Wd45 Pto troubles

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=166716

Printed Date: 26 Jan 2026 at 5:02am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Wd45 Pto troubles

Posted By: Allis Wd45

Subject: Wd45 Pto troubles

Date Posted: 17 Dec 2019 at 2:37pm

|

So, long story I was running our Pto manure agitator with my Wd45 and the Pto shaft came apart when I was dumping a load of manure when I came back to the tank the tractors PTO shaft was bent and the Ujoint piece of the agitator shaft had beaten around on the back of the tractor until it bent the tractors shaft and the PTO was still in gear and it wasn’t turning. I tore it down lastnight and the small gear Intermediate gear is missing 3/4 of its teeth the idler gear is missing a few teeth and the slider gear is missing a tooth. So I’ll need a new intermediate gear, Idler and Sliding gear that engages the pto and the shaft. Would you guys recommend getting new gears or finding good used ones? I also have to get that intermediate gear off I have heard that you can remove the frame rail and get it through the hydraulic pump hole or split the tractor behind the transmission. What is the best way to get to it, it also leaks hydraulic oil into the transmission so I would like to fix that while it’s apart also. Thanks ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Replies:

Posted By: Sugarmaker

Date Posted: 17 Dec 2019 at 2:53pm

|

Allis WD45, Well I had all this stuff out of my last project. I dont know if new gears are avaialble Might try Alex, or Sandy Lake? Might have to find good used unit/ gears?? I believe you have to take the center section out That is between the bell housing and the transmission? I am not the expert on this I do have some pictures if that would help. If you want to change the seals, Which I did also now would be the time. Other things would be to review hand clutch condition and the main clutch too. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Sugarmaker

Date Posted: 17 Dec 2019 at 3:00pm

|

Here are some pictures if it will help. Maybe there are different ways to do this repair? Others with more experience will chime in. These may not help you? Sounds like you have a pretty good idea about changing the gears.     Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Rick

Date Posted: 17 Dec 2019 at 3:27pm

| Aaron...I believe I do have all three gears...message me. Rick |

Posted By: B26240

Date Posted: 17 Dec 2019 at 4:10pm

|

if all you had wrong was the intermediate gear you can change that thru the pump and pto holes without removing frame rail or splitting tractor work best with a helper but sounds like you have a long list to fix. Sugarmaker gave you good advice, time for fixing everything in the case.

|

Posted By: Allis Wd45

Date Posted: 17 Dec 2019 at 6:07pm

|

Okay, can I take it I can get the hydraulic pump wiggled out without taking the frame rail off. The only thing I want to fix inside the tractor besides the intermediate gear is the hydraulic oil leaking into the transmission. If it comes down to splitting it I will probably also do the clutches then too. What is usually the cause of Hydraulic Oil leaking into the Transmission? Thanks again Sugarmaker, Thanks for posting the pictures they help also. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Sugarmaker

Date Posted: 17 Dec 2019 at 7:55pm

|

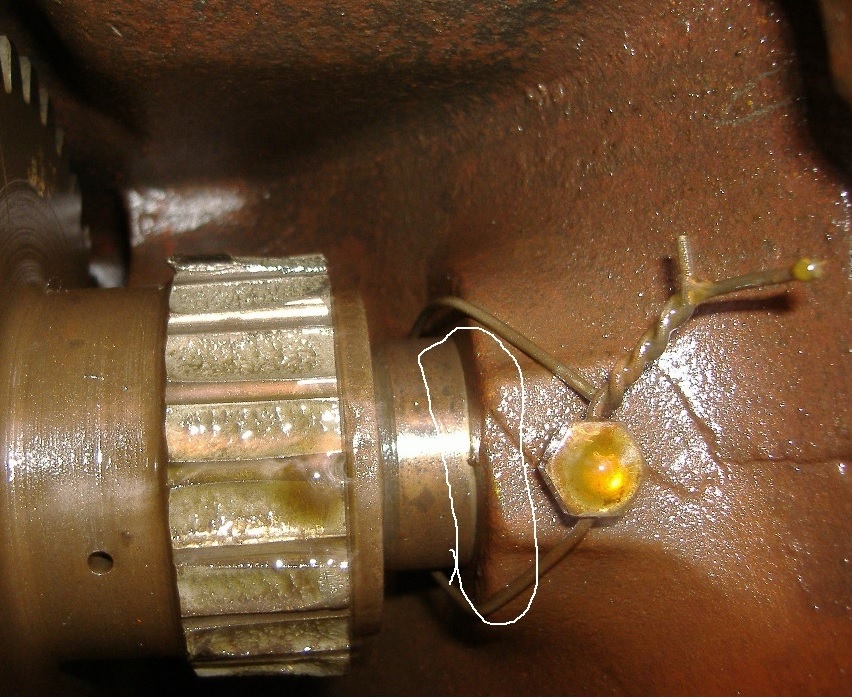

Allis Wd45, I believe the seals your asking about are around this portion of the main drive shaft. IIRC they are installed from the inside of the case. Also this picture shows how not to install the PTO gear system! Hint They have to go in after the bearing and upper drive gear are in place.  Regards, Chris

------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Bill Long

Date Posted: 17 Dec 2019 at 9:36pm

|

Allis WD45, I cannot help on replacing the intermediate gear since we did not have do that. However, one trick we used with the hydrallic pump removal was we usually flattened the end of some spikes, pushed in the hyd pump pistons and jammed them into the low position by using the spikes as a wedge. That gives you a little more clearance to get the pump out without removing the side rail. In fact, if you wiggle it right you can get it out without jamming the vales down. I have to agree with what is said above that, if you intend to use the tractor as much as you do, that while it is out review what items you want to work on so when re-assembled you will have a good working tractor. Good Luck! Bill Long

|

Posted By: Allis Wd45

Date Posted: 18 Dec 2019 at 12:09am

|

It probably seems like I'm going back to square one here but how do you get the intermediate gear out? What is that bolt with the wire holding in? Does anyone have an idea on where the hydraulic oil can get into the transmission at? Thanks again sorry for all the questions just don't want to tear down a bunch of stuff that's not necessary. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Sugarmaker

Date Posted: 18 Dec 2019 at 6:50am

I am not the best guy on this but I will give it a try. I believe the gear you speak of is the large gear on the shaft with the bolt. Well that shaft has to come out to remove that gear assembly. The bolt has a taper on if I remember correctly it locates the pin that the gears ride on. The hydraulic oil travels between the transmission and the hyd reservoir thur bad seals on the main drive shaft. The seals are back to back. Others with more experience will help you better than me. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Lon(MN)

Date Posted: 18 Dec 2019 at 7:54am

| I have all those parts on the shelf for sale. email lselkriver@gmail.com. Gear set is $50 |

Posted By: Alex09(WI)

Date Posted: 18 Dec 2019 at 8:44am

If you do not want to fix your seals that are causing the hyd oil to leak into the transmission oil, then you do not have to split the tractor to replace just the intermediate PTO gear. Your seals that are in front of the hand clutch and pto drive gear are between the hyd compartement and the transmission oil compartment. There are 2 seals back to back like Sugarmaker says (see his picture) that are shot causing the oil to leak into the trans fluid. To replace those seals, you have to split the tractor in front of the transmission and remove the hand clutch and the pto drive gear. It is possible to replace the intermediate pto gear without splitting the tractor. Remove the hydraulic pump and the pto gearbox. Remove the RH channel iron side frame and remove the small tapered bolt. Slide or press the Intermediate pto gear shaft into the hyd pump compartment and the intermediate pto gears and washers will come out through the bottom hole where the pto gearbox was bolted. MAKE SURE you have the proper shear bolt holding the pto shaft to the pto gearbox output stub!! That protects the gears that you have just shelled the teeth off of. I have the shear bolts new or used and I also have the gears (used) you need but I see a couple guys beat me to it. To answer you r question about used vs new gears, if you put the proper shear bolt in, good used gears will suffice. If you a perfectionist, go with new gears, an AGCO dealer should have them, but I expect they would be pricy compared to $50-$150 for the 3 used ones you need. ------------- www.awtractor.com A&W TRACTOR 920-598-1287 KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY |

Posted By: SteveM C/IL

Date Posted: 18 Dec 2019 at 9:54am

| You can leave the frame rail in place. The pump comes up and out,won't go out the bottom. Takes a little squeeze against rollers but not bad. Wedge roller arms with nails like Bill says and they fall back in place. Getting shaft slid back and forth can be challenging.Need some thick grease to hold the hidden washer in place. Just remember,IT CAN BE DONE. You may have moments that you don't think we know what we're talking about. |

Posted By: Ray

Date Posted: 18 Dec 2019 at 9:59am

|

Sir Sorry to hear of your break down.I would have the parts on the shelf. Slider gear 25 tooth: no 224527 Idler gear 18 tooth: no 203236 Intermeter gear 19 tooth and 33 tooth; 227323 Pto shaft no 22266 Good,used,original $265.00 for every thing. Thank You and Good Luck |

Posted By: Allis Wd45

Date Posted: 18 Dec 2019 at 3:21pm

|

Thanks for the Responses I got the Hydraulic Pump out and it looks like it was due to have the sludge cleaned out of the hydraulic pump cavity. I'm going to see if I can get the intermediate gear out without splitting the tractor. But I might end up splitting it anyway so I can fix the Hydraulic oil into transmission leak. Since its this far apart can you tell the condition of the hand clutch without taking it apart? It works fine but if I'm already that far into it and it looks like it could be replaced I might as well do it. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: SteveM C/IL

Date Posted: 18 Dec 2019 at 7:54pm

| Difficult to see how worn plates are when together in tractor. If it snaps in tight and doesn't slip or pop out when lever bounces from a bump,I wouldn't worry about it. If a little soft you just remove a shim or two(equal at 3 positions) and try it. If the Shims are gone ,the clutch is about there too. |

Posted By: Allis Wd45

Date Posted: 18 Dec 2019 at 9:28pm

|

Ok, It dont pop out or slip I can see if there are shims there but I might just leave it. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Phil48ACWC

Date Posted: 19 Dec 2019 at 5:53am

|

https://www.ebay.com/sch/i.html?_from=R40&_trksid=m570.l1313&_nkw=Allis+Chalmers+WD45+PTO+Gear+box&_sacat=0" rel="nofollow - https://www.ebay.com/sch/i.html?_from=R40&_trksid=m570.l1313&_nkw=Allis+Chalmers+WD45+PTO+Gear+box&_sacat=0 Click on Above.

|

Posted By: Sugarmaker

Date Posted: 19 Dec 2019 at 8:13am

|

Allis wd45, 1. seals:  this is the forward seal in the bell housing:  PTO drive gear and shaft out.  Just the shaft and the collars:  If you do split the tractor: i had to use a puller to remove the gear that drives the PTO: There is a snap ring that holds it in place that has to come off first:  This is the driving flange that your hand clutch bolts too. 4 bolts with lock tabs.  If you have the hand clutch out might as well check this bronze bearing where the two shafts mate too. Mine was bad:  Found this you have to have the bearing in place before you install the PTO gear assembly:  2. If you split the tractor the hand clutch can be removed easily. On the inspection process: There are three shim packs around the perimeter. Take a picture of these and post. I think the original shim pack thickness is around .25 inch? If it is still near that dimension the clutches have not been adjusted. If it is way less then you may need new clutch plates? or if the clutch plates are good then removing shims can get it fully functional again. I believe the service manual covers this pretty well too. This is the shim pack:  rebuilding the 3 plate clutch (there is a very good youtube video done by Dennis, forum member, on this work too);  Dont forget about your new output seals on the PTO shaft cover. I doubled up on these as recommended by several folks on here.  Sorry this is a picture heavy post and not very organized. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 19 Dec 2019 at 7:02pm

|

Chris, Thanks for the Pictures I found a complete gearbox and shaft. I will wait to order gaskets and seals in case I find something else wrong because the closest AGCO dealer to me is about 3 1/2 hours away and I have them mail me the parts. Did you use the original size seal on the PTO gearbox cover when you doubled them up? I may do the same. Also I see in the parts book there are a bunch of shims for the pto gearbox cover, but I only see 1 gasket listed. Do I use that gasket or does it change depending on backlash when putting it together? ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Sugarmaker

Date Posted: 19 Dec 2019 at 7:17pm

|

Allis Wd45, Yes I believe I just ordered two of the output shaft seals and installed them in the same direction. On the shims for the cover: Your service manual may be better than I can tell you? Save the metal shims, the paper ones are the ones you can get to set the back lash. That may be called the gasket? See if I can find picture of that?? Guess I dont have any pictures of those/ shims and paper gaskets?   Maybe someone will jump in give us some expert advice on that too? Regards, Chris

------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 19 Dec 2019 at 7:57pm

|

Maybe so, again thanks for the pictures that helps a bunch being able to see what is behind things before you take it apart. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Allis Wd45

Date Posted: 20 Dec 2019 at 3:56pm

|

I was able to get the Intermediate gear shaft into the hydraulic compartment about 1/2" and it wont go any more. The bigger part of the shaft is flush with the hole on the PTO side. Is there any tricks to get it out the rest of the way? ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Sugarmaker

Date Posted: 20 Dec 2019 at 7:34pm

|

Ok your testing the old brain and its not working well tonight! If I had it open on the bench I could help you. But I just have not done enough of these to have all the moves memorized. Maybe try to call Don (MO) in the morning, I bet he would be kind enough to walk you through the removal. Glad you got the parts. The rest is just figuring out the puzzle. Regards, Chris

------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Alex09(WI)

Date Posted: 20 Dec 2019 at 9:18pm

|

Regarding the pto gearbox, there was originally a very thin paper gasket between each shim for the output shaft bearing carrier, but the local Agco dealer told me last year the gaskets are not used anymore, I just made sure each shim was clean on both sides and an extremely thin layer (like barely visible) of silicone between each shim. You remove a shim if you have too much end play in the shaft and add a shim if you can't turn the shaft by hand easily when the bolts are tightened down. Make sure you keep checking the shaft by hand when tightening the bolts becasue if you don't have enough shims at first the bearing will be too tight when you tighten the bolts down ------------- www.awtractor.com A&W TRACTOR 920-598-1287 KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY |

Posted By: smoen55

Date Posted: 20 Dec 2019 at 9:44pm

| Hi, I'm restoring my first AC WD. I just put the two seals that keep the fluids separated. And they were 100% shot. So if the fluids are mixing then they are both likely bad. They are opposing seals. Of course my tractor was completely apart when I installed them but it was not to difficult. |

Posted By: smoen55

Date Posted: 20 Dec 2019 at 10:03pm

| If you have plenty of shims left you then the plates are probably okay. If you split the tractor I would just do a touch up on the hand clutch. Take it apart, clean it up. Take the ring out by applying pressure with vise or press and rotate the plate (about an inch) that holds the clutch in because it does wear in groves as mine was. The rollers were in good shape but now holds like new. Also take out two shims to start and see how it goes. Shims can be removed anytime just by taking cover off and loosening bolts then slipping them out. |

Posted By: Allis Wd45

Date Posted: 21 Dec 2019 at 1:18am

|

Okay, there are still 2 shims in the hand clutch all the way around so it cant be worn too badly. I will call Don tomorrow to get some more advise, I will also ask about splitting the tractor. I don't use the hydraulics at all so its not a big deal. I just don't want the pump to run out of oil. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Sugarmaker

Date Posted: 21 Dec 2019 at 10:06am

|

Allis WD45, Hand clutch review: There should be many shims in each of the three packs, unless theay have all been removed due to worn out clutch linings! Each shim pack is a stack of brass shim stock maybe they are .005 each?? Stacked to .25 inches when new. And If you didnt know new shim stacks are gold plated :) so handle them with care! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: TimCNY

Date Posted: 21 Dec 2019 at 10:19am

|

huh... Well, I bought the paper shims from Sandy Lake when I repaired the PTO gearbox on my WD45. AND used copper gasket sealer. No issues. Not that expensive at all. ------------- I need more than 200 characters for my "signature." I'd love to see that changed to 250! |

Posted By: Sugarmaker

Date Posted: 21 Dec 2019 at 2:56pm

|

Tim, I was speaking of the shims in the hand clutch. I think we have a couple shim topics going on at the same time. Good to know those paper shims are still available too! I just spoke with Brenda at Sandy Lake today! Good folks there! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 08 Jan 2020 at 10:19pm

|

So, I got all the parts yesterday and I've been working on getting the intermediate gear out. I got it slide about 1" into the hydraulic pump chamber. It's to the point where I cant reach it with a punch anymore to drive it through. I'm trying to use the gear as a slide hammer as described above but the shaft will not move when I do that. Any Suggestions? ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: DrAllis

Date Posted: 09 Jan 2020 at 8:44am

| You have the hydraulic pump removed from the tractor, right ?? |

Posted By: Allis Wd45

Date Posted: 09 Jan 2020 at 10:06am

|

Yes ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: SteveM C/IL

Date Posted: 09 Jan 2020 at 10:50am

| Been too long ago to remember process but if you need to push shaft and its inside gear,you have to come up with some spacer of sorts to place on shaft then push it. It's not rocket science. You will have fun keeping washer in place that's hiding behind gear. Dry everything off and use sticky gun grease to hold it....could take a few tries.... |

Posted By: Sugarmaker

Date Posted: 09 Jan 2020 at 10:54am

|

Allis Wd45, Ok I have forgot most of the assembly/ diss assembly on those gears. Guess i blocked it out of my mind? The shaft has to slide through the gears and collars. The big end of the shaft is opposite the large gear and the shaft has to move the big end out first. Correct? You should be able to tap on the small end of the shaft just below the hand clutch assembly? If this doesnt make sence I could be looking at it wrong. This is the point where I would call Don (MO)!:) Glad you got the parts and I hope your in a warm shop too! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 09 Jan 2020 at 12:05pm

|

Correct, the big end of the shaft slides out first. But with the hand clutch still in the tractor you can’t get at the end of the shaft to tap it through. It is in a shop it hasn’t been that cold really but I do have a kerosene space heater if I need it. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: stu(ON)

Date Posted: 09 Jan 2020 at 12:49pm

|

You probably have the back end of the shaft out of its recess. Reach in from the bottom opening where the PTO drop box was and lift up the intermediate gear with your left hand. At the same time, use a channel-lock or battery pliers to increase your purchase on the front end of the shaft as you pull it out. You will either have to get in there and manipulate this yourself, or get a helper to handle one end of the shaft for you. There is a lot of weight hanging on the back of the shaft. You will have to manipulate that weight while giving a firm pull on the front end. You will get this with perseverance, as have many others of us.

|

Posted By: Allis Wd45

Date Posted: 09 Jan 2020 at 5:53pm

|

Stu, I haven't tried the pliers method yet, I was afraid of chewing the shaft up with the pliers. I'll give that a try. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: stu(ON)

Date Posted: 09 Jan 2020 at 6:34pm

|

I do not think that you will easily mar that shaft. But, if you did, a file would quickly remove any protrusions. Your first job is to remove it. The shaft is double-indexed for orientation. There is the dimple and there is the flat side on the rear end of the shaft. If you are able to get a grip on the front end of the shaft and turn it, you know that you are free of the rear recess. You have already moved it forward by tapping on the punch. The rest is just likely work and patience. Some do come harder than others. Try rotating the shaft with pliers. If it turns, you have another means of working it loose. Some work here can save a lot of work later. Don't worry about scars on the shaft; the set screw is what will keep it in place when you rebuild. Use your imagination and get in there and get rough if you have to. You are working with WWII technology and it tolerates rough handling.

|

Posted By: Sugarmaker

Date Posted: 09 Jan 2020 at 6:41pm

|

Allis Wd45, Sounds like good advice from stu! I was thinking that maybe the shaft had some damaged due to the failure?? I have only done one and its shaft slid out pretty easy, and I did have the hand clutch out. Now getting it back it with all the parts in place makes you hold your mouth just right and stand one one foot too! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 18 Apr 2020 at 3:51pm

|

I've been working on other projects and now have came back to the WD45, I still have no sucess getting that intermediate gear out. I have the shaft moved about 3/4" into the hydraulic compartment. I was able to pry it forward using a pry bar on the front side of the intermediate gear. But I can't reach it with the pry bar anymore. I have tried grabbing it from the hydraulic compartment and it's tight there is no movement in that shaft at all. Any other ideas? I really don't want to have to split the tractor. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Sugarmaker

Date Posted: 18 Apr 2020 at 4:43pm

|

Wish I was the expert on these have been in there but I had mine all apart when I did it and got through it. Maybe Mack or the Dr. will be along. You know that the shaft may have been damaged during this event also. Just a guess. Might cause the shaft to have a burr? Have you reviewed the service manual and or called maybe Sandy Lake if Bill is still there? Someone said he retired? Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: NE GA Allis

Date Posted: 18 Apr 2020 at 4:48pm

|

Is there enough space in the hand clutch compartment to put a clean socket up against the small end of the shaft and pry against it? Been too long since I messed with those gears and bearings to remember. Unfortunately as well, I had my tractor split apart when I did it though. Don't remember it being too difficult but like I said the tractor was split apart. Also would be a very good idea to make sure that the 6 bolts that hold the hand clutch together are tight. You don't want all this work to be messed up if a bolt comes loose and falls out. I got a WD once that one entire side of the flange on the torque tube where the pto bolts to was blown off. The only thing that I could think of that could do that much damage to the casting was if one of those bolts fell down into the gears causing catastrophe. When I disassembled the tractor there was a bolt missing off the hand clutch. ------------- Keeping Allis alive with: 2 B’s, 1 C, 6 CA’s, 2 WD’s, 1 WD45, 3 D15D’s, 1 D17 |

Posted By: Allis Wd45

Date Posted: 18 Apr 2020 at 11:36pm

|

There isn't enough room to pry against the shaft with the hand clutch in there.If it comes down to it I can split it, just wasn't wanting to if I could fix it without splitting the tractor. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: SteveM C/IL

Date Posted: 19 Apr 2020 at 10:44am

| All your work should be through the bottom dealing with shaft and gear. Hand clutch is not in the way. Last time I had more trouble with mine than years before. I ended up making half moon spacers(more like 1/3 moon and maybe 1/8in thick?) the width it took to slip on shaft after prying gear fwd ( seems like 1/4 in ).Spacer pushed on edge of large dia of shaft when prying gear fwd. Install next spacer and pry. Think it took 3 spacers but it's been a few years. Removal is ALL FROM THE BOTTOM!!! |

Posted By: stu(ON)

Date Posted: 19 Apr 2020 at 2:14pm

|

I got a notification that this thread came back to life. Don't know that I can add much, but I want to ask SteveM about his method, to see if I can picture it. SteveM, do I understand correctly that you were working on your back and going up from underneath? If so, then was your pry point on the front (end of tractor) on the intermediate gear? Did you find that as the shaft crept forward, it left a space in the cast housing bore that allowed you to insert 1/3 moon thin spacers that allowed you to fit a pry between the washer (or spacer) of the gear and actually pry into the bore via the spacer? It was a very long time ago that I did this job, and mine came relatively easy, so I did not use the opportunity to see if pry space was created. It is hard to create a picture with words, but if I can picture what you did, Allis Wd45 likely can too.

|

Posted By: SteveM C/IL

Date Posted: 19 Apr 2020 at 8:29pm

| You got it. The front of shaft is larger diameter and protrudes past bore. Remove lock and pry gear fwd. Now you have room to insert spacer between shaft head and washer. Pry gear again. Repeat. You keep pushing shaft fwd. First one I did slid easy by hand. This one took a while. Removing frame rail is waste of time. You can force pump rollers by top of hsg. To install easy flatten some 1/8in wire/nail,push roller against the body and insert nail in edge of lever by pivot. When back in the hole pull nails out of levers. My dad apparently never knew the nail trick because he had a piece of bent tin he put over gasket and forced the pump back in. He worked on a bunch over the yrs. |

Posted By: stu(ON)

Date Posted: 19 Apr 2020 at 8:57pm

|

Let's see if I can do this from an old pic.  Viola

|

Posted By: SteveM C/IL

Date Posted: 19 Apr 2020 at 9:56pm

|

Posted By: Allis Wd45

Date Posted: 20 Apr 2020 at 1:17am

|

Steve, i just saw your reply my uncle stopped by tonight and I had him take a look. Did exactly as you said and with 3 spacers made out of a piece of pipe it slid right out. Thanks a bunch guys now to get it all lined up and back in place. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Phil48ACWC

Date Posted: 20 Apr 2020 at 6:03am

|

https://www.ebay.com/sch/i.html?_from=R40&_trksid=m570.l1313&_nkw=Allis+Chalmers+WD+45+PTO+Gear+Box&_sacat=0" rel="nofollow - https://www.ebay.com/sch/i.html?_from=R40&_trksid=m570.l1313&_nkw=Allis+Chalmers+WD+45+PTO+Gear+Box&_sacat=0 Click on above and check these items.

|

Allis Wd45 wrote:

Allis Wd45 wrote: