WD Pulley

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=163164

Printed Date: 14 Oct 2025 at 3:48pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: WD Pulley

Posted By: EPALLIS

Subject: WD Pulley

Date Posted: 28 Jul 2019 at 1:23am

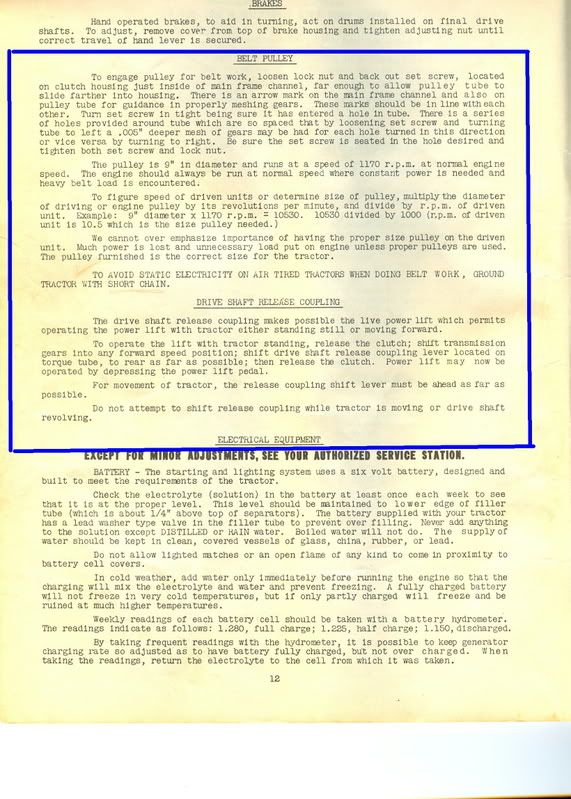

| My 1951 WD has a pulley on the side. Unfortunately for me, the pulley use was before my time. I tried to read up on how to make it turn. Seems that there is a "large set screw type bolt" above the pulley. Something about removing that and pushing the pulley in and then "reinserting it" makes it turn? Does that sound correct? The set screw is pretty dirty so I thought I would remove it, clean it with gasoline and re-insert it. I don't plan on using it yet. However, it was nice to know how it is supposed to turn. Thanks in advance! |

Replies:

Posted By: JayIN

Date Posted: 28 Jul 2019 at 6:12am

|

Belt pulley. For flat belt work. If it is a v groove then it had a mounted sycle bar mower or a mounted cornpicker. ------------- sometimes I walk out to my shop and look around and think "Who's the idiot that owns this place?" |

Posted By: Sugarmaker

Date Posted: 28 Jul 2019 at 8:11am

|

EPAllis, Sounds like the way they should work. Not a lot of flat belt pulley action anymore but it was a optional accessory that came on most of the AC tractors of that time. Good luck with your tractor! We need some pictures too!:) Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Ed (Ont)

Date Posted: 28 Jul 2019 at 8:23am

|

Just as you said. Loosen set screw, push pulley in all the way- usually about an inch. Tighten set screw. Look at the big pulley shaft. You should easily see how much it has travelled in and out by the wear mark on shaft unless it has never been used. Push it in hard to make sure it bottoms. You will hear and feel it. These tractors worked well on pulley! :-) |

Posted By: JK in Pa

Date Posted: 28 Jul 2019 at 8:36am

| Never do this while the engine is running! |

Posted By: JoeM(GA)

Date Posted: 28 Jul 2019 at 8:57am

https://s33.photobucket.com/user/Joecdeere/media/tech%20pic/beltinst.jpg.html" rel="nofollow"> ------------- Allis Express North Georgia 41 WC,48 UC Cane,7-G's, Ford 345C TLB |

Posted By: EPALLIS

Date Posted: 28 Jul 2019 at 1:16pm

| You guys are awesome! It is a v groove pulley. Since the WD has an air cleaner stack with "screen" around it, that seems to indicate it is a corn picker pulley. However thanks for offering it could of also been a mower. Great information about "arrow marks" on main frame and pulley tube. I'll look for those next as they are currently not obvious to see. They might be covered up with paint and/or dirt. Also, thanks for posting about shutting the tractor engine off. There is no warning sticker on it, so I'll be sure the engine is off when doing any thing with it. Special thanks to Joe M for taking the time to post the actual bulletin on the belt pulley. Really appreciate the extra effort you went to upload that information! |

Posted By: BigGuy1000

Date Posted: 28 Jul 2019 at 7:13pm

|

The mark may not be an arrow, may be only a small punch mark on the main channel above the pulley, as it is on mine, it may be hard to find, clean the top of channel well to see. May only be a small mark on the pulley shaft as well, although on mine it is a chisel cut about an inch long, so easy to see! |

Posted By: SteveM C/IL

Date Posted: 29 Jul 2019 at 9:22am

| There are a series of set screw holes on a spiral so you can achieve correct backlash if i remember correctly. |

Posted By: JoeM(GA)

Date Posted: 29 Jul 2019 at 1:07pm

|

yes there are https://s33.photobucket.com/user/Joecdeere/media/tech%20pic/beltdrive2.jpg.html" rel="nofollow">  ------------- Allis Express North Georgia 41 WC,48 UC Cane,7-G's, Ford 345C TLB |

Posted By: Jim Hancock

Date Posted: 29 Jul 2019 at 11:20pm

|

And I'll add in here to allow 1/8" rotating backlash when you find the hole that allows that much play. This slack is to allow for the metal to expand as the gears heat up while running and therefore tightening up into the matching gear without putting anything into a bind. My dad informed me of this when we'd belt up to the hammer mill to grind feed. You can look into the screw hole and see one of the holes on the pulley shaft as it slides in and know which hole to square up to give you that play. The set screw will fit in the hole to lock it in place and the big lock nut will keep it from backing out once cranked down. HTH. ------------- How blessed we are by HIS GRACE! |

Posted By: Ed (Ont)

Date Posted: 30 Jul 2019 at 9:00pm

|

I just looked at mine to see the markings. It has 3 punch marks on the big shaft. 5 on the side of the frame aligned with the ones on the shaft and 2 more on the top side of frame that are easily visible. So its well marked.. All in line. |