AC 655 Shuttle Clutch

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=164642

Printed Date: 06 Feb 2026 at 4:46am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: AC 655 Shuttle Clutch

Posted By: Mikeys250

Subject: AC 655 Shuttle Clutch

Date Posted: 27 Sep 2019 at 3:14pm

|

New to the forum and new to owning a dozer. I picked up this 655 Track loader for $3k not to long ago, it runs great but it needs a shuttle clutch. I have the parts and the service manual and Im pretty mechanically inclined so I am going to tackle this one on my own. So what i was hoping for is somebody has some pics or videos or just tips on splitting the case to get to the clutch out. Thats the only part Im really concerned with. I have searched for a while trying to find any videos on splitting a dozer/crawler and can not find anything.

|

Replies:

Posted By: Randaleky

Date Posted: 27 Sep 2019 at 8:09pm

| Have you checked the pressure to the shuttle shift valve ? or the filter up front behind the screen ? any leaks of convertor oil on the ground ? |

Posted By: Randaleky

Date Posted: 27 Sep 2019 at 8:14pm

| does unit move in either direction? oh by the way welcome to the forum . Nice looking loader. I have Hd4 dozer and track loader . Hope I can help you . |

Posted By: NomoreJohnDeere

Date Posted: 27 Sep 2019 at 8:42pm

|

you got a good deal I know skwat but wonder if clutch/shuttle can be pulled without splitting......... does it have a plate you can remove and take a look? ------------- HD3 |

Posted By: Randaleky

Date Posted: 27 Sep 2019 at 10:32pm

| must be split . 6 inch plate on side where lines go in but too small for shuttle removal . |

Posted By: Mikeys250

Date Posted: 28 Sep 2019 at 4:02pm

|

Thanks for the replies. I haven’t checked the pressures. It runs strong for the first 20-30 minutes till it gets hot. I’m pushing trees on a hill so I’m running it hard. I know it’s slipping because I can hear it and I can idle down, get it to catch and then idle up and pull. Any tips on splitting it? |

Posted By: Mikeys250

Date Posted: 28 Sep 2019 at 4:05pm

|

Also it’s weaker in reverse than forward when it starts slipping which is another reason I am ASSUMING the pressure is good. The manual gives me directions on checking pressure so I will check it just to be sure. I was wrong one time before lol. |

Posted By: Big Jim

Date Posted: 28 Sep 2019 at 6:04pm

|

I think the clutches are alright. It sounds to me like when everything gets hot the pump is sucking air on the return line. Check pressure when hot. then check the rubber hose at the end of line next to the transmission. I think this is where your problem is. |

Posted By: Randaleky

Date Posted: 28 Sep 2019 at 9:31pm

| since it works very strong till it gets hot , it is not the clutches. Jim is right. suction line or pump , and check the filter for starters . |

Posted By: david a

Date Posted: 30 Sep 2019 at 4:08pm

| good place for parts redoing one in my 816 was told none available. found this companythey still have some of the parts sales@joseph.com |

Posted By: Mikeys250

Date Posted: 30 Sep 2019 at 5:41pm

|

David Steiner tractor has all the parts I needed. |

Posted By: Mikeys250

Date Posted: 30 Sep 2019 at 5:43pm

|

So I checked the shuttle pressure and I can only get up to 150psi at wide open throttle. I drug the bucket and loaded it up and it jumped to 175ish one time. Looks like a am going to change fluids and filters and see what happens before I do clutches. |

Posted By: Randaleky

Date Posted: 01 Oct 2019 at 1:53pm

| be sure to check the suction line after it gets hot. most likely the problem . |

Posted By: Randaleky

Date Posted: 01 Oct 2019 at 1:59pm

| also, rather than dropping the belly pan , run it till it gets to slipping and check the pressure and then tighten the clamps on the return suction line. look down the left side of the convertor tube and you will see it and the clamps . should fix it . |

Posted By: Mikeys250

Date Posted: 01 Oct 2019 at 3:46pm

| I know where the filter is but how do i get to the "screen" |

Posted By: Randaleky

Date Posted: 01 Oct 2019 at 7:13pm

|

you talking about the suction screen on the return line or what ? |

Posted By: Mikeys250

Date Posted: 02 Oct 2019 at 7:46pm

|

Yeah whatever screen there is in this system. Update I checked pressure, couldn’t get over 150psi and mainly hovered around 100psi. It jumped around a good bit. I changed the fluid because it looks like it may have a little water in it. Changed the filter and tightened all the band clamps on the rubber boots. Filled it back up let it warm up and put it in gear. Now I can barely get over 50psi??? I thought it may be air in the line so I let it run for about 15 minutes then I Moved back and forth for about 15 minutes and the result didn’t change. |

Posted By: Randaleky

Date Posted: 02 Oct 2019 at 10:17pm

| you could put a pipe t in the line coming out of the filter that goes to the shuttle valve. insert the pressure gauge to see if pressure is 150 or more. if not check back toward the pump which is fed from the sump line . there is supposed to be a screen in the line from the pump to the convertor tube. did you find hose that connects to the shuttle sump located at the convertor tube. there are clamps there also. sometimes the rubber hose over the metal sleeve at the sump gets rotten and allows air to suck into the system. tough location especially on the loaders. |

Posted By: Mikeys250

Date Posted: 03 Oct 2019 at 7:46am

|

I will check the line coming from the filter. Also I tightened the clamps on the rubber boots at the pump and at the converter tube. I cleaned them up and checked them best I could without removing them and they seemed to be intact. I didn't want to remove them and break the seal if there was one. |

Posted By: Randaleky

Date Posted: 03 Oct 2019 at 2:52pm

| sounds good . were you able to get all the way down to the sump connection ? I do not believe you have a serious problem . Might take line coming from the filter to the shuttle valve loose and put it into the location where you add fluid for the torque tube. start it up on idle and see if you get any air out of the system. You may want to let it pump into 2 gal. jug or bigger. the convertor fill tube may not take it fast enough. just a thought. |

Posted By: Mikeys250

Date Posted: 04 Oct 2019 at 7:14am

|

Yes I got all clamps from the pump to the sump on both sides. I will try to crack a line tonight and see what happens. What is the line that runs from the pump to the sump on the left side ? what is the line that runs from the pump under the engine and to the back of the trans on the right side? Randal if you were a little closer I would just haul it to you and we would get it figured out quick Im sure. |

Posted By: Randaleky

Date Posted: 04 Oct 2019 at 10:12am

| Yes if only we were closer we could get it fixed. The line from pump under engine to the right side is for the hydraulics. The line on the left side to sump is the suction line for the back end of pump that is for shuttle clutch you are checking. |

Posted By: Mikeys250

Date Posted: 05 Oct 2019 at 11:49am

|

I’m officially stumped. I changed both rubber boots at the sump and at the pump. Checked all my fittings in the system for leaks and I’m up to 60psi. I took my gauge off the tee and let it purge out for a second and didn’t get any air. It’s got ok flow but it’s not 250pei worth. I don’t know what to check now |

Posted By: Mikeys250

Date Posted: 05 Oct 2019 at 1:00pm

| And one more thing. I can’t find the screen anywhere in this system. Where is it? |

Posted By: Big Jim

Date Posted: 05 Oct 2019 at 3:51pm

|

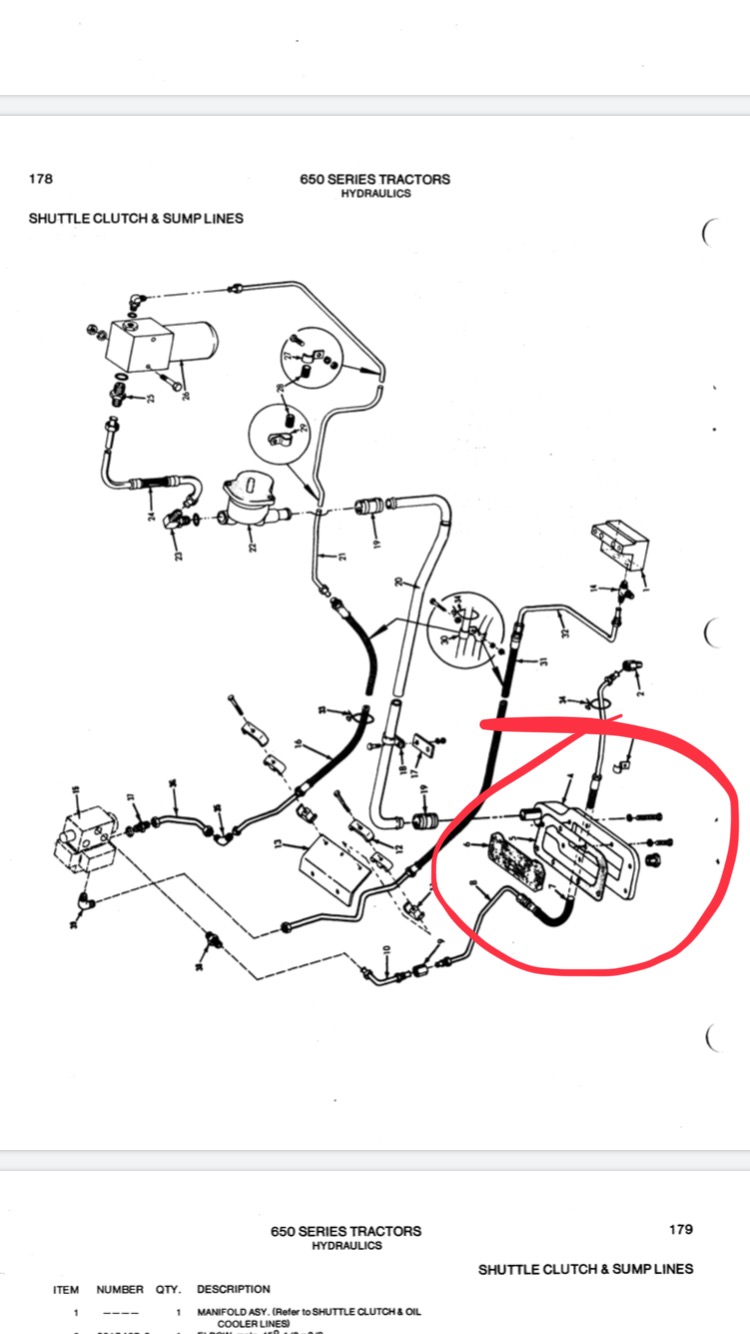

You said you had the service manual, but do you have the parts manual? they are most times together. The parts manual show a brake down of this sys on page 178 with the screen. I thinking your trouble maybe with the relief valve or spring in the shuttle valve on page 188. If you do not have these send me private message with your address and I will mail you copies. Jim |

Posted By: Mikeys250

Date Posted: 05 Oct 2019 at 3:57pm

|

I have a digital copy of the parts manual. I think I should have said how to I get to the screen in the sump? I think you may be right about something in the valve. The manual says if it’s only 50 psi is the relief valve but I’m tryong to get everything else clean before I get to it. |

Posted By: Big Jim

Date Posted: 05 Oct 2019 at 4:11pm

| The picture shows you how to get to the screen. |

Posted By: Mikeys250

Date Posted: 05 Oct 2019 at 7:37pm

| Which picture? |

Posted By: Randaleky

Date Posted: 05 Oct 2019 at 8:17pm

| If you can not get pressure on the line at the filter there would be no way to get it at the shuttle valve. I still think the problem is between the pump and sump. could be a crack in the metal line from pump to sump ? is the convertor tube still full of ATF fluid ? The torque convertor holds several quarts itself. By the way how did the front filter look ? any metal or things that should not be there ? |

Posted By: Mikeys250

Date Posted: 05 Oct 2019 at 8:52pm

| Everything looked pretty clean except some signs of water in the ATF from the old cracked cap I believe. I actually cleaned the whole metal line from sump to pump and it wasn’t wet anywhere. |

Posted By: Randaleky

Date Posted: 05 Oct 2019 at 10:55pm

| if you checked pressure at the filter and only got 60 then it appears like problem is back toward the pump. I an wondering if the back end of the pump which is for the convertor side is driven by a keyed shaft and the key could be sheared ? I will look it up on my parts book and see . this is stumping me also. |

Posted By: Randaleky

Date Posted: 05 Oct 2019 at 11:36pm

| when the problem first happened after operating 30 minutes , did the hydraulics for the loader bucket loose its power ? |

Posted By: Big Jim

Date Posted: 06 Oct 2019 at 11:15am

| the picture in the parts manual shows where it is. |

Posted By: Mikeys250

Date Posted: 06 Oct 2019 at 11:50am

|

No the loader hydraulics stay strong at all times. I really think I’m gonna find this sump screen clogged and starving the pump for fluid. Since I had 150psi and I drained the fluid and I dropped to 50psi I think more settled on the screen when the fluid was drained. |

Posted By: Randaleky

Date Posted: 06 Oct 2019 at 4:41pm

| My parts manual for the HD4 shows the screen assembly to be in line just short of the bend in metal line where it turns down to the sump. My HD 4 dozer does not have a screen in the line . I think many screens were eliminated by the owners . Might be some type of screen in the tube attached to the sump pan. |

Posted By: Mikeys250

Date Posted: 06 Oct 2019 at 6:05pm

The way I’m looking at mine it looks like it’s either bolted to the bottom of the rear compartment or inside the compartment.

|

Posted By: Big Jim

Date Posted: 06 Oct 2019 at 6:06pm

|

If you go down the line to the rubber hose. The hose goes on the cover asy. The cover is held on with 8- 5/6 bolts. the screen is inside. |

Posted By: Mikeys250

Date Posted: 06 Oct 2019 at 6:20pm

| So I’m gonna loose all the fluid when I do that correct? |

Posted By: Big Jim

Date Posted: 06 Oct 2019 at 6:33pm

| I hate to tell you, yes. |

Posted By: Randaleky

Date Posted: 06 Oct 2019 at 9:27pm

| should be a drain plug on bottom of torque tube . use a plastic drain pan to save the fluid . |

Posted By: Mikeys250

Date Posted: 09 Oct 2019 at 11:30am

|

Ok folks. I haven't made it the sump yet but I have another question yall might can help me with. Does anybody know of a boneyard or anything that might have used loader buckets that will fit this tractor? Once I get it all running right I would like to put a 4 in 1 on it since its already plumbed for it. |

Posted By: NomoreJohnDeere

Date Posted: 10 Oct 2019 at 8:30am

|

https://www.facebook.com/marketplace/item/507274356711480/" rel="nofollow - https://www.facebook.com/marketplace/item/507274356711480/ ------------- HD3 |

Posted By: Tracy Martin TN

Date Posted: 10 Oct 2019 at 9:17pm

|

Blount used parts, Hoboken, GA. HTH Tracy ------------- No greater gift than healthy grandkids! |

Posted By: Mikeys250

Date Posted: 25 Oct 2019 at 1:33pm

| Well I got the pressure up to about 230psi finally. Found the sump clogged and the line comes from the pump to the winch control valve and I was loosing pressure somewhere in the winch or valve so I bypassed they winch valve completely. Now I have full power in reverse all the time and only full power forward until the fluid gets up to temp. Stumped again. I’m chasing my tail it feels like |

Posted By: Mikeys250

Date Posted: 25 Oct 2019 at 2:34pm

| Correction. I had the pressure up. I took the gauge off and started working it. Strong when cold but I put the gauge back on and I’ve lost pressure again. Also have a whining sound coming from valve once hot. Maybe the relief is sticking? |

Posted By: Randaleky

Date Posted: 25 Oct 2019 at 10:47pm

| May need to take the shuttle shift valve apart to find problem . could be broken springs or gunked up. |

Posted By: Randaleky

Date Posted: 25 Oct 2019 at 10:54pm

| or could be yet a problem in sump , lines , or even the filter . At least you know you can get pressure and clutches are ok. Hang in there . |