WD lift arms - pump or seal issue

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=174054

Printed Date: 07 Nov 2025 at 8:43am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: WD lift arms - pump or seal issue

Posted By: cooz65

Subject: WD lift arms - pump or seal issue

Date Posted: 03 Sep 2020 at 9:35am

|

Hey Guys, I'm venturing into an area I'm not real familiar with - hydraulics. I just picked up a 3 point conversion (got a heck of a deal!) but before I can plug it in to the snapcoupler - I need to get the rear lift arms to hold. Push the lever up - arms go up. Lever in the middle, hold position, I can push the arms down, not easily, but if I can with my hands, any couple hundred pound implement surly can drop them. Lever at the bottom, and they push in easily, gravity fed I've read so that makes sense. Now before we get in to the lift arms and the hold position, I've read a lot about the adjustments on the pump, I want to clarify one thing. I have a bucket for this that the hydraulics plug in to the rear auxiliary port (not sure if that is the right terminology). When I have the bucket raised, with dirt in it, so quite a bit of weight hanging out there, and the lever is in the middle, hold position, that bucket does not drop. Will stay up all day long. So that makes me question if I have a pump related issue, or the seals in rear lift rams have gone bad. Just looking for areas to start trouble shooting. Thanks

|

Replies:

Posted By: SteveM C/IL

Date Posted: 03 Sep 2020 at 10:30am

| Both are plumbed into same hold valve. If it holds loader it should hold arms. If seals are leaking it will be pouring oil to the outside. They are one way push cylinders. What you're stating doesn't make sense. |

Posted By: cooz65

Date Posted: 03 Sep 2020 at 11:02am

| When I got the tractor from my Father-in-law this spring, it had been sitting for 10+ years. The rear arms only had about half of the range of motion. They wouldn't go all the way in. I was able to slowly work everything back and forth to regain that full range of motion. However since I've been having this issue of not holding, I have not noticed any oil leaking out of the rams. Which you're saying if the seals were bad, I should see oil leaking from the rams. |

Posted By: CTuckerNWIL

Date Posted: 03 Sep 2020 at 11:47am

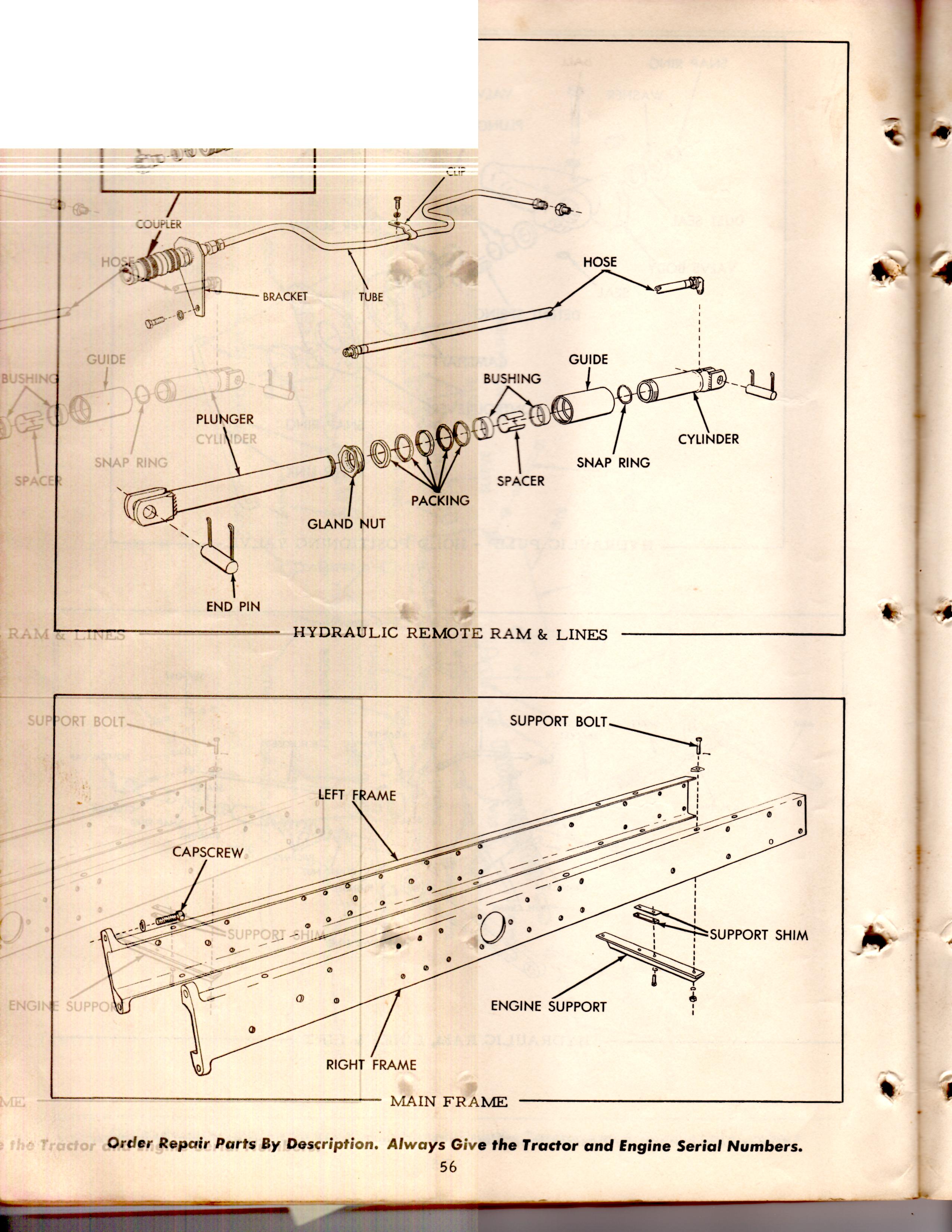

|

That's right. There are no pistons or seals in those cylinders. There is just a rod with a snap ring on the bottom to keep it from coming out, and a packing nut on the cylinder. There is nothing internal that can let it leak down. If you plan to use a 3 point, you will have to block the loader up and unplug it from the tractor, or install a diverter valve to direct pressure to either the lift arms or the loader.  ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: DrAllis

Date Posted: 03 Sep 2020 at 6:13pm

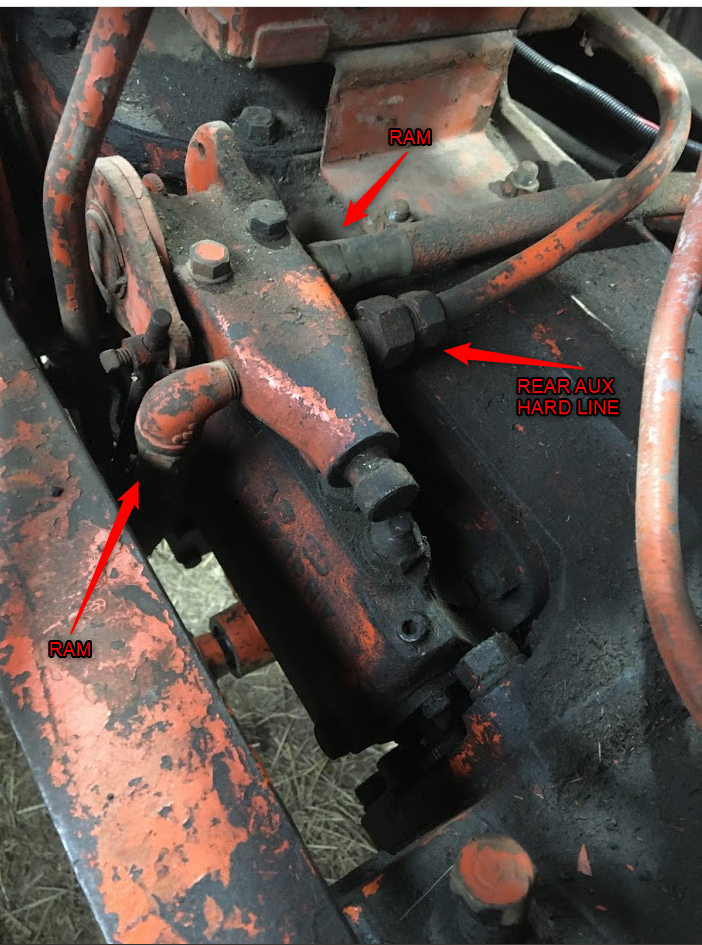

| The "hold" position only blocks one of the two lift arm cylinders and I think it is the right lift cylinder that actually holds. The right lift ram hose should be connected to the right side of the hold valve. The left lift cylinder should be connected to the left side of the hold valve at the REAR port. The remote outlet (loader) connects to the LEFT side of the hold valve in the FRONT port with a steel tube running under the battery box and coming out under the seat. Anything that has been replumbed or jury-rigged in a way that isn't OEM is possibly the issue. Also, you must have the hydraulic pump actually set/adjusted for the "Hold" position, which I think you do. I just think hoses/lines are NOT connected correctly. |

Posted By: SteveM C/IL

Date Posted: 03 Sep 2020 at 6:20pm

| Forgot about the ram plumbing for delayed cultivator lift. When I hung an RG630 on the back of my 45,I plumbed both cylinders to the hold side with a tee. Otherwise the lift shaft twisted and drooped one side when holding. |

Posted By: cooz65

Date Posted: 08 Sep 2020 at 1:57pm

I checked over the weekend and the plumbing is done how DrAllis had said. If only one side truly does hold, I do like what Steve had said about plumbing them both to one side to keep it from twisting. I talked with my F.I.L and he was talking about setting it up for the hold position, but after looking in the manual, it appears that it already is, and since the loader holds, I'd have no reason to believe it isn't. Right now I don't have the loader plugged in. I took it off for the summer as I only need that in the spring time to scoop the padock, so I don't plan on using both the loader and 3 point at the same time.  |

Posted By: SteveM C/IL

Date Posted: 08 Sep 2020 at 8:06pm

| I put a Tee where the outside elbow is and used the elbow in the tee to hook other hose to. I got some JIC fittings to make the hose connections easier. |