Did I go wrong????

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=185540

Printed Date: 01 Feb 2026 at 5:48pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Did I go wrong????

Posted By: COD

Subject: Did I go wrong????

Date Posted: 04 Jan 2022 at 3:45pm

I bought this thing on a whim. It has sat for about 20 years. The tracks, rollers, sprockets, and rails all look to be in good shape. No one has tried to crank it. Before I do I wanted to get it brought home and look it over good and change fluids if deemed worthy. They said it ran and worked well when parked by an old man who passed away. I gave $850 for it. The hydraulic tank looked to be full of sludge so I was looking into possibly replacing the pump if need be. I figure it’s worth that in scrap if it doesn’t work out.

|

Replies:

Posted By: steve(ill)

Date Posted: 04 Jan 2022 at 4:26pm

|

if the pins and bushings look OK.... you got 2-3 times that much value just in the undercarriage.. ------------- Like them all, but love the "B"s. |

Posted By: Lee Bradley

Date Posted: 04 Jan 2022 at 5:02pm

| Looks like a brand new spocket on this side. Even if you part it out, you did good. |

Posted By: JohnColo

Date Posted: 04 Jan 2022 at 5:20pm

|

I think you done good! Looks like a bit of TLC and you will have a fun toy to play with. |

Posted By: Coke-in-MN

Date Posted: 05 Jan 2022 at 11:04am

|

If the tracks are good , you got your money back , rest if parted are a bonus . The 2-71 is a easy engine to work on if needed . Hydraulic pump is problem if bad as hard to find any replacement easily but would not rule out it's OK . 33 link track on the 5B dozers , Put some effort into it as it may be slow but can still be a working machine ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: COD

Date Posted: 05 Jan 2022 at 6:40pm

| Anybody know weak places in the block to check for freeze damage? Rats/mice had chewed into the bottom radiator hose and there was no fluid in the radiator to see if it had any antifreeze. They said it did when parked but no way of knowing for sure if it was sufficient. |

Posted By: DonBC

Date Posted: 07 Jan 2022 at 1:19am

|

Even a fairly weak mixture of antifreeze offers protection as it forms a slush and not hard and expansive like freezing water. ------------- Jack of all trades, master of none |

Posted By: CTuckerNWIL

Date Posted: 07 Jan 2022 at 7:24am

If the bottom hose was chewed thru and most of the coolant leaked out, I seriously doubt there is any freeze damage to the block or coolant system. The problem could be rusty scale build up, from being exposed to the atmosphere for who knows how long a period. Many of these old engines have sat for decades and been revived. Just KNOW what you're doing with the fuel injector system before cranking it. Run Away's can destroy an otherwise good engine. At least be ready to close off the air intake before cranking. That would get put to regular use if it was in my possession. My OC46 track loader isn't much of a dozer  ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: COD

Date Posted: 07 Jan 2022 at 8:06am

| Thanks for the advice guys! Just FYI I did open the valve cover and make sure the rack moved freely. One injector was stuck but I worked if free by removing the fuel lines, squirting in some brake cleaner to flush it out, followed by some PB Blaster. Let it set for a bit and tapped the plunger down and pulled it back up a couple times. Flushed it out again and the rack moves nice and free now. Went ahead and flushed out the other injector in the same manner. I haven’t tried to roll it over yet, but I’m bringing it home next week……I hope.🤞 |

Posted By: pinball

Date Posted: 07 Jan 2022 at 5:33pm

| Ya know you never know what you have until you try to start it. it wouldn't surprise me if most everything is okay. that motor seems to be a good motor. change the oil and you never know. price seems good to me. but the real deal is when you get it operating and play/use it. that in itself is worth whatever you have in it. good luck and put another photo with you in the driver's seat when finished. It's always good to see these old machines brought back to life. they were a good old workhorse in its time. |

Posted By: COD

Date Posted: 08 Jan 2022 at 5:56pm

| Well my son and I got the blade up and chained off today. We also tied my truck to it and with a little persuasion we managed to get it unstuck from the ground where it rolls free. Will be going over next week to load it on the trailer and bring it home. Then let the fun (or lack thereof) begin! I actually enjoy giving old machines a chance to be useful again. Good thing about this is you can take a standard socket set, standard wrenches, and a hammer (gotta have a hammer) and work on just about everything on it. |

Posted By: DougG

Date Posted: 09 Jan 2022 at 1:55pm

| So very true ! Good luck with it , may not be bad at all |

Posted By: COD

Date Posted: 11 Jan 2022 at 7:09pm

| Got the old girl home today. Will be removing the blade and pressure washing over the next week…weather permitting. |

Posted By: HD6GTOM

Date Posted: 11 Jan 2022 at 11:53pm

| Bee carefull power washing the radiator. I've seen a couple damaged with a high powered washer. |

Posted By: COD

Date Posted: 12 Jan 2022 at 11:53am

| Thanks for the heads up Tom. I will be sure to avoid hitting the radiator with the high pressure. |

Posted By: COD

Date Posted: 14 Jan 2022 at 4:57pm

| Is there a good way to see if the blower is locked up other than pulling it off? When I try to roll the crank with a pry bar there is a slight movement followed by a “clank” in what sounds like the front end (gears behind the front cover). |

Posted By: gemdozer

Date Posted: 15 Jan 2022 at 8:08am

| You can removed the air filter pipe and the adaptor with 4 bolts on top blower and you should see the rotor inside and could be the startor freeze and you could removed the exhaust manifold you can see the piston and sleeve he could have some rust. |

Posted By: Codger

Date Posted: 15 Jan 2022 at 9:05am

|

I would probably pull the injectors out and fill the holes with a mix of ATF and diesel fuel. A couple of days later repeat. Then attempt to bar the engine over. Sounds like you may be hitting a rust ridge that has formed in a cylinder wall stopping piston travel. Most times this can be overcome but you don't really want to do it by brute force or you'll have an oil burner, or low compression for sure. Sometimes however, it simply cannot be helped as there is no other way. Give the oil solution a few days to work an loosen/soften the rust, (if culprit) before forcing the engine to rotate. Once it's rotating, I would ensure you are not too overfull on the crankcase dipstick before starting the engine.

|

Posted By: COD

Date Posted: 15 Jan 2022 at 11:16am

|

I removed the old rotten exhaust manifold and the valve cover. I depressed the exhaust valves and squirted a 50/50 mix of transmission fluid and acetone into the cylinders. I put about 1/2 a pint into each cylinder. I also removed the side cover and sprayed PB blaster on the pistons via the sleeve ports. I have not put much force on it so far I’ve just been working it back and forth. It just barely moves but when it does I hear that clang in what sounds to be the gears behind front cover. It moves just enough for gear lash or maybe it’s just slop in the main/rod bearings. I wasn’t able to watch through the side cover and rock the crank because I was by myself. There are no belts on it either so no parasitic drag from that. Gem I did remove the intake on the top of the blower and cleaned the screen. When I look down in there I can only see the casting of the body. I wasn’t able to see the lobes. I will remove the starter to eliminate that |

Posted By: COD

Date Posted: 15 Jan 2022 at 11:21am

| Another thing I noted is the exhaust valves and stems didn’t have any rust on them looking through the exhaust ports. I did not see any rust on the pistons looking through the sleeve ports. I can see one piston’s rings and they looked good with no rust. |

Posted By: Codger

Date Posted: 15 Jan 2022 at 11:23am

|

You are on the right track I'm thinking. Someone needs to look at those intake ports while a compadre works the crankshaft to ascertain which piston(s) are stuck, and which are attempting to move so you can drill down to which needs additional attention. |

Posted By: COD

Date Posted: 18 Jan 2022 at 6:18pm

| Well found the problem today. Pulled the starter off, which needed to be lubed up and connected to a battery and cycled several times to get it to work properly. Couldn’t move the engine at the flywheel with a pry bar afterwards. Removed the blower to be sure it wasn’t locked up. It wasn’t but it did need a good washing out. Then I pulled the cylinder head. One of the liners was rusted pretty bad. I used a brass wire cup in a drill to remove most of it and then vacuumed it out with my shop vac. I then oiled the cylinder and hone up and tried to smooth it out as best I could. Cleaned it out real good and soaked it with PB blaster. After that the crank broke free pretty easily. That cylinder was going down. I got the piston out of the way and honed it again to remove the rust I couldn’t get to at the beginning. Bumped the crank back and forth when it would get a little snug and now it moves free. Neither cylinder had a ring ridge that I could feel with my fingernail. At the very least it will need a piston and a cylinder and some gaskets. The cylinder head wasn’t too bad. I used the brass brush to clean it up. My goal is to get it running long enough to see what else is wrong with the machine before I bury money in the motor and there be another issue. I am going to try to mount the blower and the starter again tomorrow. |

Posted By: pinball

Date Posted: 18 Jan 2022 at 6:28pm

| Sounds as you're doing a good job. let's hope it runs okay. |

Posted By: COD

Date Posted: 19 Jan 2022 at 2:08pm

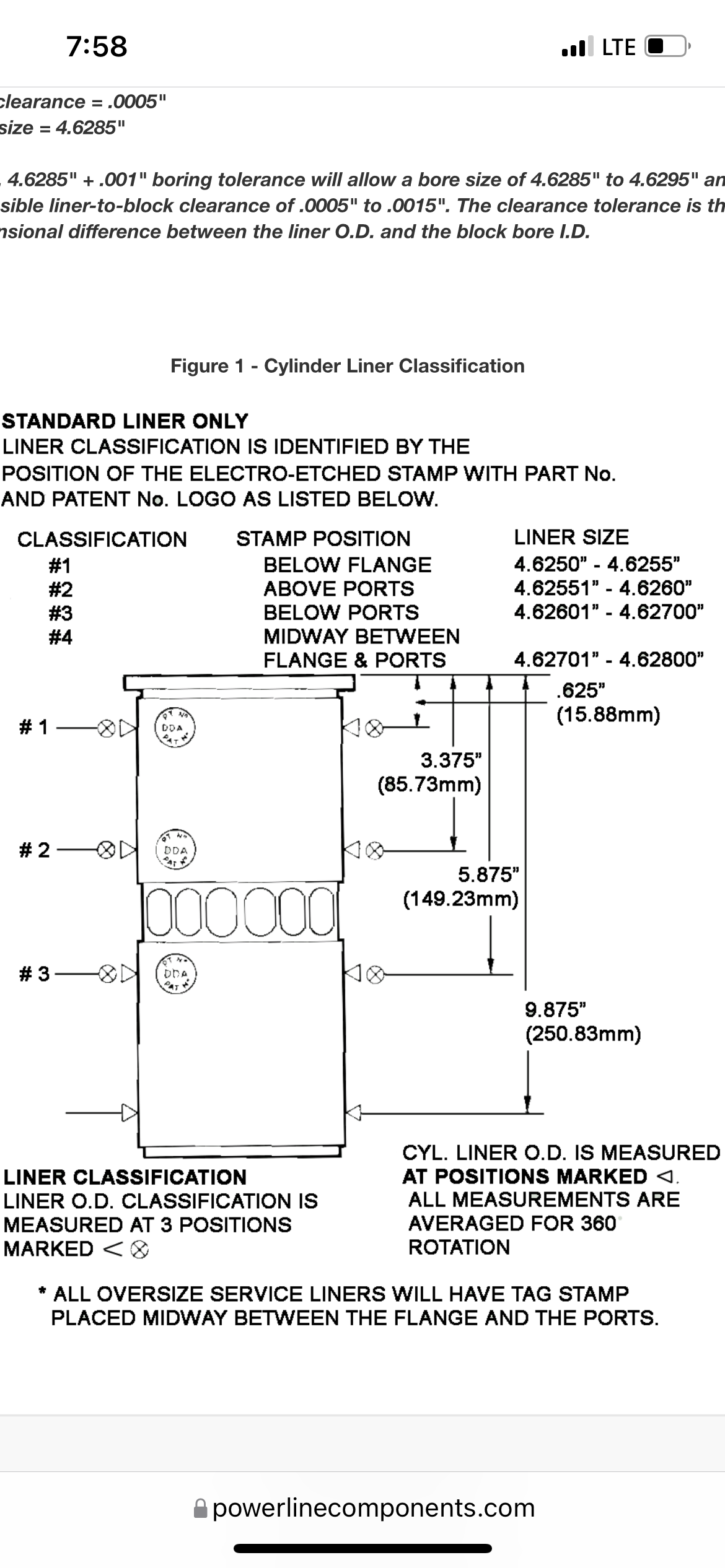

| On a cylinder kit, I’ve noticed there seems to be a 1, 2, and a three. What is the difference and how do you know which one you need? |

Posted By: CAL(KS)

Date Posted: 19 Jan 2022 at 2:40pm

------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: COD

Date Posted: 19 Jan 2022 at 2:46pm

| Thanks Cal! I figured it was something along those lines. So the sleeve will have a number stamped in it? |

Posted By: CAL(KS)

Date Posted: 19 Jan 2022 at 2:51pm

|

yes, on the outside below the ports if i recall ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: COD

Date Posted: 19 Jan 2022 at 2:53pm

| OK. Thanks |

Posted By: DMiller

Date Posted: 19 Jan 2022 at 4:45pm

|

1 should be standard, IIRC 2s were .005 Oversize and 3s .015. Detroit used to rubber stamp ink them in different positions on the liners, Close to Top rim was a Heavy where close to bottom was a Light sized. Midway on sleeve was exact to size. If a sleeve Falls in do NOT try to use it as will sheer at the air box holes. Needs to be a semi snug Slip fit.

|

Posted By: COD

Date Posted: 19 Jan 2022 at 5:03pm

| Thanks. I will check it out once I see if she will runs and see if things operate on her or not. |

Posted By: SophyCi

Date Posted: 20 Jan 2022 at 1:48am

| I think you did well! It appears that with a little TLC, you will have a great toy to play with. |

Posted By: COD

Date Posted: 11 Feb 2022 at 7:07pm

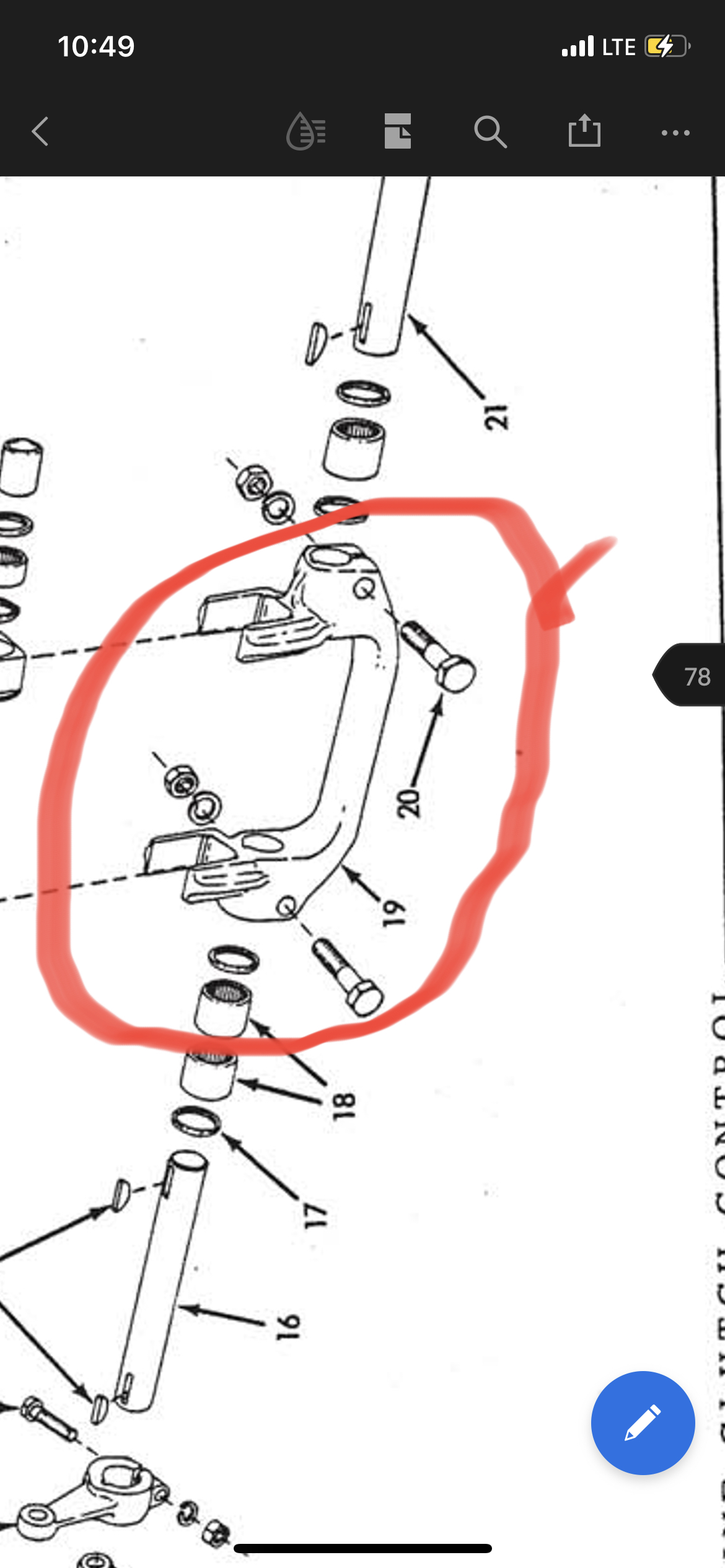

| So I’ve got the engine and engine clutch out. I have removed the engine clutch, clutch housing, flywheel, and the bell housing. I’ve got to get longer bolts to bolt it to my engine stand so I can start the tear down. One question though. When I was removing the assembly from the dozer I accidentally pulled the locking plunger out too far. How do you line this thing back up? What does it attach to inside the gear shift housing? The service manual and parts manual are unclear. |

Posted By: COD

Date Posted: 04 Mar 2022 at 10:07pm

So I got the engine tore down. How do you tell if the liner is a 1, 2, or a 3? I don’t see anything marked on it that would denote which one it is.

|

Posted By: 200Tom1

Date Posted: 04 Mar 2022 at 11:52pm

| Good luck with her. I wish I had kept my last HD 6. Sure miss that clank, clank. |

Posted By: jaybmiller

Date Posted: 05 Mar 2022 at 6:20am

|

how ? Have AFIS check that fingerprint !!!!  Now a clever parts numbering guy would make 5149211 a '1', 51492112 a '2' .... More 'numbers' fun.... my BUDA 4BD153 can have either a 3 or 4 ring set per piston...HOW can anyone tell BEFORE tearing it all apart...sigh..... same boat, different paddle. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: COD

Date Posted: 05 Mar 2022 at 7:12am

| Lol. I realized it after I posted the pic. Hope there is no one with the FBI on the forum!😂 |

Posted By: DMiller

Date Posted: 05 Mar 2022 at 7:15am

|

Used to be listed in the DD service manuals, that and the micrometer dimension of the sleeves. The mark is also at the top so will be a heavy or thicker 1, 2 or 3 sleeve. I no longer have my manuals. |

Posted By: COD

Date Posted: 05 Mar 2022 at 7:52am

| When you say heavy does that mean oversized where the block has been bored or just a thicker liner from factory? |

Posted By: COD

Date Posted: 05 Mar 2022 at 8:03am

Found this on PC Industries website. Is this info correct? I don’t have a micrometer large enough to measure the outside diameter of the old sleeves.

|

Posted By: COD

Date Posted: 07 Mar 2022 at 11:59am

| Well after calling several places, I got several different answers so I’m even more confused now. |

Posted By: Codger

Date Posted: 07 Mar 2022 at 12:44pm

|

This is where the block and liners need measured by someone that has the tools and experience with the Detroit engine series. Not being sarcastic or anything of the type but the block bore needs to be known, and round to fit correct liners, then protrusion of the liners etc. More to it than just a guess. Any competent machine shop on diesel engines should be able to measure it up for you to eliminate guesswork. Very easy engine to build but you have to know the correct sized parts are going into it.

|

Posted By: COD

Date Posted: 07 Mar 2022 at 1:59pm

| After talking to pc industries, Heavy Duty kits, and diesel pro power, all three confirmed the part number from the liners I removed are a standard size three. I figure if it ran with them before it will again. Putting the micrometer on everything else, it appears this engine was rebuilt shortly before it was parked. There is also no ring ridge whatsoever in the liners. If water hadn’t gotten into that one cylinder this thing would have popped off and ran for years I believe. |

Posted By: COD

Date Posted: 27 Mar 2022 at 2:16pm

|

Got a question. My block serial number is prior to them using the longer cam bearings. Mine are 1-1/8 long and the “newer” blocks are 1-1/2” long cam bearings. The blocks appear to be the same part number and so do the cams (according to the part numbers). The 1-1/8” standard size is made from unobtainium and not available. They make a .015 under bearing for $35 per bearing. Problem is no one around here grinds camshafts. The 1-1/2” wide ones are $11 per bearing and standard size is available. Can I use the 1-1/2” wide ones as long as the oil holes line up? Basically about 1/4” of the bearing will be sticking on the inside of the block past the bore for the cam bearings. The oil holes in the 1-1/2” wide bearings appear to be off center so I think they would line up. I mic’ed my cam bearing journals and they are within spec but I may polish them a little in a jig to spin the cam using a drill and a socket. Any thoughts guys? |

Posted By: fjdrill

Date Posted: 27 Mar 2022 at 2:54pm

| Did that 5 come from over around Scooba? |

Posted By: steve(ill)

Date Posted: 27 Mar 2022 at 3:15pm

|

Dewey , if the bearing OD is the same and will fit in the block... I would think you could take a cutoff wheel and trim some off the bearings "if needed"... maybe OK they way they are. ------------- Like them all, but love the "B"s. |

Posted By: COD

Date Posted: 27 Mar 2022 at 4:58pm

| I got it from a fellow that was South of Dekalb, MS so it wasn’t far from Scooba. |

Posted By: COD

Date Posted: 27 Mar 2022 at 4:59pm

| Thought about trimming the bearings off but had rather leave them sticking a little past the bores unless it would be an issue. I don’t see where it would be but I’ve never seen an engine with bearings sticking out past the bores. |

Posted By: fjdrill

Date Posted: 27 Mar 2022 at 5:30pm

| I’m thinking that my dad’s old dozer. Bought about 1965 in Amory at a sale at one the AC dealer auctions. First dozer I ran pulling a Rome new ground disc. About 1969-70 ( I was like10 years old at the time) sold to a local. Then a Mennonite had it in Geiger Al Wondering were it went. Figured scrappers had gotten it. |

Posted By: COD

Date Posted: 27 Mar 2022 at 6:13pm

| The scrappers were next in line to get it. It’s still a solid old dozer seems like. If water hadn’t gotten into that one cylinder it would have fired off. I like to save this old iron. It was built in days where things were simple and made to last. You can take a set of wrenches and sockets and work on anything on it. Glad it brought back memories for you. |

Posted By: COD

Date Posted: 27 Mar 2022 at 6:14pm

|

It had the rear aux hydraulic hoses on it. Figured it was pulling a disc at some point. Anybody else got any feedback on the cam bearings??? |

Posted By: COD

Date Posted: 18 Apr 2022 at 1:32pm

Anybody got one of these in good shape they are willing to sell???? If so PM me

|

Posted By: Codger

Date Posted: 19 Apr 2022 at 6:24am

| The throwout bearing fork is a common part to build up with either weld, or brass. |

Posted By: COD

Date Posted: 19 Apr 2022 at 12:04pm

| The forks are in great shape. My problem is the jetway on the long shaft said is worn causing a lot of play. |

Posted By: DMiller

Date Posted: 19 Apr 2022 at 6:25pm

| "Key" way?? |

Posted By: COD

Date Posted: 19 Apr 2022 at 10:55pm

| Oops. Yes keyway. I didn’t catch the autocorrect had changed it. |

Posted By: Codger

Date Posted: 20 Apr 2022 at 5:42am

| Most any machine shop could cut another Woodruff keyway into the shaft 180 degrees opposite from the existing worn keyway(s). I just had that performed on an overhead crane hoist last week rather than spend $340.00 from Budgit Hoists for a replacement shaft. |

Posted By: COD

Date Posted: 20 Apr 2022 at 7:40am

| Great idea! I didn’t think of moving the keyway around. |

Posted By: COD

Date Posted: 20 Apr 2022 at 9:24am

| OK guys I have another dumb question. I’m in the process of reassembling the engine. I am ready to put the rings on the pistons. I have looked all over the four compression rings and do not see any markings that would denote the “top” side of the rings. It’s Interstate McBee brand. I called the place I bought the kit from and they said it didn’t matter which way was up but didn’t give me a fuzzy feeling they knew what they were talking about. Anybody know for sure on this? |

Posted By: Codger

Date Posted: 20 Apr 2022 at 10:22am

| they may be correct if no markings. Most compression rings have a slight taper which goes to the top but not all. |

Posted By: COD

Date Posted: 27 Apr 2022 at 5:11pm

|

Just in case anyone else runs into this issue this may save you the trouble I went through to find out for certain on the piston rings. I contacted Intersate-McBee’s customer service and explained the issue to them. The first two people were as unsure as I was. They finally got an answer back to me today that it doesn’t matter up or down on the compression rings. On another note, my next question is this; I’m using HV7 injectors instead of the HV6. Reason being I got some rebuilt ones for a really cheap price. What should I set the injector timing to for the HV7s? |

Posted By: Codger

Date Posted: 27 Apr 2022 at 9:27pm

|

Std. timing and install a pyrometer. You are going to be dumping more fuel into that engine against a push and it will smoke more with additional heat in the exhaust. A pyro will help you keep this in check. Myself I would stay with the originals HV6 series. A turbocharged engine takes to uprating of injectors much better than a natural aspirated engine does. Hate to see you melt your hard work down.

|

Posted By: COD

Date Posted: 28 Apr 2022 at 9:16am

|

https://www.allischalmers.com/forum/hv7-injectors_topic187206_post1597904.html?KW=HV7#1597904" rel="nofollow - https://www.allischalmers.com/forum/hv7-injectors_topic187206_post1597904.html?KW=HV7#1597904 I thought the HV7s were OK to run in the 271 without problems???? I guess I’m confused. I surely don’t want to damage the engine after all this. |

Posted By: CAL(KS)

Date Posted: 28 Apr 2022 at 10:06am

|

just a little more fuel, shouldnt hurt anything, but if you can stay with same size. ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: COD

Date Posted: 28 Apr 2022 at 12:19pm

| Is anyone else out there running HV7s in their 271? If so any issues? |

Posted By: COD

Date Posted: 21 May 2022 at 1:33pm

| Since no one else seems to be running the HV7s in their 2-71, does anybody have any good HV6s they want to sell? |

Posted By: gemdozer

Date Posted: 21 May 2022 at 3:12pm

| HI I have some HV6 injectors |

Posted By: COD

Date Posted: 21 May 2022 at 7:11pm

| PM sent Gemdozer |

Posted By: COD

Date Posted: 30 May 2022 at 12:15pm

| If I use HV7 injectors what is standard timing for those? Is it 1.484 or 1.460???? |

COD wrote:

COD wrote: