Treadmill motor questions

Printed From: Unofficial Allis

Category: Other Topics

Forum Name: Shops, Barns, Varmints, and Trucks

Forum Description: anything you want to talk about except politics

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=177278

Printed Date: 17 Dec 2025 at 5:41pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Treadmill motor questions

Posted By: Thad in AR.

Subject: Treadmill motor questions

Date Posted: 04 Jan 2021 at 5:25pm

|

I have a treadmill motor o plan to use for a project. First off it needs reversed. I believe I can switch leads and make it work. The fan will then turn the wrong direction. It has a plastic fan on one end and a flywheel pulley on the other. I plan to run it without the flywheel and it would need to run continuously for an hour or so at a time. Not a heavy load. Do I need to find something different. Doesn’t have to be variable speed. |

Replies:

Posted By: steve(ill)

Date Posted: 04 Jan 2021 at 5:29pm

|

i would think if you have a cheap shroud around the fan / motor , that it would make air flow for cooling.. pushing or pulling. ------------- Like them all, but love the "B"s. |

Posted By: jaybmiller

Date Posted: 04 Jan 2021 at 6:04pm

|

Ok... what I know... usually 'free' as everyone gets rid of them once they're in great shape.... I've had 4 or 5 over the years... 'treadmill motors' are usually 90 V DC motors. As such easy to reverse ( swap red and black wires). A DPDT switch rated for 120VDC / 10A will work, just be SURE mot is NOT spinning when you change direction......oospy, POOF, lots of smoke.... hmm, could you mount the motor the other way, physically ? That changes the direction. Without the flywheel, it'll be 'jerky' depending on the load. Check the rating on the motor, most of the ones I've played with are 3500-4500 RPM. Always best to grab power supply and controller WITH the motor. Newer ones seem to all have the same 'controller' and easy to modify for speed control. LOTS of info about using them,schematics, etc. easy to find when you have part numbers.... ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Thad in AR.

Date Posted: 04 Jan 2021 at 7:12pm

|

Went to the shop for a bit. Messed with the motor. It appears noisy and bulky with all the garbage to make it work. I think I’m gonna find an small AC motor that’s 1725 rpm and clockwise rotation. |

Posted By: desertjoe

Date Posted: 04 Jan 2021 at 7:30pm

|

Well,,,,,ole BUDDY,,,,I do remember you sayin something a week or so ago bout a project you was wantin into and needing a motor off one of them exercise machines,,,,you gots my curiousity goin circles,,,,,   SOOoooo,,you gonna have to fess up,,,,OK,,?? SOOoooo,,you gonna have to fess up,,,,OK,,?? If you need some more of them motors,,I always see a lot of them exercise machines in the metal pile at the "Transfer Station",,,,,,thas what them city boys want us to call it,,,altho it depends how they act when I get there and if they gonna let me do a little "scrounging",,,else I just call it the city dump,,,,,,

That really pizzes em off,,,,, That really pizzes em off,,,,,  |

Posted By: Thad in AR.

Date Posted: 04 Jan 2021 at 8:03pm

|

Joe I’m preparing a whole bunch of brass for reloading. I’ve found a neat trimmer I want to buy. It just chucks in a drill and you can clamp the drill down and let it run. Drills are noisy and not made to run for long periods of time. I’m trying to find a light quiet motor that runs 1725 Rpm and s doesn’t take up much room. Last week I turned a collar to fit an electric ice cream maker and added a drill Chuck to it. I use this for reaming primer pockets and chamfering. Wish I had 3. I ran it for several hrs straight Sat**day. It’s way too slow for trimming but perfect for chamfering and reaming. |

Posted By: shameless dude

Date Posted: 04 Jan 2021 at 8:21pm

| washing machine motor? |

Posted By: Thad in AR.

Date Posted: 04 Jan 2021 at 8:39pm

| I’m thinking that may be the ticket would be small and quiet |

Posted By: desertjoe

Date Posted: 05 Jan 2021 at 9:15am

|

Great Idea,,Shameless,,,!! And,,,and,,Thad,,I've got one out of a 2 year old machine,,,,lemme check it out ,,see if it ain't growed feets,,,,

|

Posted By: KMAG

Date Posted: 05 Jan 2021 at 9:53am

|

Best use of a treadmill motor setup ever. Start at 4:41 in video https://m.youtube.com/watch?v=dWTKXVCW8HU" rel="nofollow - https://m.youtube.com/watch?v=dWTKXVCW8HU |

Posted By: Thad in AR.

Date Posted: 05 Jan 2021 at 5:42pm

|

Posted By: wide

Date Posted: 08 Jan 2021 at 8:57pm

|

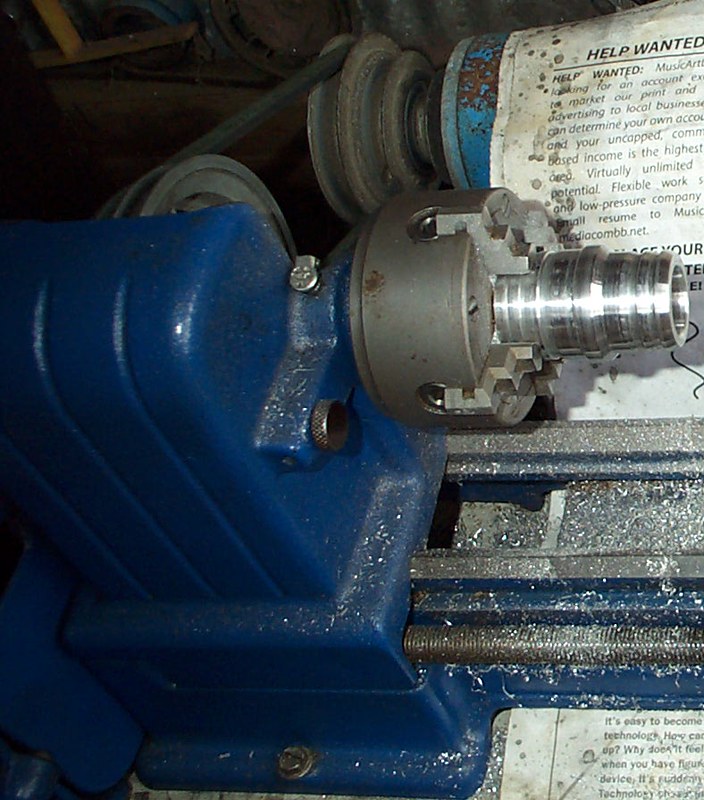

Tredmill motors are torquey but I don't think they don't go 1700RPM easy. You can use a J6 belt on the stock pully. But the pully is so small. I have one running my little old atlas lathe. https://flic.kr/p/2iL4epP" rel="nofollow">  https://flic.kr/p/2iL4epP" rel="nofollow - lathecoupler by https://www.flickr.com/photos/147103123@N05/" rel="nofollow - vwfatmobile , on Flickr https://flic.kr/p/2iL4epP" rel="nofollow - lathecoupler by https://www.flickr.com/photos/147103123@N05/" rel="nofollow - vwfatmobile , on FlickrI kept the old controls and it has speed control and several safety features. I can clip the cord to my waste and if I fall down while working on my lathe it shuts off.  Don't tell OSHA or they will make that manditory. They do make a nice DC generator if you can spin them fast enough. You can get them up to 250 volts DC. https://flic.kr/p/2eLNDfi" rel="nofollow">  |

Posted By: jaybmiller

Date Posted: 08 Jan 2021 at 9:35pm

|

EASY, if you use the 'controller' that was on the treadmill or a variable DC power supply. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: thendrix

Date Posted: 09 Jan 2021 at 7:28am

|

With as many chicken farms as there are in Arkansas you can surely get a used fan motor somewhere for a song. The 36 inch exhaust fans usually have 1/2hp, 120/240, CW/CCW, 1750 RPM motors with a 1/2" keyed shaft. Might be bigger than what you want but it's an option. ------------- "Farming is a business that makes a Las Vegas craps table look like a regular paycheck" Ronald Reagan |

Posted By: Thad in AR.

Date Posted: 09 Jan 2021 at 9:05am

Yes and I want one of those big fans for my shop next summer. I found the perfect motor. Small 1/19 go 1550 rpm came on a squirrel cage fan off of some appliance. The shaft is 3/8” same as the trimmer. All mounted on a 10” long 2x6. Neat and fits in a drawer. The motor is 4” diameter and 4” long. All free from our hvac guys at work. It’s brand new. I googled it and they cost $ 100.00 Online. It will be mounted and switched today. Now just waiting on the WFT trimmer. |

Posted By: desertjoe

Date Posted: 09 Jan 2021 at 7:50pm

|

Hey Wide,,,that looks like my old Craftsman 109,,,great little lathes,,! Thas another one of my "Projects" I kinda pushed to the side,,I got it down from rafters to clean it up for sellin and,,,,,,,you just reminded of it,,,,,

|

Posted By: thendrix

Date Posted: 09 Jan 2021 at 8:34pm

For a shop fan you don't want one with a slant wall kit. You'll need to look at some from an old farm that shut down. A lot of the older farms had box fans attached to the wall. Slant wall fan boxes are wider at the top than the bottom so they point toward the ground more. ------------- "Farming is a business that makes a Las Vegas craps table look like a regular paycheck" Ronald Reagan |

Posted By: Ted J

Date Posted: 10 Jan 2021 at 3:15am

|

TYler, just turn it upside down..... Thad, I want pictures when you get it done!! Here's the one I bought..... https://www.dacamreloading.com/cube/reloading-tools/trimmers/.html" rel="nofollow - https://www.dacamreloading.com/cube/reloading-tools/trimmers/.html ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: Thad in AR.

Date Posted: 10 Jan 2021 at 8:37am

|

Ted I can’t get your link to work. I have the unit built now just waiting on the trimmer to arrive. Sending you a pic in a text. |

Posted By: Thad in AR.

Date Posted: 10 Jan 2021 at 8:48am

Thank you and that’s good information to know. Gonna have a couple machinist questions in a bit. |

KMAG wrote:

KMAG wrote: