crossbreeding

Printed From: Unofficial Allis

Category: Other Topics

Forum Name: Pulling Forum

Forum Description: Forum dedicated to Tractor and Garden Pulling

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=42382

Printed Date: 28 Feb 2026 at 7:37am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: crossbreeding

Posted By: wi50

Subject: crossbreeding

Date Posted: 19 Dec 2011 at 7:44pm

|

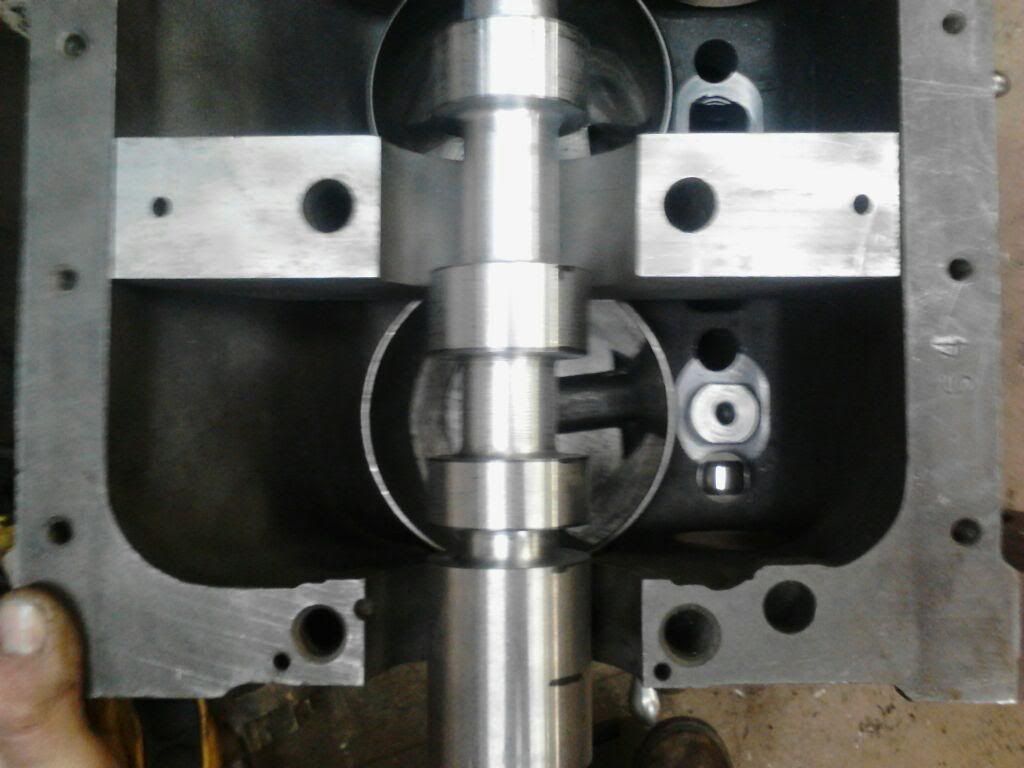

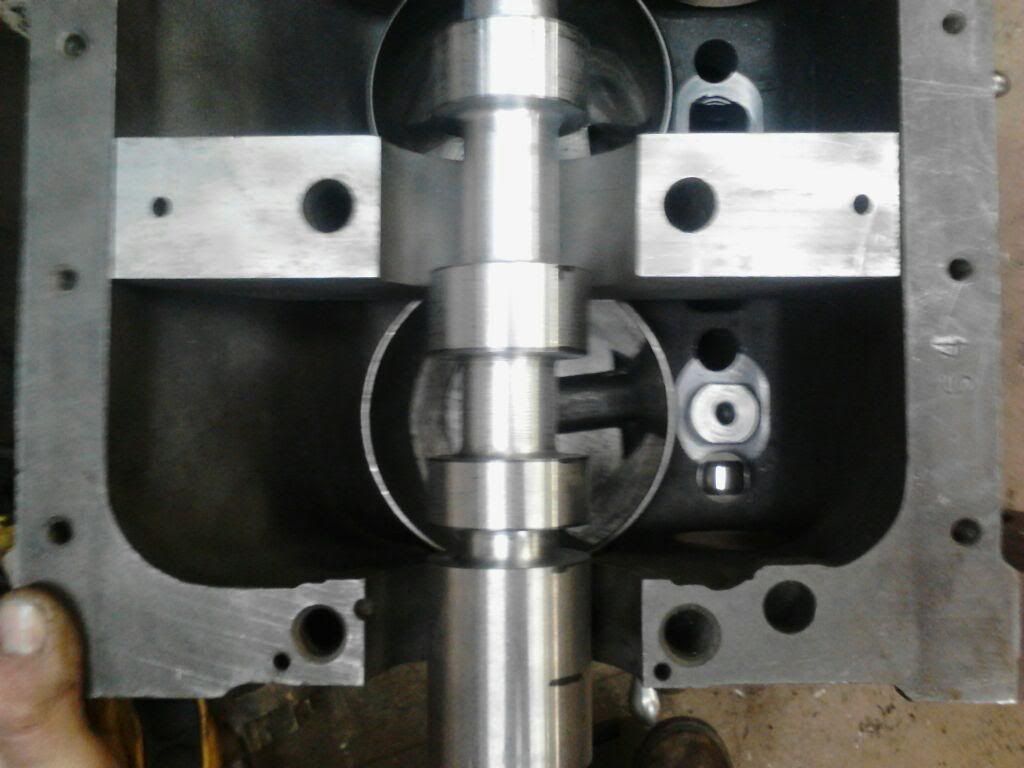

Here's a couple pictures of something I'm buuilding. I made mention of getting pics posted a while agoe and never got around to it. It's a 5 main counterweighted crank going in an Allis 226 block. Some of you may have seen pictures of my old engine and the main cap assembly I made to tie it togather. This one will finish out similar with 2 more mains bolted into the block.

I made a new cylinder head for the project and have to finish my guide plate for it. I'll get pictures of it up soon when I get around to takeing them.

In a few weeks I hope to have some pictures to post of a finshed assembly, or at least finished enough to go to the machine shop for line boreing. I'm so busy with customer projects, my own equipment and building our alcohol superstock that I don't know how much time I'll have to put into the Allis engine. Thank God for good employes.

------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Replies:

Posted By: DrAllis

Date Posted: 19 Dec 2011 at 7:50pm

|

Well, I'm impressed !!!......now, what is the crankshaft out of (if I might ask)?? |

Posted By: SteveM C/IL

Date Posted: 19 Dec 2011 at 9:12pm

| Your tag line says it all. I wonder what kind of trouble you caused your school teachers! LOL! |

Posted By: Jeff Z. NY

Date Posted: 19 Dec 2011 at 9:15pm

|

Nice work.

I thought this post was going to be about something else. LOL ------------- I Love Meatballs and Dumplings on Toast with Gravy and Rosemary and ??? {Open For Suggestions} |

Posted By: Jeff Z. NY

Date Posted: 19 Dec 2011 at 9:21pm

|

Maybe next time. eh!!! ------------- I Love Meatballs and Dumplings on Toast with Gravy and Rosemary and ??? {Open For Suggestions} |

Posted By: mark vaughn

Date Posted: 19 Dec 2011 at 10:21pm

| Im speechless that is BEAUTIFUL WORK. |

Posted By: Rod B

Date Posted: 19 Dec 2011 at 10:29pm

|

Now that's neat. Anyone can bolt parts togather but few can design and build from the ground up. Keep up the good work!!! |

Posted By: wi50

Date Posted: 19 Dec 2011 at 10:53pm

|

thank's fella's.

There's a lot more to it than just machining or bolting togather parts. One needs to worry about what this or that can support, how strong of parts am I working with for a given project and what comprimises do I have to make in order to make it work and stay togather at it's desired speeds or sizes. What a head can flow, what a specific engine designs airflow requirements are, at different points in it's cycle and how to match them togather. What valve opening rates are needed and how to get them. I've made billet cams and custom rocker arms. I don't know how many hundreds or thousands hours I've spent machining something from scratch, modifying something existing and flow testing this or that and running the numbers. Don't get stuck in the single dimensional thinking that some people have that this is alwayse better than that........and don't think that just because the computer says it will work, or it works on paper that it's going to work in real life.

Dr Allis, lets just say I'm pretty loyal to my Deere equipment. The 4 cyl engine family weather it's an old 202, gas, diesel, or a new 4045 have a lot of things in common.

Here's an old picture that was in my file here of my old 201 block with a Leroi crank in it. At least one can see what a finished product looks like. I built this a long time agoe, like winter of 2001-2002 if I rember right. Picture was taken this spring when we re assembled the engine.

------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: wi50

Date Posted: 01 Jan 2012 at 3:41pm

I had a chance to get my liners made the other day. Used a set from a Deere 466, 7.6L or 8.1L engine as they are all great quality hardended liners and good easily avaliable cantidates to start with. A friend has a boreing bar and when we get a little time we will set up to bore the block and press the larger liners in.

------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 01 Jan 2012 at 4:35pm

|

I dont see a square step to keep the sleeve from pulling through the bottom ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: AaronSEIA

Date Posted: 01 Jan 2012 at 4:48pm

|

I see what looks like a lip in the top picture. Not a very big one, but a lip none the less. AaronSEIA

|

Posted By: Rod B

Date Posted: 01 Jan 2012 at 4:53pm

|

Ml's eyes are clouded by jelousy. Again. I see a step around the top also and what looks like the top counterbore, barrel, bottom counterbore and relief on what hangs in the crankcase. |

Posted By: mlpankey

Date Posted: 01 Jan 2012 at 5:02pm

|

I am getting old but i dont see a square step about 2 inches from either end to be a bottom counter bore . It cant have any radius ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: AaronSEIA

Date Posted: 01 Jan 2012 at 5:10pm

|

Well, then...won't you be happy when this POS he's building sucks all the sleeves into the crankcase and consumes his didn't really make it on his own crank. I swear, you guys need to go out back and settle this. I like reading about people who have the time, money, and talent to do stuff like this. That goes for WI50's builds and the one you worked on the last year or so. If every puller had the same thing it'd be like IROC in NASCAR. It's getting old watching people with talent, money, and time have their work shot down by others. AaronSEIA P.S. Keep posting what you are accomplishing...both of you. |

