lubrication of track rollers?

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=167056

Printed Date: 05 Feb 2026 at 11:37pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: lubrication of track rollers?

Posted By: scooper

Subject: lubrication of track rollers?

Date Posted: 31 Dec 2019 at 9:11pm

|

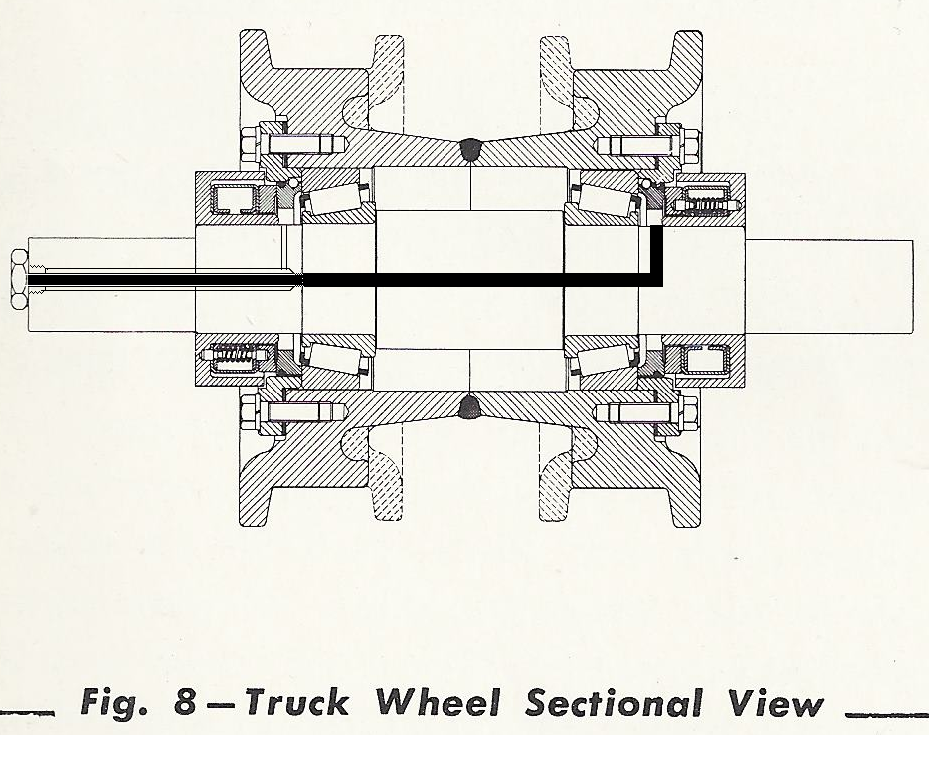

HD 16 cable dozer Question. bottom track wheels have no grease zerts or plugs only way I can see how to lubricate is to work a grease needle into bearings Any other suggestions?

|

Replies:

Posted By: JC-WI

Date Posted: 31 Dec 2019 at 10:44pm

|

No grease zerks or plugs? Some had button zerks like this, Some used a plug at the end of shaft and put a tube in that screwed inside the shaft and pumped oil in until it flowed clean around the tube...  and others were just simply lifetime sealed rollers and when they went dry, their life was basically used up and you replaced them, or rebuilt them. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: DiyDave

Date Posted: 01 Jan 2020 at 4:56am

Some also used a square drive plug, the plug was located on the wear surface of the roller, smart, huh? ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: Ray54

Date Posted: 01 Jan 2020 at 1:59pm

|

When did AC go from 1000 hour greasing of rolles to sealed for life rollers. And sealed for life Cat rollers will live a second life time if you add cornhead or other lite grease as soon as you see a leak. The one I did not grease last 2 or 3 days before it was junk.

|

Posted By: scooper

Date Posted: 01 Jan 2020 at 8:48pm

|

When I dismantled the junk roller the shafts had no grease channels drilled in them Therefore they must have been lifetime sealed. I think I have a method to grease these lifetime sealed rollers I will post if I am successful

|

Posted By: Ray54

Date Posted: 02 Jan 2020 at 3:32pm

| I took a plug from a junk Cat roller drilled for a grease fitting and pumped it full. |

Posted By: scooper

Date Posted: 18 Jan 2020 at 9:32pm

That's what I did That's what I did First picture shows the space between the bearing races of a dismantled roller  |

Posted By: scooper

Date Posted: 18 Jan 2020 at 9:41pm

|

I will try to post sequential pictures first picture shows area between bearing races on a dismantled roller second picture shows where I drilled hole for grease fitting this can be done with roller still on machine

I drilled and tapped for a grease fitting on a non contact portion of the roller Used pneumatic grease gun 1 and 1/2 tubes of grease Removed grease fitting Sealed with socket type pipe plug         |