D17 Industrial Series III - brakes

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=8136

Printed Date: 29 Dec 2025 at 6:39am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D17 Industrial Series III - brakes

Posted By: TomMN

Subject: D17 Industrial Series III - brakes

Date Posted: 15 Feb 2010 at 1:27pm

|

What could cause the brakes to disintegrate like this? I have new parts from Agco and have put pictures of them on my page: http://home.comcast.net/%7Eold_allis/ac-D17-brakes.html - http://home.comcast.net/~old_allis/ac-D17-brakes.html I'd like to avoid having it happen again since the new parts are somewhat more than cheap. Thanks. Tom |

Replies:

Posted By: Eldon (WA)

Date Posted: 15 Feb 2010 at 2:06pm

|

My guess would be the balls and plate got worn to the point they wedged together....heavy tractor, high speed, on pavement, apply brakes and POP! My D17 and 175 are too that point where the wheel occasionally locks up. It makes a scary sound and if you are in soft dirt it will spin the tractor around.....new parts should cure the problem. ------------- ALLIS EXPRESS! This year: |

Posted By: TomMN

Date Posted: 15 Feb 2010 at 2:41pm

| Thanks, I'm hoping the new parts are the cure. The service manual I have doesn't mention the series III and IV brakes, even though it has other series IV stuff. Other than shims on the final drive side friction plate I don't see any side to side adjustment, and I don't know what the spacing should be with no brakes applied. Tom |

Posted By: Eldon (WA)

Date Posted: 15 Feb 2010 at 2:52pm

|

Here's what the IT manual says for the 170....I'd think they would be the same.

A dimension of 2.034-2.044 inches should be maintained between the outer brake friction surface and the brake friction surface on the differential bearing carriers. To check this dimension, install final drive units without brake band or drum and disc units and measure distance between friction plate and bearing carrier brake friction surfaces with an inside micrometer. Use shims between the outer friction plate and final drive pinion shaft sleeve to obtain the correct dimension. ------------- ALLIS EXPRESS! This year: |

Posted By: Gatz in NE

Date Posted: 15 Feb 2010 at 2:54pm

|

Scanned page out of I&Ts AC-201 Shop Manual.

The dimension is fairly critical.

|

Posted By: Gatz in NE

Date Posted: 15 Feb 2010 at 2:57pm

|

The shims Eldon is referring to are Item 9 above. (Not Item 9A) and, yes... you have to make this adjustment without the brakes or disc in place.

|

Posted By: TomMN

Date Posted: 15 Feb 2010 at 3:39pm

|

Thanks guys, excellent information. I'm no where near ready to re-assemble things yet so I'll have to copy this out and add it to my service manual for use when the time comes. Looks like just what I was in need of. Tom |

Posted By: Gatz in NE

Date Posted: 15 Feb 2010 at 6:53pm

|

Also,

Get new springs...the small tapered ones with a hook on one end as per your picture.

Do not pull too hard on these when installing.

Do not use any lube on the balls or tracks....they are to stay dry and clean.

|

Posted By: TomMN

Date Posted: 15 Feb 2010 at 8:51pm

|

I bought those tapered springs when I got my new parts so I'm ready there. I haven't installed them yet, I'll have to make sure I don't stretch them like you said. Thanks for the no lube info too. Tom |

Posted By: RichinWis

Date Posted: 21 Feb 2010 at 2:27pm

| Tom, Interesting to hear you have a Series III industrial! Doesn't seem to be many around, I have one also with the TS 1000 loader on it. Quite the machine. Good luck Rich |

Posted By: TomMN

Date Posted: 21 Feb 2010 at 3:50pm

| Hi Rich, I haven't seen another one like this before, the TS 1000 is quite a heavy duty loader. Is the one you have functional? Mine is in need of many things. |

Posted By: orangeman

Date Posted: 21 Feb 2010 at 6:17pm

|

Tom and Rich: Can you post a pic of the D17 industrial??

Was the 1000 series loader the same as the loader on the 615 machines?

|

Posted By: RichinWis

Date Posted: 21 Feb 2010 at 6:20pm

| Tom, Yes mine is functional, although not currently a showpiece, it all works, and is my loader tractor |

Posted By: RichinWis

Date Posted: 21 Feb 2010 at 6:57pm

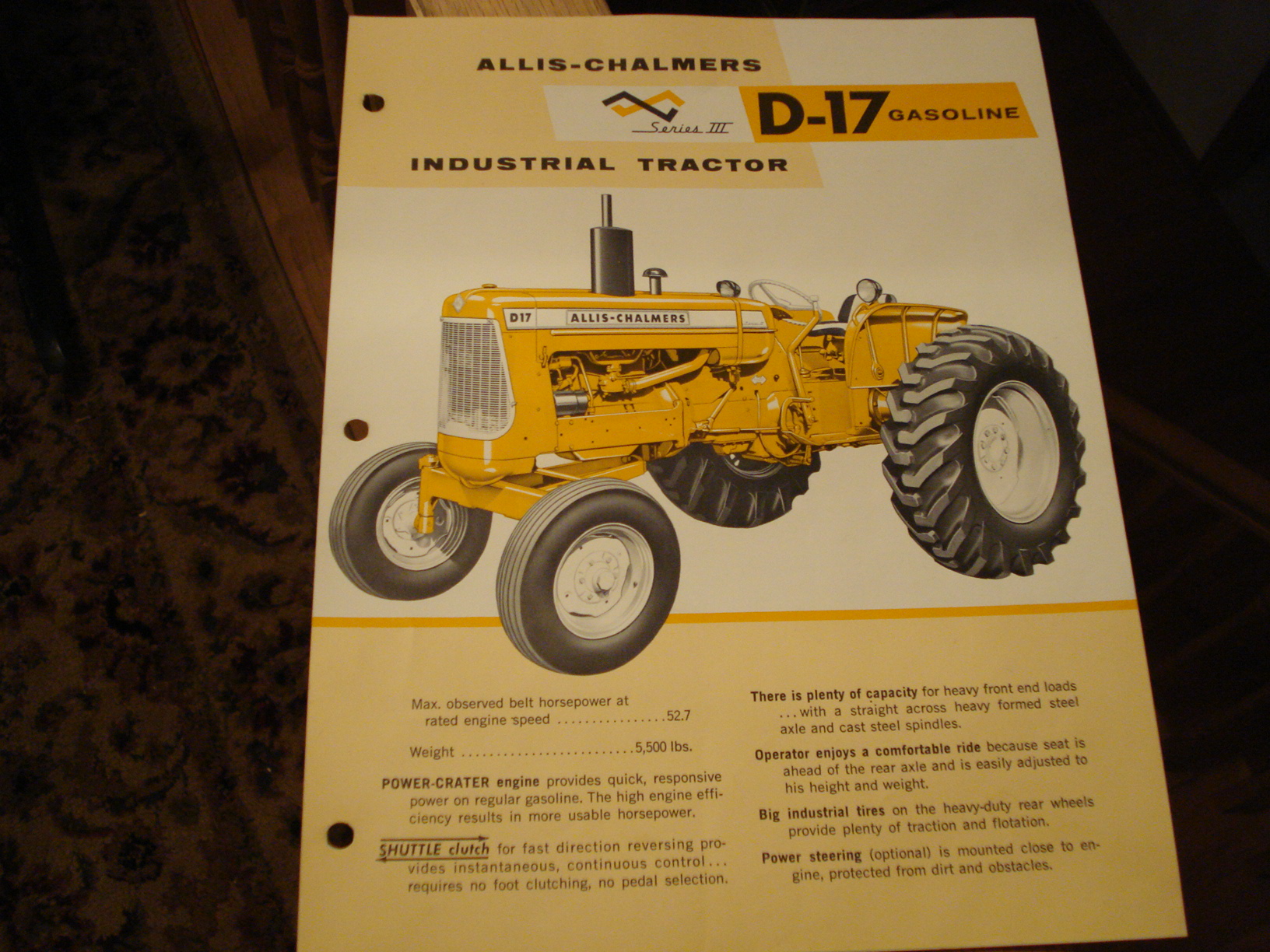

Here are some lit. pictures, I will try to find some of my tractor Here are some lit. pictures, I will try to find some of my tractor

|

Posted By: RichinWis

Date Posted: 21 Feb 2010 at 7:15pm

Here is a picture of the TS1000 loader, mine does not have the hoe on it, HTH Rich Here is a picture of the TS1000 loader, mine does not have the hoe on it, HTH Rich

|

Posted By: TomMN

Date Posted: 21 Feb 2010 at 8:19pm

|

This is mine. Not much to look at yet. Here is a link to my page for it: http://home.comcast.net/%7Eold_allis/ac-D17.html - http://home.comcast.net/~old_allis/ac-D17.html |

Posted By: RichinWis

Date Posted: 21 Feb 2010 at 9:39pm

| Well Tom, It certainly looks like a real find to me. You will find it is a very good loader tractor. You have all the important parts except the rear wheels that are unique to the industrial. I know you will have it like new when you are done. Looks like it was a twin to mine. |

Posted By: orangeman

Date Posted: 22 Feb 2010 at 3:01pm

|

Tom: I would like to make a recommendation to you regarding the front rims for this machine. The bucket that is shown in the photograph is very similar to the bucket on a 615 Industrial.

Given that the bucket will hold a capacity of 7/8 yard struck and material weights ranging from 2,000 - 3,000 pnds it would be useful for you to consider upgrading the rims from those shown in the photo's to 11L x 16 10 ply. This size rim rim (deep dish) along with the wider cross section will carry the load much better than the narrow rims illustrated in the photo. Unfortunately, I do not know who manufactured the wider deep dish rims for Allis, but they are common on all the 615 machines I have seen that were equipped with a loader. I believe the rims were optional equipment.

Just thought I would mention it. If you go with the factory rims shown on the AC literature post above, anticipate wheelpath rutting in soft conditions.

Wish you the best in your restoration!! Orangeman

|

Posted By: TomMN

Date Posted: 22 Feb 2010 at 4:16pm

| Thanks for the tire size recommendation. I was thinking of going bigger too. |

Posted By: orangeman

Date Posted: 22 Feb 2010 at 7:54pm

|

Tom: One other thing to consider, not sure what your plans for the loader are, but the pic you posted does not show any weight on the rear. The factory lit. posted above shows the hoe on the back which serves to offset or counter balance the weight of a bucket when loaded with material.

Recommend you consider some factory weight on the rears as well if you are not going to have a hoe on the back. This will help with the weight balance when the bucket is full.

Again, wish you the best on this D17 Industrial, hope you keep a good journal on your restoration of this machine. If you are the fellow that did the WC journal with pics, you did a swell job, I found your documentation excellent and most informative. Keep up the good work!!

|

Posted By: TomMN

Date Posted: 22 Feb 2010 at 8:49pm

|

I didn't get the back hoe, it had been cut off with a torch. The whole thing was going for scrap when I bought it. I have the loader off and the rest of it in the garage in several big pieces. I plan on using it as a loader tractor so I will indeed need some weight on the rear. I have taken lots of pictures but haven't made the time to update my page. My plan is to post it on my page like I did the WC and the WD45D. I was working on the RC's before this came along too and they are not getting the attention they used to either. Thanks Tom |

Posted By: cmpman

Date Posted: 23 Mar 2010 at 8:11am

| HEY ALL I have a 1963 d17 indusrtial with ts1000 loader not pretty but works great new motor in it. Need info on it would love to find that industrial manual. |

Posted By: David Maddux

Date Posted: 28 Mar 2010 at 9:29pm

| Tom: You asked what the cause was that created the problem. I have had the same problem on a series3 that I had. I think a lot of the problem was mouse nest and mouse urine. It rusts things up, then when you hit the brakes hard the ball dislodges from it's socket. At least that is what mine looked like. Fix it, clean it up and adjust according to the book and it probably won't happen again as long as you own it. Dave. |

Posted By: David Maddux

Date Posted: 28 Mar 2010 at 9:31pm

| Tom: If you haven't already got new parts, you might think of finding used parts and having the discs and bands relined. I bought all of my parts for one side and then linings for the other side from Agco a few years ago and I think I had over 700.00 in that fix. Dave. |

Posted By: Russ-neia

Date Posted: 06 Apr 2010 at 8:50pm

|

Some of the Gleaner combines had the 11.00 x 16 industrial style tires. Our F combine that is being salvaged where we traded it still has them. Talk to Jim-IA about it. ------------- The innovators offer what others will imitate. |

Posted By: acisbest

Date Posted: 07 Apr 2010 at 7:16am

|

Tom, Your work is making me feel sick.... I want to give up on my projects... Was just poking around your web site.... Such nice work, Ugh... I'm just not that good/patient. I have too many projects. I do good functional work... Your work is perfection.... Can't wait to see this D17 when its done. |

Posted By: TomMN

Date Posted: 07 Apr 2010 at 9:55am

|

Thanks for the comments, but I don't have any real deadlines since this is a hobby for me. I have to say I have a great deal of respect for the folks that needed to fix these things and get them back in the field before the weather changed. It's fun to take these old things apart and see some of the stuff that was done "temporary" and stayed that way. Tom |