Posted By: mlpankey

Date Posted: 01 Jan 2012 at 5:32pm

|

AAron get a life .if it has a square step its good if it has a radius step . he should turn it square. but he could be planning on none of the sleeve protruding out the bottom and making a step by not running the boring bar all the way out the bottom like we do straight barrel repair sleeves in damage v8 cylinders. Allis OEM sleeves protrude through . I just love commenting mind readers who knows my intentions ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: D-17_Dave

Date Posted: 01 Jan 2012 at 6:00pm

|

Don't worry Aaron, a kicked dog is the one that barks. ------------- Yea, I can fix that..... |

Posted By: MACK

Date Posted: 01 Jan 2012 at 6:40pm

| Can you turn enough RPMs to make a 2 finger Crower clutch engauge? MACK |

Posted By: wi50

Date Posted: 01 Jan 2012 at 8:18pm

|

To clear up someones confusion there is a flange on top of the liners for them to hang on or seat in the block. They press fit into the bottom counterbore only to seal. They need to hang into the crankcase to support the piston at BDC.

Now I offset bore the blocks to gain clearance for large bore diamters. The flange hangs slightly into the original head bolt holes but it gets clearanced a bit. I do not want to leave a straight wall liner and seat in the bottom counterbore for strength purposes. I want that flange on top of the sleve to hold the liner in place, and by pinning the bottom of the liner I now help tie the block deck down. Now I do not need much of a flange. I have a slight undercut radius (to allow clearance for the radius) under the flange to the barrel, an undercut radius is stronger than a square cut. There's still .100 of material for the flange to seat on all the way around. .100 is plenty and would likely be fine on less than half that.

I leave the flange .300 tall and I cut the counterbore in the block .200 so the liner stands up .100, giveing me something to press against when we assemble a block.

By the way Mack, that pressure plate is just a junk one for measureing purposes, I was out to Atlas Tractor last week to pick up our clutch but it wasn't quite done. Waiting on the pressure plate and floaters. But at least I have enough now that can set my tower height and figure out my finger to crankshaft flange distance, figure my crank flange to throw out berring dimension and the depth of the clutch can. Now I can machine an adapter plate of the right dimensions to get the clutch can on the superstock engine and the complete package in the component chassis.

Yes Aaron, the last POS stayed togather for a long time, still going strong, some idiot has been worried about it since I posted some pictures of it a year agoe, though it was built 10 years agoe. Sure was nice when I didn't know how to post pictures.

------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 01 Jan 2012 at 9:03pm

|

I like your style you going to run a little g226 engine in 500 ci superstock class? I bet that will be a barn sitter ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Rod B

Date Posted: 01 Jan 2012 at 10:32pm

I know you seen pictures of the chassis and other parts of it as you are his stalker. You told Aaron to get a life. YOU need to get a life.

|

Posted By: mark vaughn

Date Posted: 01 Jan 2012 at 11:01pm

| wi50 I have built lots of racing engines in my time and i know nothing about tractor pulling engines but what im seeing here is really great mechanical performance knowledge. I call it WORK OF ART. Keep posting. Mark |

Posted By: AaronSEIA

Date Posted: 02 Jan 2012 at 7:26am

|

Why not. Young Blood has won 5 NTPA championships in a row with a 426 in a class that probably allows over 600. But what do I know...I need to get a life:) AaronSEIA

|

Posted By: JayIN

Date Posted: 02 Jan 2012 at 5:51pm

|

Wow, this is great! Keep us posted! ------------- sometimes I walk out to my shop and look around and think "Who's the idiot that owns this place?" |

Posted By: TREVMAN

Date Posted: 02 Jan 2012 at 10:19pm

| Prince Vallium to the rescue please! It looks like great work to me, you boys need to settle down a little, remember, we all love Allis or we wouldnt be on this site. Lets take it easy on each other, just an idea, please dont jump down my throat, Trev. |

Posted By: Rod B

Date Posted: 10 Jan 2012 at 8:33am

| Any updates? It's too bad some nit wit has to get excited every time you share your projects. Keep up the good work. |

Posted By: wi50

Date Posted: 18 Jan 2012 at 7:55am

|

I got the liners installed in the block, the billet cam blank made, and have been working on a rev kit to hold roller lifters in place but have been too busy with other projects to do much on this allis engine for a while.

I'll snap a few pictures on my phone sometime and post up of those items. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 18 Jan 2012 at 8:38am

|

What diameter roller keyed lifter you planning on using ? ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: wi50

Date Posted: 19 Jan 2012 at 9:42am

|

The lifters are not keyed, but held in place by another method. The whole trick is finding a lifter of correct useable length and haveing the base circle of the cam keep it in the correct operating zone. It's quite simple once you see it. I should get time to finish it shortly and then I'll show a few pictures. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 19 Jan 2012 at 10:05am

|

lifter cant spin in the lifter bore if it does so much for the roller. mushroom lifter is about 1.5 inches in diameter when you go to the roller you will be smaller say a .800 wheel . have you figured how much more duration it will require to open the valve at the same speed as the mushroom lifter ? ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: DaveKamp

Date Posted: 19 Jan 2012 at 11:54am

|

I was navigating a rather large vessel through a rather small channel once, and noticed a towboat operator doing something that I thought was very, very strange. I asked my dad what the other pilot was doing. My dad's reply was a piece of wisdom I'll never forget: "I don't know, but he is obviously aware of some aspect of his situation, that you're not". Which translated to everyday life, means that when one ventures to open his mouth very wide about how another individual chooses to address their own challenges, he runs a substantial risk of finding his own shoe in it. After seeing WI50's work, I'm thinkin' he knows a whole heckuvalot more about what he's doing, than anyone else does... and I applaud his work- very, very nice. The engineering, forethought, and workmanship of anybody's project, is a testament to dedication and vision- the stuff that turns the ether of dreams, into reality. I appreciate seeing things like this posted, but guarantee that if I could be there for the "It's Alive!" moment occurs, I certainly would! There's no treat like feeling sound and fury! |

Posted By: mlpankey

Date Posted: 19 Jan 2012 at 12:34pm

|

Nothing like experience . Just asking questions . Had to process through them to. Changing something as small as lifter diameter . When not thinking about it can leave one scratching his head some times.Does with me any ways. Kamp dont let the reply on the cylinder head make you mad . ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Rod B

Date Posted: 19 Jan 2012 at 7:40pm

Well put. Wi50 has posted some info in the past that a special someone was unable to digest causeing weeks of argument and a $200 offer to see the part. Lookinf foreward to see more pictures and keep up the great work. |

Posted By: mark vaughn

Date Posted: 19 Jan 2012 at 8:48pm

| wi50 I am very impressed by your work. Please keep us posted with new updates. Thanks Mark |

Posted By: mlpankey

Date Posted: 20 Jan 2012 at 7:28am

------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: John (C-IL)

Date Posted: 20 Jan 2012 at 7:58am

You know, I have the same philosophy when I see someone doing something that I don't understand. He/she must know something that I don't.

|

Posted By: wi50

Date Posted: 20 Jan 2012 at 5:30pm

|

You boys are doing a fine job.

I am haveing problems posting pictures from my phone after the forum change. I'll keep trying to get them to load and get it figured out.

But the roller lifter setup is actually verry simple. I ordered a piloted reamer to pilot in the original lifter bores and ream them to the new diameter. In the block between the lifter bores is a square hole, I find center between the lifter bores for a cylinder and I bore that square hole to a round hole, I can't clean up the whole thing or it gets to thin, but there's room to get a 7/8-14 thread in that hole. I made a plug with a flange on it and drilled and tapped the center of the plug, threaded the outside 7/8-14.

I made the dogbones to hold the lifters from some old take outs I cut and welded to a new plate with a hole in the center of the plate.

Now a simple stripper bolt with a spring on it comes down from the top of the block and goes through the dogbone and threads into the bushing I threaded in from the bottom. All this holds the dogbone in place, the dogbone holds the lifters from rotating and puts some downpressure on the cam.

The only trick is finding lifters of the right length to engage in the block material, a small enough diameter to leave plenty of materal in the block for strength and dogbones to fit in the block.

The billet cam isn't that big of a task. It takes a while to turn out a blank, and a cam grinder can do the rest.

It's all about getting the proper valve opening rates for the parts used. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 20 Jan 2012 at 5:43pm

------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Steve in NJ

Date Posted: 20 Jan 2012 at 7:50pm

|

I'm wit' you Dave! Would love to be there when that puppy is fired up! That's when I'd be all fired up! LOL! Keep the pics comin' WI50 Steve@B&B |

Posted By: SHAMELESS

Date Posted: 21 Jan 2012 at 1:07am

| yeah...i thoughts you were talkin bouts 37!! |

Posted By: Rod B

Date Posted: 21 Jan 2012 at 12:08pm

|

I thought someone posted one time that it was impossiable to put roller lifters in one of these. Not the same dolt is quoteing everything in agreement.

|

Posted By: AaronSEIA

Date Posted: 21 Jan 2012 at 12:53pm

|

I'm thinking he's talking about the alky burner he's building. Maybe I'm wrong. Performance mods for a 226 in my world involve M&W pistons. What WI50 is doing is crazy stupid fun to watch. AaronSEIA

|

Posted By: BobDinNC

Date Posted: 21 Jan 2012 at 1:16pm

| I'm with Dave on this. It boggles my mind to see what some people can think up and then DO! Keep on posting. |

Posted By: mlpankey

Date Posted: 21 Jan 2012 at 5:10pm

------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Rod B

Date Posted: 21 Jan 2012 at 8:26pm

|

How did your pulling season go pankey? I rember reading one of your rants on the yt forum how you putting off projects and useing the money to put your tractor togather. Going to go pull against Wi, make us a video and show everyone how it was done. I know at the Nat. GOTO we were sure laughing about you. |

Posted By: mlpankey

Date Posted: 21 Jan 2012 at 9:52pm

------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: wi50

Date Posted: 22 Jan 2012 at 12:14pm

|

Well it looks like this thread is getting cluttered up.

Though I did enjoy a good laugh. Almost spit my mountain dew out. Act a fool and people alwayse rember. Why would it matter how Rod B's pulling season went when once again it's a desperate attempt by someone to backpedal. The saga never stops.

I prefer to get my work done. In a matter of an hour and a half yesterday I took an old WD-45 block and cut keyways in alongside the mains. I than machined the side of the main caps with a .002 interference fit so now my mains are keyed into the block and located. Now the machine shop can line bore and I've got a nice stable platform rather than the old shim stack. I was useing up some of the parts I had laying around and had enough stuff to build a cheap and goof proof engine. Bought some cheap pistons from RaceingJunk.com, some rods and crank I had and I've got about a 320 cube engine. I'll recycle the head, manifold and carb that I worked over for my dads engine last winter to go back in a WD45 wide front that I'm restoreing and can compete in the local pulls.

My point is that in a few hours of work, I've got some nice parts made. Time better spent than trying to tell us on public forum what one doesn't know.

I still can't get pictures to go through so when I get my parts back togather enough to snap a few new ones I'll have to put them on the YTmag pulling forum. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 22 Jan 2012 at 2:11pm

|

keyways to locate . dowl pins work for us . still got 9 years left to be out of pulling before making a pull at goto. i think my planet jr could do well there. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: D-17_Dave

Date Posted: 22 Jan 2012 at 2:19pm

|

For some on here and on any given topic, the only thing that shows more than jealousy is their stupidity. ------------- Yea, I can fix that..... |

Posted By: ChuckLuedtkeSEWI

Date Posted: 22 Jan 2012 at 2:53pm

|

Marty, sent you a PM about the pictures.

It is fun to see this whole thing develop. It's funny how every time WI50 posts something, Pankey has to jump down his throat. There's alot of things you can learn from someone else if you just keep an open mind. I don't think that's the case though.

Wish I lived closer to you Marty, would love to give you a hand on the weekends and learn some knowledge. Back when I used to help some of the local late model drivers, none of them ever built their own engines. We just picked them up from the builder, did the installs, put a carb on, warmed them up, set valve lashes etc. and away we went. Back then our engine builder was up in Appleton, and a damn good builder he was so it was worth the trip. But never got to learn alot when all you did was bolt the engine in the hole.

Keep up the good work and keep us posted and a certain someone's feathers all rustled up!! LOL ------------- 1955 WD45 diesel 203322 was my dad's tractor, 1966 D15 23530, 1961 HD3 Crawler 1918, 1966 D17 IV 83495, 1937 WC 41255, 1962 D19 6221 |

Posted By: Charlie (NC)

Date Posted: 22 Jan 2012 at 4:23pm

|

Fellows, I'm not qualified to talk about WI50's machine work and I haven't been reading this forum much for a couple of years but there are a couple of things I've noticed that have proved out to be truisms and tell me all I need to know about this thread without knowing much about WI50's work. 1) If Dr. Allis is impressed it's nice work. 2) If Plankey opens his big mouth it is to insult or belittle someone else and try to make himself look big and important. Nuf said

|

Posted By: geb

Date Posted: 22 Jan 2012 at 8:34pm

| I dont't usually get involved if dirty diaper sports, but I feel compelled to so this time. The only thing I know about Plankey is that I offered him some advice once for a firing problem he was having (use a electronic distributor out of a Chevy Chevette with a little machining to solve a lot of problems in a 201/226 block). As far a wi50 goes know absolutely nothing except from what I have read on this forum. I know just a little bit about engine machining but wi50 has put me in awe with his knowledge. It's obvious that he has forgotten more about engine machining than most of us will ever know and that includes you Plankey. Also Plankey, if you would start trying to learn from wi50/s post, as most of us are trying to do, instead of making an ass of yourself by offering suggestions that are antiquated by wi50's level of expertise, you would be much better off. It is easy to see you know a little about engine machine work but you nor I are in the same class as wi50. Set back, enjoy the roses, and learn with an open mind. |

Posted By: TREVMAN

Date Posted: 22 Jan 2012 at 9:01pm

| You know, I love Allis and Gleaner. Burned into my brain when I was a kid in the 60's. I come on this site everyday cause I like to see what others are doing, to see pics of machines that remind me of the past, and sometimes to get info and parts for the few pieces I have. If I want to listen to bitchin and stupidness, all I have to do is turn off the computer and talk to my wife or boss. What the guy is doing is way beyond me, but I like to look at it, knocking it down or saying stupid things is just small. Like i say to my gal when Ive had enough, You do You, and I'll do me, and everything will work out. Leave the dude be, who cares how many tractor pulls he won or lost, he is doin some cool stuff. Just my humble offering to promote sanity, Trev. |

Posted By: mlpankey

Date Posted: 23 Jan 2012 at 7:51am

------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Brian G. NY

Date Posted: 23 Jan 2012 at 4:33pm

|

Well, I don't claim to know much and I don't!

However, someone told me a long time ago........It is better to keep your mouth closed and let people think you are stupid than to open it......and prove it!

Ain't saying any more but I think you get my drift?!

|

Posted By: wi50

Date Posted: 23 Jan 2012 at 5:28pm

|

A couple friends and I are togather on a component alky tractor. My incomplete pictures of a clutch for it are because the pressure plate was not finished last time I was at Atlas Tractor..... but he had a scrap one I could use for dimensional purposes to get the clutch can to block spaceing correct. Wednesday though I'll have the good one. Just in case some idiot can't understand why I would have a 4 disc slipper laying around. Now projects like this Allis engine or the superstock take a lot of time. In the first post I did say it's a work in progress. 99.9% of you realize this, though I do get time on it now and then and have a lot of the parts well under way or completed for the next step in the process. There is an order of operations one must go through in order not to back track to much.

I was on the road today, but I did get to the shop late this afternoon and took some pictures. I'll send them to Chuck in a bit so he can post them. I'll post them on YT mag tractor pulling forum shortly.

Ladies and gentlemen, let someone's drama continue. I'll spend my time on my family, my work and my projects. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 23 Jan 2012 at 6:22pm

|

I give you a A in trick photogr aphy .I think I will lay a 226 block on its side and set 8-71 on top of it and call a two stroke in progress. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: TREVMAN

Date Posted: 23 Jan 2012 at 7:45pm

| Someone lock this thread, WOW...Trev. |

Posted By: ChuckLuedtkeSEWI

Date Posted: 23 Jan 2012 at 8:42pm

|

Sorry for the delay, here are WI50's pictures.    ------------- 1955 WD45 diesel 203322 was my dad's tractor, 1966 D15 23530, 1961 HD3 Crawler 1918, 1966 D17 IV 83495, 1937 WC 41255, 1962 D19 6221 |

Posted By: Charlie (NC)

Date Posted: 23 Jan 2012 at 9:52pm

| only problem with this thread is Plankey. Maybe someone can lock him. |

Posted By: Butch(OH)

Date Posted: 24 Jan 2012 at 10:02am

|

Hey WI50,

Just a lil hint to help ya out.

If you was to put the crankshaft where you have the cam blank and move the cam somewhere else it will go together with less hassles

|

Posted By: mlpankey

Date Posted: 24 Jan 2012 at 12:57pm

|

Assume both paired lifters are in the lifter bore and the reason only one lifter trunion shows is to show the independent vertical movement the pair has .looks like thethe five mains come at a price of small bores also ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Coke-in-MN

Date Posted: 24 Jan 2012 at 1:12pm

|

And I thought the political section was the rough place to hang out , now i see there are other sections of disagreement and controversy .. LOL ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: wi50

Date Posted: 24 Jan 2012 at 1:21pm

|

. The bore is currently at 4.562 or if my stalker had paid attention he would have read that they were from a Deere 6076 and been able to figure out what the ID is to start with. So there is plenty of room to bore to 4.75+ ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 24 Jan 2012 at 1:34pm

|

Well that address that can we see the center main .didn't address the lifter though. Please address all or none thanks ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: mlpankey

Date Posted: 24 Jan 2012 at 1:37pm

------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: wi50

Date Posted: 24 Jan 2012 at 2:30pm

|

Well be more carefull pank. My old engine was put togather well over 10 years agoe and it goes strong yet today. The liners are identical dimensions od the ones I made for this engine. You were most likely dreaming of pulling then the same as you are now. And yes the lifters move verrtical. Enough of the stupid questions. I'd be happy to adress any legitimate ones from anyone with enough intelligance to ask. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mlpankey

Date Posted: 24 Jan 2012 at 3:01pm

|

How long is the flat on the lifter. Stock small blocks that use a dog bone roller lifter design are. 632 long and you don't get much over factory lift before having to change them to a design with more individual verticle movement. Probably not intelligent enough to answers intelligently. Pulling same engine ten years seams like you should have got the natpa build but you didn't kurt hamill did. ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: GBACBFan

Date Posted: 24 Jan 2012 at 4:44pm

|

Spanks, you have the ego of a mosquito floating down the river on his back with an erection shouting, "Open the drawbridge!" ------------- "The trouble with quotes on the Internet is that you can never know if they are genuine." - Mark Twain |

Posted By: Gary in da UP

Date Posted: 24 Jan 2012 at 4:57pm

| wi50, nice build, I appreciate your doing it your way. It is a shame that our resident "keyboard puller/engine builder /performance guru" is so envious that he has nothing useful to add to or real knowledge to share, but simply is here to diss others and waste bandwidth. But that seems to be how he compensates for his own lack of [fill in the blank]. Mitch, siddown and shudupp. |

Posted By: TREVMAN

Date Posted: 24 Jan 2012 at 5:49pm

| Lock the dude out, geeeez, PLEEEEEZ! Trev. |

Posted By: Rod B

Date Posted: 24 Jan 2012 at 8:28pm

|

Does not mean that the guy is not buying different parts for final assembly than the ones he is useing for mock up and build purpose. I'd swear that pankey fella gets a little dumber every time he posts. To bad he has to clutter up good threads that the rest of us enjoy. Over 5100 views of the guy makeing a fool of himself.

|

Posted By: D-17_Dave

Date Posted: 24 Jan 2012 at 9:36pm

|

Don't everyone forget that stroke means nothing in pulling. ALL power comes from RPM's only.......... ------------- Yea, I can fix that..... |

Posted By: mlpankey

Date Posted: 25 Jan 2012 at 6:13pm

------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Butch(OH)

Date Posted: 25 Jan 2012 at 7:19pm

Thanks man, Now I have to clean the spit & Pepsi off my screen and keyboard   |

Posted By: mark vaughn

Date Posted: 25 Jan 2012 at 7:21pm

|

Staying on the subject of tractor pulling, what class would the wi50 fall into? What are the class rules , such as tractor weight, limitations and other requirements? Due to not being knowledgeble with pulling, I was just curious. Looks like wi50 would have some very competetive engines in whichever class it would be in. Wi50, I have been reading some of your posts and you seem to know exactly what you are talking about. Lots of good up to date knowledge!! Sounds like lots of fun and very competetive!!! |

Posted By: D-17_Dave

Date Posted: 25 Jan 2012 at 7:25pm

------------- Yea, I can fix that..... |

Posted By: mlpankey

Date Posted: 25 Jan 2012 at 8:17pm

Just going by one of your previous ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: Rod B

Date Posted: 26 Jan 2012 at 10:35am

|

By reading some old threads why would you limet your cubes than pankey by useing buda rods in your engine? By the pictures you didn't even narrow them to lighten them and strengthen the crank. Such a tall and heavy clumpy piston hanging on top also.

You could have built a much larger and stronger engine useing different rods.

Prior to that I read something about farmall rods with a 1.75 crankpin being used and breaking the crank.

Maybe reading magazines is what you should stick to.

Also while you are on a rant over this post, please explain why you did not put your engine back togather and show us all like you said you were going to do.

I'm not into the dirty diaper sports either fella's but by what I know this pankey fella is full of bs and trolls these forums trying to boost his ego.

|

Posted By: JayIN

Date Posted: 26 Jan 2012 at 11:17am

|

Gentlemen, please continue! ------------- sometimes I walk out to my shop and look around and think "Who's the idiot that owns this place?" |

Posted By: wi50

Date Posted: 26 Jan 2012 at 2:05pm

I think I am able to post pictures now, and I'd like to share a pic of my rod and piston assembly. I put an original crank in a block and a cam to check for clearance before nailing down my final dimensions on an engine and make sure that there is enough clearance for the added stroke and the rod combination, or that I can make clearance before commiting to a combination. With the 4.5 stroke crank I've still got about .750 clearance to the cam at it's closest point, so that gives me quite a bit of room for the bore/stroke combination I'm going to run.

And before our resident nit wit wants to astonish us with his lack of thought the pictures are in a plain old take out block as I have not notched the sleves in the big bore block but needed to check cam clearance.

------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: wi50

Date Posted: 26 Jan 2012 at 2:21pm

I'm makeing the cylinder head for this engine in the posts. But that doesn't happen overnight. I'll share pictures of it someday, but some people can't handle simple items like blocks or cranks. We'll save that saga for later.

I'm also at a point now where I have the necessary items for our alky superstock and that's my main priority so this Allis is going to have to go on the back burner for some time. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: mark vaughn

Date Posted: 26 Jan 2012 at 4:53pm

| wi50 This all sounds so neat and i would like to see pictures of the head work during the different stages of progress. Thanks so much and good luck. Mark |

Posted By: mlpankey

Date Posted: 26 Jan 2012 at 7:14pm

|

Pistons weighed 750 grams . Rods were bushed and crank was ground for. .020 side clearance. I guess you guys can't read pictures we'll to. I don't see a sleeve in the block. Don't see the side where you would have to cut out to place roller lifters in from the top either.bulky rods don't give much room for stroke. You planning on running more than 300a lift at lifter.flat spot in lifter doesn't look in picture that it would not have much more than that ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: wi50

Date Posted: 26 Jan 2012 at 9:39pm

Prepare to be astonished fella's.

I have to wonder if you read or just post, open mouth (keyboard) and insert foot. Go actually READ the post above post and look at the pictures. Now THINK and you will know why you do not see a sleve in one block.

What's even worse is that I said in the post exactly what our resident idiot would astonish us with what he doesn't know.

Now I'll explain it to him..... not that I should waste my time but he might just get it if he reads.

In one picture you see an extra main cap in the block, you can also see above the front main where the block was cut into the crank case for the sleves, can probably even see the sleves. Now that would be a block pictured earlier in the thread that has the boreing done, getting the main caps fabricated in, etc. I can check and KNOW how much clearance I need to cut in the sleves for the rod....... BUT why would I cut the clearance before the final boreing is done? That would be stupid to do as than there would be an interupted cut when boreing.

Like I've said in the past, there is a certain order of operations to go through in order to make the next phases go easier, better and not have to backtrack or make anything harder than it needs to be.

In the other picture you see a stock block with the sleves knocked out and no bore work done, you see a stock crank holding a rod to check clearance to the cam. Now that would be a plain old stripped down and cleaned up block.

In my post I even say that I was checking cam clearance in a un molested block. Cam clearance is cam clearance weather it's this block or that block, I just need to know approxamatly how much room is between the two, and if and how much I'll have to clearance the block.

So now I know how much I need to notch my liners and I know that theres a tad over .750 clearance from the rod to a cam with a 4.5 stroke, so that gives me potential to go to 6" stroke easily with this connecting rod and not have to clearance anything. Where will the final bore and stroke be? I'm not going to say. It may be fairley small, in the low 300's for displacement, maybe a 4.6X5, it may be over 400 at a 4.75X6.125 engine as there's room for that. Will it be a 2500 RPM engine or will it be a 6500 RPM engine?

------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: Rod B

Date Posted: 26 Jan 2012 at 9:51pm

|

Is it possiable for pankey to get any dumber?

I bet he can.

A wise man posted earlier that the only thing he shows more than his jelousy is his stupidity.

|

Posted By: D-17_Dave

Date Posted: 26 Jan 2012 at 10:20pm

------------- Yea, I can fix that..... |

Posted By: GBACBFan

Date Posted: 26 Jan 2012 at 10:46pm

One wouldn't think so, but for the folks that enjoy watching someone that repeatedly reinforces their own ignorance he's the gift that keeps on giving.

------------- "The trouble with quotes on the Internet is that you can never know if they are genuine." - Mark Twain |

Posted By: mlpankey

Date Posted: 27 Jan 2012 at 3:16pm

|

Your going to use roller lifters and have no way of replacing or checking the lifter each season after sleeves get installed ------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: SteveM C/IL

Date Posted: 27 Jan 2012 at 5:07pm

| PFFFFTT!!! |

Posted By: ChuckLuedtkeSEWI

Date Posted: 27 Jan 2012 at 5:54pm

|

Hey GBACBfan, it's present time!!!!! LOL ------------- 1955 WD45 diesel 203322 was my dad's tractor, 1966 D15 23530, 1961 HD3 Crawler 1918, 1966 D17 IV 83495, 1937 WC 41255, 1962 D19 6221 |

Posted By: Rod B

Date Posted: 01 Feb 2012 at 11:08am

|

Do these pictures cause the ignorant to show their jealousy, or do the jealous show their ignorance?

|

Posted By: 427435

Date Posted: 01 Feb 2012 at 12:59pm

Does that mean someone with an old MM with the 504 cube engine can put in the 800 cube engine?? ------------- Mark B10 Allis, 917 Allis, 7116 Simplicity, 7790 Simplicity Diesel, GTH-L Simplicity Ignorance is curable-----stupidity is not. |

Posted By: mark vaughn

Date Posted: 01 Feb 2012 at 8:41pm

| 427435 That would be a killer setup with that mighty moe power plant. Another great engine would the 427435 Rat power but thats just my thoughts. |

Posted By: wi50

Date Posted: 02 Feb 2012 at 8:05pm

|

Around here the 800 moline is just fine. The "farm stock" classes have turned into 4 mph for the lighter tractors and 6 or 8 mph for the heavier tractors. Then there's the "hobby stock" or some other name depending on the pull and who puts it on, but the rules are to be naturally aspirated, safety equipment, etc....... just hope you brung enough under the hood. The heavier classes are turbocharged and limeted to a certain size, usually 3X4 charger but some places unlimeted. Then we have the "open class", multi charger, or single, no real limets.

And yes boys the lifters come out the top, or the bottom just fine if the cam is out. The dogbone and assembly need to be loaded from the top. What I should do is machine the top of the block between the push rods on center for a plug and make a long post with a snap ring groove so I can load the whole assembly from the top.

I've got to many cylinder heads to get done and parts for our superstock now to put much time into this Allis engine. Though I did have a few pictures in my phone I loaded here to share of boreing a couple of blocks. I made a blueprint of the block deck hole and bore locations, than I can square it up in the mill and use the DRO to move the bores offset EXACTLY where I want them. I made a tool to fit in a boreing head that works just great to do block work. I do leave the finish boreing of the cylinders for a friend with an automotive boreing bar and he can power hone for proper finish when done.

------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: SteveM C/IL

Date Posted: 02 Feb 2012 at 8:27pm

| Excellent!! We'd all be interested in pics of the Super progress since you don't have time for this project. It might be top secret though so we'll understand if you can't. |

Posted By: mlpankey

Date Posted: 02 Feb 2012 at 8:31pm

so when is the truck going to bring me your block for me to complete it like this one.

lol lol------------- people if they don't already know it you can't tell them. quote yogi berra |

Posted By: wi50

Date Posted: 02 Feb 2012 at 8:47pm

|

After seeing pictures of some of that stuff like the scrap front pulley, cobbled oil lines, light duity soft rods, heavy clumpy pistons, I do not have to wonder why pankey got a whopping 5 runs out of an engine.... before it came apart. And that awesome wheelie bar setup..... a 7th grader can weld better. So to answer the question in one word. NEVERI like to be able to accuratly controll the bore spaceing on a block, tough to do with a standard boreing bar that centers on an existing bore. If I want to angle bore to gain clearance it's real easy to do...... and my Bridgeport has many other advantages. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: wi50

Date Posted: 02 Feb 2012 at 8:49pm

|

By the way pank, you have no credibility with me, nor many others as some have pointed out.

------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

Posted By: Rod B

Date Posted: 02 Feb 2012 at 9:04pm

|

Holy $#!* the machine shop let that fool past the front door. I seen those pictures years agoe. Those bores in p's block are not near close enough to the head bolt holes to get all those cubes he's worried about.

Wi I see one block in the backround on the mill and one partially assembled. How many of these things are you working on?

|

Posted By: wi50

Date Posted: 02 Feb 2012 at 9:37pm

|

Urr a funny guy Rod

There's a few projects in the works, weather it's mine or someone elses.... I don't post pictures or mention much of anyone elses.

Steve,

sure I can put up a few pictures of the super, I'll take a few shortly of some of the things I've got laying around the shop for it and the chassis is at a friends shop. There's 3 of us togather on it. Nothing is to top secrete. Just useing a bunch of junk that was laying around, we bought a good component chassis and trying to shoehorn a modified 504 Case into a frame that's to narrow for the block. I'm converting a set of alumnium Indy Cyl Heads to alky for it and makeing new manifolds. Makeing brackets and an adapter plate to hold a SFI clutch can on a narrowed up Case block right now. We plan to build a 3 turbo IH engine shortly but want to run a year or two with the existing engine. ------------- "see what happens when you have no practical experience doing something...... you end up playing with calculators and looking stupid on the internet" |

mlpankey wrote:

mlpankey wrote: