HD5 DD 2-71 governor not working.

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=83151

Printed Date: 07 Feb 2026 at 7:32pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: HD5 DD 2-71 governor not working.

Posted By: rwhendrix

Subject: HD5 DD 2-71 governor not working.

Date Posted: 13 Jan 2014 at 7:32am

|

Hello, thought I would pick everyones brain before I begin any repair attempts. I have a otherwise good runningn detroit diesel 2-71 in my HD5G dozer. Well it is a little hard starting in cold weather. I use a bit of either then it fires right up. Anyway, up until this past summer, the governor worked as it should. But it doesnt now. The linkages all still appear intact and move with the throttle. But it will not adjust for load and the engine will not keep up. Even idling the gov wont adj to keep rpms level. I have good throttle control and power, just no governor to steady rpms any. Strange. I have already pulled fuel filters and replaced. Pulled injectors, cleaned, and replaced the little filters and copper rings. The injectors moved freely. They are original I think. HV7s. But they are both clean and working. I did the screwdriver test on them and rpm dropped on both cylinders about the same. No visible leaks from the fuel lines under valve cover. It runns pretty good actually. Just wont hold level rpms under any load with the governor. So, have any of you seen this kind of thing before? Could there be something broken inside or disconnected? I havnt tamperd with it yet other than pulling cover, nothing looked broken or was siezed up. But I dont see the little arm from the box moving like it is trying to adjust throttle position any. Any ideas or suggestions? HD5G, s# 11667, DD 2-71 Im gonna open up governor and see if its broken.

|

Replies:

Posted By: rwhendrix

Date Posted: 13 Jan 2014 at 8:10pm

|

Took the governor out tonight. Only thing I noticed was that the fly weights dont move much at all. I would have expected more travel, at least enough outward swing to cause the little fork behind to move its linkage. I think I may have located the problem. But as I dont have any example as to the normal amount of movement Im at a loss. I didnt find any loose or missing parts inside. So any ideas?

|

Posted By: rwhendrix

Date Posted: 13 Jan 2014 at 8:17pm

|

Posted By: rwhendrix

Date Posted: 15 Jan 2014 at 7:06am

|

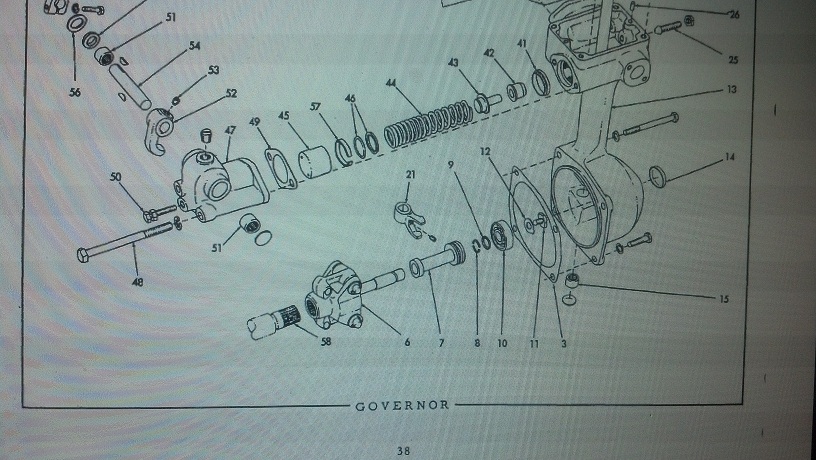

In the above diagram, the little tube #7 was frozen in place on #6 shaft. This is supposed to slide on the shaft to move the fork #21 and linkage as the weights swing in and out. I was suprised it was siezed up on the shaft as the whole thing was oil soaked inside the governor casing. To free the tube #7 from shaft #6, I used a torch to heat up to a low red. when it cooled I was able to tap it off with a hammer and flat punch. I will say that the whole thing is a pain to tear apart when its stuck as you cannot move parts into position to remove. I was able to not damage the casing which is aluminum. The small bearing and washer on the end of #7 was broken on removal. I will have to come up with a replacement for that. Cant wait to get it all back together and see it work!

|

Posted By: TramwayGuy

Date Posted: 15 Jan 2014 at 8:31am

|

WHEN YOU START IT UP FOR THE FIRST TIME AFTER WORKING ON THE GOVERNOR, PLEASE BE READY TO CLOSE THE AIR INTAKE WITH SOMETHING in case the engine decides to 'run away'. If there is no 'flapper' on the blower, have a board ready to block off the intake pipe. Otherwise, you might be looking at a mess of 'exploded' parts.

|

Posted By: HD6GTOM

Date Posted: 15 Jan 2014 at 8:32am

| make sure your fuel shutoff is in good working order before you try to start her. If that gov is not perfect, they take a matter of seconds to run away. I've seen it happen with inexperienced mechanics, results are usually bad. |

Posted By: HD6GTOM

Date Posted: 15 Jan 2014 at 8:33am

| I guess tramway guy and I were thinking the same thing at the same time. |

Posted By: rwhendrix

Date Posted: 15 Jan 2014 at 9:01am

|

OK thanks. I will remember that. Yes it has a air shut off flap above the compressor. Ive had this dozer rev up and run away just like you say. Scary. At the time I hadnt ever known they could do that so I was in shock as it was happening. lol But i was able to shut it down by simply closing the shut off air flap by the knob provided for the operator. I will keep you informed as to how everything goes on re assembly and start up.

|

Posted By: DMiller

Date Posted: 15 Jan 2014 at 3:55pm

| Be mindful, does not happen often but on shutting air flow off can suck the blower seals, if does you will have to await the engine running out of oil before it will shut down. |

Posted By: rwhendrix

Date Posted: 15 Jan 2014 at 6:45pm

| That would really suck.... lol. Ok thanks. I have a fuel shut off too. I will try to be careful. |

Posted By: rwhendrix

Date Posted: 18 Jan 2014 at 1:00pm

I found the problem was with a tube called the riser assembly. It was rusted stuck to the weighted shaft. Strange how it could get rusted even tho there was some oil in the governor housing casting. It was difficult to remove as the pieces were stuck together but I managed to do so. A propane torch heated up the tube and I was able to remove it. After cleaning all the parts, inspection and lubrication, I was able to reassemble the governor.  I was able to move the fly weights and observe the linkage movement. I will install it back on the engine and follow the manual to set spring tension and linkage. I will be as careful as I can to follow your warnings about first startup and run away engine revs.

|

Posted By: rwhendrix

Date Posted: 18 Jan 2014 at 1:14pm

I was able to put the original riser tube assembly back together. But I did look around on the internet to see price and availbility on a replacement. Part# 5155571. For Detroit diesel 2-71 engines with variable speed governors. I found about 6 sources for anything from custom built to new old stock part. From as low as $65 NOS to as high as $198 built !!. |

Posted By: DMiller

Date Posted: 18 Jan 2014 at 5:36pm

|

You will need to run a full rack adjustment, it is in the manual and follow the instructions EXPLICITLY. This is not something you want to go haywire. If the tube was freed to your satisfaction, you did oil it up well prior to re-install and you can pour some oil thru it to make sure all the moving parts are lubricated prior to a start on adjusting the rack. Good luck, should do fine. |

Posted By: rwhendrix

Date Posted: 20 Jan 2014 at 6:34pm

|

It runs great! Thanks for your advise guys. I was able to adj the rack and linkages by following the instructions in the operatiors book. It was really close already. Started right up. Better than it had in years. better than when I first ran it in 2005. Im very pleased. Anyway, I wanted to share a video I made of this repair. Thanks for keeping me motivated with your forum. http://www.youtube.com/watch?v=UWxrJA639OQ&feature=youtu.be" rel="nofollow - http://www.youtube.com/watch?v=UWxrJA639OQ&feature=youtu.be |

Posted By: JC-WI

Date Posted: 20 Jan 2014 at 7:17pm

|

Very Good. Thanks for taking the time to put this video together. I enjoyed seeing it. JC ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |