Switching to negative ground

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=169557

Printed Date: 18 Dec 2025 at 1:54am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Switching to negative ground

Posted By: Mdguy

Subject: Switching to negative ground

Date Posted: 28 Mar 2020 at 1:21pm

| On my D17 I’m switching to negative ground. From what I’ve read I switch the wires on the ammeter and flash the regulator. How would I flash the regulator I have done it before when I replaced the voltage regulator few years ago but I’m assuming it’s different when switching to negative ground? Reason I’m switching is the battery has been borrowed from this tractor few times by my brother or nephew when they have been working on cars and even when I’ve told them it’s positive ground usually the battery is hooked up wrong. Getting old replacing voltage regulators. So just want to make it “normal” with modern times. Thanks |

Replies:

Posted By: Boss Man

Date Posted: 28 Mar 2020 at 3:42pm

| same weather pos or neg. |

Posted By: Krazy Karl

Date Posted: 28 Mar 2020 at 5:20pm

|

Also got to switch wires on coil |

Posted By: Sugarmaker

Date Posted: 28 Mar 2020 at 6:46pm

|

Maybe consider going to a alternator (Denso type) and eliminating the voltage regulator all together? Maybe a little more work but it would be up to date then. I use a volt meter rather than a amp meter. But that's just me. My 17 is still working well with the positive ground and original generator and voltage regulator. But if when it stops working it will be switched over to alt, negative ground. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Mdguy

Date Posted: 28 Mar 2020 at 8:15pm

|

Dumb question but the few times it has been hooked up negative to ground and I have used it it’s always ran fine without switching wires on the coil. Like using it in a pinch to put hay out or something. Just curious why the wires on the coil would have to be switched. Some research I’ve done on other forums have said need to switch wires on coil and others have said no need to switch wires. Just was wondering if there’s a specific reason the wires needed to be switched. Thanks again |

Posted By: AaronSEIA

Date Posted: 29 Mar 2020 at 6:20am

|

I think not switching the coil wires makes for a much weaker spark. Don't ask me how. AaronSEIA

|

Posted By: Stan R

Date Posted: 29 Mar 2020 at 6:29am

| I'd consider changing out your system to an alternator system with electronic ignition (negative ground). I converted our D17 IV last spring and have no regrets. Lot of wiring gets yanked out with that conversion. |

Posted By: Rick of HopeIN

Date Posted: 29 Mar 2020 at 8:29am

|

I have a electronic ignition on the D14, that is now running 12V positive ground. If I switched it to neg ground someday I would have to change the electronic ignition module. Most of them are ruined if you reverse the polarity. Don't ask how I know. Never thought about the coil polarity. I was not aware it made any difference. I know the old car guys always add a coil resistor when they switch to 12 volt. ------------- 1951 B, 1937 WC, 1957 D14, -- Thanks and God Bless |

Posted By: DaveKamp

Date Posted: 29 Mar 2020 at 9:51am

|

The coil polarity is a point of disagreement in many. With a point-condenser ignition, there were some (earlier) condenser designs that tended not to last long with the battery polarity reversed... and the plating on contact points was chosen and positioned in an attempt to reduce the rate of deposition and erosion as electrons attempted to pass during opening. Most of this is a moot point now, as neither modern condensers nor points are worth a crap, they don't last long regardless  The next point is actually how it affects (or doesn't) plug electrode temperature. Just like in DC welding, the flow of current focuses the arc heat either towards one side of the gap, or the other, based on polarity. The heat, being directed towards the grounding electrode, would cause it to be receiving the arc heat, rather than the center electrode and insulator. It's the latter which is designed to manage plug temperature, so if the alleged heating-direction theory were true, the engine would not respond much with change of heat range, and it would suffer preignition by virtue of the overheating grounding electrode. The final point, is how the coil is wound inside, and at which point the coil is grounded. For a variety of performance reasons, most ignition coil is actually made more like an autotransformer, and the secondary windings carrying spark current are SHARED with the primary, such that when the points open, the primary and secondary are both carrying spark current. There are three ends to the circuit- the high voltage tower, the coil + terminal, and the coil point (-) terminal... and then there's the coil case, which is, by virtue of the bracket holding it, also grounded. The internal windings are at very high voltage in some areas, and those areas are wound to be in farthest proximity to the coil case, so it doesn't internally arc... the primary (contact point current) is usually closest. The concern for coil polarity (and it's probably well founded in some coils, but not others) is that running polarity reversed would place the HV component within reach of arcing to the case, because the electromagnetic polarity occurring across the polepiece is 'directing' the electrical flow in the opposite direction (towards a grounded surface, rather than the insulated spark tower). This is simply because an electric arc can be 'directed' with a magnetic field. (If you do a bit of welding, and your arc won't go where you want it to go... one of the reasons why this happens, is because there's some strong magnetic field, either in the parent metal, or in the vicinity, that's pulling the arc to one side or the other. in DC welding, it will 'drift' either towards, or away from the magnetic field, and in AC welding, the arc will splatter right-to-left in line with the field). But the GENUINE argument, is that in theory, everything matters, but in practice, some of it not-so-much... and that is because in the scheme of things, there are much more significant variables elsewhere, that make coil polarity too insignificant to yield commensurate performance variability. I've seen tractors run both ways. I've seen coils live, and I've seen 'em die... and the worst, are ones that won't die, but they don't live well... which is hell... when you're a half-mile through a mostly-plowed field, and it's starting to rain.  ------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: Mdguy

Date Posted: 29 Mar 2020 at 10:51am

| To switch to an alternator is there a wiring diagram that anyone has that they can post. I’m no electrician or even mechanic so something that be easy to follow so I won’t mess anything up. |

Posted By: AaronSEIA

Date Posted: 29 Mar 2020 at 11:09am

|

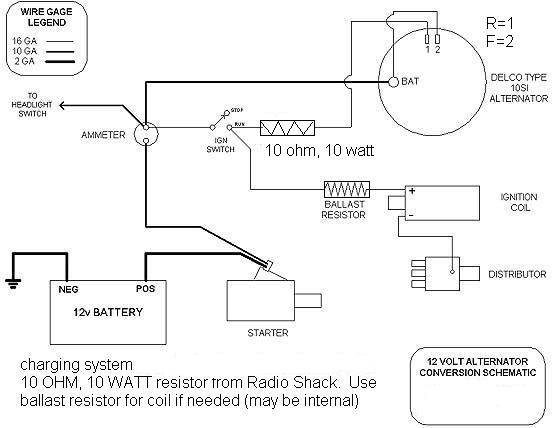

This is the one I used. I put a diode in where they show the 10 ohm 10 watt resistor. An idiot light would work as well. AaronSEIA  |

Posted By: AC Steve

Date Posted: 29 Mar 2020 at 12:01pm

| Also the positive and negative posts are a different size. So to do the conversion right you need to change the cable ends or the entire cable.. if I had a vote I would keep it original. |

Posted By: Steve in NJ

Date Posted: 29 Mar 2020 at 3:27pm

|

That diagram is a pretty simple diagram. The only thing I would loose is the ballast resistor and install a coil with the resistor built inside so Mother Nature doesn't mess with it. Speaking of coils, 4 cylinders on 12V's need 2.7-3.3 ohms of resistance in the ignition circuit, so a 3.0 ohm coil will fit the bill. Also, Alternators and Ammeters don't mix well. A Voltmeter is much safer. With a Voltmeter the wiring would be run a little differently. Any questions drop me an e-mail. Be glad to help ya out if you decide to change over to 12V. I also offer complete 12V conversion kits to if interested.... Steve@B&B bb-customcircuits.com ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: bendts

Date Posted: 01 Aug 2020 at 6:21pm

|

Also plan to switch mine to a positive ground - But what about the starter? ------------- 1960 D17 Gas # 28849 |

Posted By: jaybmiller

Date Posted: 01 Aug 2020 at 6:26pm

|

Starters are not 'polarity sensitive'....kinda magical that way... However hitting a 6 volt starter with 12 volts does make it spin faster..so far after 20 years of abuse 'Troy' is still happy.... ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: bendts

Date Posted: 01 Aug 2020 at 6:28pm

|

OK Great - I was wondering about that as I never see anyone mention the starter in the conversion. ------------- 1960 D17 Gas # 28849 |

Posted By: jaybmiller

Date Posted: 01 Aug 2020 at 6:50pm

|

To be a 100% 12 volt conversion, you 'need' to repalce with a 12 volt starter or have yours converted ( swap field coils, maybe armature ?). Steve @B&B will know for sure. Rumour has it he can do the conversion in his sleep.... Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: bendts

Date Posted: 01 Aug 2020 at 7:08pm

Yup already have the 12v starter. Already started the re-wire as it came with an Alt also - but the owner had the wiring all copped up. ------------- 1960 D17 Gas # 28849 |

jaybmiller wrote:

jaybmiller wrote: