49 Allis g timing issue?

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=160425

Printed Date: 05 Feb 2026 at 4:52pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 49 Allis g timing issue?

Posted By: Bob B

Subject: 49 Allis g timing issue?

Date Posted: 27 Apr 2019 at 10:49am

|

Hi all, first time poster. Recently inherited 49 Allis g, in shed 10 yrs or so. Tank cleaned, new fuel lines, carb rebuild kit installed, new plugs, wires,coil. New points and condenser. Engine cranks over, spark to plugs ok. Getting little smoke and a few pops through exhaust but will not start. When #1 @ TDC, the pulley mark is 90 degrees short of lining up with the hole at the bottom. Have tried distributor positioning per the manual as well but no luck. Any suggestions would be greatly appreciated. Thanks |

Replies:

Posted By: Dick L

Date Posted: 27 Apr 2019 at 1:19pm

|

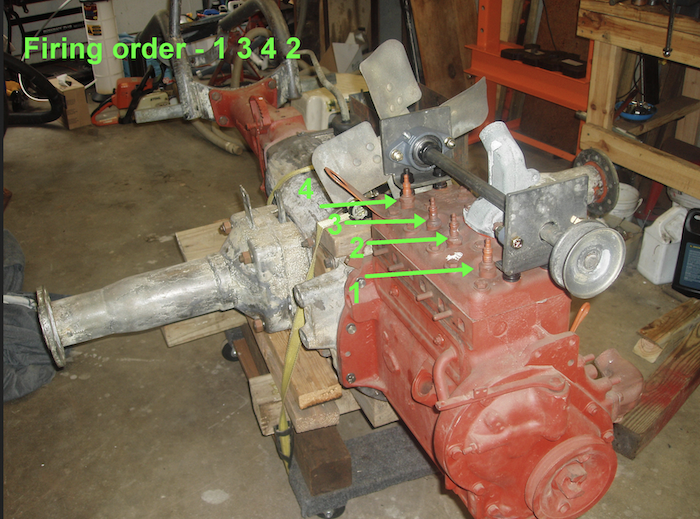

Welcome aboard to one of the best boards on the net. Number one cylinder is at the rear of the tractor. Firing order is 1-3-4-2 on the G. With the number one cylinder at top dead center (TDC) on the compression stroke remove the distributor cap and point the rotor at the number one wire terminal. If it has been messed with you may need to lift the distributor out and reset it so the rotor points the correct direction. Loosen the distributor base and rotate it back and forth watching the points and tighten it back down when the points are closed and about to open. That will place you in time. Make sure of the firing order as this is a Continental engine not an Allis Chalmers. |

Posted By: Bob B

Date Posted: 27 Apr 2019 at 4:14pm

|

Thanks for the reply. Did what you recommended and the backfire from the exhaust stopped but just won't start. I have made it this far with little experience just by reading this fine forum. Confident this will run, eventually 👍 I guess the thing I am most confused about is the timing mark on the pulley. Manual says 6:00 position when #1@TDC but when I stop at #1 TDC using a wire, the mark is at 3:00 on the pulley. Not sure what that is telling me, if anything. |

Posted By: Dick L

Date Posted: 27 Apr 2019 at 5:10pm

Your sure your on the compression stroke? The piston comes up to TDC on both the compression and the exhaust. It is hard on that tractor to hold your thumb over the spark plug hole to feel the pressure. |

Posted By: Bob B

Date Posted: 27 Apr 2019 at 6:11pm

|

Yes sir, on the compression stroke. Not sure what it means though. Should note there is no air cleaner, just the tube. It is clean and I put a cloth over it. Not sure that means anything regarding tractor not starting. Starter seems to crank slow, but likely from overcharging battery while trying to start engine. Starter has not been replaced. Thanks |

Posted By: Dick L

Date Posted: 27 Apr 2019 at 7:10pm

The compression stroke means that both valves are closed when the piston comes to the top to compress the air fuel at the point of detonation to create larges explosion possible to turn the crankshaft. The next time the piston comes up one valve leading to the exhaust manifold is open to clear the cylinder to draw the fuel air mixture in on the way back down. The air filter will cause no problem not being there in starting or running. that filter is to keep dust and dirt out of the engine when running in a working condition. If your sure you have timed as described you might give it a whiff of starting fluid to see if it will fire. You might take the distributor cap off and watch the rotor turn to make sure the plug wires are in the correct rotation and the wires are going 1-3-4-2 starting at the crank pully end with 1 with 4 toward the seat going to the engine spark plugs. a good spark at the correct time and a proper fuel air mixture under compression is all it takes to make the engine run. |

Posted By: Bob B

Date Posted: 27 Apr 2019 at 8:25pm

|

Thanks for the explanation. Will try watching the rotor when it spins. It is so close to starting compared to when we brought it home a couple months ago. Has kinda gone from a challenge to a quest lol. The manual does mention to point the coil terminal at #1 plug and point the rotor to the clip farthest from the terminal before putting the distributor in. But that makes the rotor point away from #1 cylinder. When lined up this way it gets pop or backfire thru exhaust. When I change rotor position to point to #1 and move wires accordingly, the backfire stops but doesn't try to start. Puzzling. Thanks, need all the advice I can get to see this machine run |

Posted By: Dick L

Date Posted: 27 Apr 2019 at 9:23pm

Normally when that happens you have it firing on the exhaust stroke. That is called 180º off. I am more than a couple miles away so this is the best I can do. That is correct, the spiral distributor gear turns the rotor as it is installed so it needs to reset until the rotor points to the correct position. |

Posted By: Bob B

Date Posted: 28 Apr 2019 at 7:06am

|

Appreciate your patience and explanations, will try these procedures again. Thanks |

Posted By: Gerald J.

Date Posted: 28 Apr 2019 at 11:16am

|

The shop manual may have some useful hints. http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf" rel="nofollow - http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf Gerald J. |

Posted By: Bob B

Date Posted: 30 Apr 2019 at 8:55am

| Thanks for the link. Tried again yesterday and now have created new issue. Starter is cranking very slow. Took battery to local shop and it tested good. Brand New battery cables, 00 wire from welding supply store. Must've worn out starter from trying to get this machine started or something. |

Posted By: Dick L

Date Posted: 30 Apr 2019 at 10:56am

It could be the starter switch on the starter being dirty or scared up from time of use. |

Posted By: Dusty MI

Date Posted: 30 Apr 2019 at 3:52pm

|

I have known that the advance retard mechanism to setup in advance and give problems. ------------- 917 H, '48 G, '65 D-10 series III "Allis Express" |

Posted By: Bob B

Date Posted: 07 May 2019 at 8:37pm

|

Potential new issue. New starter switch helped with slow cranking, re-checked timing, still pops thru exhaust ever so often. Noticed fuel leak from air intake after quite a bit of cranking. Checked float, seems ok. Pulled plugs and they were completely dry. Would think they would have been wet after all the attempted starts. If I were to try starter fluid, where on this model would I apply it? Air intake tube? Bottom of carb? Little square plug in side of exhaust manifold? Any help and/or recommendations how to proceed greatly appreciated. BB |

Posted By: Don(MO)

Date Posted: 08 May 2019 at 7:27am

|

I'd pull the manifold off and clean the mud dobbers out of it and the engine. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Bob B

Date Posted: 08 May 2019 at 11:20am

| Being in KS, understand muddobbers can be a problem. Just don't see how they could get in there. |

Posted By: chaskaduo

Date Posted: 08 May 2019 at 11:28am

|

A squirt of gas from a spray bottle might be easier on the engine than starting fluid if using the stuff a lot. ------------- 1938 B, 79 Dynamark 11/36 6spd, 95 Weed-Eater 16hp, 2010 Bolens 14hp |

Posted By: Dick L

Date Posted: 08 May 2019 at 11:28am

| It wouldn't matter much where you give it whiff of starter fluid. A whiff is not a stream. |

Posted By: Bob B

Date Posted: 09 May 2019 at 8:59am

|

Thanks for the replies. Have now re-tried timing settings several times with no luck. Tried whiff of starting fluid up thru bottom of carb and still get nothing, not even a pop. Checked carb float, needle, has spark at plugs, but getting nothing when cranking. Starter cranking speed slowing down again even with new switch and charger on battery (which checks good). Plugs are clean and dry as if no gas or starter fluid getting to them. Not sure what to try next. Please advise, thanks BB |

Posted By: Don(MO)

Date Posted: 09 May 2019 at 10:08am

|

Have you run a compression test and checked for mud dobbers they can get inside through the muffler and you said the air cleaner is off? ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Bob B

Date Posted: 09 May 2019 at 10:24am

|

Have not tried compression test. I do get a fair amount of air escaping around my finger when locating TDC. Will give this a try. Looks like should get about 90psi for a good reading on compression. Air cleaner was off, but tube was covered with a rag. Is it possible for muddobbers to get past/thru the carb to manifold? |

Posted By: Don(MO)

Date Posted: 09 May 2019 at 10:49am

Yes they can move inside like a pro-stock car can move down a drag strip. lol I see this happen in the Midwest on old tractors that have sat for years all the time.

------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Bob B

Date Posted: 09 May 2019 at 11:15am

| Ok, thanks. Will remove manifold and check it out |

Posted By: Bob B

Date Posted: 09 May 2019 at 7:45pm

|

Update: no obstruction found in the manifold. If not getting gas or starter fluid to the spark plug then must still be carb problem? |

Posted By: Don(MO)

Date Posted: 12 May 2019 at 9:49am

That's great, I hope you also looked in the In and Ex posts too. What was the comp. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Steve in NJ

Date Posted: 12 May 2019 at 2:22pm

|

Need spark and fuel to make an engine run. You have one (spark) but if the plugs came out dry with all the cranking you did, your minus the fuel side of it. Coarse being out of time doesn't help, but if it was getting fuel, it would be back firing all the time either out the intake or the exhaust. You have two problems. TIming/compression or lack of fuel to me. If the valves are to tight, that won't let fuel into the cylinders either. Did you have the cylinder head off? Steve@B&B ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: Bob B

Date Posted: 13 May 2019 at 2:53pm

|

Thank you guys for the response. Seems new (and old) issues keep popping up. Starter is back to turning very slowly after new switch installed. So, wondering is it possible to perform compression test using hand crank? Had starter tested. They said it tested a little slow but still ok. Beginning to think I may need new starter. Have not had cylinder head off.... afraid to due to my lack of experience. Anyways, thanks as always for your help. Any/all suggestions welcome at this point. BB |

Posted By: Alvin M

Date Posted: 13 May 2019 at 3:07pm

| if ground cable is hooked to batt box had some that the box was not grounded at lower mounting plate |

Posted By: HoughMade

Date Posted: 13 May 2019 at 3:23pm

|

Starter turning a little slow ill not keep it from starting. If everything else is right, it will start when it barely turns over. I think it's still your timing or magneto. The gas dribbling out after some cranking is just the engine vacuum pulling it up into the throat. No issue, at least not an immediately important one. ------------- 1951 B |

Posted By: Dick L

Date Posted: 13 May 2019 at 4:29pm

| One other guy a few years a go has similar problems. As I remember the venture was missing in the carburetor. |

Posted By: Bob B

Date Posted: 14 May 2019 at 3:37pm

|

Update: did compression test with the slow cranking starter today. Got up to 30 psi after about three revolutions and then the starter switch started smoking. Desperately needing something to go right on this project soon. Suggestions please Thanks BB |

Posted By: Dick L

Date Posted: 14 May 2019 at 4:05pm

| The switch is held on with two screws. It might be full of bugs and stuff. If the smoke came out of the starter that is a whole different deal. |

Posted By: Stan IL&TN

Date Posted: 14 May 2019 at 4:26pm

|

I would think you should have more than 30psi with 3 revolutions. Cylinders may be dry from sitting so long. Remove plugs and shoot some oil in each cylinder then retest compression. ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: Bob B

Date Posted: 14 May 2019 at 4:32pm

|

Switch is new. Will try small amount of oil in cylinders next. Thanks BB |

Posted By: Stan IL&TN

Date Posted: 14 May 2019 at 5:26pm

|

Bob you can also leave out all tha spark plugs when you do the compression test as it will be easier on the starter to turn the engine over. Also put throttle wide open for the test. ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: Bob B

Date Posted: 14 May 2019 at 10:15pm

| Took plugs out and tried again. Got 50 on #1, 60 on #2 and then the starter switch crackled and sparked and smoked. Not sure but seems to be burning the very center of the pircr inside switch that moves when lever pushes the button. The slanted copper button on the starter has a groove burned in it where the switch makes contact. |

Posted By: Dick L

Date Posted: 15 May 2019 at 5:54am

| You can have a new stud put in at a starter shop or you can file the stud some to get a better contact. |

Posted By: Bob B

Date Posted: 15 May 2019 at 7:52am

| Am I correct in assuming the slanted part of the stud is oriented so the push button makes full contact with the slanted portion of stud? It looks like the very center of the push button piece has been melted some, which may have been smoke I was seeing? |

Posted By: Bob B

Date Posted: 15 May 2019 at 2:15pm

|

Got the starter and switch to cooperate long enough to get compression readings for each cylinder. #1@50, #2@60, #3@35, #4@40. Would these readings indicate there should be enough to pull air/fuel mix into cylinders? Thanks, BB |

Posted By: Dick L

Date Posted: 15 May 2019 at 7:15pm

|

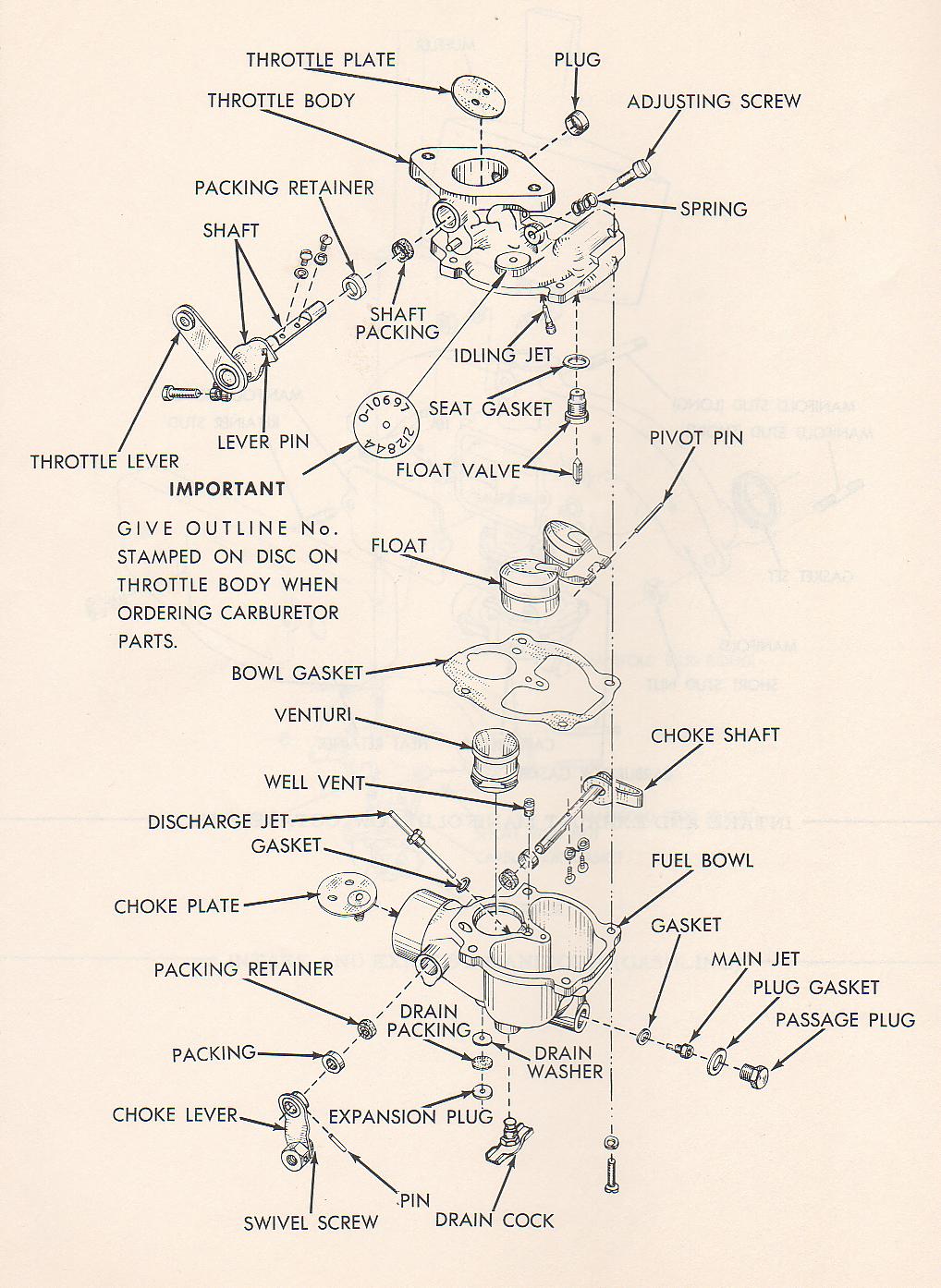

I am now thinking you might be missing the venturi in the carburetor. Dang auto correct. I didn't catch it the first time but this time I had to change the I from E back to I three times before it put the red line under it for me to add it to my dictionary. I bet several was wondering where the venture was. The rotating engine pumps air in thru the carburetor which without the proper size venturi it increase the vacuum on the feeder tube to draw fuel thru the jets it will not get fuel into the firing chamber. The venturi in that carburetor is not very large. I don't have a drawing for that carburetor but this will show where it is located.

|

Posted By: Bob B

Date Posted: 15 May 2019 at 8:44pm

| Venturi is there. Would low compression possibly be the problem in not getting fuel mix to the plugs? |

Posted By: Stan IL&TN

Date Posted: 16 May 2019 at 12:35am

|

I was always told that you need 80-90 psi minimum for an engine to run. I'm far from an expert but I believe that is the main problem. If you can get it started those numbers should go up some. ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: Stan IL&TN

Date Posted: 16 May 2019 at 12:45am

|

Low compression can be caused by worn rings, worn valve seats, sticking valves or valves with zero clearance and keeping the valve from closing all the way. Surface rust on the cylinder walls and the valve seats will also allow compression to escape. A bad head gasket might also do it but it is unlikely that it would affect all the cylinders. A complete engine overhaul may be in your future. Just saying. ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: Dick L

Date Posted: 16 May 2019 at 5:18am

| With what compression he has it should at the very least sputter and make some smoke. It does have get fuel to the plugs to do so. |

Posted By: Bob B

Date Posted: 16 May 2019 at 3:49pm

|

Well, tried once again with starter fluid and the starter switch burned out completely after just a couple revolutions. Metal connector on the switch button burned thru and came off the post. Never a chug, pop, or smoke from exhaust. Hate to even think about hand cranking trying to set timing right, get fuel, etc. Sure wanted to get this to run by myself (with help from this forum, of course). BB |

Posted By: Stan IL&TN

Date Posted: 16 May 2019 at 7:16pm

|

As far as the starter issue goes I'm thinking either the starter needed to be rebuilt as it is obviously pulling too many amps or that engine is that tight and hard to turn. I would pull the spark plugs out and using the hand crank I would manually turn over the engine. It should turn pretty darn easy with the plugs out. If it is hard to turn then that is not good and another indication the engine needs to be pulled and gone through. ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: john2189

Date Posted: 16 May 2019 at 9:59pm

|

Could he have a stuck open valve or two? ------------- '41 Allis B '45 Allis B '49 Farmall Cub '72 IH Cub |

Posted By: jaybmiller

Date Posted: 17 May 2019 at 5:47am

|

compression is too low to start it, there's a lot of 'dead 'weight to push with a wimpy bang. Need to remove valve cover and plugs then slowly rotate engine and CONFIRM all 8 valves are going up and down. That engine does not have sleeves in it, though you can buy them and have installed($$$$). get the starter system fixed, NO amount of hand cranking is better ,and it's a LOT safer !! You need 4 things to get her 'up and running'. 1) good,proper spark 2) good gas 3) ballpark timing 4) compression having one or two of these slighly off ,it'll still cough and maybe run, but 4 out of 4 is trouble. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Dick L

