7045 Front Axle Spindle Assy

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=167889

Printed Date: 11 Sep 2025 at 5:34pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 7045 Front Axle Spindle Assy

Posted By: Tbone95

Subject: 7045 Front Axle Spindle Assy

Date Posted: 30 Jan 2020 at 2:50pm

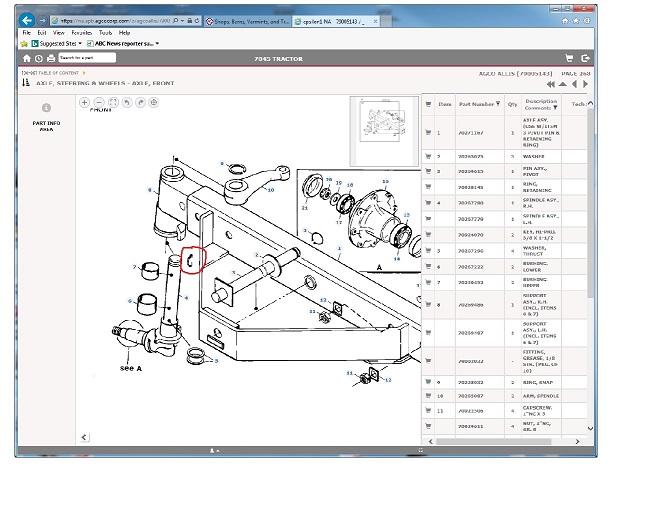

Both front wheels wobble something awful. It is not in the tie rods or steering cylinder or anything like that, because the slightest movement of the steering wheel pulls on the steering arms. You then have to move the steering wheel a LOT to actually begin to move the wheels. I'd like to get it fixed if I can before planting season. So this is from Agco parts obviously. What am I looking at for wobble? Just that key I circled in red, and a keyway in the spindle assembly??? What kind of $$$ do you suppose I'm looking at?

|

Replies:

Posted By: Dave H (NE)

Date Posted: 30 Jan 2020 at 3:07pm

|

Jack up the front end. move the wheels by hand you should see what is worn. if the arm is not tight on the spindle to fix it right you would need the spindle and arm. |

Posted By: bigal121892

Date Posted: 30 Jan 2020 at 5:25pm

| You are probably going to need to replace the bushings, items 6 and 7. You may also need to rebuild the key ways, on the spindle and the spindle arm. The spindle arm will need to be pulled off. If you try to press the spindle out, you will push the key into the side wall of the spindle holder, and can cut a grove all the way down the side. |

Posted By: MACK

Date Posted: 30 Jan 2020 at 9:14pm

|

I would say spindle shaft is worn out where bushings run. I have built them up and turned back down. There is probably ware in tie rod ends along with cylinder bolts and bearings. A little looseness in each will add up to slot. MACK |

Posted By: Tbone95

Date Posted: 31 Jan 2020 at 6:53am

|

Well, in usual assemblies like that, a guy would probably replace the bushings as a matter of while you're in there you might as well. What I don't understand though, is how that would create wobble in this direction. I can see it being worn to where your spindle clatters around in the housing because of the wear clearance if jacked up or driving. This is only (or majority of) in the plane of steering. With the tractor parked and running, turn the steering wheel, IMMEDIATELY all the way from the steering cylinder, tie rods, and the arm all responds. The arm then sweeps quite and arc, 20 degrees or more it seems, before it begins to turn the wheel. I realize I'll just have to take it apart and study it......But my question remains, is that one key at the top of the spindle in the spindle and arm the only thing that holds rotation? That, and the squeeze of the arm??

|

Posted By: Acfarm

Date Posted: 31 Jan 2020 at 1:12pm

|

I have seen both where the bushings being worn and the keyway being rolled can contribute to steering slop. I had one tractor I purchased where the previous owner had actually welded the tops of the steering arms to the spindles. |

Posted By: SteveM C/IL

Date Posted: 31 Jan 2020 at 6:32pm

| The key and the fit are it.....My 220 had loose and worn arms when I got it. Wore the spindle too. I welded and turned the bushing areas but didn't mess with the arm area. To fix that right it would need welded and turned and a key way re-cut but how to you address the worn arm? I don't remember for sure but I believe the arm was NLA. Anyway,the farmer fix was to weld the arms on and keep it greased. The arms on my 8070 are nice and tight even after pounding them off and on when repairing the spindle bushings and shafts. I'm guessing the larger spindle shafts helped the 7-8000 series to stay put plus maybe they gave them a tighter fit. Haven't been around that many 7-8000's to know if they had problems but I've not seen one. |

Posted By: DSeries4

Date Posted: 31 Jan 2020 at 9:49pm

|

You will not know until you tear into it. I am going through it

on my D21 right now. I knew the key on the left side was sloppy and

when I removed the right tire to paint the rim and put new rubber on, I

noticed a huge amount of wear in the spindle bushing on that side. Safe

to say they are all getting addressed now. The tie

rods were perfect, no slop at all - just bent! The balls and sockets on the

steering cylinders were well worn too - could make a slight difference.

Go through everything and fix what ever seems sloppy.    ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: MACK

Date Posted: 31 Jan 2020 at 9:53pm

| The knee is too short, causing too much wear on bushings and spindle shaft. Deutz had some ugly spindles with top bushing above axel, but didn't wear out. MACK |

Posted By: BigGuy1000

Date Posted: 31 Jan 2020 at 10:30pm

|

This happened to our 175D WF. The keyway in the spindle has been "wallowed out" as the old time mechanics would say. New spindle and arm and key are available from Agco dealer and others who advertise here but are poor quality(Chinese A&I). If you can find a good machine shop in your area, they can weld and remachine both and you would still have the original AC quality parts. Now comes the tricky part: this is designed to be done as a "shrink fit" where the arm is heated to 700F so that it expands enough to go onto the spindle when hot and shrinks TIGHT when cool! This is necessary because the small half moon key and keyway is not enough to hold against the torque which the wheel applies to the spindle, without motion, which will wear the keyway and key. (The engineers call this an "interference fit"). For this size spindle, machine the arm to .002 in. undersize. (The new Chinese arms are too undersized, they must be machined too.) Then get out your propane or charcoal grill and heat the arm for an hour at 700F. Grab arm with vise grip, put the key in place on spindle, arm will slide down over the spindle and key, may need a tap of small hammer also, make sure down far enough for snap ring clearance. Let cool, it's TIGHT! Amazing part is that most of these arms are still tight after 50+ years, only a few were improperly installed at AC, too loose! |

Posted By: DrAllis

Date Posted: 01 Feb 2020 at 6:57am

| Since the beginning of the D-series, the spindle and spindle arm design has remained pretty much the same. A very HARD key (Hi-Pro key) and an interference fit of the arm onto the spindle. If you compare to competitors designs (IH and Deere) of a tapered splined arm with a nut on top, you should appreciate what AC did. It was relatively cheap to build and honestly worked pretty well for 80% of the tractors built. When you drop a front wheel in a hole or use the tractor for a lot of abusive loader work, you could find the arm loose on top of the spindle. I guarantee the Hi-Pro key will be fine, but the keyways in the arm and spindle will be damaged. Welding the arm to the spindle (minus the snap ring) has been a common repair, because technically, both parts are junk, so why not?? As long as the spindle bushings aren't worn too bad, it's a good fix in the sense that things are now tight again. Something that could be tried is heat the arm quickly with a rosebud until it is quite red around the spindle and then let it cool down slowly. This will shrink the arm hole, and if the wear isn't too bad, fit tight again with the keyway still damaged. Like welding, make sure you have the arm positioned/degreed where you want it to be when cooled down. This would actually be a good thing to do if you intend to weld, as it would make the arm tight and then the weld has a better chance of keeping it tight. |

Posted By: Tbone95

Date Posted: 01 Feb 2020 at 4:45pm

| So welding that, it is cast, correct? |

Posted By: DrAllis

Date Posted: 01 Feb 2020 at 7:45pm

| Cast steel. Very easy to weld. |

Posted By: MACK

Date Posted: 01 Feb 2020 at 9:30pm

| Split the arm down the side then weld the split will make it even tighter. MACK |