190 XT reverse shift lever

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=204366

Printed Date: 06 Feb 2026 at 9:31pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 190 XT reverse shift lever

Posted By: festus

Subject: 190 XT reverse shift lever

Date Posted: 30 Nov 2024 at 6:49pm

|

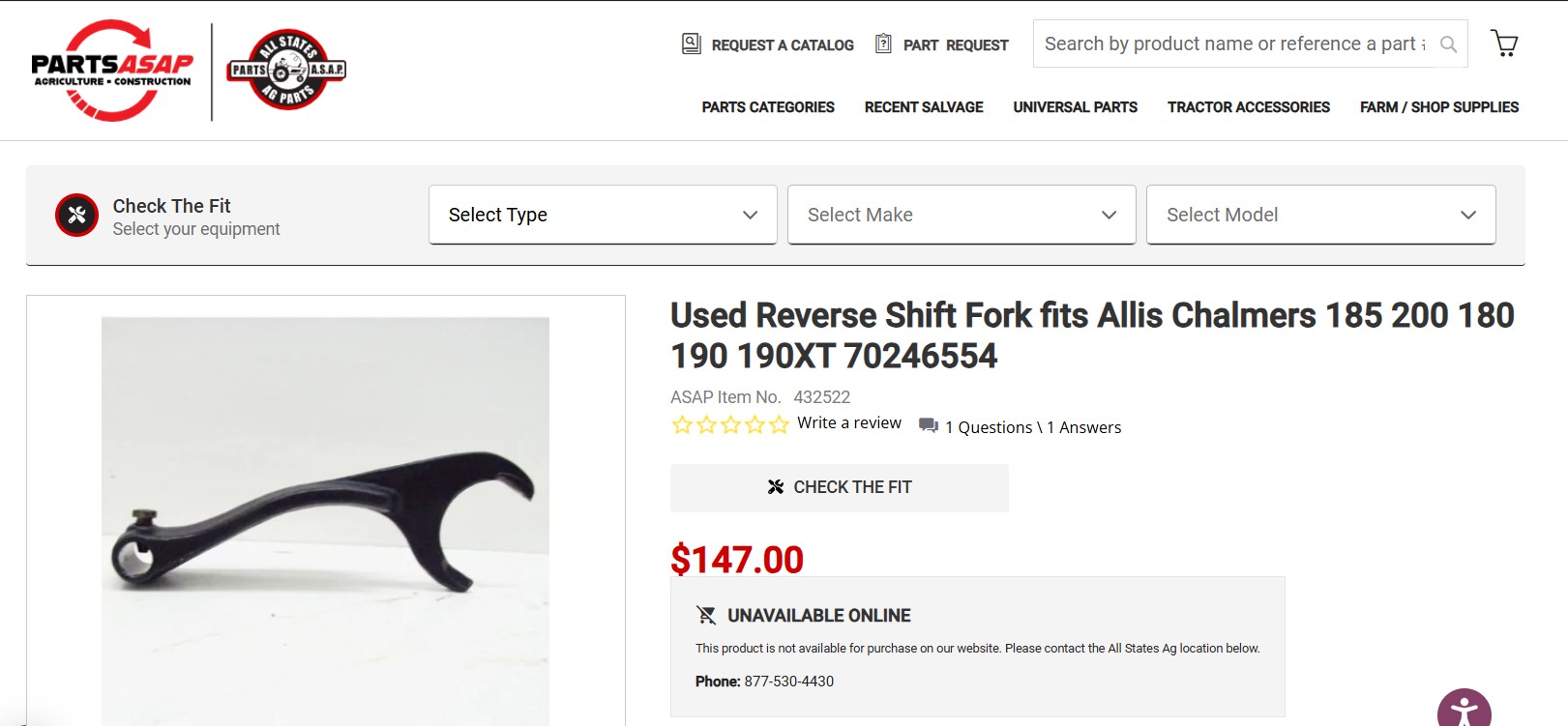

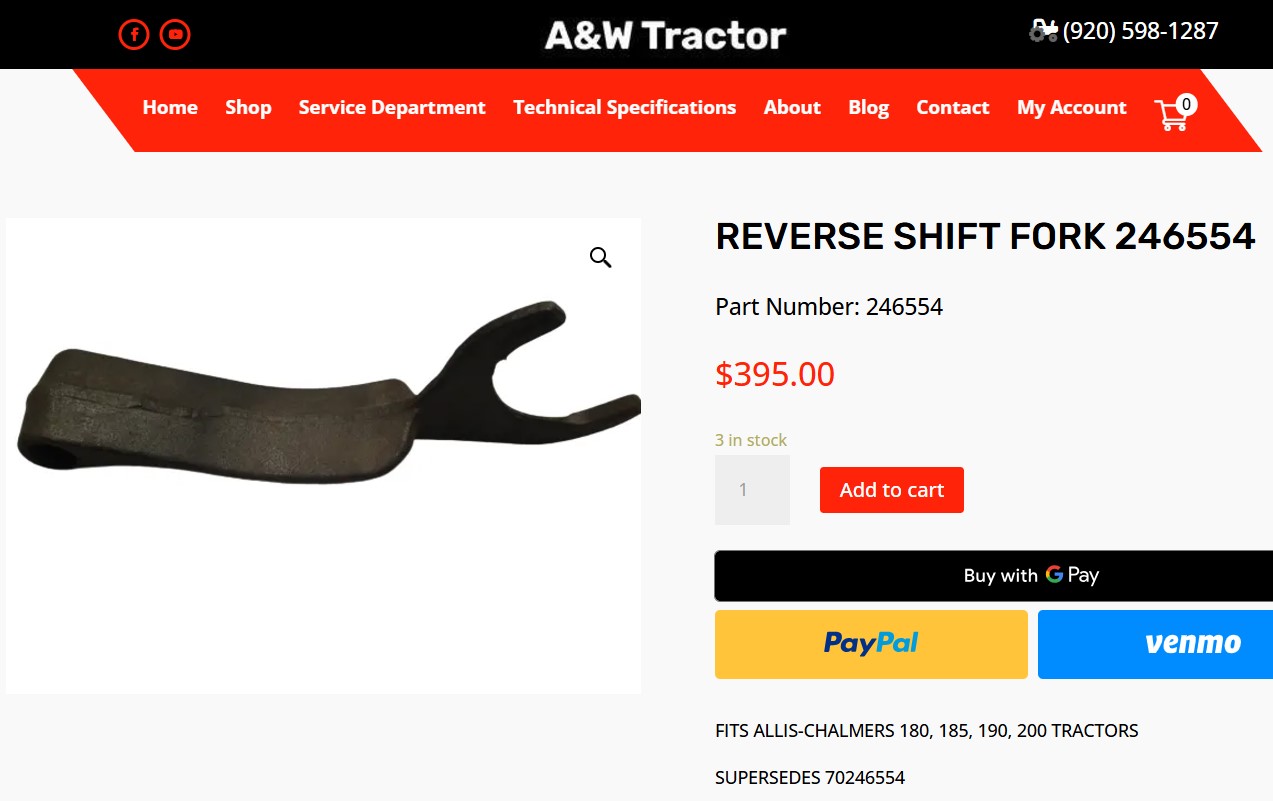

Broke the lever today. It looks like these are almost impossible to find. My tractor appears to be a 64 XT gas. I see where some have been able to braze them or in some cases weld them back together. This one broke on the flat part a little above the numbers. I'm a little Leary of brazing it and expecting it to hold. Make I am overthinking it. I am assuming it is cast steel so welding may be a decent option. I have an Ac stick welder and A wire welder which I assume is a no. Will An old fashioned Lincoln Ac buzzbox work for the needed rod? What rod would you recommend? Will another shift cover with the levers attached interchange with mine? I found a case where a guy found another lever from a yard , but it was different than his. My rails were rebuilt 6-8 years ago so I would prefer to use it if possible. The part number on mine is 246554 Thank you for any suggestions |

Replies:

Posted By: Joe Goodwill

Date Posted: 30 Nov 2024 at 7:06pm

| We broke the reverse shift fork on a 185 30+ years ago on a weekend during a blizzard! Opened it up took the fork to local shop where old AC mechanic worked. He was a master with brass and a torch. 15 minutes to fix 1 hour to enjoy the bottle of dark rum payment and it is still working today. Don’t be afraid of a proper brazing repair. |

Posted By: Mikez

Date Posted: 30 Nov 2024 at 8:14pm

| 246554 looks to still be available |

Posted By: elmer

Date Posted: 30 Nov 2024 at 10:33pm

| Thanks Joe . That gives me some hope if it comes down to that. I used to have to braze together 2 oil pick up tubes on Chevy race engines years ago. It has been several years since I have had to do any brazing. |

Posted By: elmer

Date Posted: 30 Nov 2024 at 10:34pm

|

Mikez , Where did you find that available? Thank you

|

Posted By: grinder220

Date Posted: 01 Dec 2024 at 6:30am

| Agco still sells them. Bargain price of $782 according to the online parts book. I'm pretty sure I have a good one laying in the shop I'd sell for $50 plus shipping. Im in east central Iowa |

Posted By: steve(ill)

Date Posted: 01 Dec 2024 at 8:03am

add a "70" to the front of that part number when you GOOGLE... A few used ones around but they sell pretty fast..... grinder has a GREAT price aat $50. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 01 Dec 2024 at 8:11am

or NEW... ------------- Like them all, but love the "B"s. |

Posted By: elmer

Date Posted: 01 Dec 2024 at 11:06am

|

Grinder Thank you for the help. I am also in Iowa . What is the best way for me to get you paid? I just figured out how to send you a PM so my information is there. Thank you !

|

Posted By: Dakota Dave

Date Posted: 03 Dec 2024 at 11:25pm

| I took mine out several years ago took it to a local black smith. He brazed it back together. It’s working great. a good braze job is just as strong as the cast part was to begin with. We brazed a shift fork on dad’s dozer back in the 70s. It was still working 20 years later when he sold it. |

Posted By: elmer

Date Posted: 09 Dec 2024 at 2:25pm

|

Got the reverse fork today from Grinder220 below. Thank you sir for your help! Now I have to change it. When I try to take the rail out to swap the lever will there be a detent ball to catch like the other rails? Thank you

|

Posted By: SteveM C/IL

Date Posted: 09 Dec 2024 at 3:12pm

| I'd assume so. What else keeps it in place? Be prepared.... |

Posted By: festus

Date Posted: 09 Dec 2024 at 8:05pm

| Thank you.. haven't had one apart all the way have seen where people loose the ball. Hopefully I can get it apart and get the lever in the correct spot without loosing parts. |

Posted By: grinder220

Date Posted: 09 Dec 2024 at 8:43pm

| Best and easiest thing to do is get a bolt or rod the same size to but up against the shift rail so the ball and spring stay compressed. You can rotate the rail enough to get out of the detent and it will slide out nice and easy. |

Posted By: WF owner

Date Posted: 10 Dec 2024 at 6:38am

That's a great idea!!! Maybe this should be in the Knowledge Based section as a reference to anyone that tackles this job.

|

Posted By: elmer

Date Posted: 10 Dec 2024 at 12:27pm

Thank you

|

grinder220 wrote:

grinder220 wrote: