HD6G Shift Lever Problem

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=99279

Printed Date: 08 Feb 2026 at 4:03pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: HD6G Shift Lever Problem

Posted By: dccarpenter

Subject: HD6G Shift Lever Problem

Date Posted: 21 Dec 2014 at 11:29am

|

Hello all, I just bought a HD6G track loader, had it dropped off at my house and it moved fine off the trailer just as it did when I went to look at it, I moved it from forward to reverse multiple times when I ran it at the previous owners house. I moved it around in my yard a few times and after playing around for 5 minutes I went to put it in reverse. It won't seem to engage into neutral or reverse, the shifter seems to move out of the forward position and towards where it should be to be in reverse but I don't have any resistance and it won't lock into reverse. Regardless of the position I move the shifter the loader is in 'forward' as whenever I pull in on the clutch lever the machine moves forward just as it does when the loader is in forward gear. The lever feels 'loose' so to speak but I removed the lever and the upper connection seems to be fine. Is there any type of serviceable linkage that I may have messed up or that I can adjust ? Thanks a ton for any help. |

Replies:

Posted By: DMiller

Date Posted: 21 Dec 2014 at 4:55pm

| Sounds like the lever has come out of the shift forks, may need to remove the shift cover and inspect for worn area it could have slipped thru. |

Posted By: michale34

Date Posted: 22 Dec 2014 at 6:56pm

| Mine had done that before my dad called it hung in high gear. I take the shifter out pour a little oil down the hole and take a flat bare and line the forks back up |

Posted By: HD6GTOM

Date Posted: 23 Dec 2014 at 7:39am

| the last 1 I had the shift lever broke off inside the housing, just a matter of taking out the bolts and having it welded up. |

Posted By: dccarpenter

Date Posted: 27 Dec 2014 at 6:02pm

|

I removed the shifter and lined the forks back up with a long screwdriver. It works for about 15 minutes of use and then seems to slip out again while shifting. We are trying to baby it but it seems no matter what it will get hung up between gears again. The forks don't appear to be worn so I'm unsure what is causing the problem. I did top up the fluid for the transmission by adding gear oil in the reservoir as well as putting a small bit down on the forks to help the thing move. I had a diesel mechanic take a quick look at it and he was unsure what's going on either. |

Posted By: michale34

Date Posted: 27 Dec 2014 at 10:48pm

| mine is bad about doing it when i use other gears other than low so i just use low gear does yours have the straight stick or the stick with a bend in it |

Posted By: DMiller

Date Posted: 28 Dec 2014 at 4:12am

|

Are three places that wear on shift mechanisms, the end of the lever itself, the slots in the shift rail/fork engagement point for the lever and the forks themselves where they ride on the gearing, with wear on one they will do OK, with wear on all three they can look fine but have enough clearance to fall away from each other. Peer down into the area where the lever engages the forks, see if it appears to have room between the forks that could allow the lever to get between them, inspect the ends of the cast forks to see if there is wear there also that is allowing a engaged fork room between to allow the lever to fall away. Look at the lever tip, is it fairly consistent as to thickness, does it seem to have lost metal at the ends of the tip, all of which can lead to the lever falling out of slot. |

Posted By: Coke-in-MN

Date Posted: 28 Dec 2014 at 6:52am

|

couple wear areas , the ball on end of shifting lever the bolts through the tower the round spacer between bolts in tower the pin that goes between shift fork and spacer the shift lever should have no twist in it (rotation) just fwd and back and side to side should be in straight line also . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: dccarpenter

Date Posted: 28 Dec 2014 at 7:08pm

|

Thank you for all the replies. As far as shifter goes I have a shifter with a bend in it, not a straight shifter to respond to michale34's question. If we stay in just the high gear and reverse we don't pop out but when I move to the forward right to go into low gear that is when I seem to have problems with it getting stuck between gears. The mechanic added a small bit of material to the end of the shifter rod via welding/grinding to try and keep it from popping out but it didn't help any. Nevertheless I'm sure the bottom of the shifter is no longer the problem. Is there any way to replace the forks without dropping the whole transmission? I can only assume they are worn at this point, the pin and all parts I've had out looked pretty decent. If there was an access panel my mechanic is an excellent welder/fab guy perhaps there is something he could do. I really only need low gear, neutral and reverse so perhaps there is some way he can lock out the other gears. Also, I will inspect the bolts on the tower as it is currently stuck out of gear/between gears. When you reference round spacer do you mean the rubber gasket piece? I have ordered a service manual but don't have it yet so I'm flying blind on what it should look like normally. |

Posted By: Coke-in-MN

Date Posted: 28 Dec 2014 at 7:39pm

|

there is a steel tube (spacer) which is held in place by the 2 bolts through tower , these bolts have the ends turned down to fit in that tube to allow it to move . In the center of the tube (spacer) is a pin which holds the shifting yoke with the ball end . if this pin is loose in the yoke it allows the ball end to be out of alignment with rails and can cause it to slip out . the pin wears as well as the pin holes in yoke, by drilling spacer for larger pin to fit worn holes in yoke it will tighten up full mechanism . I made new bolts , then found larger pin to fit yoke , then ground flats into side of pin so it is held into position by bolt ends , I needed to shim bolts to get right fit . With the offset lever force is applied at a angle to full tower and wear is worse than on straight lever . When you shift its like the yoke is trying to rotate some also and that wear on pin and yoke happens . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: Dozer

Date Posted: 29 Dec 2014 at 9:07am

I have not done this but it looks like you do not have to remove the transmission to get the forks out. |

Posted By: Dozer

Date Posted: 29 Dec 2014 at 9:16am

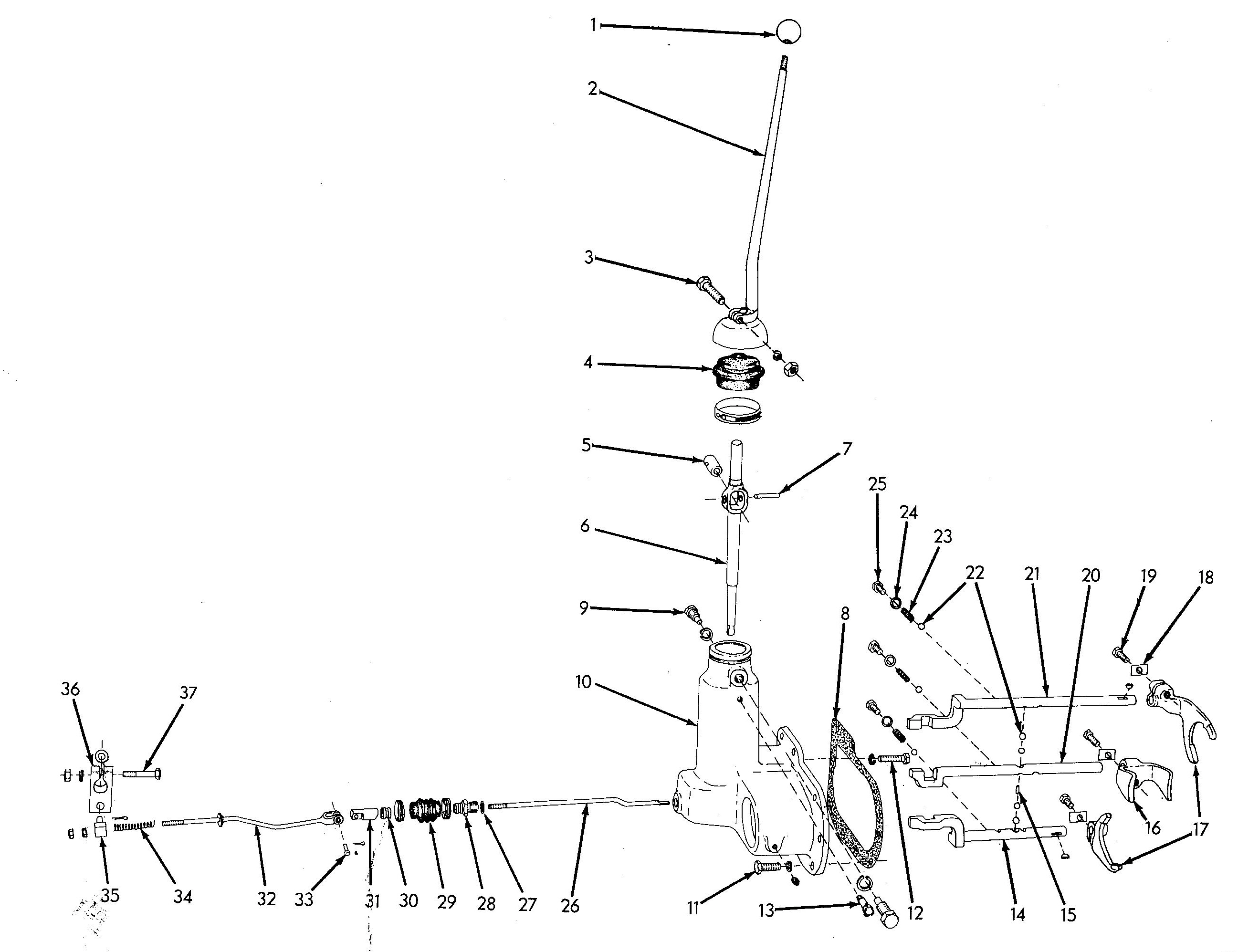

|

Sorry It looks like I uploaded a large picture The interesting part is bottom right. |

Posted By: Coke-in-MN

Date Posted: 29 Dec 2014 at 10:30am

|

fixing 5 , 7 , 9 and building up end of 6 solved my problems and that of 3 other machines I worked on . The 5B I had the lever was straight and less wear than the 5G with offset lever ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: gemdozer

Date Posted: 29 Dec 2014 at 4:08pm

| The lever shift 086705 is straight and the one on photo is the rod locking plunger |

Posted By: dadsdozerhd5b

Date Posted: 01 Jan 2015 at 7:34am

|

it sounds like your issue is in the shift tower like Coke said. if you had a shift fork issue it should not get bound up in 2 gears or neutral. When you pull out the shift fork and reset the fork levers, are 2 of them out of place? if the problem was inside the transmission the fork levers would be lined up when you took it out. it does not take much wear to make them be out of line and do exactly what you are describing. Like Coke said there should not be any rotational twist in the shift handle. ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: AC Mel

Date Posted: 01 Jan 2015 at 10:50am

| Here's a post you could revisit from almost two years ago of a discussion about shift linkages. May or may not be helpful. http://%20www.allischalmers.com/forum/forum_posts.asp?TID=69356&KW=&PID=545985&title=55-hd5-transmission-question#545985" rel="nofollow - http:// www.allischalmers.com/forum/forum_posts.asp?TID=69356&KW=&PID=545985&title=55-hd5-transmission-question#545985 |

Posted By: AC Mel

Date Posted: 01 Jan 2015 at 11:08am

|

Ok, that one doesn't work I'll try again. Nope still won't work. it was a post started on April 26 2013. I added some pictures of an HD6 shift lever that was worn for discussion of different problems. Any way, HAPPY NEW YEAR ALL !! |

Posted By: Coke-in-MN

Date Posted: 01 Jan 2015 at 12:44pm

|

tried the way back machine post search site and says that page isn't archived on that site Hmm and that search use to work good for old posts . http://archive.org/web/" rel="nofollow - http://archive.org/web/ ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: AC Mel

Date Posted: 01 Jan 2015 at 8:46pm

| Coke, Thanks for taking time to look into that post. So FYI I remembered that we had that discussion and I posted some pictures. I did an advanced search on my posts using AC Mel, found the post ,emailed the link to my email and it worked fine. I copied and pasted it thru the hyperlink on the forum website and you know the rest of the story. But it still is in the system somewhere |

Posted By: Coke-in-MN

Date Posted: 01 Jan 2015 at 8:50pm

|

was just thinking - if you find the site again - just make a post onto it and it could bring it to the top of the page here . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: Coke-in-MN

Date Posted: 02 Jan 2015 at 12:02pm

|

http://www.allischalmers.com/forum/forum_posts.asp?TID=69356&title=55-hd5-transmission-question" rel="nofollow - http://www.allischalmers.com/forum/forum_posts.asp?TID=69356&title=55-hd5-transmission-question

Now the link works back to some good pictures of worn parts and what to do to fix the problem . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: dccarpenter

Date Posted: 03 Jan 2015 at 10:33am

|

I really appreciate all of the replies, especially the link to the previous thread with photos. I've managed to take the play out of the shifter by tightening up that bolt/pin area with some welding and shaping. We also welded onto one of the forks where we could see that it was worn, it was tough on the welder but he was able to do it and weld some nickel rods onto there. I used the machine for 2 days with no problems but it yet again slipped out of gear. It looks like fork wear may be my culprit and I may have to have him do some more welding there. The gearshift seems pretty solid now. |

Posted By: Coke-in-MN

Date Posted: 03 Jan 2015 at 12:49pm

|

remember any slop is modified in it's movement over a distance , so a couple 32nd inch play in bolts could be 1/4" at ball on shifter , it all needs to be tight and aligned ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: dccarpenter

Date Posted: 03 Jan 2015 at 4:23pm

|

It is far from perfect at the moment, I'm thinking I need to pull it and have a machinist rebuild entirely with new bolts and pins. The only area I'm uncertain on how to approach with the machinist is the bottom end as far as how big I can go with it as I don't have the original dimension and I know if it is too big it obviously won't fit but if too small will pop out easily. |

Posted By: DMiller

Date Posted: 03 Jan 2015 at 7:15pm

| An easy way to determine the amount to size up would be to measure the gate throat on the best shift rail at the point of least wear, give the shifter 1/32" at each side of throw or so, .030-.060 of clearance and should work like a champ. Main thing is to get the lever to sit and stay seated straight in the gates. |