Rod bearing question

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=186743

Printed Date: 23 Oct 2025 at 3:31pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Rod bearing question

Posted By: Hunt4Allis

Subject: Rod bearing question

Date Posted: 28 Feb 2022 at 6:15pm

|

I'm wondering why no manufacturer has come out with a replacement rod/rod bearing for older worn crankshafts ( spun bearing or just worn smaller crankshaft) so you wouldn't have to split a tractor to replace crankshaft when worn out? All I read about are once crankshaft/ bearing surfaces are worn then splitting tractor is only option to get tolerance back in check. I realize it would mean a lot more manufacturing but I would pay a premium to not have to split a tractor to replace crankshaft and many others I'm sure. You would think if one could mic there crankshaft diameter s that then all you would need to do is match as closely as possible with bearings and no need to split machine replace crankshaft! I know this would not be a perfect fix but could give option to costly split. I realize why you do it the standard way but in our fast pace world I can't believe no manufacturer has done something like this? |

Replies:

Posted By: DrAllis

Date Posted: 28 Feb 2022 at 6:55pm

| So what kind of bearing would you want made for a crankshaft journal that is worn egg-shaped/oval shaped (not round) ?? or even tapered...worn more on one end than the other. Crankshaft bearing tolerances must be held within a couple of thousands of an inch for successful service life. |

Posted By: Hunt4Allis

Date Posted: 28 Feb 2022 at 7:04pm

| Ok, gotcha |

Posted By: HudCo

Date Posted: 28 Feb 2022 at 7:06pm

| would never last long enought to get out of the yard ,and not to mention all of that metal ready to grind somthing easle apart |

Posted By: Hunt4Allis

Date Posted: 28 Feb 2022 at 7:07pm

| I guess my mind was on one caught early enough before it's wear pattern is terrible |

Posted By: Codger

Date Posted: 28 Feb 2022 at 7:14pm

I'll bet "Hayes" could could come up with a solution as they have with fasteners: |

Posted By: steve(ill)

Date Posted: 28 Feb 2022 at 7:18pm

|

Older motors like the B and C farm tractors had shimmed bearings.. Maybe .006 inch per side... So if you had a couple thousands wear, you could take out a shim or two to tighten them up..... Newer motors normally have no shims and they do make aftermarket bearings that are .010 , .020 oversize and you machine a worn crank so those will fit.... So if your talking .002 -3 wear i see your point... but at some point the wear is EGG SHAPED and your not doing yourself any favors by not pulling the crank. ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 28 Feb 2022 at 9:04pm

| Ok, so it may be possible to only need rod bearing if they sell undersized shims if not egg shaped. Or a knock sound could be a broken ring or something else... |

Posted By: 1963D17

Date Posted: 28 Feb 2022 at 11:06pm

| Allis offered .002 undersize bearings at one time. I installed a set in a WD45 20-25 years ago. IH still does for the 460 thru 706 gas and diesels. I sold a lot of those back in the day. |

Posted By: Hunt4Allis

Date Posted: 01 Mar 2022 at 4:41am

| Hmmm, ok so it may be worth looking into if I need or can utilize and undersized bearing on my G188D motor. She's a smoker and I bet at a minimum it needs a upper half overhaul kit, would cracking line loose on each cylinder for the injectors tell me if that cylinder is one making noise by stopping it from firing?( I'm trying to figure the theory of doing that one out!Thanks for the info |

Posted By: WF owner

Date Posted: 01 Mar 2022 at 7:10am

|

If it needs an "upper half overhaul kit" and rod bearings, why not do it right and rebuild the whole engine. I'm betting you would be a lot happier in the long run. Every time I have seen a partial engine rebuild job, it has turned out to be an eventual nightmare.

|

Posted By: Les Kerf

Date Posted: 01 Mar 2022 at 8:20am

|

As mentioned above, many older engines (not just AC) were designed to allow bearing adjustment using shims; about 20 years ago I did an in-frame freshen-up on a neighbor's Model M Farmall using 0.002" undersize rod bearings. It still runs fine. I freshened up my 1941 John Deere Model A about 30 years ago; it has the poured babbitt rod bearings with shim adjustment. I forget how many shims I removed, but it wasn't over 0.003" or 0.004". I'm pretty sure my grandson will still be running it after I am long gone. Some years ago an old retired mechanic friend was cleaning out his shop as he was downsizing; he showed me some tapered shims for putting underneath rod bearing shells. He said he hadn't done that in many years though. I wish that I had asked him for them just as memorabilia. I have seen rods that someone filed the caps by hand to tighten up bearing clearances. The engines ran successfully for many years, but I still do not recommend it. |

Posted By: Hunt4Allis

Date Posted: 01 Mar 2022 at 9:00am

| Everything I've researched says if rod bearing are bad the noise gets louder with rpm( mine doesn't get louder so I'm tempted to do a oil/ filter change, add some Lucas high milage oil stabilizer and see if it quiets down) |

Posted By: DrAllis

Date Posted: 01 Mar 2022 at 9:03am

| What is a G188-D engine ?? |

Posted By: Hunt4Allis

Date Posted: 01 Mar 2022 at 9:33am

| 50 hp-4 cylinder diesel |

Posted By: IBWD MIke

Date Posted: 01 Mar 2022 at 9:36am

|

Posted By: steve(ill)

Date Posted: 01 Mar 2022 at 9:37am

|

We have a CASE 530 backhoe with a 159 gas.......... but i think the G188 was the diesel option.

------------- Like them all, but love the "B"s. |

Posted By: DrAllis

Date Posted: 01 Mar 2022 at 9:47am

| Well then, a diesel engine that you want to try and patch up a rod bearing ?? That is a BAD idea. Deezel engines have twice the compression as any gas engine and have more pound to them when they fire. You've got a knock you say ?? Does the exhaust emit any white puffing smoke ?? A really bad (beyond fixing) rod bearing will lower the compression on ONE cylinder and can make it knock and partially miss-fire. The piston could also be hitting the cylinder head if bad enough. I saw a D-19 turbo-deezel that bad once and it only took a new crankshaft and connecting rod to fix it. |

Posted By: Hunt4Allis

Date Posted: 01 Mar 2022 at 10:40am

| I'm not trying to patch anything I'm looking at what options are available if possible depending on what it looks like when I take it apart. It's how I normally approach things that I don't know is to obtain some information first and this place is normally a great resource. |

Posted By: steve(ill)

Date Posted: 01 Mar 2022 at 12:47pm

|

Hunt, i think the moral to the story is that a knock , can be a rod bearing, can be a wrist pin, can be a cracked piston... or who knows... You really cant tell until you do a Complete inspection......... If you doing it in frame, and pulling the head and piston / rods out ... you can leave the crank in the tractor "until" you determine the extent of damage and if the crank journals are round or not..... at this point, you just dont know.. ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 01 Mar 2022 at 12:56pm

|

Right, I've also heard it could be a injector not firing/ or properly and causing an off sound( this is my only old diesel so it could be something else also I guess being I'm not used to hearing what one sounds like...) It does smoke white a bit but not terrible seing how it's a 1972 that probably at a minimum needs new piston rings/ sleeves if never been done! |

Posted By: DrAllis

Date Posted: 01 Mar 2022 at 1:01pm

| You haven't answered the question about the exhaust puffing any smoke, white or black. Your engine is not a direct injection engine. It is the old LaNova system like Buda and Oliver used. They do not "knock" from cylinder firing. They are smooooth. So, if you have a knock, I'd bet it was mechanical. |

Posted By: orangereborn

Date Posted: 01 Mar 2022 at 3:43pm

|

There was such a device/tool...Removed the starter and put an electric motor in it's place. Little hand held belt sander and follow the journal. Generally they came right to your location and did the job...At the curb of your home...Where-ever there was electricity...Middle 1960's he got a little generator. I think it was a Honda...He did tractors/all types vehicles...And yes, some of them were orange...Some were a complete success and some maybe made it to the resale lot...But that's the way it was then... In the mid 1960's I was on my way to Mason City IA to get a load of AC parts and whatever and was to tow a combine (72?)back to SE MN. Just at the MN/IA border the 1951 IHC truck started to knock. I pulled into a little park on the north edge of Chester IA and dropped the oil pan and found a bad rod bearing...Walked into Chester and called the shop...(from the post office I think)...Decided that the engine shop would come out repair it. Did not have to take it into town as he now had a generator...He came 70 miles did the grind, Right there in the park...I put it back together, and finished the trip...Worked Good...In the winter slow months I rebuilt the motor...I recall Lyle Joy the Allis "block man" was at the dealership at the time and stopped by as he was also heading to Mason City...I go thru there often and think of the event...Dale

|

Posted By: Hunt4Allis

Date Posted: 02 Mar 2022 at 4:59am

| Wow, thanks for the story! Gives hope to enginuity😜 |

Posted By: Codger

Date Posted: 02 Mar 2022 at 5:30am

| Yup. One such apparatus was marketed by "Storm Engineering", (later Storm-Vulcan). I've not seen one in years but a guy with some time could make effective repairs to get a job done. Don't think I'd ever seen one used but have seen the kit and read the literature in the case briefly as was intrigued by the process. |

Posted By: Hunt4Allis

Date Posted: 02 Mar 2022 at 6:29pm

| Ok sooooo, pulled drain plug today and green anti- freeze( probably about a quart) came out first then oil so I'm guessing I've got a blown head gasket to start with... Probably the cause of my white smoke. One positive about the short time I was able to spend after work before dark was one of my worries was breaking free my lug nuts on all 4 rims, which had me worried a bit since these tires look original and probably never been off but thankfully looks like some never seize was on threads! It will be a long process but it was at the right price and I'm not in any hurry to get projects done I have planned so I'll need some more time to explore and fix her up! |

Posted By: DrAllis

Date Posted: 02 Mar 2022 at 6:36pm

| No familiar with that little 4 banger, but all the larger Case engines were wet sleeves. |

Posted By: steve(ill)

Date Posted: 02 Mar 2022 at 7:32pm

|

------------- Like them all, but love the "B"s. |

Posted By: DrAllis

Date Posted: 02 Mar 2022 at 7:36pm

| Bingo!! So proper diagnosis would be pull the oil pan and pressurize the cooling system and determine EXACTLY where the coolant is coming from. |

Posted By: steve(ill)

Date Posted: 02 Mar 2022 at 7:40pm

|

YEP... just like ALLIS... could be liner o-rings , could be freeze plug, could be gasket. ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 02 Mar 2022 at 7:51pm

Yup it's a wet sleeve according to the shop manual I have for it... |

Posted By: steve(ill)

Date Posted: 02 Mar 2022 at 7:54pm

|

Hunt... with the valve cover and oil pan off.... fill the radiator with water and look to see where it is coming out... ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 02 Mar 2022 at 8:00pm

Ok thanks fellas |

Posted By: Hunt4Allis

Date Posted: 03 Mar 2022 at 6:05pm

I'm not quite envisioning how removing a shim could tighten anything up? I'm not trying to start any arguments or be difficult I'm just not experienced but trying to learn anything that anyone can tell me that is helpful so if you can add anything to what you're saying to help me understand I'd appreciate it? |

Posted By: Hunt4Allis

Date Posted: 03 Mar 2022 at 6:09pm

I haven't run this much but it kind of perplexed me seeing a bunch of separated antifreeze come out when I pulled the drain plug like it was or had freshly emptied into the oil so I am not sure what I will be able to see as far as where it's leaking from with the head still on the block and as far as adding water it's actually completely full in the radiator of antifreeze now (I refilled it because when I bought it they said it had a small pinhole leak in the radiator so that's where I figured the antifreeze was going but I guess it could be partially true but it's definitely going into the oil one way or another? Thanks Matt |

Posted By: steve(ill)

Date Posted: 03 Mar 2022 at 6:10pm

|

Hunt, the OLDER engines did not have the bearing caps bolt up FLUSH against the rod ( or the block on the mains).... There were several thin SHIMS in a PACK that set between the rod and the cap with the bolt running thru them... Normally this was .006 inch... After the crank wore down 3-4 thousands ( including the bearing wear) , you could take out some of the shims to get back to proper clearance.. When you took out all the shims, the cap was setting FLUSH on the ROD and the bearing would actually be .006 smaller in the vertical direction.

------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 03 Mar 2022 at 6:14pm

OK... taking the pan off allows you to see if there is antifreeze dripping around the liners ( o-rings worn out)... taking the valve cover off allows you to see if there are holes rusted thru any freeze plugs on top of the head... The radiator will go down a couple inches if the freeze plugs leak... will be half empty if the liner o-rings leak.. If it only leaks when RUNNING, then probably a very small crack in the head gasket , or head itself.

------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 03 Mar 2022 at 7:35pm

|

Steve, thanks much makes sense to me. If radiator is already full will I be able to see antifreeze leaking out somewhere with head on? ( Once I get this far in I will pull head off and keep checking deeper until I feel I'm at the cause of sound motor is making and how antifreeze is getting into my oil) thanks Matt |

Posted By: steve(ill)

Date Posted: 03 Mar 2022 at 7:41pm

|

depends on where the leak is compared to level of the radiator... sometimes you can take a hand pump and put 10 psi on the radiator cap and "LISTEN- LOOK" to see if there are any leaks on top of the head or under the cylinder liners....... If nothing, then head or head gasket crack is a good bet. ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 03 Mar 2022 at 9:02pm

| Ok, need a 10 psi hand pump for radiator cap, thanks |

Posted By: steve(ill)

Date Posted: 03 Mar 2022 at 9:21pm

|

you can rent one at Auto Store, or you can take a Weed Sprayer, take off the nozzle and connect the wand tube to a modified cap, heater hose fitting, block drain ... etc. ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 04 Mar 2022 at 6:21am

|

Ok thanks for info I wonder if this motor has shims like you talk about( I will find out once taken apart but would that be shown in my repair manual I bought for it?) It very detailed around 1500 pages... I bought the best one that I could find b/c I knew buying this one needed some TLC! It's a 1972 case diesel 4 cylinder 188cu engine if anyone knows anything I'd appreciate any info you can share as these motors were pretty commonly used for many different machines case put out |

Posted By: steve(ill)

Date Posted: 04 Mar 2022 at 7:56am

|

Most of the engines with SHIMS were gasoline and from the 1930 -50 era .... Pretty sure the G188 Diesel from 1972 did not have shims. .......... i think most of the discussion above about shims , started when you brought up oversize bearings....not really a concern with the G188. ------------- Like them all, but love the "B"s. |

Posted By: injpumpEd

Date Posted: 04 Mar 2022 at 8:07am

|

All shimmed engines like mentioned above are like Steve said, low rpm low compression gas engines. I cannot think of a diesel engine that would be like that. Way too much loading on the rods/bearings to have that non precise fit lol! Shimmed ones were also poured babbit too in some cases, which is where the need arose to start with. The introduction of replaceable bearing shells kind of made that setup obsolete. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: Hunt4Allis

Date Posted: 04 Mar 2022 at 8:13am

|

Ok, good to know Thanks |

Posted By: Hunt4Allis

Date Posted: 04 Mar 2022 at 8:09pm

| I'm reading about fuel injector being stuck open can cause a engine knock sound. It sounds like to me that if I crack each one of the four injector lines and I get to one that when I crack it the knock goes away or drastically lessens then it could be a faulty injector, does this sound correct in procedure to troubleshoot? I would think if it was a rod bearing or any other kind of bearing or something mechanical that if I crack the injector line a slight bit individually and the noise never goes away then it's probably not the injectors correct? |

Posted By: steve(ill)

Date Posted: 04 Mar 2022 at 8:47pm

|

another way to look at it is, if you open the fuel line and nor injection, then no explosion and no great downward force on the piston..... i would think that would change the "noise" if it is internal ..(bearing). ???

now if you tested the injectors... then switched them to different cylinders and the LOSS of noise followed the injector, that might prove something... dont know if it works or not.

------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 04 Mar 2022 at 10:27pm

| I would think even just because of the other three cylinders still rotating that you would still get noise if it's a worn rod bearing. I think the only thing that it will tell you is that if your injector is let's say still working but not correctly as in if it's plugged slightly or badly and you crack the line to it and the knocking noise stops then from what I've read and other places it means the injector is needing either cleaned or replaced, I may try this over the weekend. The only thing that has me concerned is that it's being fed from a high pressure pump so when I crack it will it spray 2,000 PSI diesel all over the place? |

Posted By: Hunt4Allis

Date Posted: 05 Mar 2022 at 6:17am

| Most conversations I hear talking about injectors are people troubleshooting them to see if they are working or not by cracking the line that feeds them. not cracking the line to check to see if it's mechanical knocking. I guess if I do it and find one that stops the noise I know I've got a faulty injector. I don't like how close this will be to the exhaust manifold in relation to fuel possibly spraying out near that that is very hot? Some places say to put a rag around it to limit spray? |

Posted By: Ray54

Date Posted: 05 Mar 2022 at 1:22pm

|

My guess is Steve is correct that with a whole that is not firing the bearing will not get pushed as hard and would sound different. But if you can hear this with all the other sounds I have no idea. One of the times a stethoscope might be handy. You don't have to have the line clear off. Just lose will relieve pressure so injector will not pop open. But always better safe than sorry, so a rag to stop spray would be good.

Experience would be good. Experience would be good.  Until to much experience is bad in that your hearing is not so good. Until to much experience is bad in that your hearing is not so good. Combine per season fix it week, go to town for parts and get lunch. Leave a flat tire from pickup to be fixed, do the other things in town. They put fixed tire on head home. Going down main street in town 30 mph me in the middle of dad and uncle windows down. I hear air hissing dad says cannot be, nobody could hear that. Uncle says stop. The newly repaired tire is hissing good. Just made it back to the tire shop. The good old days of tubes in tires. The tube was pinched in the bead. But that was over 50 years ago, my ears are no longer near that good today.   Dam noisy tractors, an I was using cotton in my ears before I got out of high school running the HD 5 with DD 2 cycle. Then discovered the real foam ear plugs in my 20's. Dang I hate sitting next noisy cars, trucks, and motor bikes at stop lights. Just thankful I hear as much as I do. Dam noisy tractors, an I was using cotton in my ears before I got out of high school running the HD 5 with DD 2 cycle. Then discovered the real foam ear plugs in my 20's. Dang I hate sitting next noisy cars, trucks, and motor bikes at stop lights. Just thankful I hear as much as I do. |

Posted By: CTuckerNWIL

Date Posted: 05 Mar 2022 at 2:38pm

If you have an air compressor, you don't need any kind of other pump. What you need is a regulator to put on your air hose and set it to 7 to 10 PSI. Then you put regulated air pressure to the top of the radiator. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Hunt4Allis

Date Posted: 05 Mar 2022 at 6:45pm

| Okay I bet I can even get one that's already attached to a radiator cap right? |

Posted By: Hunt4Allis

Date Posted: 06 Mar 2022 at 7:39am

| Well I did some searching and cannot find a radiator cap that has a fitting in the top for pressurizing the system with an air compressor? |

Posted By: plummerscarin

Date Posted: 06 Mar 2022 at 8:34am

| Is there a pipe plug on the block or head somewhere. That is how I tested a 170 once. Replace plug with an air fitting |

Posted By: steve(ill)

Date Posted: 06 Mar 2022 at 8:41am

|

look for a heater hose plug, or put a TEE in the heater hose, or a block drain valve or drain plug as plummer said.

or take an old cap and drill a hole thru it for 1/4 inch pipe fitting.

------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 06 Mar 2022 at 11:46am

| If the radiator has a pinhole in it going to the block would be a better place also correct? I don't know how that works if I pressurize the block at the drain plug will it pull the antifreeze out of the radiator and still show me the leak? Not sure how these are connected technically? |

Posted By: steve(ill)

Date Posted: 06 Mar 2022 at 12:26pm

|

everything on the cooling system ( antifreeze) is connected.. You can put pressure on the radiator, block , head fitting, drain, heater hose, radiator hose... anything... and it will pressurize everything.. With pressure on the block drain, you will get leakage at the pin hole on the radiator. ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 06 Mar 2022 at 2:13pm

| Ok thanks |

Posted By: Hunt4Allis

Date Posted: 06 Mar 2022 at 2:59pm

| I guess with the sound that I'm hearing that if I can't confirm that it's a injector fault that's causing it that putting compressed air into it to find where it's leaking is probably in my mind I keep thinking is it worth doing that because I'll probably need to take the head off to replace the parts that are damaged or worn anyways correct? |

Posted By: steve(ill)

Date Posted: 06 Mar 2022 at 4:31pm

|

getting as much info before hand is a good idea.. What if you take the head off and see nothing.. Then take the oil pan off and see one rod bearing is damaged.. You replace the bearing and the head gasket and your done ?................. what if the o-rings on the cylinder liner were damaged and that was causing the antifreeze leak into the oil pan, and that caused BAD lube to the crank bearing ?? ............ more info is always better... unless you are pulling the crank and all liners and doing a COMPLETE inspection. ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 06 Mar 2022 at 5:54pm

| Ok, I think before I pull anything apart I'll see if cracking lines on each injector tells me anything, if not then I'll drain oil pull oil pan and valve cover and see what I can( any tips on pulling head if I get that far into it? |

Posted By: Hunt4Allis

Date Posted: 07 Mar 2022 at 12:23pm

| I know my regular set of mic calipers should fit up inside to measure the crankshaft for the rod end but how can I measure what bearing thickness I need with crankshaft still in motor? ( I'm asking b/c the motor overhaul sets have standard,. 010,. 020,. 030 bearings I will need to specify before ordering) will my book call out how much Freeplay there should be between bearing and crank and bearing to rod or is there a industry standard for this? Once I can get time to start I'd like to have some idea of what measurements should be... Thanks Matt |

Posted By: steve(ill)

Date Posted: 07 Mar 2022 at 12:44pm

|

You can NOT use oversize bearings unless you you turn the crank journals UNDERSIZE.. You are not going to have .020 clearance between the rod and crank on a running motor. You would not be able to maintain oil pressure... If the motor has been overhauled BEFORE, then the back side of the bearings should have a stamping on it for size. You can not order bearings until you measure the crank and see if it is GOOD and IN SPEC. Proper bearing clearance to the crank is normally .001 inch per diameter of crank journal... If your crank is 2.5 inch diameter, then the clearance would be "about" .0025 inch.

------------- Like them all, but love the "B"s. |

Posted By: Codger

Date Posted: 07 Mar 2022 at 12:49pm

| One of the first things a machine shop does is measure up the existing parts to ensure ordering the correct bearings, pistons, rings, etc. |

Posted By: WF owner

Date Posted: 07 Mar 2022 at 4:02pm

| If you aren't going to remove the crankshaft, the only thing you can do is replace the existing bearings with the exact size that are in there now. The best practice would be to remove the crankshaft, have it miked, and, if the crankshaft is out of spec, have it turned. |

Posted By: Hunt4Allis

Date Posted: 07 Mar 2022 at 5:10pm

| Ok, great info! Thanks fellas |

Posted By: Hunt4Allis

Date Posted: 09 Mar 2022 at 6:10am

|

I'm not sure what makes the whining noise towards the front of motor( on start up it's not doing it but within a couple seconds it starts) kinda to me sounds like a noisy pump bearing but not sure how to pinpoint it? Could be oil pump or coolant pump right? |

Posted By: DrAllis

Date Posted: 09 Mar 2022 at 6:23am

| Hydraulic pump for the loader/backhoe. |

Posted By: Hunt4Allis

Date Posted: 09 Mar 2022 at 8:29am

|

I know I need a new radiator while I have this torn apart this far so that's in the plans (anyone have a recommendation for a maker of one? I found a couple on eBay that are custom TIG welded for $150 cheaper than regular old black steel one- commercial made) I'm wondering since I'm that far in I should probably see what the whining noise is is why I'm asking... I will look into the hydraulic pump. I'm obviously not a motor guy I'm just learning as I go and trying to pick up on the correct way to do things and I need to look into my manual to even see where this hydraulic pump is located. Is there any reason to look at the oil pump for the motor while I'm doing all this or the water pump? By saying this I'm assuming there's all three? Thanks Matt |

Posted By: DrAllis

Date Posted: 09 Mar 2022 at 9:14am

| A big hydraulic pump like on a machine like that often does make some noise. It also could have worn out hardware on the pumps drive shaft, which could make noise. |

Posted By: Ray54

Date Posted: 09 Mar 2022 at 11:29am

|

If you get the pan off as your worrying about rod bearing, yes look at the oil pump. Everyone needs to learn from experience. There's or others. Sounds like you could use more experience. See if you can find some equipment similar to yours and see if owner will start it so you can hear what "normal" sounds like. Hydraulics make more noise than you might think. But caution can be cheap, rather than charging ahead without thought. But if you add new parts that are not needed, that is expensive. I tend to be paranoid about my equipment after fixing things and think I hear all kinds of "new" noises. I do not recall any of those being a problem, just my worries.

|

Posted By: steve(ill)

Date Posted: 09 Mar 2022 at 12:22pm

|

Everyone needs to learn from experience. There's or others. Sounds like you could use more experience. See if you can find some equipment similar to yours and see if owner will start it Hunt ---- one GOOD OPTION for you would be to look for someone in your area that is experienced and possibly is rebuilding a motor at this time... Any brand / and motor... If you could talk to him for a couple hours, look at what he is doing, visually SEE what different parts are doing, WHERE normal wear occurs.... That might help a bunch... I would think most people would be willing to show you the ropes, if you could find someone local. ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 10 Mar 2022 at 9:19am

|

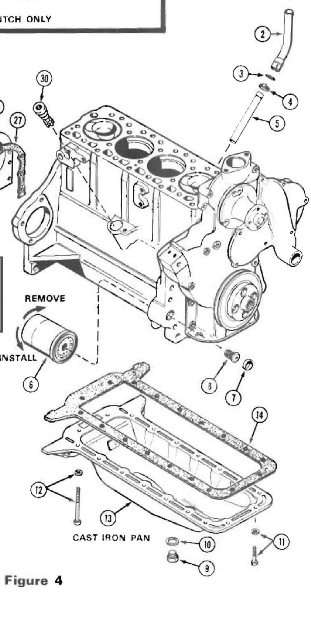

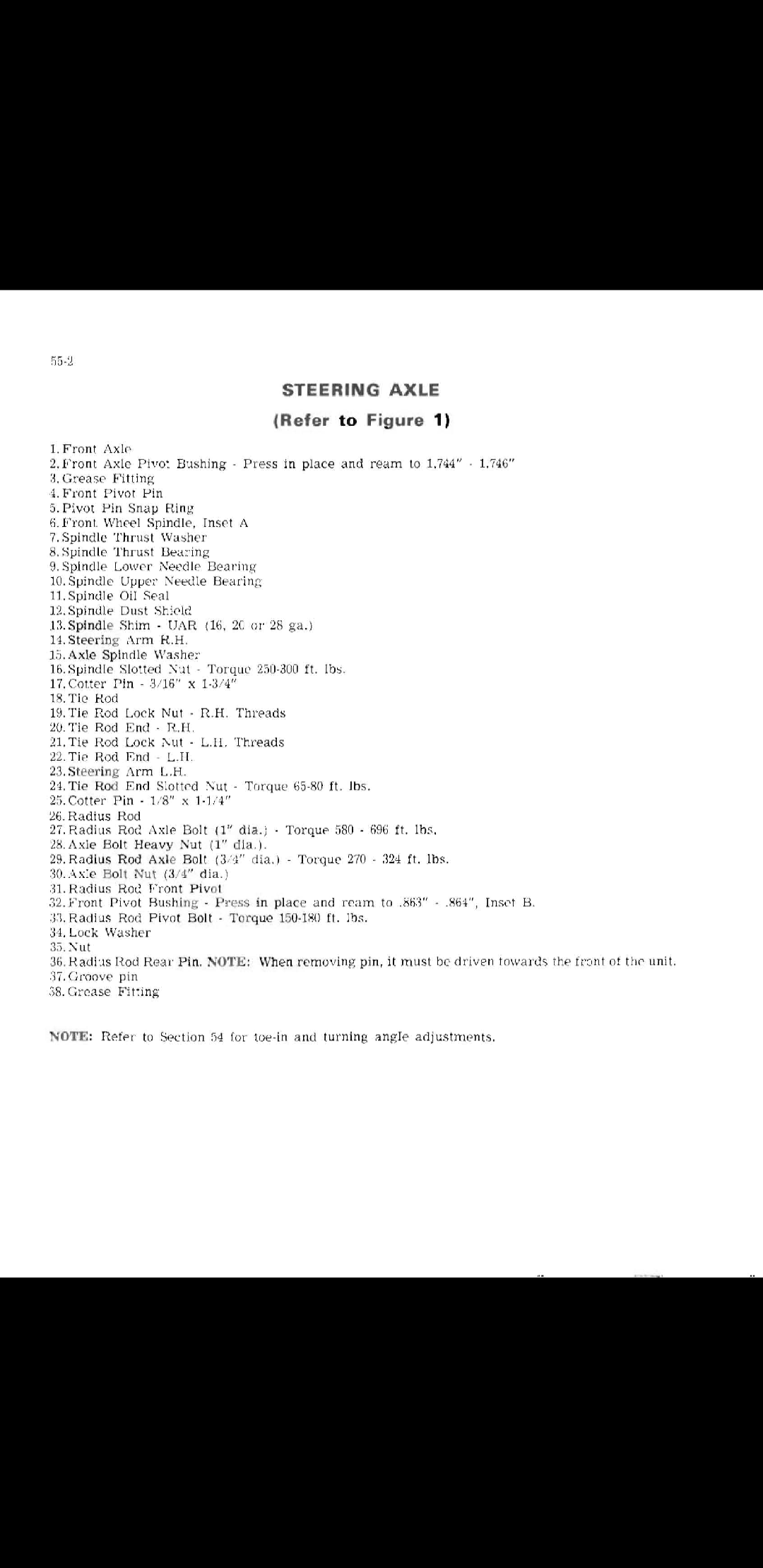

Crawled under to look at removing oil pan and it's a cast iron one that is somewhat "pinned" together (incorporated) with the front axle support as can be seen in attached screenshot of parts manual. For removal it says" remove oil pan" !?! Well I'd like to just unbolt it but it has me allittle hesitant to do so since it seams pinned together to front axle support? What are people s thought here?

|

Posted By: Hunt4Allis

Date Posted: 10 Mar 2022 at 9:38am

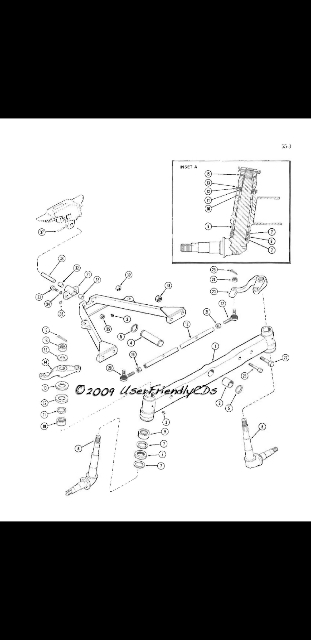

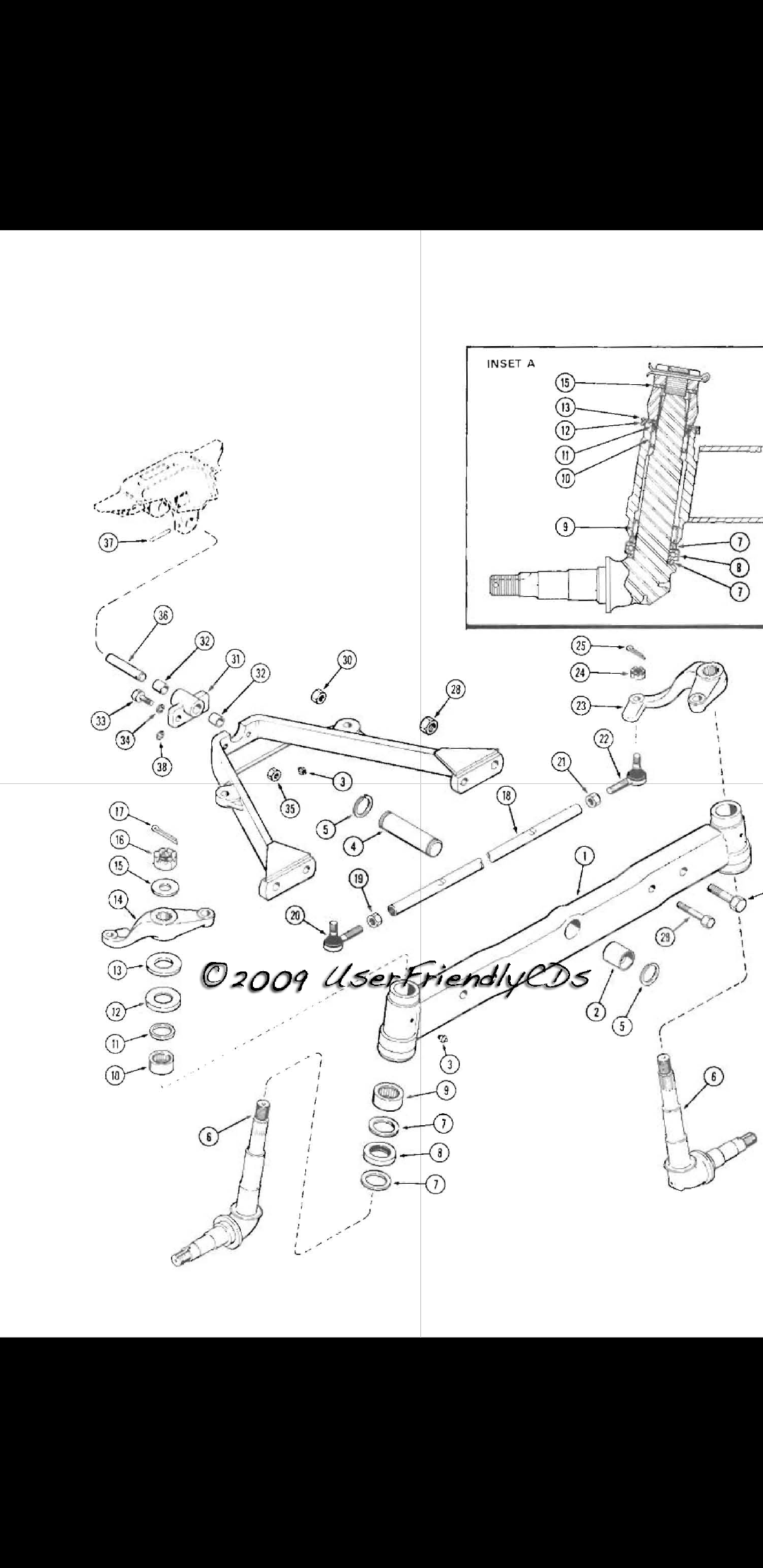

_  Here is more on how it goes together, I just want to make sure I can remove pin without steering arms falling or if I should support somehow( it's parts 36+37 that pins thru cast oil pan... Thanks Matt |

Posted By: steve(ill)

Date Posted: 10 Mar 2022 at 12:41pm

|

Hunt, its hard to see the item numbers in the photo above... I would look at the pan a little closer.. It would be very abnormal to connect anything to the oil pan.. The rear pivot pin for steering is normally connected to the bottom of the bell housing and it is very CLOSE to the pan, but should not have anything to do with the pan. I could be wrong, but very abnormal to connect steering linkage to the pan. ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 11 Mar 2022 at 9:38am

|

I will take picture of What it looks like and post it here .let me see if this is clearer

|

Posted By: Hunt4Allis

Date Posted: 12 Mar 2022 at 9:20am

|

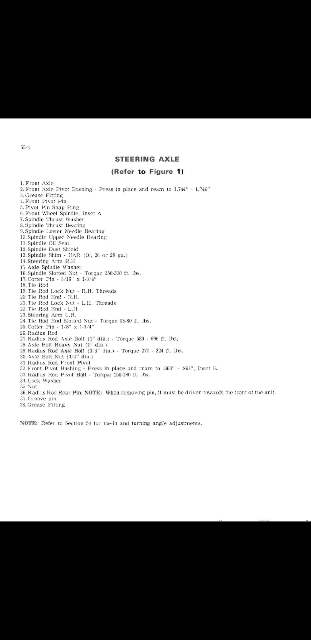

Here's a picture of under oil pan I think the whole wish bone will need removed and the round steering cross arm

|

Posted By: steve(ill)

Date Posted: 12 Mar 2022 at 12:03pm

Our backhoe has the G159 gas motor in it... When i was going to rebuild it, i blocked under the transmission and loader frame in that area... Removed the radiator / hood.... Pulled the mounting bolts and pins on the axle and front end bolster, and rolled it forward 12 inches toward the bucket........... Then i pulled the motor and lowered it to the ground and set on a piece of plywood ...... then drug the plywood out with the motor setting on it... I was working under a 7 ft awning.  ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 13 Mar 2022 at 11:14am

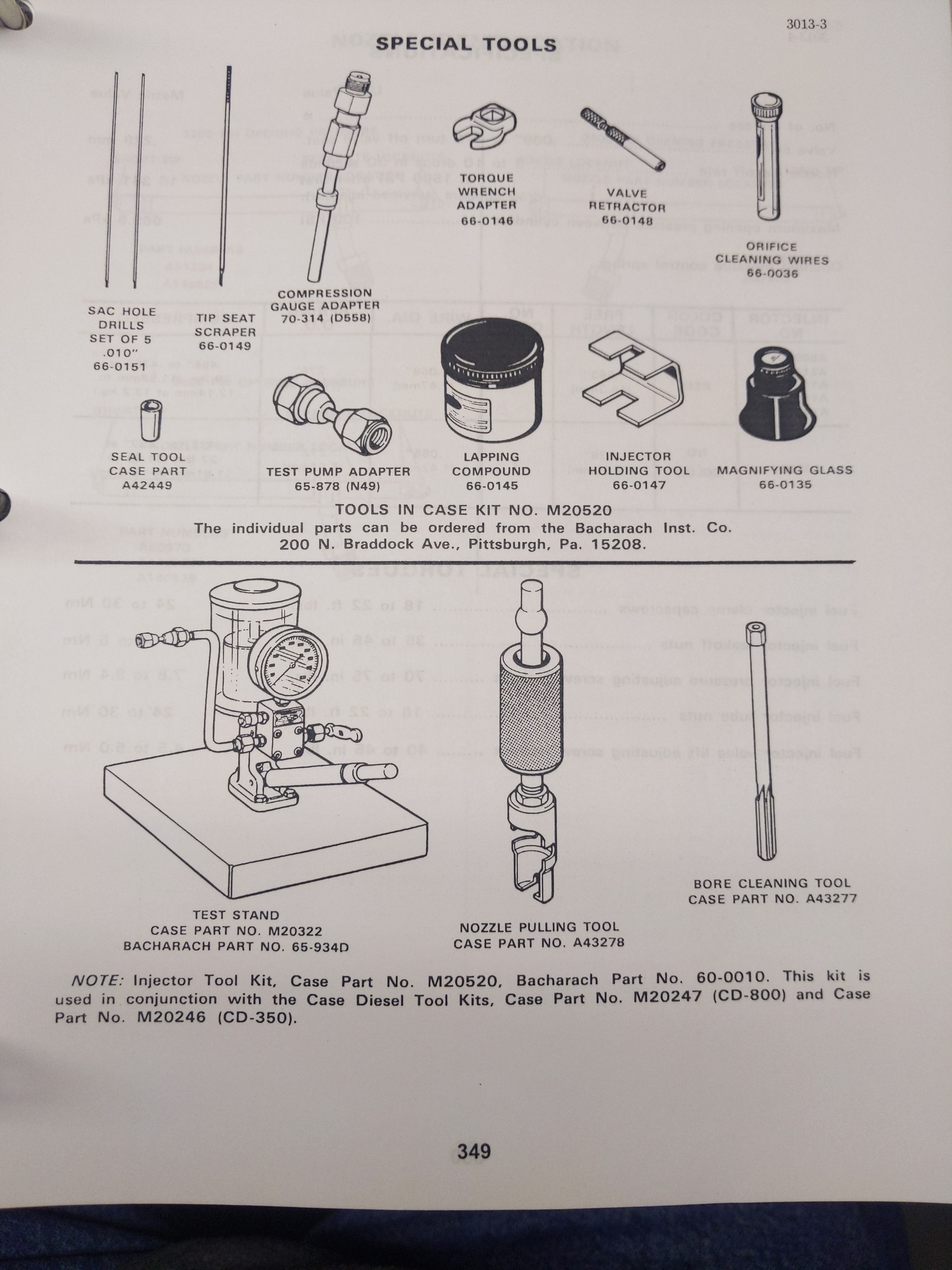

| Okay it looks like you had somewhere to rig to overhead to utilize a chain fall to lower the motor down correct? I often hear about when a new crankshaft is needed that the front bucket and rear bucket need to be removed and the tractor needs split in half which creates a ton of problems for me at least at the time because I don't have a large enough area to rig anything overhead like that. Most places around me want somewhere between $2,500 and $5,000 just to split the motor from the transmission which is not going to happen. That is only for splitting it. I plan on starting the process of taking it apart and seeing what all is going on. In my manual it says to remove the injectors which I don't understand what that has to do with taking the valve cover off? I do realize that I will have to remove them and I've started looking at what type of puller is needed to get them out. I will post on here a puller part number from my manual to see if anyone knows what can be cross referenced with it. |

Posted By: Hunt4Allis

Date Posted: 13 Mar 2022 at 11:38am

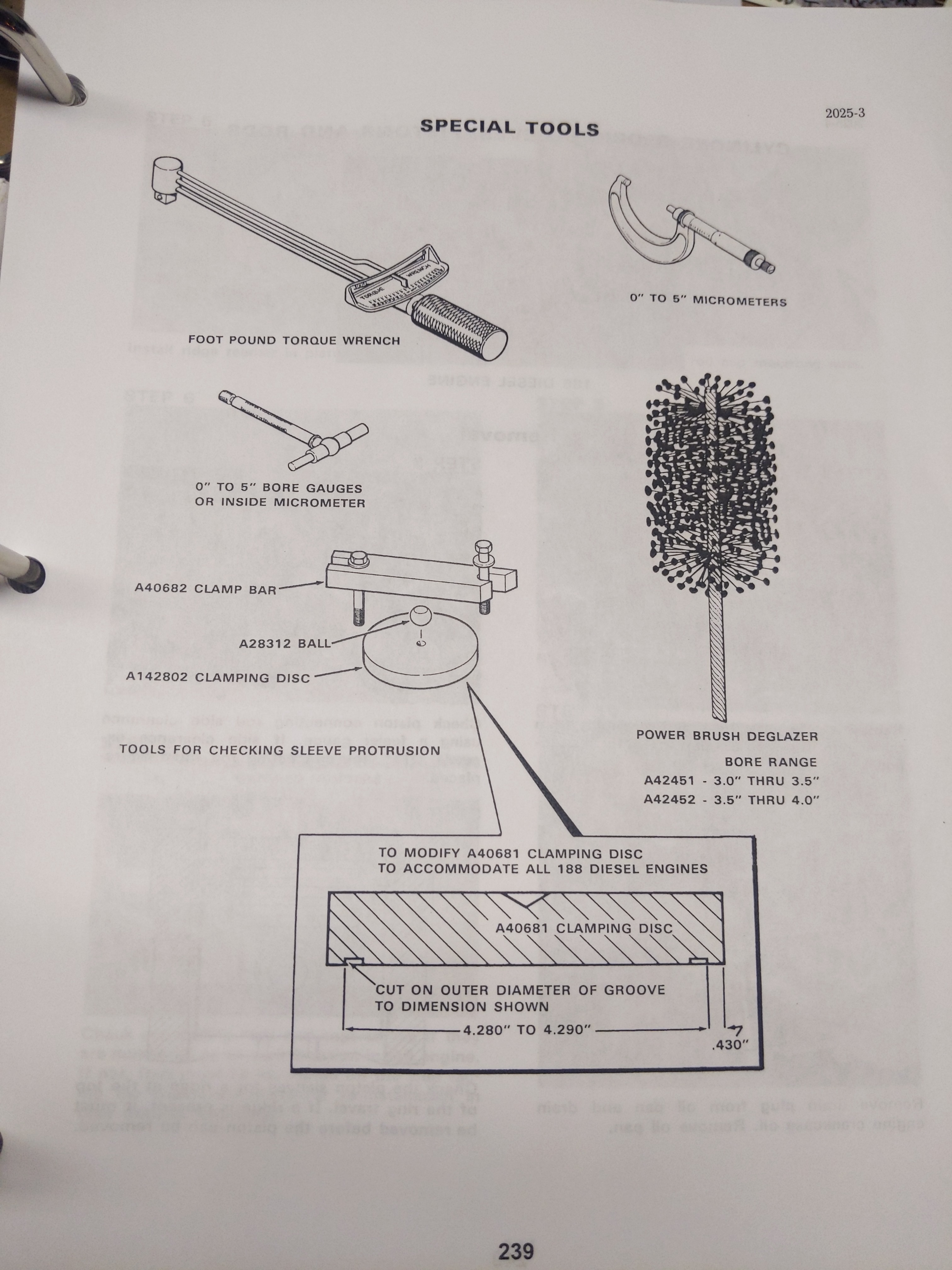

Here's the picture of the injector puller part number(it sounds like I should first try to pull them out just by hand the way it reads in the manual and then if they won't move I need to use a puller of some kind which I need to get what size I need for the manual somewhere) and also something I found interesting for putting new sleeves and has this clamping disc and a ball to reseat the new sleeves after pulling the old ones, anyone know what this is about with the clamping disc and ball? |

Posted By: steve(ill)

Date Posted: 13 Mar 2022 at 12:34pm

|

Okay it looks like you had somewhere to rig to overhead to utilize a chain fall to lower the motor down correct? I often hear about when a new crankshaft is needed that the front bucket and rear bucket need to be removed and the tractor needs split in half A small motor only weights maybe 3-400 pounds. You can normally rig that to any overhead rafter or a movable beam made out of a couple 2 x 6 s........Normally a tractor has to be split if your taking out the transmission... Many tractors can have the motor pulled out forward, after removing the radiator and dropping the front axle... as i did above... you can then get the crank out of the motor. ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 14 Mar 2022 at 4:44am

| Anyone seen a "clamping disc/ metal ball to reseat sleeve? |

Posted By: WF owner

Date Posted: 14 Mar 2022 at 6:32am

|

if it's a wet sleeve engine that is not needed. Clean the counter bore very well. Lubricate the sleeves and o rings with dish soap and water and set your sleeves. Even of you used some sort of device like their "clamping disc", as soon as you remove it, you could move the wet sleeves by hand. |

Posted By: DrAllis

Date Posted: 14 Mar 2022 at 7:42am

| Wet sleeves always need to be installed without the Orings to make sure they will fall into place easily and I like them to be able to rotate in the block. I have always used vegetable oil or Crisco smeared on the lower block bore and the sleeve Orings. |

Posted By: Hunt4Allis

Date Posted: 14 Mar 2022 at 1:23pm

I'm confused by you say wet sleeves need to be installed without the o-rings and then at the end of the sentence it says in the sleeve o-rings? |

Posted By: Tbone95

Date Posted: 14 Mar 2022 at 1:34pm

Pretty sure he means as in a "test fit" to be sure they fit easily / correctly. Then take them out, lubricate, assemble with orings.

|

Posted By: DrAllis

Date Posted: 14 Mar 2022 at 1:36pm

| No Orings to be SURE the block is clean and not warped and rotating the sleeves while in the block without Orings on them.. The sleeve standout is checked with no Orings on the sleeves for accuracy. |

Posted By: Hunt4Allis

Date Posted: 14 Mar 2022 at 1:48pm

| Okay no o-rings to check for fit, then install o-rings and press into place. |

Posted By: WF owner

Date Posted: 14 Mar 2022 at 2:14pm

|

You won't need to "press into place". As Doc says, dry fit them with no o rings, then install the O rings and seat the sleeves by hand turning them slightly as you push them in. If everything is clean, they should push in quite easily. Don't remove the nuts until you are ready to install the head gasket and head.

|

Posted By: Hunt4Allis

Date Posted: 14 Mar 2022 at 5:52pm

|

Posted By: WF owner

Date Posted: 14 Mar 2022 at 6:09pm

| The washer covers the top of the sleeve, holding it in place. |

Posted By: Hunt4Allis

Date Posted: 14 Mar 2022 at 6:47pm

| The washer holds down on the sleeve so it cannot push up and down, I get that but I believe there's a flange on the sleeve that stops it from falling through the block downward |

Posted By: WF owner

Date Posted: 14 Mar 2022 at 7:10pm

| Yes, there is a counterbore that holds the sleeve from going down. The washers are to keep the sleeves from falling out when the block is inverted to work on the bottom end or from moving the sleeves when you are turning the engine over to bolt in the rods. |

Posted By: steve(ill)

Date Posted: 14 Mar 2022 at 7:35pm

|

note the bolts/ washers holding the liners down while he measures the liner rise above the block face. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 14 Mar 2022 at 7:44pm

|

Hunt, here is a link to Marvs page about rebuilding a motor.. He has plenty of photos and step by step.. You should read the entire post and examine the photos.. Its a excellent reference. https://www.allischalmers.com/forum/201-engine-assembly_topic118485.html" rel="nofollow - https://www.allischalmers.com/forum/201-engine-assembly_topic118485.html ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 15 Mar 2022 at 6:21am

|

Ok, I see the confusion here... I will be doing a in-frame overhaul kit most likely so no flipping over although thanks for tip and links fellas ( just what I needed) I have rebuild detailed book but they don't tell you tricks like this! I will update as I go along with engine overhaul. Thanks Matt |

Posted By: DrAllis

Date Posted: 15 Mar 2022 at 7:16am

| If you install a new sleeve/Orings and do not bolt it down, when you install the new piston with new rings on it in that particular sleeve, the chances are very good when you rotate the crankshaft to install other pistons and rods the friction/drag of the new rings on that new piston in the unrestrained sleeve will push the new un-bolted down sleeve right out of the block, upside down or not. |

Posted By: Hunt4Allis

Date Posted: 17 Mar 2022 at 7:18am

|

Okay I get it I will bolt them down with washers on top Thanks for the tip fellas! Once I pull the old sleeves out is it recommended to run a honing tool to clean up the block before reinstalling new sleeves? Thanks Matt |

Posted By: steve(ill)

Date Posted: 17 Mar 2022 at 7:21am

|

no hone... power wire brush, sand paper, etc. ------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 17 Mar 2022 at 6:53pm

| Okay okay thanks |

Codger wrote:

Codger wrote: