My D17 S1 always ran cold. When I first got the tractor I discovered the thermostat was more or less rotted away and the temp gage didn't work. I bought a new thermostat and new temp gage, but the engine would never heat up unless I covered the rad. Plowing in the summer on a 80F day would be the only time it would get warm with no cover. In the winter I had to completely cover the rad just to get the temp gage to move off of 130F.

Last summer the engine spun a cam bearing so thanks to a fellow forum member I put in a gleaner engine. Works great, but still ran cold. The rad was rotten and more of a antifreeze sprinkler system than a rad so thanks to another forum member I found a replacement (I work for a large radiator manufacturer, but we serve the mining industry and our rads usually start at 1000+hp, and business has been pretty awful lately so home projects are tough to get done).

So with my new engine in I was determined to get it to run at the proper temp. Here is the existing tstat housing:

I tested the new thermostat:

I found that the thermostat was not completely sealing against the rad side of the housing. There is a rubber ring, but it looked like there was an 1/8" or so gap between the tstat and the rubber ring. Fellow forum member Carbonite and I looked around the shop and found a piece of exhaust pipe the right size, so we cut a ring and after some experimenting on height, we seemed to hit on the correct size:

So installed it and tightened everything down filled up the system. There was a bit of an interval (2 months) before I could check it out as work and other things got in the way.

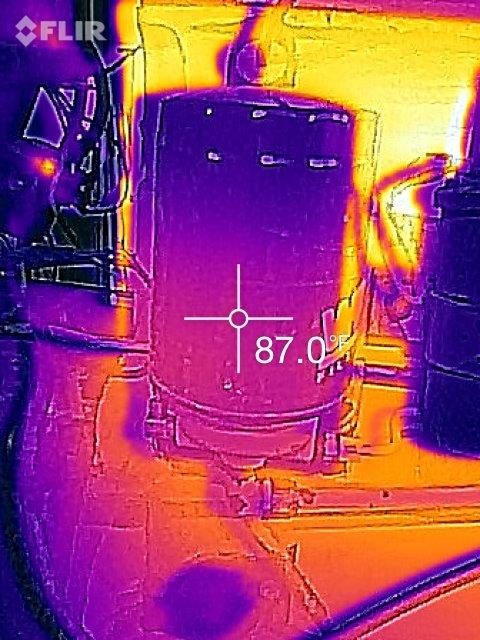

So last weekend I got the IR camera and fired up the engine. Here it is cold:

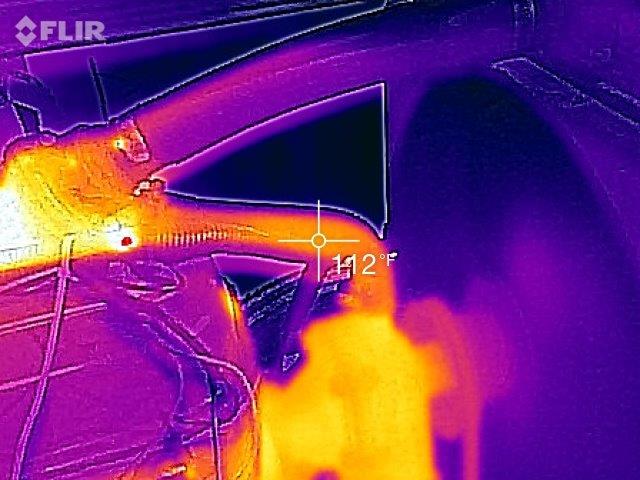

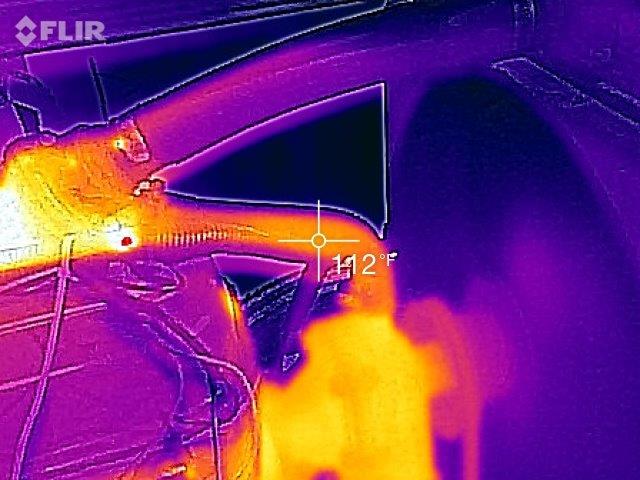

The engine is warming up, but no flow is going to the rad. Mission accomplished? I rad it for a few minutes until the temp gage hit 180F, you could see the stat open up and vent water to the rad, then close, open and close until it reached an opening that held the engine at about 175F. Haven't put it to work yet, but will try it this weekend. here is the engine hot:

One thing I noticed that even though the oil pan read 80 - 90f, the oil filter was only getting flow in the bottom section. This new engine is the full flow style, so it looks like the cold oil in the top of the filter is not moving. I imagine if I ran it for more than 20 minutes the oil would eventually warm and flow through the entire filter. I'll have to check that when I start plowing later this month I hope.

cheers,

Creek

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

IBWD MIke wrote:

IBWD MIke wrote: