AC Mower 80S or 82S?

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=168238

Printed Date: 06 Sep 2025 at 9:31pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: AC Mower 80S or 82S?

Posted By: AC720Man

Subject: AC Mower 80S or 82S?

Date Posted: 11 Feb 2020 at 6:43am

|

Just purchased a side mount mower for my WD. How do I tell if it’s a 80S or a 82S? This is a trip mower. PTO shaft attaches to a rear mounted assembly driven by a drive belt off a pto pulley. That pulley also has a male shaft that can power a pull behind hay conditioner. Need to order a manual for it. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Replies:

Posted By: Gary(VA)

Date Posted: 11 Feb 2020 at 6:54am

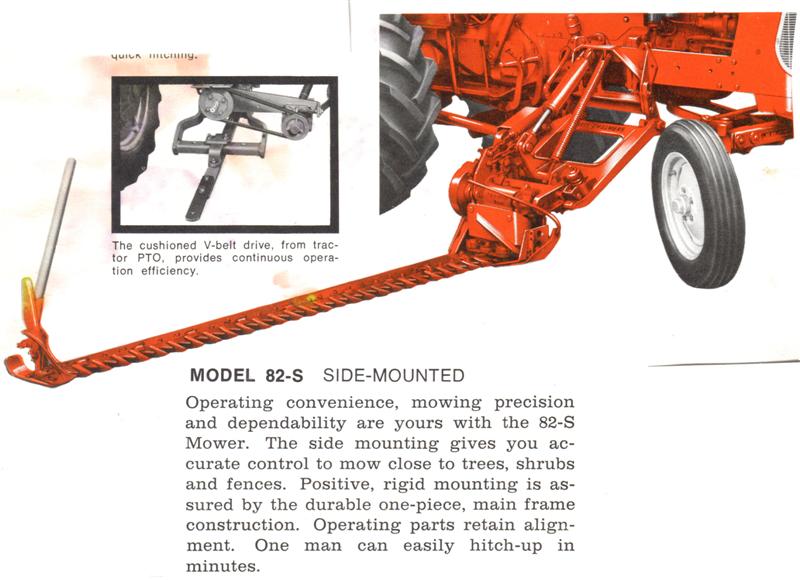

| 80S has frame that goes back to drawbar mounts. 82S mounts just to siderail and only PTO shaft goes back. If it's a 80s I may have a manual and some extra parts you can have. |

Posted By: AC720Man

Date Posted: 11 Feb 2020 at 7:34am

|

It has the mounting plate that bolts to the frame only on the right side. So I guess it’s a 82S. PTO shaft is the only part going towards the rear of the tractor. The drive assembly slides over the pto shaft on the rear of the tractor and bolts to the hitch. Thanks Gary ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: AaronSEIA

Date Posted: 11 Feb 2020 at 7:38am

|

Side mounted frame is 82S. Huge box frame is 80S. AaronSEIA

|

Posted By: Mikez

Date Posted: 11 Feb 2020 at 9:02am

| Isn't the 80 cable lift and 82 hyd lift. |

Posted By: Gary(VA)

Date Posted: 11 Feb 2020 at 9:07am

| Yes, 80 has a cable that runs back to the lift arm. |

Posted By: AaronSEIA

Date Posted: 11 Feb 2020 at 9:07am

|

Yes. The 82 has the small side mounted frame. The 80 has the massive rectangle frame that mounts front and rear. The 82S really is a side mounted mower. The 80S is more of a mid mount. 80S is really hard to mount and the 82S is hard on radiators. AaronSEIA

|

Posted By: Brian G. NY

Date Posted: 11 Feb 2020 at 10:21am

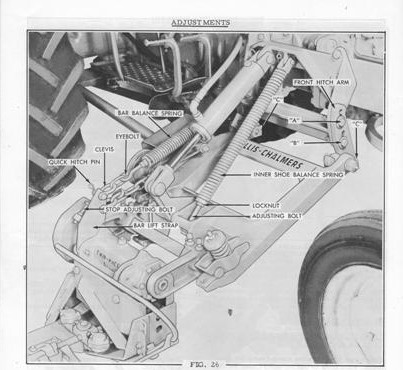

You didn't explain.....I'm assuming because it might have a tendency to twist the frame? I have an 82S on a WD-45 and haven't had that problem. However, I did attach a link to the LH frame to provide more lateral support. The 82S is far and away the better mower not only for ease of installation but because improvements were made in the hinge system using ball bearings, increased thickness of the bar from 5/8" to 3/4" and a much heavier "cage" around the gear box. Some of the later 80S mowers may have also benefited from those improvements but I'm not sure. The 82S has its own hydraulic cylinder which gives it the ability to be raised fully vertically right from the seat.   |

Posted By: Gary Burnett

Date Posted: 11 Feb 2020 at 10:56am

|

I've never seen a 82S that would raise completely vertical,only the 82SI would do that I think. |

Posted By: Brian G. NY

Date Posted: 11 Feb 2020 at 11:21am

|

Believe me, they can be "tweaked" to do it. I don't know whether or not they are supposed to do it....I messed with the chain lengths a bit to make it happen. Where I mow, it makes life a lot easier and you can 'trim" the small limbs on trees while you're mowing.

I don't even have a support rod on mine. I cut my bar down to 5-1/2' to get around the scrub apple trees easier which probably makes it pop up a bit easier. |

Posted By: AaronSEIA

Date Posted: 11 Feb 2020 at 11:53am

You didn't explain.....I'm assuming because it might have a tendency to twist the frame? I have an 82S on a WD-45 and haven't had that problem. However, I did attach a link to the LH frame to provide more lateral support. Dad shook the radiator out of his WD twice running one. Just too much vibration hanging off the frame. I'm sure I'll be told his is the only machine that ever happened to. In my experience none of the 80/82 mowers as balanced as they needed to be to run smooth. AaronSEIA

|

Posted By: Brian G. NY

Date Posted: 11 Feb 2020 at 12:05pm

|

In my experience none of the 80/82 mowers as balanced as they needed to be to run smooth. AaronSEIA [/QUOTE]

They run fairly smoothly when everything is set up correctly......I thought cutting a foot and a half off the cut bar might cause some balance problems but its not noticeable.

|

Posted By: Gary Burnett

Date Posted: 11 Feb 2020 at 12:28pm

|

I've run 82S mowers on a D19 and a D14 never seen where it had more vibration than any other sickle mower.What will cause excessive vibration is running a dull sickle,which I always ran a sharp one,new sickle assembly at least every year and never tried to run one that was so called 'sharpened'. |

Posted By: Charlie175

Date Posted: 11 Feb 2020 at 12:49pm

What? Dad would grind the sickles and reuse them as long as he could.  ------------- Charlie '48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD |

Posted By: Brian G. NY

Date Posted: 11 Feb 2020 at 4:33pm

|

Neighbor farmer used to loan me a mower tractor every year to clean up around the property before I had a tractor of my own. The first one was an 8N with a side mounted Dearborn sickle mower that also raised vertical with hydraulics. Then, he got this nice D-17 with an 82S mower which he also loaned me. The one thing that always amazed me was how he cut straight corners without stopping. I had always thought that was possible only with a rear mounted mower. When he came to a corner, he would pull the PD into low, hit the right brake and give the wheel a quick turn and the bar would come around and make a perfect corner without leaving a stalk of hay. Power steering was a big help in making this possible. This picture of me on the borrowed tractor was taken in 1965.  |

Posted By: AC720Man

Date Posted: 11 Feb 2020 at 7:50pm

|

Charlie is correct, dad sharpened the whole bar on a narrow bench grinder. No teeth left and it still mowed well. I’m replacing all the knives and attaching with bolts instead of rivets. So much easier and quicker to service the bar. The mower has the hydraulic lift. From a picture I found on the ole web, the mower mounts farther forward than I would have thought, Charlie said probably due to the trip ability which makes sense. Looking forward to getting the manual and installing it to see how it does. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: Gary Burnett

Date Posted: 12 Feb 2020 at 5:41am

|

Most people I know that sharpened sickle bar mower sections quit using a sickle bar mower and went to a haybind because the mower wasn't getting the job done.I still cut all my hay with a sickle bar mower and get it cut just fine. No amount of sharpening will get the section back to cutting like it was when it was new.I have bought a lot of sickle bar mowers over the years that I assume were being used to cut hay of some sort and I have never bought even one with a blade in it that I would take to the field to cut hay.Even a slightly dull sickle will cause all sorts of problems.And I'll take rivets over bolts too but that is another discussion.

|

Posted By: Charlie175

Date Posted: 12 Feb 2020 at 5:58am

|

Granted, ours was mainly used for pasture mowing and other stuff later in life after dad got the 390. ------------- Charlie '48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD |

Posted By: Charlie175

Date Posted: 12 Feb 2020 at 6:00am

|

Not to hijack the thread, but dad's mower is a 80R3 that he bought new in 1968 along with the D15. Looks like the R3 came out in 1963 but it looks like it was still made for a good while overlapping the 82 series? ------------- Charlie '48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD |

Posted By: Farmerjim

Date Posted: 12 Feb 2020 at 8:22am

| I have a 82s but no mount for my D17, if anyone has one. |

Posted By: AC720Man

Date Posted: 12 Feb 2020 at 10:03am

|

Gary, I am using bolts instead of rivets for the pure ease of replacing them in the field. Loose rivets or a broken knife requires the removal of the bar to repair. Can be repaired in the field I guess but not so easy. By using bolts I can remove the guard at the effected area, replace the knife and be on my way in 10 minutes or less. Originality is gone, but the time and aggregation it will save me means more seat time on my WD with a smile. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: Gary Burnett

Date Posted: 12 Feb 2020 at 11:19am

What I do is to buy riveted blades they are cheaper and I think the riveted section don't break out as easy.When a section breaks out I take the guard off with an impact.drive the rivet out the blade and knock bolts into the section .Then put the section in and the nuts will be on the bottom so no tall hold downs are needed.plus if you notice the unthreaded part of the bolt goes beyond the section and into the blade since the section is thinner giving a more secure fit.

|

Posted By: Gary Burnett

Date Posted: 12 Feb 2020 at 11:38am

|

I'll add the New Holland guards that are on the NH 456 mower I'm now using don't have quite enough clearance for the nuts on the bottom and have to have about 1/8 inch ground off.But AC guards are made a little different and the nut has good clearance so since I have several hundred AC guards around here I'm putting them on the NH mower as needed.

|

Posted By: tomstractorsandtoys

Date Posted: 12 Feb 2020 at 12:52pm

|

As far as the radiator problem maybe you could make a bracket to attach to the opposite side of the tractor and come under it and strengthen the existing bracket. I have a Deere No. 10 mower on my 2510 and that is how my brackets are.I also have an 82s for my D15 but it needs some work to use again. Tom |

Posted By: WD45

Date Posted: 12 Feb 2020 at 3:16pm

|

We have 82S on a D15 Series II. Does good job cutting ditch banks etc. ------------- Fred Dunlop, G,B,CA, WC,WF, 3 WD45`s,gas, diesel and LP,U,D10 series III, D12,D14,D15 SERIES II,D17 Series IV in Gas and Diesel ,D19 GAS and D21,170 185,210 ,220 an I-600 8070 fwd, 716H and 1920H |

Posted By: AC720Man

Date Posted: 12 Feb 2020 at 4:20pm

|

Picked up some really nice Herschel knives for it today. Much better quality than TSC sells and less expensive which shocked me. Hoping to have it mounted by next weekend. Still need to get 2 new belts. One pto locking pin was broken and SLI shipped it out today. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: AC720Man

Date Posted: 15 Feb 2020 at 6:19pm

|

Installed the side mount today. Working on installing the rear drive assembly also. At over 600 lbs seams like a lot hanging off the frame. Ordered 2 new drive belts, should arrive next Wednesday. Sickle is almost complete, waiting on 10 more knives to arrive. Anyone have a rear safety shield for sale? ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: Gary Burnett

Date Posted: 16 Feb 2020 at 6:39am

|

Put a couple extra weights on the rear left wheel,you'll need them on a hill if you raise the cutter bar. |

AaronSEIA wrote:

AaronSEIA wrote: