D17 Hydraulic line routing

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=206992

Printed Date: 05 Feb 2026 at 4:06pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D17 Hydraulic line routing

Posted By: Steve A

Subject: D17 Hydraulic line routing

Date Posted: 05 Jun 2025 at 11:38am

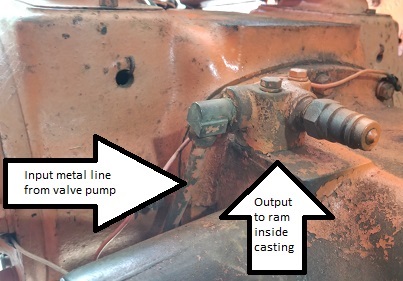

1957 D17 Series I: Is the flow of the hydraulic from the pump/valve body up through the external steel lines to the distribution block on the rear casting behind the seat? See Pics. Yes I have all three manuals--Operators, AC Service and the infamous IT--but I want to confirm before adding valve body. Have a slow drift down of lift arms under load. Possible worn levers/out of adjustment or worn internal control valve.

|

Replies:

Posted By: A-C_220

Date Posted: 05 Jun 2025 at 2:17pm

| I fixed a D14 once that the lift arms sunk, was the internal cylinder and hose leaking. I could tell because the transmission was overfull and hydraulic oil was low |

Posted By: DSeries4

Date Posted: 05 Jun 2025 at 3:03pm

|

The external line you are pointing to is the return line. Everything else is internal. If your arms are drifting down, it could be the seal in the lift cylinder or the line inside the tractor. Either way, nothing on the outside of the tractor will solve the problem. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: Steve A

Date Posted: 05 Jun 2025 at 4:00pm

| Thanks, that's why I asked... |

Posted By: Steve A

Date Posted: 05 Jun 2025 at 4:37pm

|

Still not grasping the concept. What does that internal flexible hose leading to and from the ram connect to? I was assuming that was the source of the oil powering the ram. Since it is a ram--no down pressure-- I was making the assumption the flow goes to and from in the same line. If that isn't the case how does it become pressurized to lift? |

Posted By: Steve A

Date Posted: 05 Jun 2025 at 5:15pm

|

This still may be adjustments and not necessary. But where I'm coming from: My WD's have rams on both the loader and the rear lift. At the factory valve where the ports lead to the rams I have run 3/8 line to a standard 3 spool valve. One out line leads to the ram. The normal second "output" I plumbed line back to a spin on Hydraulic filter mount. The normal return line from the 3 spool goes back to the filter as well. From the filter it returns to a pipe fitting that I drilled and tapped--3/8 pipe-- into the top of the hydraulic reservoir of the torque tube. I've also seen them returned to the drain plug hole at the bottom, but that just stirs whatever settles around and defeats the purpose of settling. As long as you keep the pressure relief of the add on valve set below the max pump pressure, it all works fine. It pressurizes the ram, lifts, and when I move the valve to the other position the oil flows back into the return system. I turn the "pump on" --move it to "lift" from the stock lever on the steering column quadrant-- it powers the system. When I'm done I turn the pump off. It's also easier for me to run the loader, tilt the bucket and lift the back blade that way without needing a diverter or moving the quadrant lever back and forth. The pump on the D17 doesn't have any trouble lifting. So maybe adding the valve would fix my issue. I haven't had it long enough to do much with the rear lifting arms. They worked fine with no load but very slowly sink when I put the rear blade on. |

Posted By: DrAllis

Date Posted: 05 Jun 2025 at 6:09pm

| The steel line directs oil from the pump to the lift arms or lift cylinder on an implement to lift a load. The pump has a hold valve built into it. No adjustment. The steel line holds the oil when the pump is in HOLD. When you lower anything, the hold valve on the pump opens and the oil returns back thru the steel line the other way. Having trouble holding an implement or lift arms?? #1. a bad hose inside the lift arm housing. #2. leaking seals on the lift arm cylinder inside the lift arm housing. BOTH of these will cause oil level to go up in the transmission and down in the hydraulic compartment. #3. A bad hold valve on the pump. Three things. And the only things it can be for leaking down. |

Posted By: Steve A

Date Posted: 05 Jun 2025 at 8:02pm

| Thank you once again!! That is the way I interpreted it, and what I was hoping to hear. It has no problem lifting 5 ft rotary mower, but then very slowly settles after two or three minutes. Looked at the oil levels in both compartments just now: Neither seems excessively high or low, but this is the first time I've put any real weight on the lift system. Will keep a close eye on the levels. The detent on the hydraulic control lever (on steering column) is worn down to a rounded off nub. Guessing previous owner used the heck out of it. |