Date Posted: 17 May 2019 at 6:13am

No valve cover to remove.

|

Posted By: Dick L

Date Posted: 17 May 2019 at 6:31am

|

To get an accurate compression test on a non running engine that has set for a long period it has to rotate at starter speed with oil in the plug hole ten or more revolutions. I would also run the starter without plugs until I had oil pressure on the gage. The starter needs to work to get a dry engine lubed up or pulled for a distance. I would still open up the carburetor to make sure it had the venturi. Without it fuel can not get drawn thu the discharge jet. No fuel, No fire in the hole. Same if the carburetor has a plug somewhere. |

Posted By: Stan IL&TN

Date Posted: 17 May 2019 at 7:57am

|

Hey Dick you would think that the piston rings would get snagged coming up out of the block like that.............ok I'll go stand in the corner with my fingers crossed now.😳 ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: Bob B

Date Posted: 17 May 2019 at 8:20am

| Thanks. Will try to get starter to a shop for thorough checkout. |

Posted By: Bob B

Date Posted: 17 May 2019 at 8:29am

|

Thanks again for all the advice. Opened the carb, Venturi is there and really appreciate the continued education am getting here. If I pull it, do you mean try to pull start it or just pull it with plugs out and everything off to get engine lubed up? Thanks to all. Feeling hopeful again. BB |

Posted By: HoughMade

Date Posted: 17 May 2019 at 9:24am

|

I agree with the above advice to get it spinning before trying to start. There's a good chance you will see your compression rise if you can get it spinning. Plugs out, a little light oil in the cylinders and a willing youngster to crank and crank is one way. A big drill rigged up to the crank snout is another. My last choice would be the starter itself as it seems like a weak link in your case. ------------- 1951 B |

Posted By: Dick L

Date Posted: 17 May 2019 at 11:06am

|

I would pull it with the plugs out to get the oil thru the engine and cylinder walls. I would be a pain but you could pull it to get a good compression reading if your tester has a check valve to hold the high pressure reading on the gage. Always easier to use the starter. |

Posted By: Dick L

Date Posted: 17 May 2019 at 11:09am

The pistons have to be installed from the bottom. I decided it would be easier to put the rings on with the pistons up and use a ring compressor the same as any other engine that they are put in from the top. |

Posted By: cabinfourus

Date Posted: 22 Jun 2025 at 12:09pm

On the engine, starting at number one cylinder, are the cylinders 1234 and the timing is 1342 at the distributor? I guess I am asking if the cylinders are in a normal order of 1234 starting at the fan?

|

Posted By: JoeM(GA)

Date Posted: 22 Jun 2025 at 10:14pm

|

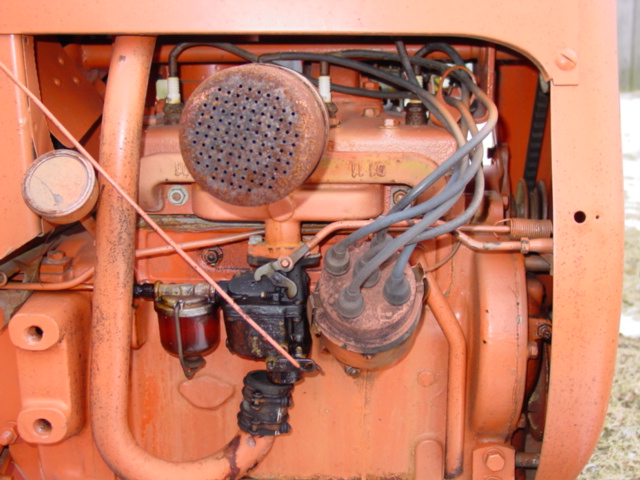

Remember, engine is mounted backwards!  ------------- Allis Express North Georgia 41 WC,48 UC Cane,7-G's, Ford 345C TLB |

Bob B wrote:

Bob B wrote: