Found a snap coupler 160 mower

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=199151

Printed Date: 07 Feb 2026 at 5:53pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Found a snap coupler 160 mower

Posted By: Allis dave

Subject: Found a snap coupler 160 mower

Date Posted: 10 Jan 2024 at 10:24am

|

Hi Guys I was lucky and brought home an Allis Chalmers snap couple 160 rotary mower. I've seen some pull types but not to many snap couplers. It seems to be in pretty solid shape and not rusted out. Blades are good but need sharpened. Previous owner took off the front skids but they came with it.

It has a homemade tailwheel on it, but it should work ok. The slip clutch has been welded together so that will need some attention.  |

Replies:

Posted By: AC WD45

Date Posted: 10 Jan 2024 at 12:11pm

|

Sure don't see very many of those. I bid on a 3 point version 10 yesrs ago at an auction but the deck was rusted right out and I wasn't paying near what it went for ($450 i think was the sale price) ------------- German Shepherd dad 1957 Allis Chalmers WD45 #WD234847 1951 Allis Chalmers WD #WD88193 |

Posted By: DiyDave

Date Posted: 10 Jan 2024 at 4:39pm

|

Early Danuser made unit, nice find! ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: jvin248

Date Posted: 10 Jan 2024 at 4:48pm

|

That lookes like a rare find indeed. I have a drawbar pull type mower with the two side wheels. Works well on the WD for chopping corn rubble after ear picking. Had to use it a bit on the shaggy lawn after the zero turn decided it would only drive in circles... Another repair to do. Was the wheel put on your mower find to run with a bad hydraulic lift? Or just ensure consistent height cutting? .

|

Posted By: Macon Rounds

Date Posted: 10 Jan 2024 at 7:41pm

|

That will be fun to attach to the tractor. And yes Rare find !!!!! ------------- The Allis "D" Series Tractors, Gravely Walk behind Tractors, Cowboy Action Shooting !!!!!!! And Checkmate |

Posted By: Allis dave

Date Posted: 11 Jan 2024 at 5:41am

|

So did these snap coupler mowers not have any tailwheel from the factory? This tailwheel was in it when I got the mower. This is the only one I"ve ever seen that wasn't pull type Looking at the way the hitch is solid you might not need one. |

Posted By: Dave (NE)

Date Posted: 11 Jan 2024 at 9:06am

|

Mine has a factory tail wheel. Below is a picture of mine with the tail wheel. The manual shows them both with and without a tail wheel. Mine has a sheer bolt rather than a slip clutch, but the manual shows the slip clutch as an option. Wish mine was six foot rather than five (don't know if they made them six foot) and that it had a slip clutch. It is not difficult to mount. ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: Allis dave

Date Posted: 11 Jan 2024 at 10:41am

|

Thanks for the pictures Dave. That's a nice mower with a facotry tailwheel! Your's is the first one I've seen other than the one I just bought. I have a snap coupler Wood's mower too, but I never got it running. Sounds like maybe mine came wihtout a wheel and someone wanted on. seems like it would be nicer wiht a tailwheel. 3-point mowers tend to just dig in if they ride on the ground. I looked and there are several options to buy new aftermarket slip clutches for under $100. It will probably go on my D17 becsaue I'm nervous to hit somehting and tear the PTO gears out of my WD45. I wish it was a 6' also to at least cover the tracks |

Posted By: Dave (NE)

Date Posted: 11 Jan 2024 at 11:57am

|

Yeah, I've looked into some aftermarket slip clutches, but they didn't appear that they would work. Be neat to find a factory one! Being just five foot, it doesn't cover the tracks on my '45, so I generally use my six foot pull type, with the mower wheels set in the back of the mower. ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: 55allis

Date Posted: 11 Jan 2024 at 11:21pm

|

I got my 160 as a pull type but made it into a snap coupler. I would like to make a rear dolly wheel sometime to make it better. Dave, what size of tail wheel is that? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Dave (NE)

Date Posted: 12 Jan 2024 at 8:15am

|

Well, I found some notes from when I was looking for a new tire for it. Notes say 4 x 16 semi-pneumatic tire. Like a planter packing wheel tire. ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: IBWD MIke

Date Posted: 12 Jan 2024 at 9:28am

|

One of those would look great behind the D-15! Wouldn't think they would be hard to hook up at all, probably do it all from the seat but the pto shaft. Had a Woods Dixie cutter that was snap-coupler, 5'. Sold it after getting the 7' Mohawk. Sometimes wish I had kept it. Did a great job and I had fixed everything that needed attention. Only dislike was that it would come unlatched sometimes in rough terrain. |

Posted By: 1963D17

Date Posted: 13 Jan 2024 at 8:25am

| I have one just like it as well. It's actually supposed to be an overrunning clutch, not a slip clutch. Mine also was welded up. With a transmission driven pto it is necessary because of the blades momentum. I bought one of those overrunning pto adapters that goes on the tractors pto shaft. |

Posted By: Allis dave

Date Posted: 01 Apr 2024 at 2:15pm

| Started working on this and found the gearbox is full of grease. Output shaft may have a little play but need to investgate further. Are seals and bearings still available? |

Posted By: Kenny L.

Date Posted: 01 Apr 2024 at 3:13pm

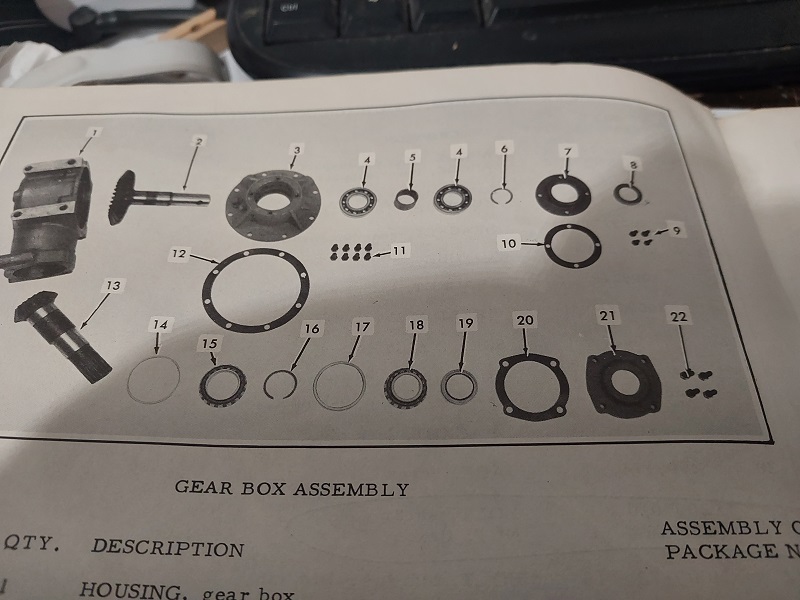

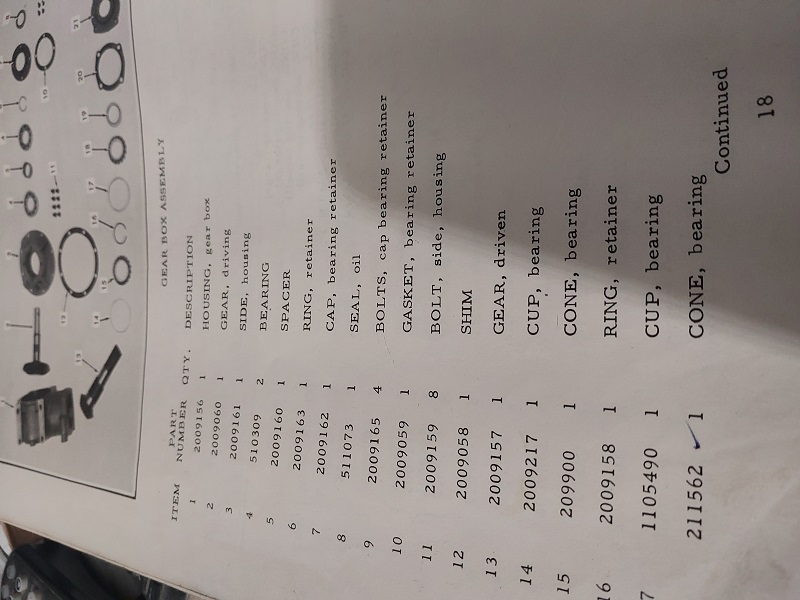

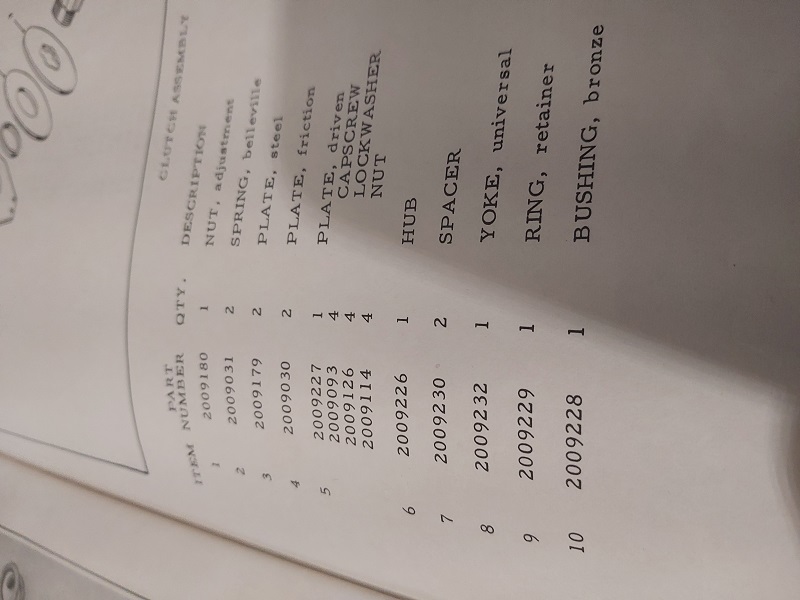

Dave here's some pictures out of my 160 parts books you'll have to a a 70 to the front of the parts number.   |

Posted By: Allis dave

Date Posted: 01 Apr 2024 at 4:17pm

| Thank You!!! That's very helpful. Now I can call and see what's available before I tear it apart. I"m guessing the bearings and seals are just a standard size that could be matched up. |

Posted By: Mikez

Date Posted: 01 Apr 2024 at 5:35pm

|

Kenny not 70 on all those numbers. Just 7 to the seven digit numbers. You want to end up with eight digits for agco numbering. Which parts are you looking for. I’ll check our stuff

|

Posted By: Gary

Date Posted: 01 Apr 2024 at 6:04pm

|

I have one of those very tongues on my fence line. G |

Posted By: Allis dave

Date Posted: 02 Apr 2024 at 7:28am

|

Hi Mike, I'd be interestd in the whole slip clutch assembly if you have one. As far as the gear box, I havne't torn it apart yet

|

Posted By: IBWD MIke

Date Posted: 02 Apr 2024 at 10:20am

|

I'd like to have one of these mowers with the S/C hitch preferably. |

Posted By: Dave (NE)

Date Posted: 02 Apr 2024 at 11:51am

|

I'd take a slip clutch assembly too, if you have additional ones Mike. Thanks, Dave ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: Mikez

Date Posted: 02 Apr 2024 at 2:19pm

| Do you have part numbers |

Posted By: Kenny L.

Date Posted: 02 Apr 2024 at 5:15pm

Mike, call me when you can, I've one that I might sell.

|

Posted By: Kenny L.

Date Posted: 02 Apr 2024 at 5:27pm

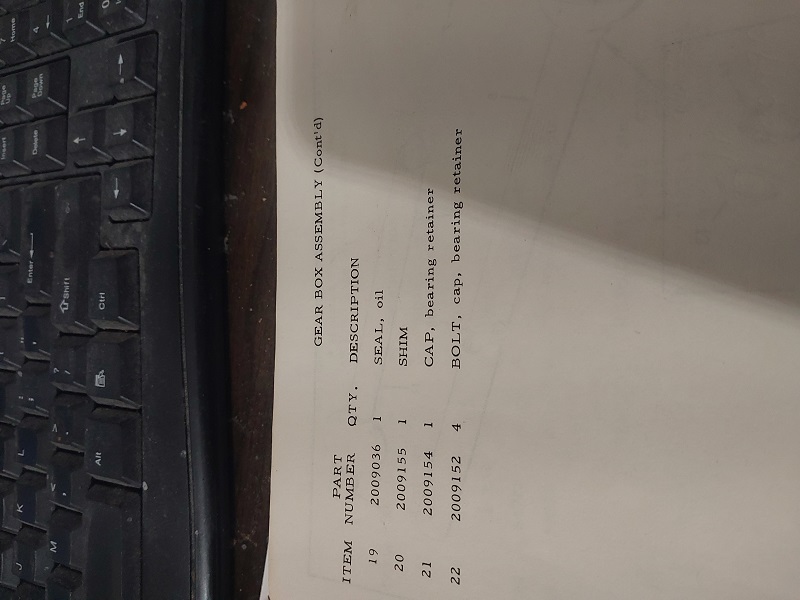

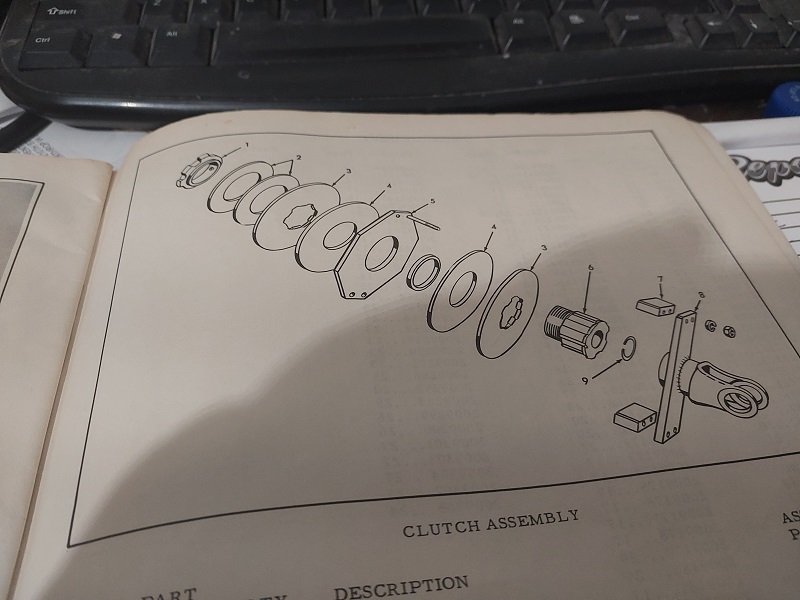

This all I can find in the book I've.  |

Posted By: 55allis

Date Posted: 02 Apr 2024 at 6:47pm

I’ve been living with a shear bolt and it will only shear when I have it on my 45 with a D262D mowing trees  I rebuilt mine years ago ( its on this forum somewhere) with Timken bearings and 85-140 gear oil. I’ll look and see if I can find the thread… ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Dave (NE)

Date Posted: 02 Apr 2024 at 7:42pm

|

Well, my owner's manual does not show a part number for the slip clutch. It simply says the mower can be purchased with a slip clutch as a factory installation and has a picture. ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: Mikez

Date Posted: 03 Apr 2024 at 3:23pm

| Dave show me what you have. I’ll see what I can find. The picture that Kenny put up looks like Dave’s first picture |

Posted By: Dave (NE)

Date Posted: 03 Apr 2024 at 3:58pm

|

Here is a picture of the slip clutch from the manual. ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: Dave (NE)

Date Posted: 03 Apr 2024 at 3:59pm

|

Oh, I see there is a number at the top of the page I didn't see before; 532768. ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: Mikez

Date Posted: 05 Apr 2024 at 10:31pm

| The only parts we have left is #4 and #8 in Kenny picture |

Posted By: Allis dave

Date Posted: 15 Jul 2024 at 9:16am

|

Hi guys, I've been slowly working on this mower over the summer. I'm almost finished rebuilding the gearbox becasue it leacked and was full of grease. While waiting for a bearing I'm working on the frame There are 2- 1/4x2x2 angle irons that run underneath from the front of the mower to the gearbox to support lifting. These were all bent up and torn off behind the gearbox so I don't know how far back they should go. I'm replacing these with new. The way the holes line up it looks like these should be 5' long and run from the front of the mower clear to the back. It seems like that would make good lifting support as you'd be lifting from the front middle and back. Can anyone confirm on their mower if they have these supports underneath and were they attach? The issue I'm solving is the gearbox is sitting on top of angle irons welded on top on the frame and my replacement angle irons are bolted underneath the frame. This leaves a 1/4" gap or more (the thickness of the main frame) between my new irons underneath and the irons that the gear box sit on. I think I'm going to make a shim out of some 1/4 stock to fill up the gap, but this wasn't there originally so I'm curious if the underneath supports aren't supposed to go all the way to the back which is causing the issue

|

Posted By: Kenny L.

Date Posted: 15 Jul 2024 at 11:54am

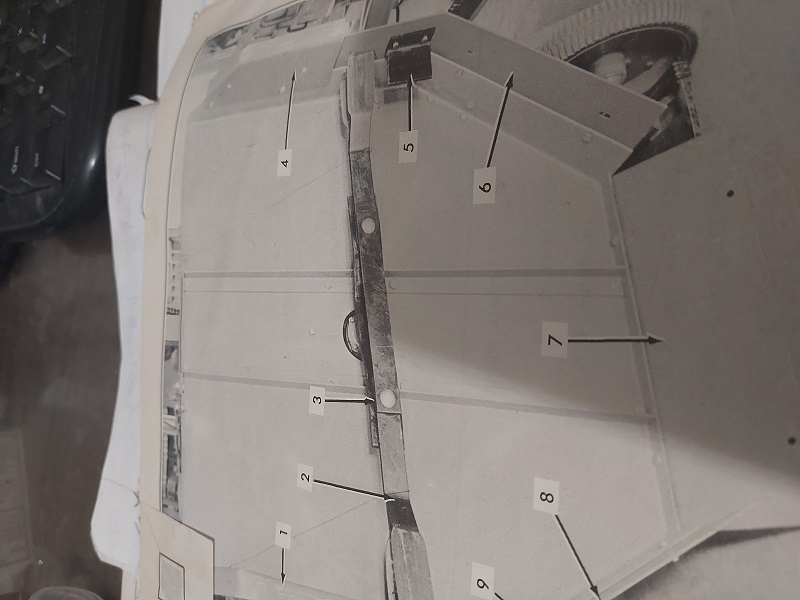

| Dave, in my operators manual and parts list for the 160 rotary mower it show two angles running from the front all the way to the back. HTH Kenny |

Posted By: Kenny L.

Date Posted: 15 Jul 2024 at 12:07pm

here a picture that's in my manual. |

Posted By: garden_guy

Date Posted: 15 Jul 2024 at 1:14pm

|

I swear blades on the 160 and 172 are nearly impossible to take off... The cotter keys basically rusted into the slots so I can't get the castle nuts off, and they point "up" so room to get an impact on there is non-existent. |

Posted By: Dave (NE)

Date Posted: 15 Jul 2024 at 1:39pm

|

Well, I went out, crawled on the ground and took a look at my shredder. I confirm, what Kenny is saying, that the angle irons do run all the way from the front to the back on either side of the gear box. There is one bolt at the front, two by the gear box, and another bolt at the back for each angle iron. Hope that helps. Dave ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: Allis dave

Date Posted: 15 Jul 2024 at 2:17pm

| Thanks guys that's exactly what I wanted to know. I installed my new ones the same way. Front to back. I'l make a couple shims to take up the space in the middle and clamp everything together tight. |

Posted By: Dave (NE)

Date Posted: 15 Jul 2024 at 5:17pm

|

did you ever come up with a slip clutch? ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: Allis dave

Date Posted: 16 Jul 2024 at 5:40am

| No, Either going to buy a new Tractor Supply clutch or just put it back together with only 2 instead of 4 1/4 bolts and see how it goes. |

Posted By: IBWD MIke

Date Posted: 16 Jul 2024 at 8:31am

Yep, that's pretty much the way bush-hog's are across the board. Nuts up, the button head on the bolt doesn't drag stuff around like the other side would. Reminds me, haven't sharpened the blades on the Mohawk yet this year. Seems like if you put a little anti-seize on things and service every year, things come apart easier.

|

Posted By: garden_guy

Date Posted: 16 Jul 2024 at 11:08am

Yeah I wound up doing this number to sharpen mine since I couldn't take them off:  |

Posted By: Allis dave

Date Posted: 16 Jul 2024 at 11:51am

| Whatever works! My gearbox is off and the blades lying on the ground. They should be a lot easier to getoff when you can hold them and not lying on your back |

Posted By: Dave (NE)

Date Posted: 16 Jul 2024 at 2:08pm

|

That's how I sharpen mine, too! ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: 55allis

Date Posted: 16 Jul 2024 at 6:40pm

|

I took a loader tractor and flipped it so the hitch was in the air, much easier to work in there. I rebuilt the gear box on mine because the races were cracked but the gears were fine. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: ac hunter

Date Posted: 17 Jul 2024 at 7:24am

|

Nice mowers. Bet AC didn't build a lot of those. Am wondering if anyone knows where to get a wheel like the tail wheel in Dave's mower picture. Looks like the depth gauge wheels on my AC snap coupler field cultivator. Mine are pretty shot, expecially the rubber. I have looked on the internet but can't find anything. May not have found the right source though. Thanks.

|

Posted By: Dave (NE)

Date Posted: 17 Jul 2024 at 8:12am

|

Good luck finding the wheel. Or even the tire. The tire is a 4x16 semi-pneumatic tire. I needed a tire and eventually got one that is used as a gauge wheel on a White 5100 planter. Is not 100% correct, as the tire is at an angle and not flat, but works. Ironically, a few months ago I was at an auction with Allis stuff. In a pile, I found a wheel and tire that was an exact match to the original. Go figure! ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: ac hunter

Date Posted: 18 Jul 2024 at 11:49am

| Thanks Dave. I was kind of thinking the tire was n't even available anywhere. Maybe I'll see about your planter wheel suggestion. |

Posted By: Dave (NE)

Date Posted: 18 Jul 2024 at 12:47pm

|

I worked with Mark Wells of Wells Implement in Plymouth NE to figure things out. The Agco part number is 71506603. He thought Agco may have the tire for a Landoll planter. You may try that also. Dave ------------- Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain. |

Posted By: 1963D17

Date Posted: 19 Jul 2024 at 11:25pm

| I have that same mower on my D17. The overunning clutch was shot. I bought an overunning adapter from tractor supply that goes between the tractor and the pto shaft. It works well. |

Posted By: Allis dave

Date Posted: 26 Jul 2024 at 7:56am

|

part number 2009269 is pictured with arrows pointing at it. Does anyone have One of these for sale? The one on the left side of the mower is homemade. Homemade one has a "X" in the picture and is missing the adjustment holes.  |

Posted By: ac hunter

Date Posted: 27 Jul 2024 at 8:01am

| Thanks, Dave (NE). I wiil contact Mr. Wells and see how that goes. Thanks for the part #. |

IBWD MIke wrote:

IBWD MIke wrote: