machine shop questions

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=161121

Printed Date: 16 Dec 2025 at 8:02am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: machine shop questions

Posted By: LouSWPA

Subject: machine shop questions

Date Posted: 18 May 2019 at 1:10pm

|

OK, I have a CA head with sticking valves, two bad exhaust valves and valve seats. I'm thinking, with the proper ream, I can clean up the guides. I can buy a valve seat cutter to clean up the two bad seats. I have a couple used valves to replace the burnt/cracked ones. lap all eight valve/seats and I'm back in business....right? Anybody see any problems with this plan? one I see is the cost of the valve cutter. I'm weighing the viability of this plan, chance of success/cost v finding a good used head. all input appreciated ------------- I am still confident of this; I will see the goodness of the Lord in the land of the living. Wait for the Lord; be strong and take heart and wait for the Lord. Ps 27 |

Replies:

Posted By: joelsplace

Date Posted: 18 May 2019 at 2:01pm

|

If that is all that is wrong with yours I would fix it. You never know what you are getting with a used "good" head. ------------- 1975 7040 w/Power Director |

Posted By: B26240

Date Posted: 18 May 2019 at 3:12pm

| Does the seat cutter come with the correct size stem for your guides? The older I get the more I'm in favor of do it yourself fixes although I must admit I don't have 100% success. |

Posted By: Gerald J.

Date Posted: 18 May 2019 at 3:32pm

|

You can grind the valve heads and the seats at the same time with valve grinding compound and a tool to rotate he valves in place. Shop manual may describe that method: http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf" rel="nofollow - http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf Gerald J. |

Posted By: LouSWPA

Date Posted: 18 May 2019 at 5:46pm

|

Thanks Gerald, I know that can be done, but these seats have a pretty good 'trough' around the circumference, where the valve wore right into the seat. I have the oscillating tool that fits in the drill, I guess it wouldn't hurt to try, that would cost nothing except some grinding compound ------------- I am still confident of this; I will see the goodness of the Lord in the land of the living. Wait for the Lord; be strong and take heart and wait for the Lord. Ps 27 |

Posted By: DiyDave

Date Posted: 18 May 2019 at 6:39pm

Labor is all the same, to R&R head, head gasket, and re-torque. Likely you can get the whole job done at a good machine shop, I think the last head I had the guides knurled, seats ground, and head pressure tested, for less than $500, and the seat cutter and other tools you might need will likely cost you more than that... ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: acd17toy

Date Posted: 18 May 2019 at 6:40pm

|

Lou, many many years ago I did what you are thinking of doing, that used valve cost me a complete engine rebuild after about 100 hours of run time after used valve was installed.

|

Posted By: joelsplace

Date Posted: 18 May 2019 at 8:24pm

|

It is actually lapping compound that you use to do a final mating of the valve and seat after cutting them. Won't do any good on messed up parts. ------------- 1975 7040 w/Power Director |

Posted By: JC-WI

Date Posted: 18 May 2019 at 8:59pm

|

At one time, you could buy valves with oversized stems and run a reamer through to refresh the guides to round. Don't know if they are available anymore. I would not bother with used EX. valves but put new ones in on recut/replaced seats... If your going to run it only a few hours a year, cheap should be sufficient but if your going to use it hard, get her done right. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: Alex09(WI)

Date Posted: 18 May 2019 at 9:48pm

|

If you feel confident in your ability then go ahead and do the seat grinding yourself. The tool is expensive but next time you won't have to buy the tool when you need it! I would not recommend using used exhaust valves, new ones are $10 or less new. While you have the head off, I would freshen up all 8 seats and freshen up all valves unless the face that contacts the seat is not grooved. Then use your valve lapping compound to lap the valves to the seats to make sure they seal good. Unless you come across a rebuilt head, might as well fix your own instead of buying a good used one. ------------- www.awtractor.com A&W TRACTOR 920-598-1287 KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY |

Posted By: Fred in Pa

Date Posted: 19 May 2019 at 7:15am

|

Make sure seat width is correct to the valve . Just my opinion ,just because people can buy tools to do the job, dose not mean they can do the job with the tools. Good luck . ------------- He who dies with the most toys is, nonetheless ,still dead. If all else fails ,Read all that is PRINTED. |

Posted By: Dick L

Date Posted: 19 May 2019 at 7:51am

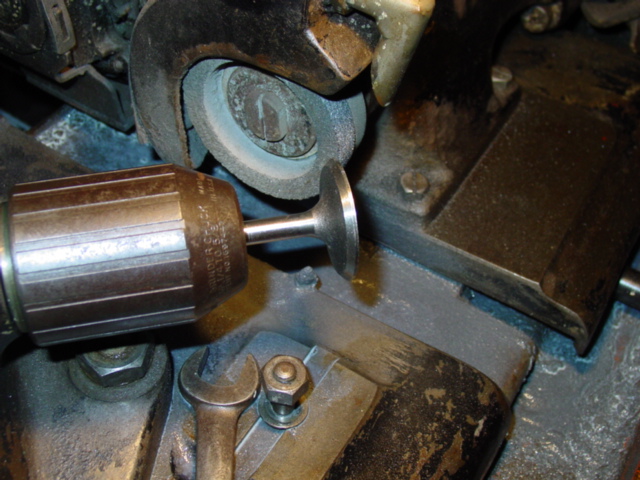

I would never try to reuse valve guides. They are cheap and easy to replace. The new ones. The ones you would take out would have a head on top and the new ones do not. Some have a scribe line for the depth. The guides that don't you just measure. I ground a block for the height. I ground a punch pin with a pilot to go inside that was slightly smaller on the outside than the guide. I mostly used a press to remove and replace the guides. I have also used the punch and a hammer.

|

Posted By: Dick L

Date Posted: 19 May 2019 at 8:16am

|

Lapping is a final step in sealing up the valve to seat. Lapping until you have groove is short term at best. I was taught to spark the new valve faces in the 1950's and would still if I was doing them now. Sparking a new valve is only seeing a spark as it rotates slightly against the wheel.

|

Posted By: Lon(MN)

Date Posted: 19 May 2019 at 8:18am

| I have rebuilt heads on the shelf. New valves, guides, springs, and keepers. manifold and head surface machined. Tested for cracks. $350. |

Posted By: SteveM C/IL

Date Posted: 19 May 2019 at 9:39am

| There ya go Lou. Cough it up and be done. |

Posted By: frnkeore

Date Posted: 19 May 2019 at 1:17pm

|

$350 is a good deal for what it includes, if you don't have to pay for shipping. Valve guilds can make or break a long term valve job. Intake clearance, generally runs .001 - .002 and exhaust clearance .002 - .003. To much intake clearance leads to pulling oil into the combustion chamber. If you see build up on the under side of the valve, the guild has way to much clearance. To much exhaust clearance will contaminate the oil, caused by exhaust gases getting into the crankcase. Bronze valve guilds are preferable, if you can get them. They last longer and will stick less. Good guilds means that the equipment doing the grinding, both the value and seat, needs to be accurate. With only .001 - .002 clearance, to work with the valve run out shouldn't exceed .001 or, the valve will hit the seat, off center.. Thoughs of you that have value grinding machines, need to check the run out, with a new valve, in place. Check it with 7/16, 3/8 and 11/32 valve stems, to be sure the chuck isn't warn over any part of that range. For valve seat grinders (or cutters), the guild for the stone and the stone arbor needs to be in good shape. If the guild isn't in the center of the of the valve guild and well seated, the seat will off center of the valve. When you lap, use Dykem or a wide felt tip pen, to mark the valve seat, lap until you get a pattern .045 - .060 on the intake and .060 - .085 on the exhaust. Then, came back with a 15 deg stone for 30 deg seat or a 30 deg stone for 45 deg seats and grind to your lapped pattern. You should also touch up the the inside of the seat, with a 45 or 60 deg stone or cutter. I like using cutters for this, stones like to grab and chatter, as well as break. One other thing, if you have a value grinder, break the back edge of the value seat, at 15 deg less, it will increase flow. You can reduce it to the valve contact area or so. Do this when you first grind the valve or to new valves. It also helps with lapping. Last, if you don't have hardened exhaust seats, have them installed. ------------- Frank 1959 D17 Series I #24001+, '59 D14 '55 & '59 Ford 850 & 861 Ferguson TO 35 Deluxe, Oliver 70 and 5 more. |