7010 hi/low range shift problem

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=175421

Printed Date: 15 Sep 2025 at 10:13pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 7010 hi/low range shift problem

Posted By: calico190xt68

Subject: 7010 hi/low range shift problem

Date Posted: 24 Oct 2020 at 3:33pm

|

I have a 16 speed power director 7010. I started putting some equipment away in the barn for winter. Was shifting out of low into park and got half way out of low and the lever got stuck. Can't move it forward or backward. Tractor won't move either so it is not in gear. I have had a little trouble shifting into park lately so this problem may have been waiting to happen. I don't know much about this setup but my guess is that it could be the park cable is stuck or it could be the hi/lo cable is stuck. Worse case scenario is the shift fork in the transmission? I think I need to disconnect the park cable and see if that allows movement. If it doesn't then disconnect the hi/low cable and see if it moves. Most importantly, looking for steps to debug the problem. Any help is appreciated! Here is a picture of the shift cable area. I used red for the hi/low cable that looks a little bent to me, and I think the blue is park cable? Last, the dang tractor is half in the barn. Can I pull it out about 10 feet so that I can shut the door? ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Replies:

Posted By: DrAllis

Date Posted: 24 Oct 2020 at 5:45pm

| You'll probably need to remove the floorboard of the cab to get to the real shift lever. If you disconnect the large cable down below and now your lever in the cab moves again, it ain't the cable. The large cable does the front to back movement and really all the work. The small cable is the side shift cable and directs the under the cab lever to the Park rail or the LOW-N-HIGH rail. I think you have shifter problems inside the shifting cover behind the small fuel tank. |

Posted By: shameless dude

Date Posted: 24 Oct 2020 at 11:31pm

| may have dirt around the buttons, blow out around them with an air hose first, have had to do this with mine several times. do it from the top. |

Posted By: calico190xt68

Date Posted: 25 Oct 2020 at 9:23am

|

All right thanks for the help. I will remove the floor board and disconnect cable and see what happens. Shameless, not sure what you mean about buttons? Are they below the cab? I don't see any buttons above the cab. Finally, is it OK to pull the tractor out of the barn 20 feet so I can shut the door. ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: SteveM C/IL

Date Posted: 25 Oct 2020 at 9:39am

| Hi low buttons for PD....don't know what your tractor has. Im not sure but don't see how a 20ft move could harm anything. |

Posted By: calico190xt68

Date Posted: 25 Oct 2020 at 10:15am

|

I have a shift lever and no buttons. Getting out of the barn gives me more light too. Thanks. ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: bigal121892

Date Posted: 25 Oct 2020 at 11:15am

You don't have two buttons on the floor, for shifting between the high and low?

|

Posted By: calico190xt68

Date Posted: 25 Oct 2020 at 4:20pm

|

I understand now what you mean. Yes, I do have the buttons on the floor which is the power director, but it is the lever on the console that is stuck. That lever does high and low and also puts it into park if you go to neutral and then pull over and back. I never made it to park as it is caught half between low and neutral. I haven't had a chance today to look at it unfortunately. Due to the fact that I couldn't get an appointment for butchering, I had to finish butchering a lamb that I had hanging. ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: calico190xt68

Date Posted: 28 Oct 2020 at 6:57pm

|

Happy to report that I have resolved this issue with the help of the forum. It ended up being a sticking hi/low main cable. My steps were: I removed the cab flooring, then the metal plate, and then the screw that tied the cable end to the final shift link. After shifting it, it was still stuck, but I noticed it moved a little. That convinced me this was not shift fork issue but rather a cable problem. I put some wd-40 on the end under the cab, then moved it back and forth and it broke loose. It looked like it was in a bit of a bind but has to be corrosion in the cable. I reconnected and was able to place into high, low and park. Tractor moved as expected. I still think it shifts hard so would like to replace the cable and be done with it since I have it all apart. Worried it might stick in the dead of winter when I really need it. Just how do you go about replacing the hi/lo shift cable? Obviously it comes off at both ends but wonder about threading it in and out of the cab? Any tricks to that? Thanks to Dr Allis and everyone that jumped in! ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: plummerscarin

Date Posted: 28 Oct 2020 at 7:09pm

|

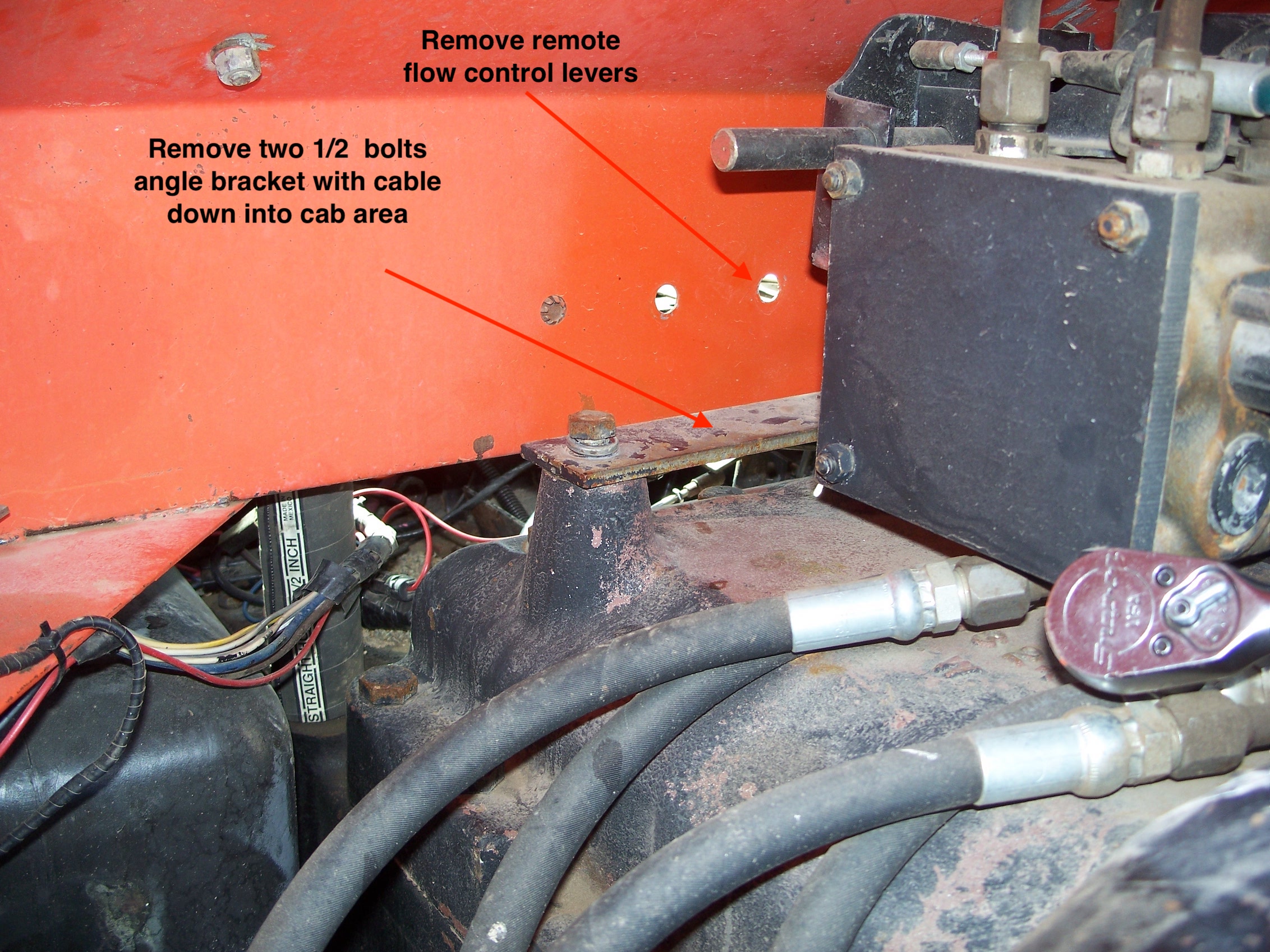

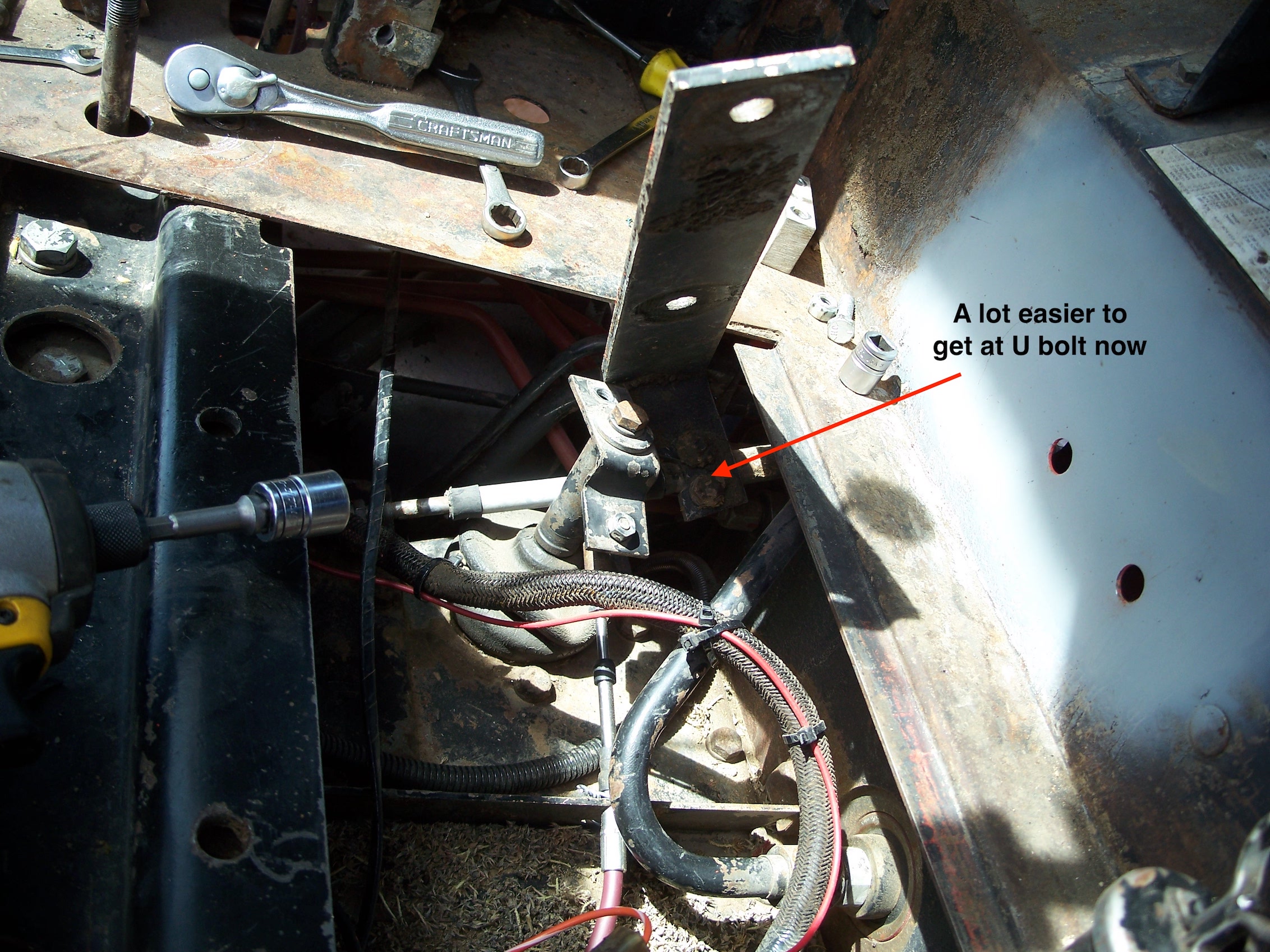

Just how do you go about replacing the hi/lo shift cable? Obviously it comes off at both ends but wonder about threading it in and out of the cab? Any tricks to that? Thanks to Dr Allis and everyone that jumped in! [/QUOTE] Coming from someone whose only done two: The cable clamps in the console should be self evident. I pulled the hi/lo cable out the back of the cab and you will find there is a U clamp holding the cable to a bracket bolted to the rear end behind the valve stack. Remove 2 bolts and move assembly forward to remove clamp through the hole in the floor. HTH. |

Posted By: calico190xt68

Date Posted: 28 Oct 2020 at 7:29pm

|

If you have done two, then you should know the steps. Hope it wasn't on the same tractor. Doesn't sound too bad. I wonder what the cable costs? I assume only from Agco? Thanks for your help. ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: SteveM C/IL

Date Posted: 28 Oct 2020 at 8:35pm

| Bunker Hill Cables |

Posted By: shameless dude

Date Posted: 28 Oct 2020 at 10:44pm

| sorry...i misunderstood which hi/low it was. |

Posted By: plummerscarin

Date Posted: 29 Oct 2020 at 6:17am

| I got mine from Agco for $200. Have not tried Bunker Hill but others say good things about them |

Posted By: calico190xt68

Date Posted: 29 Oct 2020 at 10:47am

|

BunkerHill is at around $95 versus $200. I think I will try the bunker hill since SteveM has recommended them and your comments about others. Thanks for the info. I forgot to mention that I found two bird nests under my floor board when I took off the metal plate. I also found a 3rd nest early this year when I fixed the clutch starter switch button. Is there any way to stop these birds from nesting under there? Can I put some hardware cloth around the area? Wonder how many others have birds nest and don't know it like me? I can't make my barn bird proof either. I don't drive it much until hay season begins which is usually June 1 in Indiana. I am guessing they start in April and build these nests. I wonder if moth balls repel them like mice? ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: plummerscarin

Date Posted: 29 Oct 2020 at 11:59am

| If you find a way to keep them out, let me know. For some reason they prefer the 7045 over the other two. My guess is if the tractor sits idle long enough them sparrows get bold. I see them look over those tractors constantly |

Posted By: calico190xt68

Date Posted: 29 Oct 2020 at 1:31pm

|

My current thought is to at least wrap some hardware cloth around the area below the cab around March and then remove come hay baling time. You can bend the hardware cloth around things and it will stay. Might even be able to drive it around with the hardware cloth because it will allow air flow too. If you stuff a tarp in there, then the mice will think you have built them a hotel. I will try it this spring and see if it works. It is a fire hazzard with that much hay nesting material stuffed in there. Bought me a new floor mat from Fehr to replace the indoor/outdoor carpet that exists now. It is holding moisture and causing the plate to rust. Going to paint that metal plate to inhibit more rust. Then I will buy the rest of the cab kit once I get all of this done. One fix leads to another and another and another ... ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: shameless dude

Date Posted: 29 Oct 2020 at 11:50pm

| get the part number from AGCO, go to your nearest farm store and ask them to order you a cable or whatever you need thru A&I parts. (same place AGCO gets alot of their parts) the part numbers from ALLIS are the same part numbers at A&I. and a whole lot cheaper. |

Posted By: calico190xt68

Date Posted: 02 Nov 2020 at 7:39am

|

I pulled the trigger on the BunkerHill cable before I saw this. However, I will keep this in mind for next time. I noticed some parts I got from All States Ag had the A&I tag on it but I did a search on that cable from some of the online vendors I have used and nothing came up. I looked at that u clamp and I don't know if I should loosen from the back of the tractor or try to loosen from within the cab. Both paths look pretty hard to get to and limited space for a wrench or socket. ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: DrAllis

Date Posted: 02 Nov 2020 at 8:11am

| Unbolt the U-bolt anchor plate and then position it where you can wrench on the U-bolt easier. |

Posted By: plummerscarin

Date Posted: 02 Nov 2020 at 10:17am

I did as stated above and moved the assembly forward to reach from inside the cab. |

Posted By: calico190xt68

Date Posted: 02 Nov 2020 at 3:23pm

|

Thanks to you both for the clarification. Hope to get that cable changed out by the weekend. ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: DrAllis

Date Posted: 02 Nov 2020 at 3:34pm

| You know, I've never ever changed out just ONE cable on a job like that. As much work as it is to do, change them both for very little more labor and cost. You'll be glad you did it that way. |

Posted By: calico190xt68

Date Posted: 02 Nov 2020 at 3:39pm

|

That's probably a good idea. I will order the other shifting cable. I ended up painting the steel plate and it is going to be a few days before it is dry anyway. I also had my new floor mat delivered from Fehr so might as well go all the way and replace the other shift cable. It is tough on your belly in that cab trying to wrench things to say the least. ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: plummerscarin

Date Posted: 02 Nov 2020 at 6:56pm

| When I put the cab kit in, I removed the seat. Way more room if you go that route. |

Posted By: calico190xt68

Date Posted: 02 Nov 2020 at 7:15pm

|

After I redo the floor and get the shifting cables fixed, I hope to move onto the cab kit. I can see the advantage and will remove the seat. My seat needs to have new upholstery anyway. I also looked at removing the bracket just now and initially I didn't see how that would be easier until I looked on the left side of the cab when standing in the back and saw the two bolts for the anchor bracket were accessible from the left side. Will probably get to it this weekend. I have to figure out how to do the shifting cable next. Did you do that one? If so, what was that process? ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: AllisFreak MN

Date Posted: 02 Nov 2020 at 7:17pm

|

I'm doing the same cable swap right now too. This is on a 7040 PD and what a pain in the arse it is. The park cable was fairly easy but am struggling with the U bolt on the big range cable. I will have to dive back into it tomorrow after work. How hard is it to unbolt the bracket with the U bolt Doc? ------------- '49 A-C WD, '51 A-C WD, '63 A-C D17 Series III, 1968 A-C One-Seventy, '82 A-C 6060, '75 A-C 7040, A-C #3 sickle mower, 2 A-C 701 wagons, '78 Gleaner M2 |

Posted By: MACK

Date Posted: 02 Nov 2020 at 8:51pm

| Remove that bracket, cut 1/2 moon notches in it to slide over knobs that it bolts to. Fasten cable on, then slide it in and bolt it back down. MACK |

Posted By: calico190xt68

Date Posted: 03 Nov 2020 at 8:06am

|

Mack, I am not following the half moon cuts? I think you are saying cut a slot on the anchor bracket so you can leave the bolts in place and then slide the anchor plate on after everything is in place then tighten down. I guess that prevents you from having to hit the hole with the bolt on the far side of the valve stack. It does look like a pain. That anchor plate sure is big considering what it is holding. I will find out this weekend. Still looking for guidance on the Shift cable since I have a game plan on the hi/lo cable now. Is it an equal pain in the butt? ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: DrAllis

Date Posted: 03 Nov 2020 at 8:30am

| Do not get mean and rough with the small side-shift cable. If you put any bends or kinks in it, it will not work well after installation is complete. |

Posted By: MACK

Date Posted: 03 Nov 2020 at 8:30am

| With the cable tight on bracket, cab keeps you from getting bracket back up on bracket mounts. A 1/2 moon cut in bracket allows enough room to get bracket up on mounts. MACK |

Posted By: calico190xt68

Date Posted: 03 Nov 2020 at 8:44am

|

Mack, I think I got it now. I am sure it will be more obvious once I start to secure it. The half moon notches must be on the front facing of the bracket then? Or does it matter? Dr Allis, Thanks for the advice on the smaller shift cable. Cable was $65 but don't want to screw it up. ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: calico190xt68

Date Posted: 06 Nov 2020 at 5:05pm

|

I just got back at this problem. Man that u-bolt is really tough to get a wrench on. I pulled the cable out from the console through to the back and removed the two bolts on the anchor plate. I moved it forward as much as I could which wasn't a lot. I just can't get a wrench on it to loosen the u-bolt nuts attached to that bracket. It is too small for a socket. I am going to try again tomorrow. Nothing like laying on the cab floor with the clutch pedal in your back. ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: DrAllis

Date Posted: 06 Nov 2020 at 5:12pm

| I remember standing at the left rear corner of the tractor and using an 18" long 3/8" drive extension and a wobble socket to do that job. 3 pt hitch down. Not easy, but can be done. I would have been 6 ft and 170 lbs. |

Posted By: LB0442

Date Posted: 06 Nov 2020 at 7:14pm

Here is how I did the last one I had. Took more pictures than this but this might be what you are talking about.  This one has fairly new cab mounts on it so that might have helped. |

Posted By: plummerscarin

Date Posted: 06 Nov 2020 at 7:25pm

| Good picture LB. A lot cleaner than mine. I put a smaller wrench on the bracket to slightly twist to get it to clear the mount boss and slide forward to reach through the cab floor Hope that makes sense to you. But as Doc has said be careful not to twist too much and put a permanent kink in it. |

Posted By: AllisFreak MN

Date Posted: 06 Nov 2020 at 8:30pm

|

I just finished my 7040 a few days ago and it is a real bitch. This may sound crazy but I unbolted the right rear corner of the cab (only 1 big nut and 1 bolt/nut) and jacked it up with a hydraulic jack and that made a big difference in making room to finagle that bracket under the cab and out through the cab floor. It worked for me anyways. ------------- '49 A-C WD, '51 A-C WD, '63 A-C D17 Series III, 1968 A-C One-Seventy, '82 A-C 6060, '75 A-C 7040, A-C #3 sickle mower, 2 A-C 701 wagons, '78 Gleaner M2 |

Posted By: MACK

Date Posted: 06 Nov 2020 at 8:58pm

| I remember now about cutting 1/2 moon notch in mount bracket behind the two 1/2" bolts. You can pull cable inside cab and bolt cable to bracket, then slide back under cab and up on to the mounts. MACk |

Posted By: calico190xt68

Date Posted: 07 Nov 2020 at 7:44am

|

Good news is that I got it! After my last post, I went back out to stare at and try to figure something out, so I didn't see the above posts until this morning. The big revelation is that you have to position that anchor plate against the bottom of the cab as flat as you can and then push forward. I actually didn't figure this out on purpose. A friend who hunts my property got done with his hunt and saw me in the barn and decided to jump in and help. He worked the back of the tractor and I stayed in the cab. I had actually snaked a medium sized ratchet with 1/2 inch socket into that space and loosened the nuts on the cable two clicks at a time, thinking that the anchor plate was as far forward as possible. It was not. As I was having my friend reposition the cable to get the socket on the nut, he pushed it into the cab by accident. I don't know how he did it, nor does he. When it suddenly appeared, I couldn't believe it. I am kind of glad I didn't see the post on jacking the cab up because I probably would have done it. :-) I want to point out to others that the u bolt has to be taken completely out. I thought I could loosen it and pull the cable out the back, but it fits too tight in the metal slot on the cable to do that. I cannot thank everyone enough for the posts and hope my details helps the next guy. Sounds like others have struggled as well. Couldn't have done this without the forum. Now I wonder if putting it back together will be easy? I can't tell for sure if there is a front or back to the Bunker Hill cable. There is a slight difference in length of the metal ends but not a lot. I don't want to put it in backwards and have to redo it. See my pics.   ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: calico190xt68

Date Posted: 07 Nov 2020 at 9:42am

|

Since I got the anchor plate in the cab without the half moon slots, I decided to try and get it back out without them. Admittedly, it is a better way to prevent screwing up the cable. I replaced he original nuts with the nylon locking nuts, I rotated it down and slid it under the cab. It got caught between the cab and the cast iron mounting pads for the anchor plate. That's what the half moon cuts resolve. It seemed it only lacks about 1/4 inch. So, I put a pry bar on the inside pulling it toward me and a pry bar underneath to push up. It didn't take a lot of effort and the plate popped up and out on the end you can see. can't do it with your hand though. I then pushed up on the end I could see with a pry bar and it popped up and over the mounting pad you can't see. I don't think I hurt anything and I didn't use a lot of pressure. If I had, I was going to stop. After that it was just putting the ends on, threading the other end of the cable into the cab and console and reconnecting. The only thing I see as slightly wrong, is that the shifter doesn't bottom out on lo setting. It stops about 1/2 inch from bottom. High range goes all of the way up and stays. I am guessing I need to extend the ends of he cable in the console as a starting point. Maybe that would give it more room to bottom out? Could be the end in the floor too. Did anyone else have to make adjustments like that? This job seems to be almost done! What a pain in the butt but still better than de-installing the cab Hope this helps someone else when they dive into this job. Tried to document it well. Here are some pics of what I did.    ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: AllisFreak MN

Date Posted: 07 Nov 2020 at 10:09am

|

In my case the Hi Lo cable didn't need much adjustment but the park cable gave me a little trouble. I had the ball ends screwed on to the cable until they ran out of threads and still needed a little bit more to make it shift smoothly into park. I ended up cutting off about 1/8" of the threads on the console end of the cable and re installed the ball end and that gave enough adjustment to shorten the cable and the park lever works beautifully now. I think 45 years of wear in the range lever was the cause of this problem as there was a little more slop than the factory length cable could adjust for.

------------- '49 A-C WD, '51 A-C WD, '63 A-C D17 Series III, 1968 A-C One-Seventy, '82 A-C 6060, '75 A-C 7040, A-C #3 sickle mower, 2 A-C 701 wagons, '78 Gleaner M2 |

Posted By: calico190xt68

Date Posted: 07 Nov 2020 at 6:00pm

|

Thanks allisfreakmn. Turns out that my low range works but my high range will not go into high gear. So my logic is that I need to extend the cable under can first. This should allow it to click into high. After I adjust that we will see. I only want to adjust one end at a time. This may allow it to botom out on low. Seems before I fixed it I had trouble with low. That cable was shot. ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: plummerscarin

Date Posted: 08 Nov 2020 at 5:14am

| If I understand correctly, it go into high because you are at the end of travel on the shifter? The service manual I had says to center the shift lever in the slot, the hi/lo trans lever in neutral and adjust cable to fit. I think you have cable adjustment too long? |

Posted By: DrAllis

Date Posted: 08 Nov 2020 at 6:54am

| Remember !!! Center neutral in the gate before anything else !!! Sometimes the shifting teeth aren't quite aligned keeping it from going into gear !! Engine running helps or rock the tractor a bit which is very hard to do. |

Posted By: calico190xt68

Date Posted: 09 Nov 2020 at 8:53am

|

I went back and adjusted the cable and I believe I have it fixed now. I ended up screwing both of the ends half way between the threaded part of the cable end. Previously I had them both screwed all the way back. Probably should have started there to begin with. Turns out that the shift lever when going to low gear was going back and staying, but it wasn't engaging the low gear. The high gear was engaged for the tractor to move but the shift lever wouldn't bottom out in high gear. Once I extended both ends of the cable halfway on threads, the shift lever is going into high and low all the way down and up and staying put. I need to put it on a hill and shift into park make sure that is working. I didn't see above posts related to centering the lever but I did that by accident. I need to get a service manual obviously. In my case the cable was too short because the ends were not screwed out enough. I need to drive it around a bit more though to feel good it is finally fixed. Now I have to tackle the 1-3,4R gear cable. Looks like you swing the battery and disconnect underneath cab. The console disconnection looks a little tricky but I didn't study it very long. I am guessing you thread the cable from underneath the cab into the console. Plummerscarin, what does service manual say about it? I am also suspecting that my hardware in the cab related to the twist handle is a little loose or worn or both. Seems like when shifting from 123 back to 4R it is getting in a bind. Sometimes you have to double pump it and I am not sure it is the cable, however I will find out. It was good getting the tractor moving again. Thanks for all of the help and support! ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: plummerscarin

Date Posted: 10 Nov 2020 at 6:09am

| I had to give the service manual back but what I remember is similar to hi/lo cable. Center the shift lever and adjust. I also remember on my 7045 that there is mechanical linkage for gear selection and I cut a 1/4" off the threaded rod to gain more adjustment. I know cutting some off seems a hack job but there is slop in the bushings and levers and don't know if new replacements are available. Otherwise weld and drill new holes. |

Posted By: DrAllis

Date Posted: 10 Nov 2020 at 6:32am

| Fore and aft movement is all thru iron linkage and ball sockets. The small cable only moves things side-to-side when in the neutral gate. |

Posted By: calico190xt68

Date Posted: 10 Nov 2020 at 8:17am

|

Thanks guys. I looked into the service manual. They want $152 for one. I am going to put that on my xmas list. I think after replacing the shift cable, I am going to have the same problem. The side to side movement as the handle is twisted is working just fine as I observe with the floor removed. It is the up and down movement which is catching occasionally. I don't think lubrication is going to help either but I may try something. I am going to observe the linkage parts by doing some more shifting while it is still opened up to see if I can identify the culprit. I would think used parts would have the same problem unless it was a very low hour tractor but then a low hour tractor shouldn't be in parts. Agco surprises me on what they have sometimes though. First, gotta figure out what is sticking. I am pretty confident that the hi/lo shift has improved for me with new cable and adjusted properly. I do wish Bunker Hill had created those cables in black rather than purple. I have one purple cable now and the rest are black. I supposed I could have painted it. Once I figure out the shifting slop issue, I will start a new thread. ------------- 80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

calico190xt68 wrote:

calico190xt68 wrote: