Radiator fluid in oil Allis B

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=166313

Printed Date: 14 Oct 2025 at 3:50pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Radiator fluid in oil Allis B

Posted By: gman54313

Subject: Radiator fluid in oil Allis B

Date Posted: 02 Dec 2019 at 9:41pm

SO I finally pulled the oil pan and am planning to pressurize the cooling system to find my leak when I decided to just take a look up at the bottom of the sleeves. there on no.1 and 3 were very obvious drips of coolant. So then I pulled the head to look/inspect the cylinders and pistons and I find a fairly deep score on number 4 and some dents on top of piston # 2 guessing the Allis had been worked on before the question I have is would it make more sense to get a in frame overhaul kit considering I could only get 90lbs of compression out of this engine plus or minus 5lbs on each cylinder. or just replace the O-rings for the liners. I know that sure if money is no object I would overhaul everything but as with many things in life I need to weight the pros and cons. Just looking for your 2 cents I am also wondering what the SP stamp on the top of the piston means.

|

Replies:

Posted By: JC-WI

Date Posted: 02 Dec 2019 at 10:06pm

|

Did you check the frost plugs in the head for pinhole leak/s? Just wondering. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: WF owner

Date Posted: 03 Dec 2019 at 5:47am

|

I agree that you should check the core plugs in the head. It has been my experience that these are usually the culprit when there is antifreeze in the oil in these engines. With that said, I would definitely replace (at least) that sleeve with the gouge in it. If money is a big factor, I have installed a used sleeve in a tractor that I didn't want to spend much money on. I have reused the head gasket, too (if it was in good shape). I know everyone is going to say do a complete overhaul, but I live in the real world where not everyone can afford to sink the money in an old tractor that they won't use very much. Make sure to do a good job honing the sleeves. I would install new rings, new O rings on the sleeves and have the valves done. You may have to buy (or make) new shims. New cam bearings will only cost about $30. Use plastigauge on the main and rod bearings. Good luck !

|

Posted By: gman54313

Date Posted: 03 Dec 2019 at 7:14am

| JC the frost plugs look new from the top and because I did not do a pressure test I am not sure if they leak but because of how inexpensive they are I will be replacing all three anyway |

Posted By: Sugarmaker

Date Posted: 03 Dec 2019 at 8:06am

|

gman, I understand the logic of not sinking a whole lot of money in one of these. But for sure that one cylinder sleeve has issues. Either a cracked block or bad o-rings. Yes used sleeve as mentioned would be a option along with the honing and fresh rings. By the time you get to that point it will feel like you did a engine rebuild but may save hundreds of dollars. I went through the same issues on my 45 project. And it did consume many many dollars to get it completed. I sat down and did some soul searching for a while and then started in to it. Little marv has a excellent thread on a C or CA engine he did. I know one thing that if your going to fix it you got to take it apart. After that it will tell you how far you have to go. Then you need to decide if your going to save it or not. Hate to say but some tractors do get set to the side when they have serious issues. I probably havent helped any? Good luck, and your doing a good job documenting your work. Welcome to the Forum too! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Stan IL&TN

Date Posted: 03 Dec 2019 at 9:24am

|

I would go ahead and replace the frost plugs just out of precaution. They are cheap insurance. good luck with the project!! ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: Alex09(WI)

Date Posted: 03 Dec 2019 at 2:55pm

|

I think you might want to consider replacing the o-rings on all 4 sleeves, if 1 sleeve is leaking the other 3 might be close to leaking also. And I agree, it would be good to replace the 3 core plugs while you have it apart. They rust through from the bottom to the top, so you don't see the hole till its too late. And if you pull the scored sleeve to replace the o-rings, you might as well replace with a new one or good used one. I see you are from Green Bay, I am 45 minuites NW near Shawano, WI. If you need any advice, questions, or parts, I can set you up with gaskets, and new or used sleeve. Alex ------------- www.awtractor.com A&W TRACTOR 920-598-1287 KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY |

Posted By: ac fleet

Date Posted: 03 Dec 2019 at 3:10pm

|

Might want to go with used sleeve/piston,--because a new one could add more strain on the crank. ---Its always best to try to balance the crank as much as possible. ----NOTHING wrong with used!! -- Been there, done that!-- even re-used gaskets, and made some of my own. -- It can be done and will work. --Main thing is to clean all of the surfaces real good and make sure all traces of o-rings, gaskets, sealer, etc. is removed. Just my 0002. Not sure what the sp stamp means, have seen them before but never checked out what they mean!

------------- http://machinebuildersnetwork.com/ |

Posted By: DiyDave

Date Posted: 03 Dec 2019 at 5:45pm

|

SP would be sealed power pistons, a trade mark of Federal-Mogul, would be my guess. With 90 PSI compression, I would go for pulling the liners, re sealing, re ring the pistons, since you'll have them out, anyway. When you are re-assembling, Use some plastigage to see the clearances on your crank bearings.  ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: JC-WI

Date Posted: 03 Dec 2019 at 7:03pm

|

I was wondering if they are distilate pistons to be so low on compression... ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: steve(ill)

Date Posted: 03 Dec 2019 at 7:10pm

|

groove in a liner is not good.......... BUT........ that being said, I have opened several of these motors, pulled the liners out. --new O-rings on liners --hone the original cylinders and reinstall --new piston rings --new gasket set --lap the valves for a better seat --replace the freeze plugs on top if the head. when the liners are out, look at all the CRUD in the water passage... clean and wash that out.... verify that the crank and cam are " not too bad"... you can be a little out of spec and still get by... its RUNNING NOW, RIGHT ? ... anything you do will improve quality... it don't have to be NEW or EXPENSIVE. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 03 Dec 2019 at 7:13pm

|

Since it appears the pistons might not be STOCK, pull one out and mike the diameter to see if it is 3-3/8 or 3-7/16 diameter... also measure the ring height or thickness.... I bought a set of "RINGS" once and the motor had M&W pistons in it... they would not fit.. Some rings are 1/8 inch, and some a 3/32 inch thick. ------------- Like them all, but love the "B"s. |

Posted By: Dick L

Date Posted: 03 Dec 2019 at 7:41pm

|

You can't get a drip from the bottom of a sleeve from a frost plug in the head! Your going to need to pull the sleeves and install new O rings to stop the drips. After pulling out the pistons and making sure a current ring did not cause the score I wouldn't worry about it. Most likely looking at the color of the score it was done with a different piston. No way to know without taking it out and looking, Honing enough for a cross hatch should get you back running without breaking the bank. I doubt that score will cause it to burn a bunch of oil. If you decide to go this way be sure to check ring gap on the rings square down in the sleeve. I square a ring in the hole using a piston to push the ring some. I assume your not wanting to dump a bunch of money into a new kit if you can get by without or you wouldn't ask the way you did. |

Posted By: gman54313

Date Posted: 03 Dec 2019 at 9:10pm

|

JC What is a distillate piston? |

Posted By: gman54313

Date Posted: 03 Dec 2019 at 9:24pm

|

Dick, I agree with your assessment I pulled the piston out tonight and saw no ring damage to indicate scoring of the cylinder wall but I did see the rod bearing is in bad shape which tells me someone in the past may have pulled this motor apart and just replaced the piston and rings and left the bearing as is. I am also in agreement that you can't get drip in the bottom from a frost plug. The service manual says end gap of .007-.017 not sure what land clearance is if you or someone could advise me on that it would be helpful.

|

Posted By: SteveM C/IL

Date Posted: 03 Dec 2019 at 9:54pm

| Land clearance is what you measure with a feeler gauge stuck in the ring groove along with the ring. Too much "flop" leads to broken rings. |

Posted By: SteveM C/IL

Date Posted: 03 Dec 2019 at 9:55pm

low compression....kerosene(distillate) fuel

|

Posted By: SteveM C/IL

Date Posted: 03 Dec 2019 at 10:01pm

| That bearing is ugly but it's just the soft metal buggered up. What's the crank like? Slight scoring can be polished out but too much out of round will require grinding . Crank grinding is not that expensive and you would be buying new brgs anyway so just as well do it right? Maybe you could buy a good runner for less than fiddling with this engine. |

Posted By: Alex09(WI)

Date Posted: 03 Dec 2019 at 10:24pm

That picture of the bearing is a good indication of what happens when you run engines with antifreeze in the oil. Now I would suggest to pull the crankshaft out because there is a good chance all the other bearings look similar to that. You seem to know what your doing so you may have decided on that already ------------- www.awtractor.com A&W TRACTOR 920-598-1287 KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY |

Posted By: Dick L

Date Posted: 04 Dec 2019 at 6:03am

|

That rod bearing looks like the rod was not orientated correctly when installed. No way to have only one side of the bearing to be almost gone and the other side not showing much wear at all with the rod being installed correct. look thru my pictures ay the link. The rods are offset. you can compare how yours were with my pictures. That my not have put your crankshaft out of round. Check the journals at 90º places starting straight down. You need that rod for being bent. https://public.fotki.com/DickL/allis_chalmers_engi/allis-chalmers-c-st/" rel="nofollow - https://public.fotki.com/DickL/allis_chalmers_engi/allis-chalmers-c-st/ |

Posted By: wekracer

Date Posted: 04 Dec 2019 at 6:54am

| Have you priced an engine kit. You already talking about bearings and rings and head gasket etc. By the time you piece it together you can probably get a whole kit for about the same money. |

Posted By: Sugarmaker

Date Posted: 04 Dec 2019 at 9:46am

|

gman, Your right into it! Looks like your pretty comfortable with the work. Great pictures too. We cant help you much on the cost. Nothing is cheap any more. I set aside a WD for 2 years due to some clutch parts it needed. I had to get my mind and wallet around the project and then at that point I was good to go. Several things have to come together at the same time for these things to happen too! I spent at least 9 months on the 226 engine I overhauled. So it takes time and money. Looks like your disassembly is going to lead you to make the correct choices for you, your tractor and this engine project! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: gman54313

Date Posted: 04 Dec 2019 at 7:13pm

I am actually enjoying turning wrenches on Allis like most people I just want to be smart about it, money that is. |

Posted By: gman54313

Date Posted: 04 Dec 2019 at 7:27pm

|

Dick L. The photo album or the Alley rebuild was helpful, Wow I thought my cylinders were bad.  Good point about the wear on the bearing and possible bent rod. Good point about the wear on the bearing and possible bent rod.

|

Posted By: gman54313

Date Posted: 04 Dec 2019 at 7:44pm

|

Thank you to everyone for there input a few views I never would have thought off. Last night I pulled out # 3 and it looks like a different piston even the oil ring is different from the others. rod bearing and crank looks good or at least go enough till I mic it. After work today I pull #1 sleeve which went really well with the puller we made. I did see the bottom oring had a gap in it. guess that had something to do with the leak. my biggest concern was if there was a crack in the block which I could not detect. I will have time tomorrow after work to pull the rest of the liners and then check the crank before I decide haw far I will have to go with buying parts.

|

Posted By: Gerald J.

Date Posted: 04 Dec 2019 at 8:15pm

|

The shop manual might have some details to help figure out the conditions and repair details: http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf" rel="nofollow - http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf Gerald J. |

Posted By: Dick L

Date Posted: 05 Dec 2019 at 6:10am

That picture album was of rebuilding an engine with all in spec used parts. New rings and bearings. I did this to show that it is not always necessary to throw the bank on a rebuild. I did this ten years, nine months ago and have used the tractor with a Woods 59 under it every since to mow 3 acres of yard and mulch manure in my hay fields. It will fire up today as easy as it did then and does not smoke. The point is in spec parts will give you very good service for a long time. It is in the (DETAILS) |

Posted By: Sugarmaker

Date Posted: 05 Dec 2019 at 10:05am

|

gman, Nice work pulling the sleeves! Yes that one o-ring is compromised. Hoping you dont have block issue. I think if you clean up the webs in the block you would be able to visually see cracks. They were obvious on the cracked block I had. Your on your way. I guess my thought on the rebuilds is that I will probably never have to overhaul the engine again so the cost of getting new parts is spread over a long time. The things like mismatched pistons and new bearings lead me to think you will need a full kit with sleeves , pistons, rings, bearings, etc.... Regards, Chris Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: JimD

Date Posted: 05 Dec 2019 at 12:14pm

|

Sure looks to me like someone beat apart a stuck engine. I've made them marks myself :) But I would never re-use with the damage. Customer wanted t rebuilt and supplied the kit. JImD ------------- Owner of http://www.OKtractor.com" rel="nofollow - OKtractor.com PM for an instant response on parts. Open M-F 9-6 Central. We have new and used parts. 877-378-6543 |

Posted By: gman54313

Date Posted: 05 Dec 2019 at 7:44pm

|

Again thank you to all for your input. Today after work I was able to pull the remainder of the sleeves the fact that my plug for pulling the sleeves fit snuggly into the bottom of each sleeve gave me a clue all the bores were 3-3/8 and I did verify that with a gauge. After looking at all the sleeves two of the four had obvious gaps in the O-rings and all four look like they were 80 years old which i'm sure they are. After the sleeves where pulled and I covered up the crank journals and cleaned all the gak between the webs to inspect for cracks and to my surprise I did not see anything. I recently notice that the thermostat block and the lower radiator elbow with the peacock had been brazed. I am guessing because it froze at some point and cracked so I naturally was concerned about the block. The next step for me is to pull the crank and cam and check my tolerances.

|

Posted By: Sugarmaker

Date Posted: 06 Dec 2019 at 9:17am

|

Gman, Good pictures! Glad that block looks ok! O-rings look bad! Do you have a engine stand? Looks like that would be the thing to do next! It sure makes the inspection, cleaning, and assembly work easier. And sealing up the bottom end is much easier too. Good luck in your rebuild! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Gary

Date Posted: 06 Dec 2019 at 10:30am

|

An 'Engine Stand' is definitely recommended. Harbor Freight presently has a 3 day Sale on both Engine Hoist and Engine Stand. Both well worth the money. 1 ton Crane $128. 1000 lb Engine Stand $49. Gary |

Posted By: ACJohn

Date Posted: 06 Dec 2019 at 1:49pm

|

When installing new (or used) sleeves, use plenty of o-ring lube and deburr any sharp edges on the top side of web where the o-rings seal. I put together an entire engine only to find I cut an o-ring installing a sleeve. PITA to have to do it over!! |

Posted By: gman54313

Date Posted: 06 Dec 2019 at 2:05pm

|

you gents are reading my mind on the stand LOL Also thank you for the advise on the O-rings. I have never installed sleeves so any feedback is valuable to me. Kindest Regards Greg aka gman |

Posted By: Sugarmaker

Date Posted: 06 Dec 2019 at 5:15pm

|

gman, I had never done any till last spring. I took some lessons, did some research, got a mentor, and kept working on the seat area to get the correct sleeve standout! Was it easy? No! Was it worth the effort? Yes! Your going in the right direction. Little Marv has some good pictures of his work on your type engine. I have a thread on a WD45. and there are many folks that can help you with the little details to get it right! I know these can be re-built in frame, also block could be rolled around on a bench. But if your like me and need to check things a couple times the engine stand allows many rotations to work on the block and the components to assemble it properly. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Dick L

Date Posted: 06 Dec 2019 at 5:45pm

|

An added tip on installing sleeves! They are wet sleeves and are (not) a press fit. Without o rings the sleeve needs to be able to drop in and turn 360º with one hand. Going back to my pictures you will see a flapper in a die grinder. This is how I get the hole cleaned out so they will turn 369º It takes more than a little flapping. I find the tight areas using bluing. Paint mist will also work. A tight fit will not let the o rings enter the bore with out pinching/shearing. |

Posted By: gman54313

Date Posted: 06 Dec 2019 at 7:04pm

|

SugarMaker I am the same way in regards to want to measure twice and cut only once mentality I spent most of my younger life rolling engine blocks around on the work bench. Not much fun so I spent $60 bucks on the stand. now I just need to find some threaded rod or long bolts should have something laying around. Wait, I should first need to pull the flywheel. regards Greg |

Posted By: gman54313

Date Posted: 06 Dec 2019 at 7:14pm

|

Dick L. I have been pondering the process of the sleeve installation and how one would keep the o rings from being damaged, I am very glad you posted that tip. I recall the pic of the flapper tool and will review your post again. The bluing is a very great idea for the high spots cause I imagine one would want to keep things as symmetrical as possible. Regards Greg |

Posted By: WF owner

Date Posted: 06 Dec 2019 at 7:16pm

|

Harbor Freight's stands are good. I have four of them. I am thinking of spending a little more to get one from Jeg's that has a worm gear drive to rotate the engine. If you have ever rotated an engine on the Harbor Freight stand, you know you had better eat your Wheaties and hold on. I'm getting too old for that, so I think I may take the plunge for this stand. https://www.amazon.com/dp/B078WJM4FH?aaxitk=1Os99flvQvCsSGmXWk5Qkw&pd_rd_i=B078WJM4FH&pf_rd_p=44fc3e0f-4b9e-4ed8-b33b-363a7257163d&hsa_cr_id=9656954400401&sb-ci-n=asinImage&sb-ci-v=https%3A%2F%2Fm.media-amazon.com%2Fimages%2FI%2F61fiGis10SL.jpg&sb-ci-a=B078WJM4FH" rel="nofollow - https://www.amazon.com/dp/B078WJM4FH?aaxitk=1Os99flvQvCsSGmXWk5Qkw&pd_rd_i=B078WJM4FH&pf_rd_p=44fc3e0f-4b9e-4ed8-b33b-363a7257163d&hsa_cr_id=9656954400401&sb-ci-n=asinImage&sb-ci-v=https%3A%2F%2Fm.media-amazon.com%2Fimages%2FI%2F61fiGis10SL.jpg&sb-ci-a=B078WJM4FH |

Posted By: Sugarmaker

Date Posted: 06 Dec 2019 at 8:35pm

|

WF That has some very nice features in a engine stand! Yes if they are not fairly balanced it can be a real challenge rotating them! Only dis advantage is that you cant attach the support/ pivot to the engine first and then pick it up and insert the stand on to the rotating shaft. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Dick L

Date Posted: 07 Dec 2019 at 6:11am

I adjust an engines vertical center after adding or removing the head to keep from ripping an arm off.

|

Posted By: Sugarmaker

Date Posted: 07 Dec 2019 at 12:56pm

|

Greg, I believe that you will have to pull the flywheel to mount the engine. But I have not done one of those blocks. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Dick L

Date Posted: 07 Dec 2019 at 1:38pm

|

Posted By: Sugarmaker

Date Posted: 07 Dec 2019 at 2:16pm

|

Dick, Nice! Thanks! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: gman54313

Date Posted: 07 Dec 2019 at 5:20pm

To me that is a work of art and should be display instead of the some of these paintings/sculptures I've seen in our public museums. |

Posted By: ac fleet

Date Posted: 08 Dec 2019 at 2:13pm

|

Slick idea!!! LOL!!! ------------- http://machinebuildersnetwork.com/ |

Posted By: gman54313

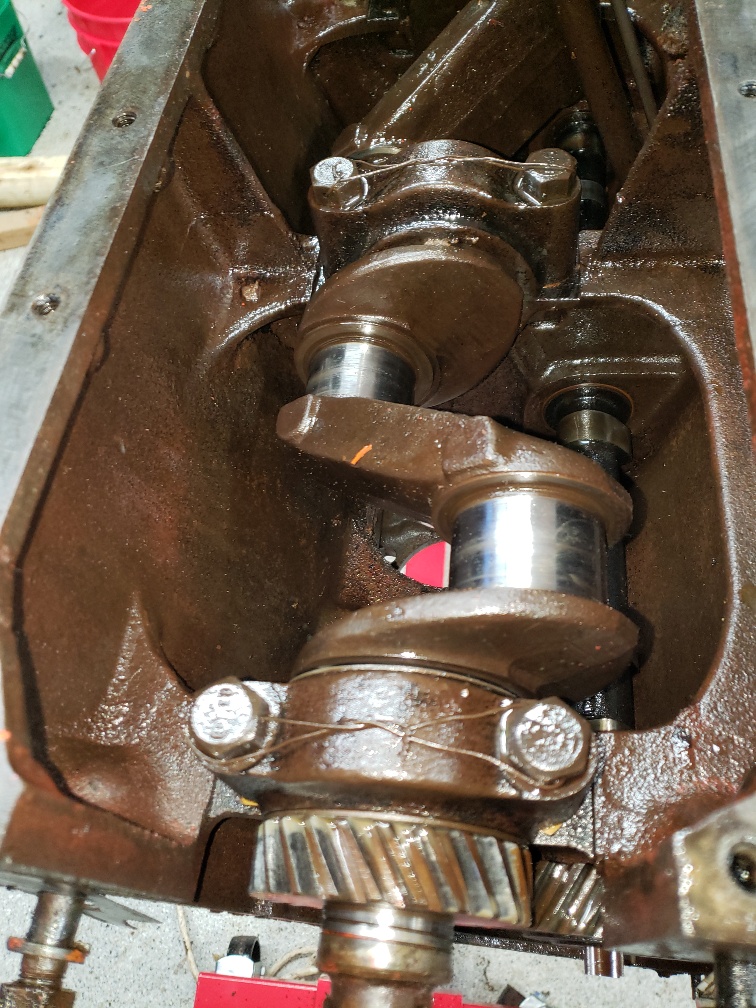

Date Posted: 08 Dec 2019 at 8:52pm

Update, I had time today to mount the engine block to the stand. Man I wish we had these things when I was younger maybe they did but I never heard of them. Anyway I was able to remove the crank caps mark them and remove the crank and the cam. sometime this week I will mic the journals' to see if they are in specs. The main journal surfaces look very smooth except where the oil groove is on the bearing that looks to be stained by something maybe water thinking emery cloth. I don't think I will be turning any wrenches this week because it is going to get very, very cold this week. But no big deal I have all winter to work on this project. A big thank you to Alex for reaching out to me with some misc. parts he has to offer. never knew there was a place only 30 minutes away from me who deals in old tractor parts.

|

Posted By: SteveM C/IL

Date Posted: 08 Dec 2019 at 10:04pm

| Always replace cam bearings on an old AC |

Posted By: Sugarmaker

Date Posted: 09 Dec 2019 at 7:24am

|

Greg, That is looking like a Allis engine torn down! Clean up and inspection next. Your moving right along! Thanks for the update on your progress! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: DiyDave

Date Posted: 09 Dec 2019 at 7:37am

I wouldn't go with emory cloth, try some of those scotch-bright pads, finest you can get... ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

gman54313 wrote:

gman54313 wrote: