| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Rickter

Bronze Level

Joined: 13 Jun 2016

Location: SW Iowa

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: WD clutch grabbing when it shouldn't Topic: WD clutch grabbing when it shouldn't

Posted: 05 Jun 2021 at 3:08pm |

|

Both transmission and hand clutch of WD seem to work well although hand clutch won't stay locked back. What has my attention: idleing in gear, hand clutch forward, tractor not moving - every so often 30 seconds or so seems like one of the clutches is grabbing enough to 'try' and move tractor forward. Doesn't go anywhere but enough to rock it forward a bit, then settles back. Hasn't always done this. Is there an adjustment? One or the other clutch needs work/replaced? Clutch shaft bolt bearing maybe?? Thanks

|

|

|

Sponsored Links

|

|

|

Boss Man

Orange Level

Joined: 03 Mar 2018

Location: Greenleaf, WI

Points: 617

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2021 at 4:16pm Posted: 05 Jun 2021 at 4:16pm |

|

Could be oil on the disk. Rear engine seal starting to leak? Could be a warped disk. Clutch been slipped a lot?

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8566

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2021 at 11:51pm Posted: 05 Jun 2021 at 11:51pm |

|

Remove the battery box and hand clutch cover and have a look. Sounds like problem is in there. Not staying locked in is not correct. At the least it needs shims removed. Wonder if the big snap ring is off the rear cover? Foot clutch would not do as you say.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4034

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2021 at 7:28am Posted: 06 Jun 2021 at 7:28am |

SteveM C/IL wrote: SteveM C/IL wrote:

Remove the battery box and hand clutch cover and have a look. Sounds like problem is in there. Not staying locked in is not correct. At the least it needs shims removed. Wonder if the big snap ring is off the rear cover? Foot clutch would not do as you say. |

X-2. Sounds like one of the linkage pins may have gotten loose. Have a look before things get worse.

|

|

Lonn

Orange Level

Joined: 16 Sep 2009

Location: Назарово,Russia

Points: 29792

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2021 at 8:22am Posted: 06 Jun 2021 at 8:22am |

Boss Man wrote: Boss Man wrote:

Could be oil on the disk. Rear engine seal starting to leak? Could be a warped disk. Clutch been slipped a lot? |

The hand Clutch runs in oil. The foot clutch is not the problem but the hand clutch, I'd say, is the problem.

|

|

-- --- .... .- -- -- .- -.. / .-- .- ... / .- / -- ..- .-. -.. . .-. .. -. --. / -.-. .... .. .-.. -.. / .-. .- .--. .. ... -

Wink

I am a Russian Bot

|

|

TramwayGuy

Orange Level Access

Joined: 19 Jan 2010

Location: Northern NY

Points: 11716

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2021 at 8:24am Posted: 06 Jun 2021 at 8:24am |

|

Maybe there’s no oil in the hand clutch.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2021 at 8:47am Posted: 06 Jun 2021 at 8:47am |

|

I have a couple model "B"..I have never had a clutch grab when in neutral, but have had the clutch STICK when you push in the clutch and it will continue to rotate.. Oil leaks out the main rear seal as BOSS said and gets on the clutch. Even when disengaged, it might tend to drag... I take out the starter and wash off the clutch with laundry detergent and water and a weed sprayer... Then hose off with water.

|

|

Like them all, but love the "B"s.

|

|

Rickter

Bronze Level

Joined: 13 Jun 2016

Location: SW Iowa

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2021 at 7:34pm Posted: 06 Jun 2021 at 7:34pm |

Thanks for the reply Boss Man. I only put two oil pans under it now! but yes still drips from fly wheel cover...and the clutch inspection cover. Last year I did the lower of the oil sump gaskets which helped a lot.

|

|

Rickter

Bronze Level

Joined: 13 Jun 2016

Location: SW Iowa

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2021 at 7:36pm Posted: 06 Jun 2021 at 7:36pm |

Thanks Steve - got the cover off transmission/hand clutch. I think I see the big snap ring and looks intact. Shop manual says with clutch disengaged and plates forward look for .030 between driven discs & pressure plate. I'm getting closer to as much as .038 with the stack 'relaxed' (hand lever forward). Measurement seems wider further away from where existing shim is or down the plates. Bump the starter to access the other shims? I'm assuming there are three locations.

|

|

Rickter

Bronze Level

Joined: 13 Jun 2016

Location: SW Iowa

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2021 at 7:38pm Posted: 06 Jun 2021 at 7:38pm |

Thanks Mike! I think I see a couple of the link pins in this photo - or maybe they're hiding inside the back plate? Is there a way to turn this for further inspection? Battery out right now so maybe not bumping the starter.

|

|

Rickter

Bronze Level

Joined: 13 Jun 2016

Location: SW Iowa

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2021 at 7:40pm Posted: 06 Jun 2021 at 7:40pm |

|

Thanks Steve - that's gotta be an interesting ride when the clutch doesn't want to let go. This is the only tractor I'm somewhat familiar with but some time ago I had a WD mentor and he made the hand clutch seem like a big deal. Good for getting in close to buildings, etc. For me its like cheating compared to the foot clutch which I can do if I really pay attention. I like the idea of cleaning the foot clutch as it is definitely dirty/oily in that housing. Brake lock or parking brake doesn't work with oil on it either.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8566

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2021 at 9:51pm Posted: 06 Jun 2021 at 9:51pm |

|

I suppose the ramp plate inside which the rollers ride could be badly worn in that spot....it can be turned to a new wear position,I forget how but don't think it's that tricky. Looks like you're about out of shims. Take out whats left and maybe it will stay engaged but I doubt it. Turn over by using 1/2 box end wrench on those bolts. Stick a punch bar inside clutch to hold when tightening. May wish to loosen all before doing one...I forget.

Oh I forgot...lock foot clutch out and turn by hand...that's why you stick a bar inside clutch to hold it while loosening.

Edited by SteveM C/IL - 07 Jun 2021 at 3:46am

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8448

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jun 2021 at 10:10pm Posted: 06 Jun 2021 at 10:10pm |

My 45 is doing something similar and I have had it apart and replaced a worn out disc. I will throw in a picture that may or may not help? Mine is a three clutch plate WD45. Yours is a 2 plate WD I believe. It looks like your adjustment shims may be all gone? Which may mean the clutch plates are worn?? You should be able to turn this unit. That's how the shim adjustment is made in the tractor. If the hand clutch is not locking back, it could be an adjustment or additional worn parts in the linkage and or 2 piece brass collar. Dont let me get you off track here. Dr Allis or Mack may be along to assist you!:)

Been a couple days since I was in there. Regards, Chris

Edited by Sugarmaker - 06 Jun 2021 at 10:20pm

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4034

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Jun 2021 at 8:07am Posted: 07 Jun 2021 at 8:07am |

Withe the transmission in neutral and the clutch depressed, you should be able to turn it by hand. You can see those pins in Chris's pic clearer than yours. That may be a long shot but I have seen it. May have been my wide-front when I tore it apart.

Like others have said, your about of shims. May be able to nurse it along by removing the last one?

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4034

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2021 at 8:35am Posted: 08 Jun 2021 at 8:35am |

Here is a link to a thread where I went through the hand clutch on my 45. Lots of pictures. It may give you some ideas.

|

|

Rickter

Bronze Level

Joined: 13 Jun 2016

Location: SW Iowa

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2021 at 3:02pm Posted: 08 Jun 2021 at 3:02pm |

Thanks Steve, Chris, Mike and everyone for suggestions and photos a big help. Foot clutch locked in easy to turn and have a look now. Bolts holding the stack together seemed tight. Loosened those and removed shims from each of the three locations. Each location had a different number of shims  - one had 1, one 2, and 3?? Probably should've marked which was which but did not and removed them all.

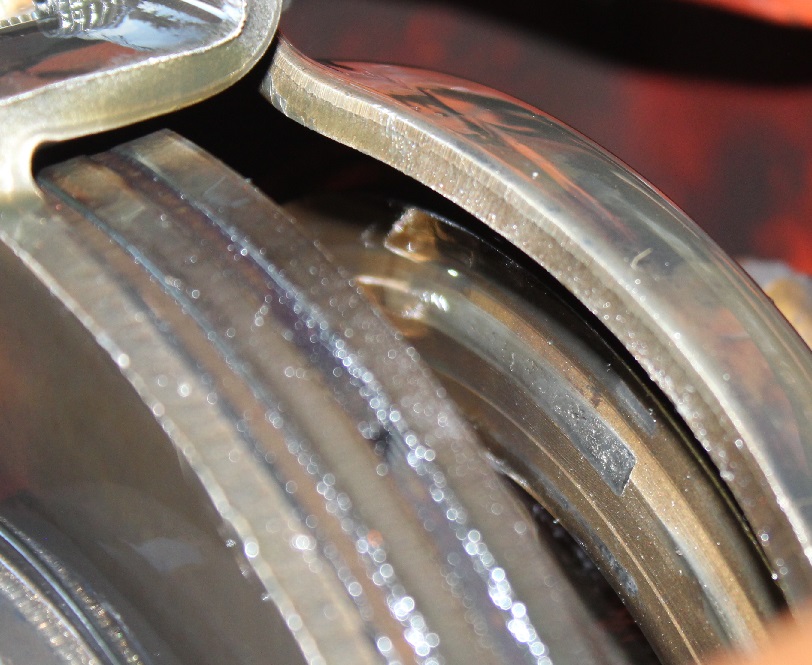

The roller levers & links all appeared complete, no missing pins although the pins all have some end to end play. Couldn't or didn't really see the contact surfaces of the rollers but the 'washer retainer' they ride on/press against as Steve mentioned did show wear. Couldn't feel much of any depressions with finger on those, could see dark areas. Soon found three areas that def could be felt with finger  :

I might be responsible for these as I was mowing last year year and there was an 'incident'. An incident where for one reason or another the mower grounded out. Tried grabbing this retainer to turn it and and make sure the rollers were in a good spot as suggested. Eventually removed the snap ring and then it was easy. Of course now I can't remember where I found the rollers.

After checking out Mikes thread (congrats Mike on that build and the thread - I know from watching at least one YouTuber regularly (Mustie1) that documenting the work adds to the work for sure) and noting the springs - they were all intact although one maybe compressed more than the others. I didn't try it but seemed like maybe these can be pulled with the stack loose?

Buttoned everything back up and mowed. The hand clutch stays locked back now which is a whole different experience than resting one hand on it all the time. The 'grabbing' that I initially was asking about is worse. Makes sense tho - removed an (odd ball?) assortment of shims decreasing the clearance between plate-disc.

I'm guessing that my mower incident last year gouged out the retaining washer and maybe bent something else causing the grabbing. Never noticed this hand clutch slipping at all, seemed to work great other than not staying locked back when under way.

I assume some new clutch parts are in order but also that this requires splitting the tube? If so that will take lots of study and prep on my part. I'm okay putting some shims back too and seeing what works best. The back plate springs Mike mentioned are my first candidate for 'grabbing' issue. One did look more compressed than the other two although I didn't get any good measure of how the plates sat. The gouged washer retainer normally stays aligned with everything else and damage there shouldn't necessarily matter...? Stays aligned barring any sudden stops.

Last thing I'll add now: following guidance here or another Allis site - can't remember for sure, I swapped position of the left ram and the aux hyd hoses where they join the pump. Last year I think and I think this fixed my 'hold' issue. I had been working on some kind of indicator that would show me what the mower level was doing without looking back all the time (Mike's skids look like a great solution!) because it def was not 'holding' (using the hold settings for hyd described in Operators Manual of course). I think the story was only one ram was lifting/holding prior to swapping? Pretty rock solid over 15-20 minutes of mowing yesterday anyway. Maybe common knowledge, maybe unapproved hack just know its working better.

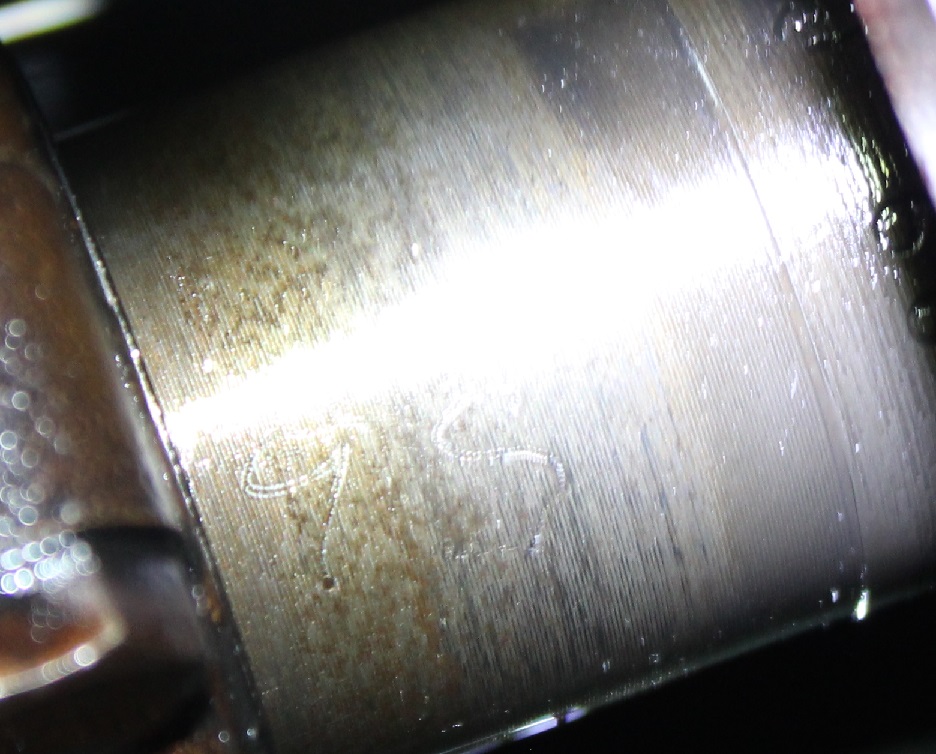

Sorry one more pic:

Kind of hard to see but looks like a "9 S" scratched on what I'm guessing is the trans shaft. As always some progress and some 'issues'. Thanks again to all for the help!

-matt

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8448

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2021 at 9:02pm Posted: 08 Jun 2021 at 9:02pm |

Matt, Your welcome, and these tractors are 70 years old and some have been worked hard. as a ref I think the shim stack is maybe .25 inch thick when new. (Maybe less???) and the clutch plate are IIRC .10 inch thick. With out taking this out there is not much other than the shim work and the brass throw out unit to be replaced. Regards, Chris

Edited by Sugarmaker - 08 Jun 2021 at 9:03pm

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4034

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jun 2021 at 8:42am Posted: 09 Jun 2021 at 8:42am |

Rickter, it sounds like the facing on your clutch discs is pretty well gone. There are options for fixing this but you're going to have to get the torque-tube out to do it. The two I've done I did a 'lazy-man's split' on. Pull the right frame rail then the engine, bell-housing, and torque-tube.

Where in Iowa are you located?

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4034

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jun 2021 at 8:33am Posted: 10 Jun 2021 at 8:33am |

I looked up another old thread of mine, unfortunately the pics were all on p-bucket and are now dead. Went through the torque-tube/hand-clutch on that one too.

I have quite a few parts for these hand-clutchs, and I'll bet LON has a lot more.

|

|

Rickter

Bronze Level

Joined: 13 Jun 2016

Location: SW Iowa

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jun 2021 at 12:30pm Posted: 11 Jun 2021 at 12:30pm |

|

The tractor is South of Bridgewater in Adair County. I split time between there and Iowa City and dream of rollback car haulers. Your thread mentioned Char Lyn - ours is in a tote. Is it the belt pulley everyone needs...and/or spindle maybe? Some part off an Olds or similar that goes for big $$ on eBay of course. I remember when you could poke around in junk yards unsupervised. Imma have to start reading the site more. Thanks take care

|

|

Rickter

Bronze Level

Joined: 13 Jun 2016

Location: SW Iowa

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Jun 2021 at 10:34am Posted: 17 Jun 2021 at 10:34am |

Chris - yes in some photos I'm like 'wow that's a lotta shim stack!' My measurement of drive discs is probably off. The shifter collar looks like it could be removed as it's two halves? There is play in all that stuff but of course I've no idea whats acceptable.

Here is a too long update but hey, pictures!

Had the hand clutch open again (and again) and tried a few different things to alleviate the very slight 'grabbing' of the clutch (enough to just rock the rear wheels forward then they settle back) when engine clutch in gear and hand/transmission clutch disengaged. Also hand clutch not staying locked back - would pop out under way.

Removing all shims had made the grabbing worse. Because I had found the shims distributed unevenly, tried putting them back similarly thinking maybe the uneven arrangement was trying to level out a high spot. One shim on each of two retainers and 4 or 5 on suspect retainer for whatever reason showing a larger gap between plates. Also a curious little divot on the back plate at this retainer location, maybe marked by someone? Removed springs - couple springs have wear spots where they are a little flat, and they aren't straight but otherwise push the plates apart.

Tested. Still grabbing, maybe a little better than 'no shims'. Clutch still locking back well.

Into the trans clutch again. Drained gear oil. 3 drain plugs 2 fill plugs. Tried to clean everything. Tried to take some measurements. Plates have a raised edge making them harder to measure, drive discs measured something like .154" and .158". Bearings and gears leading down to PTO all looked good. Grooves no smooth spots on discs and plates. Cleaned shims and put them back evenly - 2 at each retainer. Tested.

Worst damage I could find

Drive discs groovy not as thick as plates but thicker than others I've seen in photos

In first gear with hand clutch disengaged let out the engine clutch. No grabbing at all. Puttered around the yard and while much better, still wanting to grab a little bit when stopped but still in gear. Feedback thru the hand lever was much smoother whereas before you could feel more vibration thru the lever when engaging. Maybe it just needs some good hard use to wear even

As I understand it shims are typically removed as the plates wear down, evidenced by the hand lever not locking back or staying locked. I did rotate the washer retainer to a new location first time in the clutch and the lever has stayed locked back since then...so I'd like to add more shims (but I'm fresh out) to see if the 'grab' goes away and if the lever will start to pop out of lock again. Theorizing here that maybe the lock back failing was due to wear/damage on washer retainer, and not necessarily discs being worn out. Of course this is the first clutch I've played with so that theory is not based on very much.

Seems like the separation of the discs is dependent on how freely they travel - the springs of course but also maybe fit at retainers and dirt generally, like on the splines of the shaft down below. Sliding the discs by hand feels like they could get hung up or be impeded.

Plate tabs must have to slide freely here within retainer. Spring holes look okay.

Seems like about 22qts came out and only put back 18-ish as expected with PTO. Used both fill plugs.

Didn't think the rear diff was gonna yield anything until poked at the little fudge disc at the right blocking the drain. Not sure but I think 'TB' stands for Tractor Boss

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8448

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Jun 2021 at 4:14pm Posted: 17 Jun 2021 at 4:14pm |

I think this video from Dennis is a good straight forward view of these hand clutches. He is doing a WD45 version (3 plate).

Yes the brass throw out can be replaced in the tractor. Also the rod clevis adjuster on the hand clutch lever to lever coming out of the clutch housing can be adjusted to put the handle at correct location too. I like to adjust them so they dont hit me in the knee! Regards, Chris

Edited by Sugarmaker - 17 Jun 2021 at 4:15pm

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

SteveM C/IL wrote:

SteveM C/IL wrote:

- one had 1, one 2, and 3?? Probably should've marked which was which but did not and removed them all.

- one had 1, one 2, and 3?? Probably should've marked which was which but did not and removed them all.  :

:

Drive discs groovy not as thick as plates but thicker than others I've seen in photos

Drive discs groovy not as thick as plates but thicker than others I've seen in photos

Plate tabs must have to slide freely here within retainer. Spring holes look okay.

Plate tabs must have to slide freely here within retainer. Spring holes look okay.

Didn't think the rear diff was gonna yield anything until poked at the little fudge disc at the right blocking the drain. Not sure but I think 'TB' stands for Tractor Boss

Didn't think the rear diff was gonna yield anything until poked at the little fudge disc at the right blocking the drain. Not sure but I think 'TB' stands for Tractor Boss