AC Hay Conditioner

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=41980

Printed Date: 16 Dec 2025 at 12:45pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: AC Hay Conditioner

Posted By: bigbird

Subject: AC Hay Conditioner

Date Posted: 11 Dec 2011 at 8:19pm

| Does anybody have any information on a hay conditioner, we called them crimpers. My son found one in some weeds at a neighbors who was giving him the scrap for cleaning it up. It clearly has an Allis-Chalmers decal on it, but cannot find the model or any ID plate. I thought it best to scrap, but he loves anything Allis. So we took it home, put ne tires and a new chain, with about a can of penetrating oil, filled the gearbox. Lo and behopld hooked it up and ran great. It has a smooth rubber roll, and a notched steel one. A post on ebay lists a model 25, but we just don't know. Who knows a little paint and we might have something. Any ideas? I can't find anything in the Agco on-line books, and dealer doesn't have anything. Thanks |

Replies:

Posted By: Rfdeere

Date Posted: 11 Dec 2011 at 8:45pm

|

AC made a hay conditioner from 1960 to 1970. Your description describes this machine. It had 6 foot long rolls. It did not have a model number from what I have read. ------------- Randy Freshour,Member Indiana AC Partners, http://www.rumelyallis.com" rel="nofollow - http://www.rumelyallis.com |

Posted By: ctbowles58

Date Posted: 11 Dec 2011 at 9:08pm

| thay made a 904 one of the later models |

Posted By: Rfdeere

Date Posted: 11 Dec 2011 at 9:42pm

The 904 is a mower-conditioner. ------------- Randy Freshour,Member Indiana AC Partners, http://www.rumelyallis.com" rel="nofollow - http://www.rumelyallis.com |

Posted By: Bill(MO)

Date Posted: 12 Dec 2011 at 12:51am

|

I have an original operator/parts manual and there is no model number shown. The only option was a hyd. lift att. It also shows an improvement pkg shipped to dealers for models up to 1101.

Should be a serial no. stamped on R.H. side plate. Bill(MO) |

Posted By: Armand(AZ)

Date Posted: 12 Dec 2011 at 6:36am

|

The hay conditioner didn't have a model number to my knowledge. I built a model of one and have the manual. You can see the model on my website for comparison: acmodelsofarizona.weebly.com

Armand

|

Posted By: Ky.Allis

Date Posted: 12 Dec 2011 at 7:08am

| I,ve pulled one over many,many acres with Farmall H tractor. They are OK in short hay,but in tall orchard grass or fescue it will constantly wrap the steel roller. You will need a SHARP knife and tons of patience. I know it is AC,but in my opinion they aren't worth TWO DEAD FLIES. This is one machine that would even make the pope cuss. |

Posted By: AC720Man

Date Posted: 26 Dec 2019 at 9:41am

|

Found this old post and actually went to look at one the other day. Unfortunately it has a bent pto shaft. Does anyone have a measurement for a pto shaft? Not sure if Tractor supply has one the correct length? ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: michiganmarty

Date Posted: 27 Dec 2019 at 8:18pm

|

we ran one, and yes it tried your patience at time, if the divider board work on the mower, it worked ok, but if it wasnt didided clean it would plug on the end, and would need to be cut out. i think the roll was worn, and that why it did that. it worked better the newer it was. Did help dry the hay though, maybe a day or day and 1/2. earlier. |

Posted By: DennisA (IL)

Date Posted: 27 Dec 2019 at 8:50pm

|

I still use one! I’ve never had it wrap up yet and hope that it doesn’t. It does work well. ------------- Thanks & God Bless Dennis |

Posted By: AC720Man

Date Posted: 27 Dec 2019 at 9:21pm

|

Dennis, can you get me a length on the pto shaft on yours? I have seen your video and it appears to work well. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: Tbone95

Date Posted: 28 Dec 2019 at 7:45am

That’s got to be one of the most amazing posts I’ve ever seen! Never? Wow! We used one way back in the way back days. Also had a New Idea. They both plugged plenty! |

Posted By: Mikez

Date Posted: 28 Dec 2019 at 9:49am

| Wow that is something. We always thought it was certain types of hay that wrapped or not. Some fields didn't give us trouble an some did every time. I had an axe laying right on conditioner and when it wrapped would cut through the wad then take it to the nearest woodchuck mound or any other mound and drive over it, that would turn the bottom roll an turn the plugged hay out. |

Posted By: Bill Long

Date Posted: 28 Dec 2019 at 4:36pm

|

Checking with Pop's 1960 Price Book there is a hay conditioner listed. PTO Driven Includes 72" Upper rubber covered roll, 72" lower staggered bars on solid steel tube, hand lever control, two 13" discs and rims - less tires, slip clutch Enclosed Gear Box and Roller Chain Drives Hay Conditioner - less tires $ 740.00 5.90 - 15" Tires - rib implement $ 50.00 Hydraulic Lift Attachment - $ 16.00 Good Luck! Bill Long Hey Armand, Is there anything Allis Chalmers that you DO NOT have a model of - including Pop's Dealership O. E. Long & Son

|

Posted By: Mikez

Date Posted: 28 Dec 2019 at 8:05pm

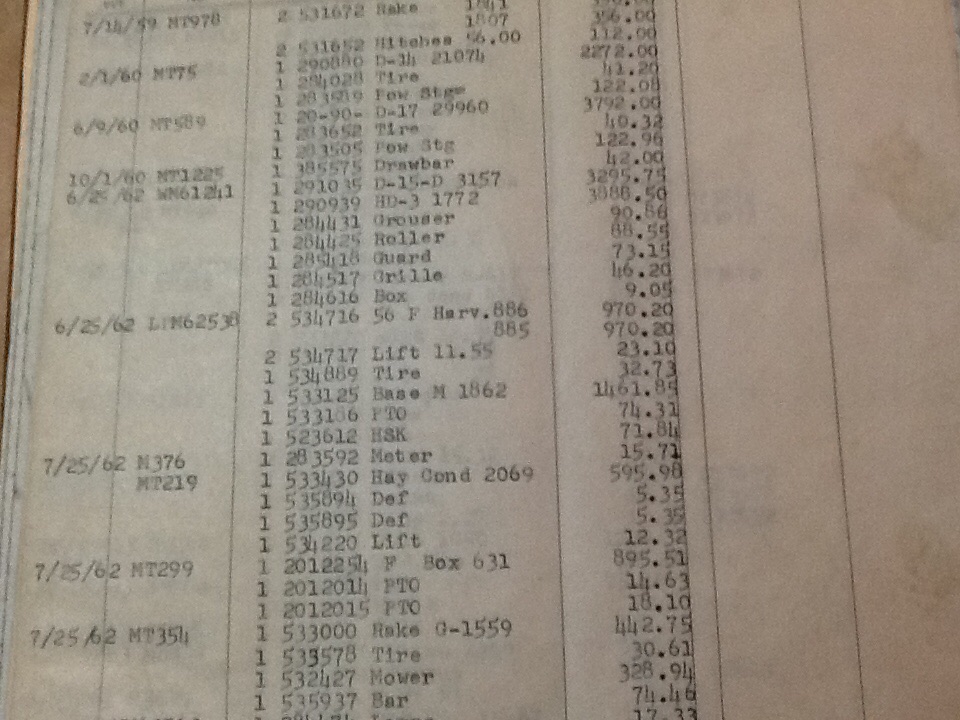

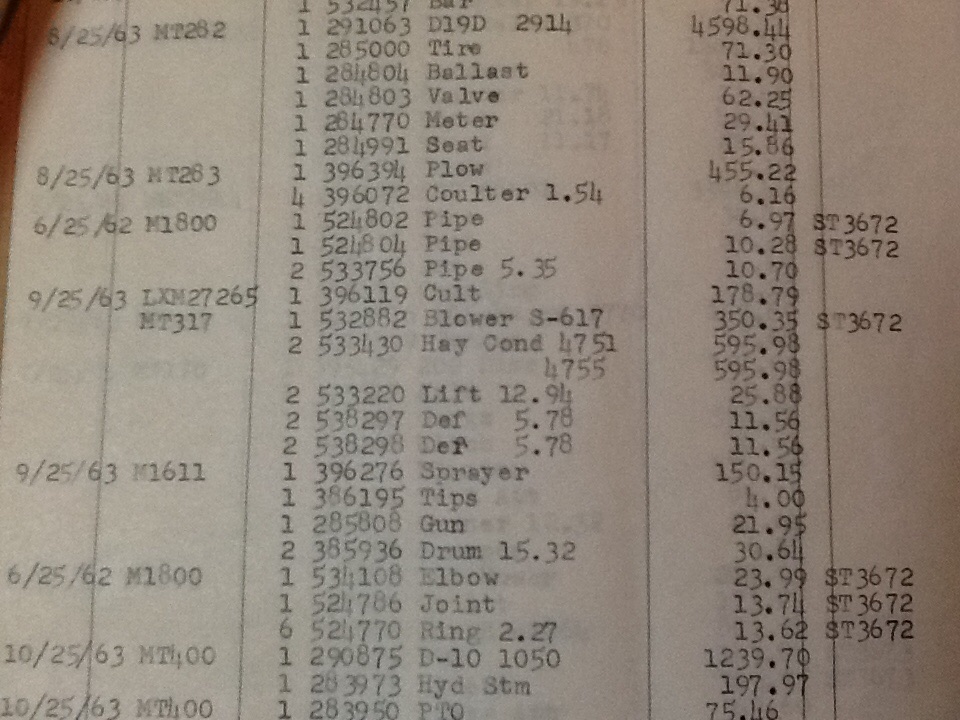

Hey bill here's a picture of a purchase statement from my grandfathers dealership. It's heading is. Allis-Chalmers manufacturing company. Syracuse, New York  In the middle is hay conditioner Oh here on the second page he got two in 63  I'll have to look SR number of the one at the farm, one of these went to they're farm an still have in barn |

Posted By: AC720Man

Date Posted: 29 Dec 2019 at 5:50pm

|

That’s cool Mike. Great to have the paperwork. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: DennisA (IL)

Date Posted: 01 Jan 2020 at 9:05pm

Here is the measurement 52.5". That is with the P.T.O. pulled out about 10" as I could not get it slid all the way in. ------------- Thanks & God Bless Dennis |

Posted By: Steve Bright

Date Posted: 02 Jan 2020 at 8:03am

| My Dad bought 1 new in 1961, I pulled it over many acres, Dad mowed hay with a WD 45, I pulled the crimper with a D 14. |

Posted By: AC720Man

Date Posted: 02 Jan 2020 at 9:27am

|

Thanks Dennis, I will see if I can find one at TSC. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: DiyDave

Date Posted: 02 Jan 2020 at 6:03pm

They'll likely charge you $300 and a 3 week wait, from my experience

Try surpluscenter, at the link, below, they might have one, hard part, sometimes is matching to the machine's end shaft...  https://www.surpluscenter.com/Power-Transmission/PTO-Shafts-Jack-Shafts/PTO-Shafts/" rel="nofollow - https://www.surpluscenter.com/Power-Transmission/PTO-Shafts-Jack-Shafts/PTO-Shafts/ ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: AC720Man

Date Posted: 02 Jan 2020 at 8:07pm

|

Thanks, I will check them out ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: Lonn

Date Posted: 03 Jan 2020 at 7:21am

|

Dad mowed with a side mount 80 or 82 and pulled an AC crimper directly behind his WD45 or WD except for the initial round. He mowed mostly straight alfalfa and it worked well but he has said it didn't like grass. Grass around here usually doesn't need crimping to dry fast. ------------- -- --- .... .- -- -- .- -.. / .-- .- ... / .- / -- ..- .-. -.. . .-. .. -. --. / -.-. .... .. .-.. -.. / .-. .- .--. .. ... - Wink I am a Russian Bot |

Posted By: AC7060IL

Date Posted: 03 Jan 2020 at 9:13am

https://www.sloanex.com/contact-us" rel="nofollow - https://www.sloanex.com/contact-us |

Posted By: Lonn

Date Posted: 03 Jan 2020 at 9:34am

|

When I worked at the local CaseIH dealer and before that the local AGCO dealer, we just built PTO shafts to customers needs. Had 10 foot long shafts of various sizes and cut to length, grabbed the correct yokes and cross bearing of the shelf and put it together by welding or pinned depending on what was needed or what worked. When I had a bent PTO shaft on my Duetz-Allis discbine I just removed old shaft from yoke went to the CaseIH dealer and they cut me off a chunk of metric shaft and I put it back together. Can't remember if it was held together with a roll pin or if I welded it together. Worked fine. ------------- -- --- .... .- -- -- .- -.. / .-- .- ... / .- / -- ..- .-. -.. . .-. .. -. --. / -.-. .... .. .-.. -.. / .-. .- .--. .. ... - Wink I am a Russian Bot |

Posted By: orangereborn

Date Posted: 03 Jan 2020 at 12:20pm

|

|

Posted By: Tbone95

Date Posted: 03 Jan 2020 at 1:21pm

| We could never get the simultaneous pull to work worth beans. Just wasn't lined up good enough, and made the plugging nightmare 3 x worse. |

ctbowles58 wrote:

ctbowles58 wrote: