Brake Pins 😮💨

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=189057

Printed Date: 19 Dec 2025 at 7:44am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Brake Pins 😮💨

Posted By: INV3RSE

Subject: Brake Pins 😮💨

Date Posted: 23 Jun 2022 at 10:42am

|

Rightyho I cant get my break pins out of the ED40. One side had rusted so bad the shoes lifted out leaving the rust bonded to the pin! The pin wont shift, I’ve made a pin puller using a threaded bar but it still won’t budge, it’s just flattening the bar threads. What are my options? I’ve got new parts coming so want the old out asap, trouble is, I’m struggling to get them out 😞. |

Replies:

Posted By: steve(ill)

Date Posted: 23 Jun 2022 at 11:14am

|

I have had good luck with HEAT / PENETRANT / then IMPACT HAMMER .... You can hit it with the IMPACT more in 1 minute, than you can swing a 5 pound hammer all day long. I assume you can get to the BACK SIDE ? If not, you might drill thru the housing on the back side for access to the pin. Im not recommending this one... just showing you what to use. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 23 Jun 2022 at 11:15am

|

Some have cut the pin ( where the shoe sets) with a cutoff wheel, then pound each remaining piece out individually. ------------- Like them all, but love the "B"s. |

Posted By: garden_guy

Date Posted: 23 Jun 2022 at 12:50pm

Is it possible to get to the brake pins in the WD with a cutoff wheel (either a grinder or a dremel), or do you need a torch to get up in there?

|

Posted By: WF owner

Date Posted: 23 Jun 2022 at 2:10pm

I've used a sawzall.

|

Posted By: INV3RSE

Date Posted: 23 Jun 2022 at 4:07pm

|

I can see the pin by looking up underneath, there’s a round hole in the tractor casing that allows you to view . I think I might have to cut it somehow. Just a bit worried once it’s cut i will then have two stick pieces rather that one! 😂 |

Posted By: Gary

Date Posted: 23 Jun 2022 at 4:20pm

|

Any one know for sure what the Brake set-up is for the British ED-40. Is it similar to a WD, a CA, or a D-14 ? G |

Posted By: Ed (Ont)

Date Posted: 23 Jun 2022 at 9:17pm

| I got one side out in my WD45. The other side I cut with a torch up thru the hole and pounded the pin in then cut again and drove it in more til it fell out. I have no idea what the accessibility is on the ED40. |

Posted By: Dirt Farmer

Date Posted: 23 Jun 2022 at 10:44pm

| Could you weld a short piece of steel to the outside of the pin. That would create heat throughout the pin, then let it cool and use that as an anchor point to use an air chisel on to drive it out. Once you start using an air chisel for tasks like this you'll wonder how you have gotten by in the past. Mine gets used nearly everytime I'm changing bearings on equipment or cutting rounded off bolts. Good luck and let us know how it turns out |

Posted By: INV3RSE

Date Posted: 24 Jun 2022 at 4:02am

|

I think its the same set up as the WD-45. Except the British one has a thread in the centre of the pin |

Posted By: INV3RSE

Date Posted: 24 Jun 2022 at 1:52pm

|

Will one of these torches be good enough to heat the pin? https://www.toolstation.com/vortex-map-torch-pack/p71324" rel="nofollow - https://www.toolstation.com/vortex-map-torch-pack/p71324 Thanks for all the help guys appreciate it. |

Posted By: DiyDave

Date Posted: 24 Jun 2022 at 5:36pm

I have one of these, pricey ($400) but worth it. If I were in your position, I'd call around to a few local muffler, or auto shops, and ask if they would be willing to heat your pins for you, if they have a bolt buster tool, or one like it...  https://youtu.be/f2A8no15Ep0" rel="nofollow - https://youtu.be/f2A8no15Ep0 ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: BrianC

Date Posted: 25 Jun 2022 at 6:17am

|

Posted By: BrianC

Date Posted: 25 Jun 2022 at 6:22am

|

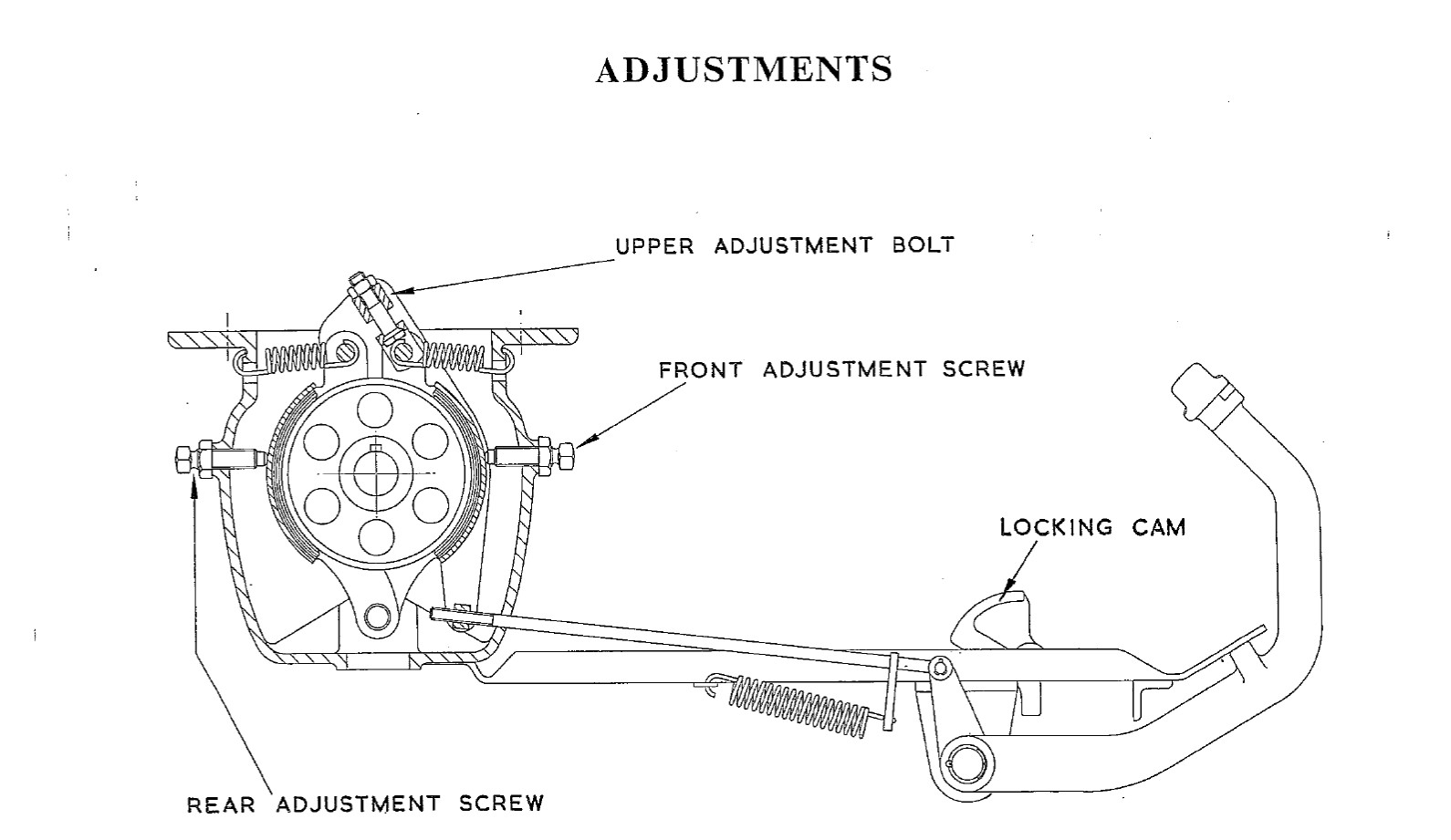

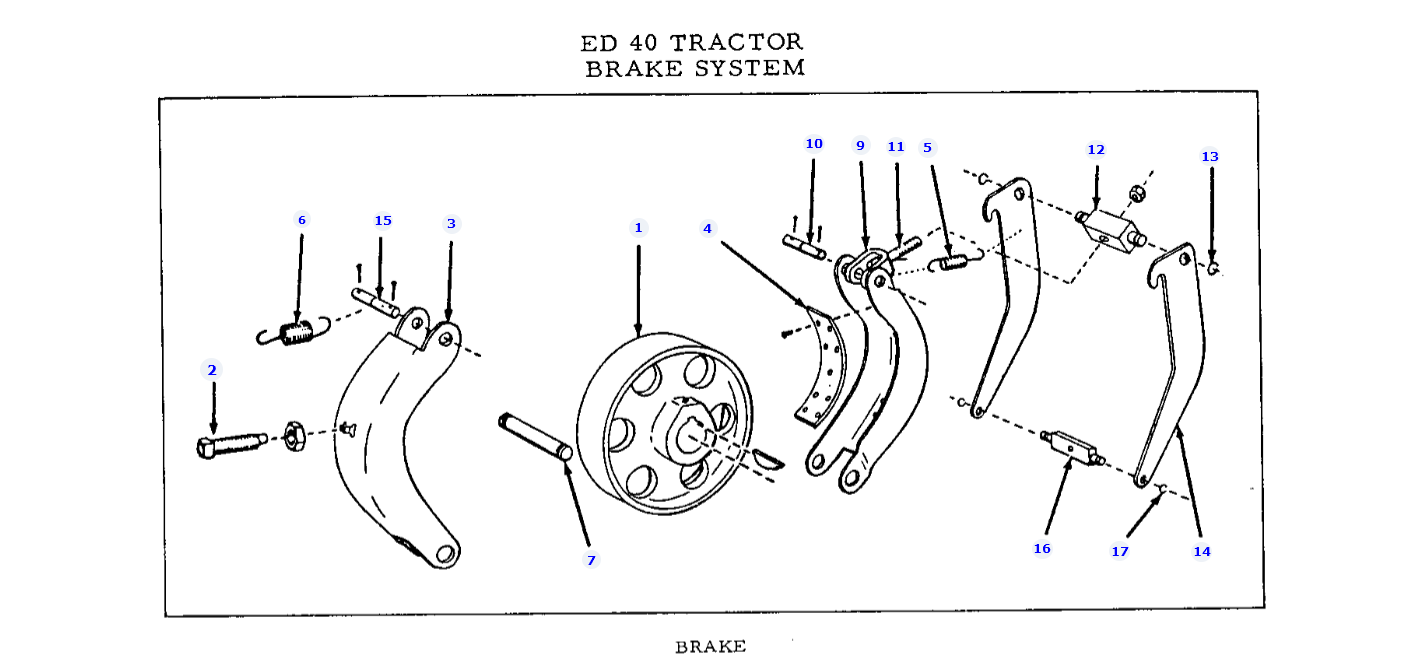

That picture is from the operators manual. The Agco parts book online shows a 3d picture of the parts. I can't tell how, but it looks like it boils down to getting that lower pin removed. |

Posted By: BrianC

Date Posted: 25 Jun 2022 at 6:46am

|

From the parts books. Still can't see how to pull the pin. I wouldn't cut anything untill your new parts arrive. A google search for Ed40 brake job didn't find anything. No good pictures of the axle housing. So I thought this thread could use the images. I saw an ED40 once.  |

Posted By: INV3RSE

Date Posted: 25 Jun 2022 at 9:36am

|

Yeah that is the set up. The inside of the pin is threaded. I’ve screwed in a threaded bar put some box steel around it with washers on the end and a nut, basically to make a puller to pull it out. The puller would work if the pin wasn’t stuck/seized! |

Posted By: steve(ill)

Date Posted: 25 Jun 2022 at 9:43am

|

can you get to the BACKSIDE of the pin ? blind hole ? Can you drill into the housing and see the BACKSIDE ?

propane or MAPP torch should be able to get the pin close to RED... at least DULL RED.. let it soak into the rust and spray with penetrant.

------------- Like them all, but love the "B"s. |

Posted By: BrianC

Date Posted: 25 Jun 2022 at 10:28am

|

Confirm the pin in question is item #7. The pin was internally threaded, perhaps for a puller? Sometimes an impact puller works better than threaded puller. That allows you to pull-tap it out. What size (diameter) is the pin, what size is the threaded rod/bolt you are pulling with? How long is the pin? I assume you can see the end of the pin, is that on the inside closer towards the center of tractor, or the outside closer to the wheel. So what direction are you currently pulling from? Is the hole in the housing a through hole, can you pull or push from either side? If yes, I would use penetrating oil and tap it some to the left, some to the right. However Allis loved their blind brake pin holes, so what are the odds. What do you suppose retains the pin in place? My C has internal clips. Item #7 picture looks as if it has grooves for retaining clips. If so they need to be removed first. new info- the parts book lists item #8, set screw 3/8NCx3/4 (not illustrated, retains item #7). So where is that? Regardless, need to remove it. If that stuck you need that torch, a few heat and cool and penetrating oil cycles will do the trick. I don't think there are any bearings or seals you need to worry about cooking. If you could post a few pictures that would help. |

Posted By: INV3RSE

Date Posted: 25 Jun 2022 at 1:13pm

|

Yeah the pin is #7 I have added a couple pictures, as you can see one pin is a lot worse than the other. I can see one end of the pin threaded internally ( that the puller goes on ) then it goes through the tractor casing and through the eyes on the shoes then back in to the casing. The end of the pin is not visible but there is a hole you can see up through. I think a MAP tortch is a good idea. I was thinking of putting the sds drill up through the hole to ratttle it a bit I

|

Posted By: INV3RSE

Date Posted: 25 Jun 2022 at 1:13pm

| Yes there was 2 grub screws that retained the pins, I have been able to remove them. |

Posted By: steve(ill)

Date Posted: 25 Jun 2022 at 1:21pm

|

YEA.... that is one NASTY looking pin.... Needle gun ... heat... penetrant...air hammer... still might have to cut in half and pound out from both ends.. ------------- Like them all, but love the "B"s. |

Posted By: INV3RSE

Date Posted: 25 Jun 2022 at 1:39pm

|

Unfortunately it’s only possible to get to it from one end and up the middle. One pin is proper nasty, other isn’t to bad..bad but not as bad 😂 I get pressure on the puller and see what heat can do, will get a MAP torch tomorrow. Can heat a cool a couple times a day until it budges. |

Posted By: BrianC

Date Posted: 25 Jun 2022 at 5:07pm

|

I see what looks like a "CA like" auxiliary clutch. Does it work? The pin that is really nasty, is the battery placed above that one? Surprised you were able to get the 3/8 grub screws out, however I don't know where they are located. I could see using my needle scaler, that rust is flakey. I have welder and oxy-acy torch. No experience with the map gas. I assume you found good shoes,pins and items 14? keep us posted. |

Posted By: Ed (Ont)

Date Posted: 25 Jun 2022 at 9:42pm

| You are probably going to need oxygen acetylene torch for that job. |

Posted By: INV3RSE

Date Posted: 26 Jun 2022 at 3:42am

|

Yes it’s a hand clutch, it next to the operators seat on the left side. The grub screws came out quite easily, they were right inside the casing tho so went trust at all, they came out silver looking like new! Not the battery, the battery is just behind the block under the left side of the hood. Yeah I have new shoes and pins ready to go in so being destructive is a option, I’m just worried if I cut them they will still be stuck just in shorter sections 😂 |

Posted By: steve(ill)

Date Posted: 26 Jun 2022 at 9:23am

|

If you cut out the center section, you have to be able to get to the BACKS SIDE to get the piece in the blind hole.... as said before, sometimes you can DRILL a hole from the back to get access, if the hole was not thru.......... On the B/C tractors, the hole was sometimes BLIND.. sometimes you could see where the drill point started to come thru.. I have drilled out several so i could IMPACT HAMMER from the backside. ------------- Like them all, but love the "B"s. |

Posted By: corbinstein

Date Posted: 27 Jun 2022 at 7:26am

|

What I would do, is clean that thing up in the center as best I could, weld a puller on the outside, heat up the area around the pin, seal up the inspection hole, and dump in some penetrating oil. let it sit for a day and start banging on the puller. Go back with a stainless pin.

|

Posted By: WF owner

Date Posted: 27 Jun 2022 at 7:35am

|

Stainless pins would be nice, if they are available, but the originals have lasted over 50 years. Chances are good they will never be pulled again. I always put a little anti-seize (the messiest thing available) on the new pins, just in case I have to take them apart again.

|

Posted By: corbinstein

Date Posted: 29 Jun 2022 at 6:32am

| made my own stainless pins on the lathe. |

Posted By: INV3RSE

Date Posted: 29 Jun 2022 at 4:54pm

|

I will certainly coat the new pins in anti seize! Judging by the state of the one’s coming out I doubt the new ones will need to come out for 50 - 60 years! |

Posted By: BrianC

Date Posted: 29 Jun 2022 at 7:20pm

|

I was wondering if you got a torch and tried the heat. If you have the replacement pins I would like to know the diameter and length. What is the existing thread size of the internal hole? |

Posted By: INV3RSE

Date Posted: 03 Jul 2022 at 1:30pm

|

Im back! Sorry guys been out with covid for a few days! Feel much better now. I my mapp torch arrived a couple days ago. I had a go with it this afternoon and it does get the pin glowing! Yes! I got the puller tight then heated it right up and tried to tighten the puller some more.. it was a bit looser the before heating so I’m presuming somethings happening! Hopefully! Il report back when Iv had a few more hot cold cycles. Yes I’ll measure the pin for you tomorrow as well Cheers |

Posted By: steve(ill)

Date Posted: 03 Jul 2022 at 3:57pm

|

When you get it HOT... SMACK it good with a hammer, even INWARD, then pull TIGHT and smake the puller... IMPACT always helps. ------------- Like them all, but love the "B"s. |

Posted By: DiyDave

Date Posted: 03 Jul 2022 at 5:16pm

Next time you get it hot, lay a bees wax candle against the pin. The wax will wick its way in. ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: INV3RSE

Date Posted: 06 Jul 2022 at 1:04pm

|

Update! I have 1 pin about 20mm out! Is doesn’t seem like much but this is a huge achievement for the amount of effort I’m putting in 😂. I got carried away and sheered off the threaded bar inside the pin but am ready with a nut and welder. I will hopefully be able to stick a weld through the nut on the the end of the sheered bar and wind it out. Then will repeat what I was doing before it sheered but with a little less muscle! Now the pins moving I’m confident it will come free! Anyway pin 1 of 2 is slowly being defeated. 🍻 🍻 |

Posted By: steve(ill)

Date Posted: 06 Jul 2022 at 4:12pm

|

instead of welding a nut on the end... you could stick a STUD in the hole and welded it... then you have a threaded rod to pull on with your puller and NUT.......... clean up the pin thru the BRAKE ACCESS HOLE . so there will be less resistance as that pulls into the outer PIN HOLE. ------------- Like them all, but love the "B"s. |

Posted By: BrianC

Date Posted: 06 Jul 2022 at 5:13pm

|

Sorry about your covid, I know three people who died from it. So it traveled out 20mm? I would say the end should be nearly out of the blind hole. So I think cutting out a section(s) of pin and pushing remainder through would work. Watch Youtube video: https://www.youtube.com/watch?v=nKLTViXeNvw" rel="nofollow - https://www.youtube.com/watch?v=nKLTViXeNvw About removing the pin from a WD45. He ended up cutting the pin in stages and driving it back in, so it dropped out that view port hole. Welding on a nut did not work. If the end piece didn't want to just drop out easy , then weld a length of All-thread to it and a nut&washer could pull it through. Leave enough length to allow this. So how to cut? Can a reciprocating saw (Saws-All) fit through that hole? In that video he used cutting torch. It's moving! You will get it. There is a UK base Facebook page about the ED40. I have been to Bristol, but not to far southwest of there. Countryside looks about the same? |

Posted By: Sanchez

Date Posted: 06 Jul 2022 at 11:12pm

| While removing brake pins on my WD45 I found that the brake shoes will bind on the pin as the pins move outward. What worked best for me was once I had the pin out a bit a big pair of vice grips on the pin and rotate it back and fourth while prying out seemed to release the binding of the shoes. One other member said they had welded a piece of 1” flat bar stock to the pin and used it as wrench to rotate the pin back and fourth and work it out. It seemed like a good idea. |

Posted By: SteveM C/IL

Date Posted: 07 Jul 2022 at 6:28am

| My experience with these pins has been that the trouble spot is on the outer end. Have not had a pin stuck in the inner hole. It's always the outer end. |

Posted By: INV3RSE

Date Posted: 07 Jul 2022 at 7:08am

|

Woooooo! After getting the threaded rod stuck in the pin.. and trying to weld a nut on ( unsuccessfully). i focused my attention on the other side to have a brake from welding. And… success! It came out with heat force and a SDS drill on hammer mode! Check out the pin 📍  Back to the other side again now I guess! Wish me luck with pin 2 😂 |

Posted By: BrianC

Date Posted: 07 Jul 2022 at 7:37am

|

Wow that is a lot different from a WD45 pin. Also doesn't look like illustration in the acgo parts book. The left side of the pin is in the blind end? I would say there is twice the engagement at that end vs. a WD45. The brake shoes must be touching (bearing on) the two inner full size diameters areas?

|

Posted By: INV3RSE

Date Posted: 07 Jul 2022 at 8:52am

|

Pin 2 is is about 1/4 of the way out. It’s out the blind hole but is binding on the shoes despite feeling loose! That’s enough tractor for one day, hopefully get it out tomorrow. Iv attached a picture of my replacement pin, it’s second hand but not as worn as mine. Just to give you a idea what it’s supposed to look like 😊 |

Posted By: INV3RSE

Date Posted: 07 Jul 2022 at 8:56am

|

Posted By: steve(ill)

Date Posted: 07 Jul 2022 at 9:08am

|

Reuben... do you guys use Anti Sieze or something similar on these parts ? Good wire brushing and liberal coat of ANTI and you should be good for another 60 years ! ------------- Like them all, but love the "B"s. |

Posted By: INV3RSE

Date Posted: 07 Jul 2022 at 9:28am

|

Cheers Steve, I certainly will be. Probably be my son who takes it apart next time! The tractor was my dads, he had it for as long as I can remember and before. It’s never seen a oil change and almost rusted to nothing. I spent some time changing fluids replacing blown hyd hoses it preparation to sell. But… Iv become hooked, managed to find all the replacement parts secondhand ( what a mission, I had no idea the parts were so rare ) Allis is putting up a fight every time I try and work on her but I know itl be worth it! Once I get this last pin rest of the way out the replacement shoes will be sent off for reline. In theory after that all that’s left is sand and spray panels, add a engine stop pull knob and she’ll be show ready! Oh and I need to make up a battery tray. All seems easy compared to these pins 😂 😆 😂 Thanks for the comments everyone, you ideas have all been helpful for me! 🙏 |

Posted By: Gatz in NE

Date Posted: 07 Jul 2022 at 11:05am

|

take a look at these...... http://www.mcmaster.com/pull-pins/head-type~tapped/" rel="nofollow - http://www.mcmaster.com/pull-pins/head-type~tapped/

|

Posted By: INV3RSE

Date Posted: 07 Jul 2022 at 11:50am

| Thanks Gatz |

Posted By: Gatz in NE

Date Posted: 07 Jul 2022 at 1:16pm

| On closer look, 4” might not be sufficient length |

Posted By: BrianC

Date Posted: 07 Jul 2022 at 3:41pm

|

The pin that he got out, is anyone doubting that it is original design pin?

|

Posted By: INV3RSE

Date Posted: 08 Jul 2022 at 5:39am

| I think it probably is |

Posted By: Sugarmaker

Date Posted: 08 Jul 2022 at 7:26am

|

INV3RSE, I have been down this road too. Had to cut chunks out of center with a torch, let them fall out the bottom and then drive the pin inward and cut off another chunk. Not for the weak of heart for sure. If you can do this job there is no reason you need to send the shoes for relining. You can do those standing on your head. Assuming you can get the pads and rivets for a supplier like Sandy Lake or others on this forum. That tractor is testing you. But now you have the passion. Great projects to take our minds off the real world stuff. Family tractor too! We need some additional pictures! Regards, Chris

------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: INV3RSE

Date Posted: 08 Jul 2022 at 9:51am

|

Cheers everyone. I’ve spent all afternoon under the tractor again…. And Success! Final pin is removed! It doesn’t look bad as the other one but it put up more of a fight!

|

Posted By: INV3RSE

Date Posted: 08 Jul 2022 at 10:01am

Here’s some picture of the tractor

|

Posted By: BrianC

Date Posted: 08 Jul 2022 at 6:08pm

|

That one pin is a work of art. Who would have know a simple pin could change into a hydraulic spool. Has anyone ever seen a WD/45 pin looking like that? I am still trying to figure out how it got like that. Rust and wear. I can see the rust in earlier pic, looks like an antique ships anchor on display at the harbor. I cut up some rotted pallets, they had nails rusted in interesting shapes. Seen fertilizer spreaders in bad shape. Don't want to be a pest, but I wish I could see your replacement shoes nested together with that rusted pin placed. That would be my "huh, look at that" moment.

|

Posted By: Play Farmer

Date Posted: 09 Jul 2022 at 6:43am

|

^^^ I was thinking the same thing! That one pin had an interesting life. |

steve(ill) wrote:

steve(ill) wrote: