| Author |

Topic Search Topic Search  Topic Options Topic Options

|

FrankB

Silver Level

Joined: 12 Aug 2014

Location: Ontario/Canada

Points: 61

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis 7060 Topic: Allis 7060

Posted: 14 Jun 2017 at 9:19pm |

Hi , I have a transmission problem on a 2979 Allis Power Director transmission. I suspect the transmission brake has failed . The tractor drags when you turn the starter on & when you are in neutral you can not put in in gear due to gear clash . Cables are good free play is good I have 200 psi at the tesr port , fork is not missing the large washer and the allen key is tight , any other suggestions would be appreciated before I split the tractor . Thanks in advance…Frank

|

|

|

Sponsored Links

|

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2446

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2017 at 9:59pm Posted: 14 Jun 2017 at 9:59pm |

|

The brake disc could be worn out, the pin in the brake piston could be sheared off,or the plates in the power director could be warped. If you believe that the clutch cable is adjusted correctly, then I would split it and look at the power director clutch.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jun 2017 at 10:15pm Posted: 14 Jun 2017 at 10:15pm |

|

Take all free pay out of cable with engine off. MACK

|

|

Dans 7080

Orange Level

Joined: 05 Feb 2010

Points: 1146

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2017 at 5:33am Posted: 15 Jun 2017 at 5:33am |

|

Make sure the cable in the top hold down is all the way to the front before tightening. A small adjustment will make a big difference.

|

|

When someone tells you Nothings Impossible, Tell them to slam a revolving door

|

|

FrankB

Silver Level

Joined: 12 Aug 2014

Location: Ontario/Canada

Points: 61

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2017 at 8:40pm Posted: 15 Jun 2017 at 8:40pm |

Thanks for the help once again . I have adjusted the cable . The tractor was working perfectly all morning , stopped for break then it would not go in gear , lots of gear clash and if you put it in gear ,put the clutch pedal down and tried to start the tractor the starter would drive the tractor forward . Seems like a sudden failure to me . Maybe the pin in the piston is sheared . Thanks all for the suggestions tractor is now ready to split , I"ll get to that job first thing Saturday .

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2446

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jun 2017 at 9:12pm Posted: 15 Jun 2017 at 9:12pm |

|

Sure sounds like warped clutch discs. If that has happened,it may have damaged the brake disc also. You will need to remove the transmission to get to the brake unless you want to reach up through the hole where the hydraulic pumps mount.

|

|

FrankB

Silver Level

Joined: 12 Aug 2014

Location: Ontario/Canada

Points: 61

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jun 2017 at 9:17pm Posted: 16 Jun 2017 at 9:17pm |

Hi Lynn , appreciate the help , Don"t know if you recall but this is the tractor that originally came to this site for help about three years ago . I had broken pinion gear , broken reverse idler gear and a broken gear in the range transmission , when we did that repair I replaced the friction discs and the spacers , the tractor has only worked 3 to 4 hundred hours per year since then so you are looking at 1000 hours max on basically a brand new clutch , the tractor has worked flawlessly since then until this happened , and the failure happened so abruptly it's suspicious . Thank's again for the help . I will be plotting the tractor on Monday , should be interesting . Thanks

|

|

FrankB

Silver Level

Joined: 12 Aug 2014

Location: Ontario/Canada

Points: 61

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 19 Jun 2017 at 8:00pm Posted: 19 Jun 2017 at 8:00pm |

Hello Lynn Marshall , Split the tractor , Took out the power director and you were 100% bang on the money,the spacers are blue from heat and the friction discs look like frisbee's they're so bent . I also discovered another problem , it appears this tractor has been apart at one point in time and put a power director unit in from a 7010 as it only has 5 of each disc instead of 6 . My next question is would 1 disc less overload the clutch with the 40 -50 hp difference or should that clutch be able to handle the difference . Is the difference in the thickness of the piston , as all other part #s look to be the same between a 7010 & a 7060 . Great call and great help from this site once again , fantastic resource thank you folks for providing it .

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Jun 2017 at 9:03pm Posted: 19 Jun 2017 at 9:03pm |

|

Piston is the difference. Either get a different piston or machine that one down.

Check pressure when you get it back to gather. Has to be a reason for the failure, don't happen that offend. MACK

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2446

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2017 at 8:02am Posted: 20 Jun 2017 at 8:02am |

|

|

|

FrankB

Silver Level

Joined: 12 Aug 2014

Location: Ontario/Canada

Points: 61

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2017 at 7:24pm Posted: 20 Jun 2017 at 7:24pm |

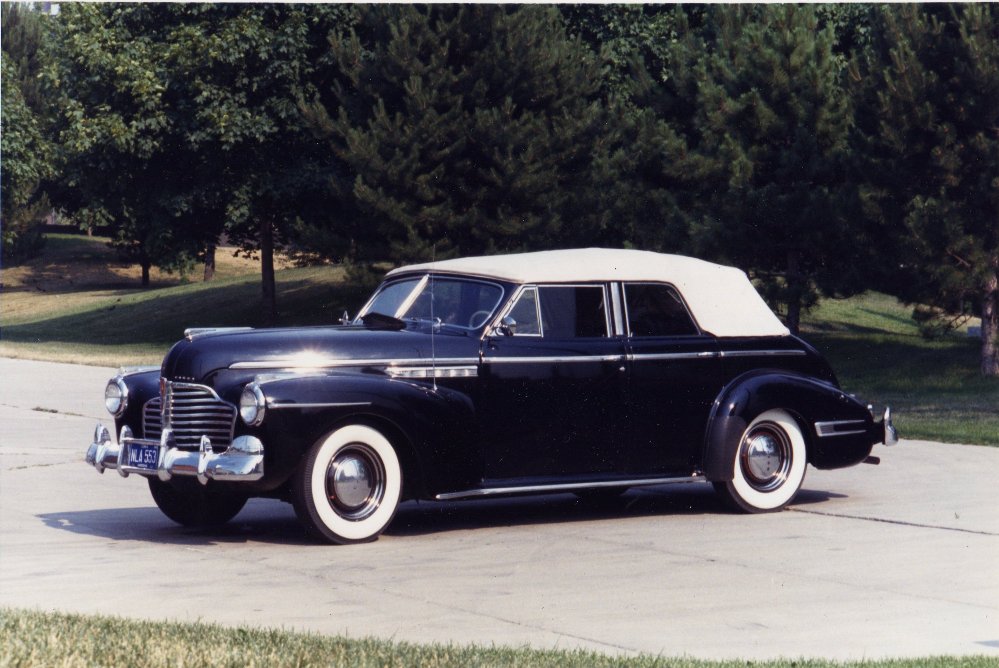

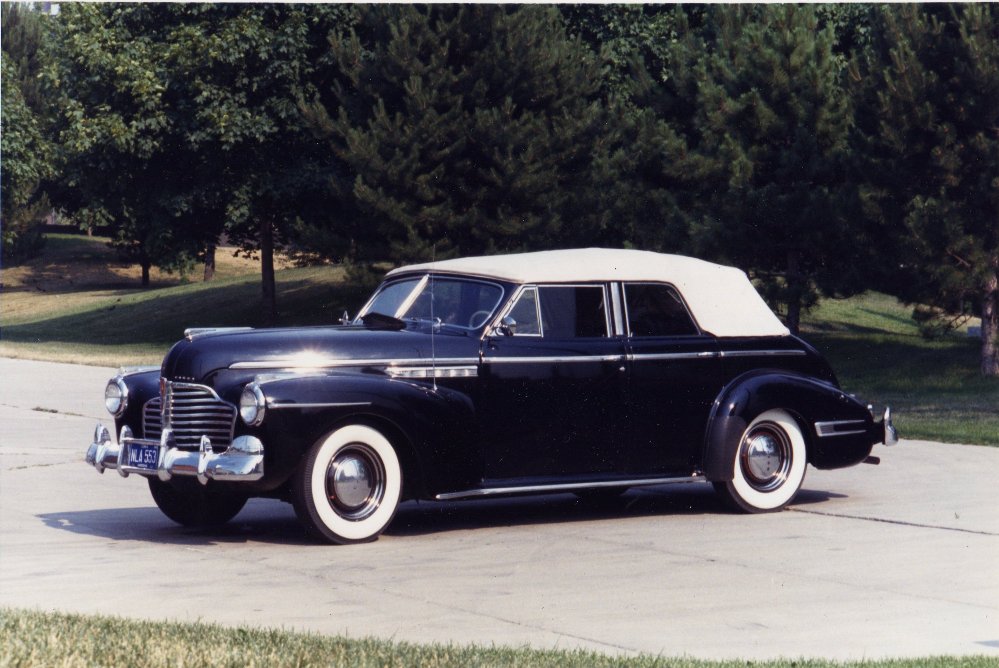

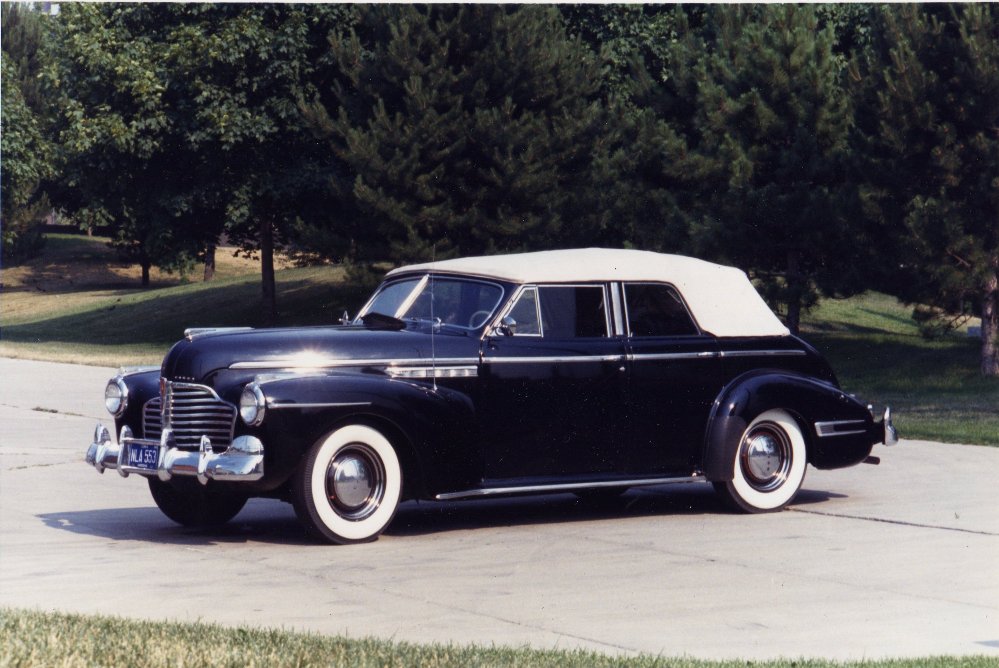

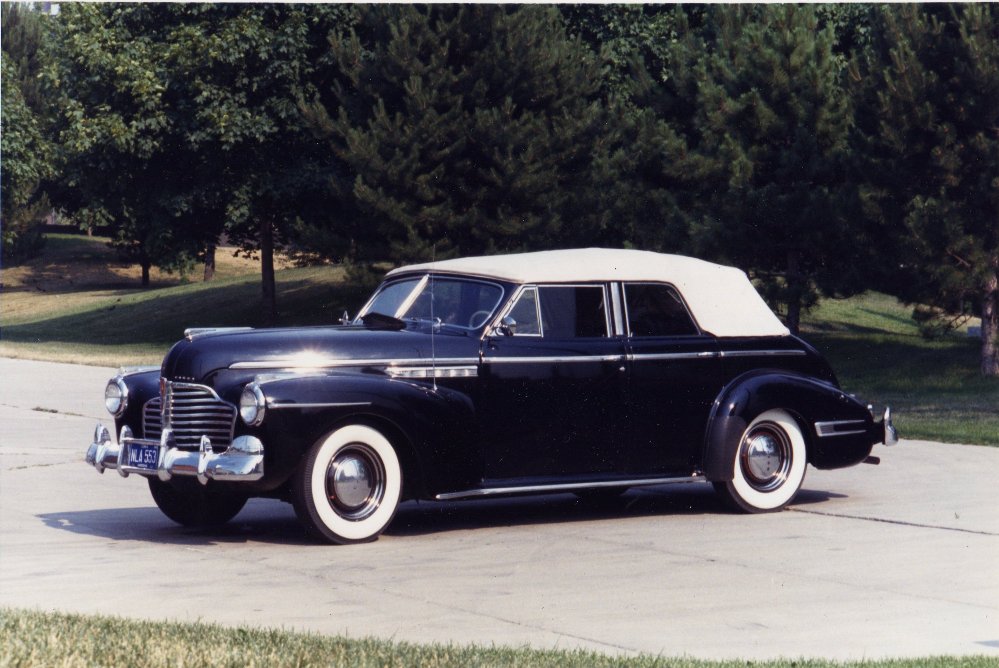

Hello Lynn & Mack , thank you so much for the help , you guys are awesome . I work with someone who is a skilled trades person, he has lathes,surface grinders & milling machines so turning the piston down may be feasible , where can I find the dimension for the thinner piston ,another option would be to put a drive disc & a separator together mic them and turn the piston down that much,is that feasible . The plates & discs I will just order from Agco , the other question would be why this happened,is it possible low hydraulic fluid could be the cause . I have some pics and will try to post them when I can thank you guys again really appreciate the help as where I live there are no more Allis mechanics or dealers still operating ,finding help is difficult ….Thanks Frank

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2446

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jun 2017 at 10:27pm Posted: 20 Jun 2017 at 10:27pm |

|

I probably have the thickness dimension somewhere in my materials. I doubt that low oil would be the cause of your problem. Low pressure could be though. Or it could have been to much power for the amount of discs it had.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)