|

Ted in NE-OH

Orange Level

Joined: 12 Nov 2009

Location: Austinburg OH

Points: 1703

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 6:43pm Posted: 22 Apr 2020 at 6:43pm |

|

I have a WD with a 3pt conversion. I use limiting chains so that the arms can only go down so far, as hydraulics want to drift down.

|

|

CA, WD, C, 3 Bs, 2 Gs, WC, I-400, 914

|

|

TimNearFortWorth

Orange Level

Joined: 12 Dec 2009

Points: 2014

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 8:06pm Posted: 22 Apr 2020 at 8:06pm |

D15 Series One will handle the 5' just fine, in most any conditions short of rocks. Need to get her where she is pitched with the front doing the cutting, otherwise you are just keeping everything you cut under the deckwhich uses more power and fuel, and throwing clumps for cuttings. 5' Cutter will not cover the PAW's adjusted all the way in on a 15 I/II, just reverse direction to catch the previous pass with a small overlap to get the brush/grass you laid down on the last pass with your tire. Make sure your blades swing freely and retainer lock nut is tight but not too tight to prevent the swing effect. With cutter all the up and a good jack stand on each side, a grinder can be used to "touch up" the cutting edge on each blade to make a substantial difference in cutting. If any major "dings" in blade cutting edges, polish off the excess vs. trying to make a new edge by re-forming the blade back to it's original shape as removing too much material will throw you off balance while running. Looks like that unit needs a chain guard or belting on the front, not good to run without one. Shear bolt in driveline AND slip clutch at tractor pto will keep from pushing you around and if you think you can always throw the PD into neutral in time, it will eventually get you. Good brakes are a must as well. Have a 5' A-C with a good size gear box but picked up a Bush Hog SQ72 (6') some years back and it is well matched for both the SI/SII units. I have no issue with cutting stuff above the radiator cap and take out trees 2" OD with a little practice. I warm her up good before tackling the rough stuff, getting the hyd. fluid good and hot. Go slow, 1st high or 2nd low on a D15 of either series for a decent cut, 3/4 min. throttle and open her up wide open in the heavy stuff. If the cutter does not have a "cintered" type vent fitting near the top of the box, money well spent to let her breath so she does not push a seal out of the front or bottom of the gear box. Grease is your friend on cutters, plenty of it and hit the tractor spindles while your at it.

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 964

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2020 at 8:33pm Posted: 22 Apr 2020 at 8:33pm |

|

I think you mean an over running clutch at the tractor pto, not a slip clutch. Over running clutch doesn't let the inertia of the implement drive the tractor via the pto. Slip clutch at the cutter gear box would be better than a shear bolt in my opinion.

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54709

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2020 at 5:05am Posted: 23 Apr 2020 at 5:05am |

Jim.ME wrote: Jim.ME wrote:

I think you mean an over running clutch at the tractor pto, not a slip clutch. Over running clutch doesn't let the inertia of the implement drive the tractor via the pto. Slip clutch at the cutter gear box would be better than a shear bolt in my opinion. |

OEM equipped AC brush cutters had an over running "clicker" clutch, next to the gearbox, then a spring-loaded "rattle clutch", in front of that. State of the art, back then!

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

Dandan111

Bronze Level

Joined: 01 Mar 2015

Location: Indiana

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2020 at 7:33am Posted: 23 Apr 2020 at 7:33am |

|

What would I want for a overrun clutch ? Just buy a new cheap one or should I look for a quality used one?

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 964

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2020 at 8:04am Posted: 23 Apr 2020 at 8:04am |

|

Buy a new one, they aren't that expensive. You can get the ones with the lock button, like a regular tractor end pto coupler, for easier removal than the ones that use roll pins to hold them on. If it has a horsepower rating be sure it exceeds your tractor's pto hp rating.

|

|

TimNearFortWorth

Orange Level

Joined: 12 Dec 2009

Points: 2014

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2020 at 8:59am Posted: 23 Apr 2020 at 8:59am |

Yes, I meant over-running clutch for an adder. A-C cutter has slip type clutch that will let the blades wind down after the PTO is disengaged and PTO on tractor is allowed to stop, mounted in front of gear box and they were a great idea, just need to keep them adjusted. Picked up a 15II that had an over-running clutch on it, been stuck on there for years as never serviced/lubed and it took some doing to get off the tractor. Good idea to remove them occasionally to make sure the pin is not distorted and they need greased also.

Word of caution on the aftermarket O/R clutches; measure the length of engagement between the cutter shaft halves before cutting then down to compensate for the length of the O/R clutch as you still need a minimum of engagement on the shaft halves and they may have already been shortened. On the other hand, not allowing the shafts enough room to slide together if you travel through a "dip" or ditch on a good angle can put undue stress on tractor internals for a heafty tear down for repair.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

CrestonM wrote:

CrestonM wrote: