WD starter removal

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=160403

Printed Date: 08 Oct 2025 at 12:42pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: WD starter removal

Posted By: Slowmotion

Subject: WD starter removal

Date Posted: 26 Apr 2019 at 3:11pm

| I don't see what holds the starter on. Do you remove the plate on the back to get at whatever holds it? And then what? |

Replies:

Posted By: Alvin M

Date Posted: 26 Apr 2019 at 3:13pm

| Bolt on the side of housing take it out the whole way |

Posted By: Brian G. NY

Date Posted: 26 Apr 2019 at 5:03pm

| That's the bolt with the locknut.....it has a tapered point that fits into a tapered hole in the starter housing. |

Posted By: garden_guy

Date Posted: 26 Apr 2019 at 6:04pm

|

Pretty easy. Jamb nut holds it in at one spot, and once you loosen that, you slide the starter straight out the back. |

Posted By: Slowmotion

Date Posted: 26 Apr 2019 at 6:41pm

| I see what look like two large, slot head screws on opposite sides of the starter. |

Posted By: AaronSEIA

Date Posted: 26 Apr 2019 at 7:01pm

|

Left side just ahead of the starter is a large set screw and jam nut. That is all that holds the starter in unless someone has messed with things. AaronSEIA

|

Posted By: garden_guy

Date Posted: 26 Apr 2019 at 7:34pm

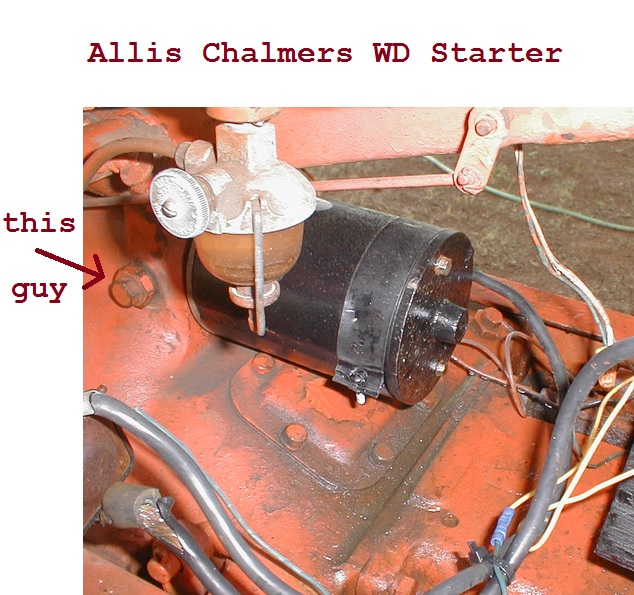

Grabbed a pic from the googles and put a bit of arrowing on it. Hope this helps. If yours looks somehow different, please provide a pic!  |

Posted By: Slowmotion

Date Posted: 26 Apr 2019 at 8:43pm

|

I found it. It's very clear with that photo. That makes sense, and what I was looking at didn't. I tried to break the bolt loose with a box end wrench this evening, but couldn't. I'll try again tomorrow with a bigger wrench. It looks like it's been many moons since the starter has been off the tractor. Thanks for all the help. |

Posted By: DSeries4

Date Posted: 26 Apr 2019 at 8:46pm

|

Between the air cleaner and headlight... ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: Eric B

Date Posted: 26 Apr 2019 at 8:59pm

|

Be very sure when you go to reinstall the starter that you back out the lock nut all the way so that the tapered bolt truly fastens the starter and then tighten the lock nut. On my one tractor I just discovered where the previous owner didn't back out the lock nut enough before tightening the bolt. The tapered bolt wasn't in all the way, this allowed for movement of the starter wearing the tapered hole bigger in the wrong direction and for some time the starter drive hasn't been engaging properly and consequently doing damage to the ring gear. This would have been so easy to prevent. ------------- Currently- WD,WC,3WF's,2 D14's B. Previously- I 600,TL745,200,FL9,FR12,H3,816 LBH. Earth has no sorrow that Heaven cannot heal! |

Posted By: Brian G. NY

Date Posted: 26 Apr 2019 at 9:23pm

| Break the nut loose before trying to break the bolt loose....that's why they call it a "lock" nut. |

Posted By: WF owner

Date Posted: 26 Apr 2019 at 9:53pm

|

If you have a 6 point deep socket, they work best to loosen the jam nut. |

Posted By: Slowmotion

Date Posted: 27 Apr 2019 at 2:47am

| So what I'm looking at is a tapered bolt with a smaller head passing through a larger lock nut/jam nut? I've never encountered anything like that before. If I turn the larger nut, it looks like the bolt will have to turn with it. I don't understand how it works. |

Posted By: Stan IL&TN

Date Posted: 27 Apr 2019 at 3:06am

|

Loosen big nut first. Then remove bolt. You will understand after it is removed.👍 ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: Jim.ME

Date Posted: 27 Apr 2019 at 4:59am

Here are a couple photos of the starter mounting setscrew and nut. It is possible that the nut will be rusted to the setscrew when you remove it and they can and will come out together at times. You can free them up after they are out. Clean the threads and coat with anti-seize before installing.

|

Posted By: jaybmiller

Date Posted: 27 Apr 2019 at 5:43am

|

On 2 of my D-14s, the bolt and nut came out as one unit. I put the bolt head in a vice ,then added some propane torch heat, some oil and carefully removed the nut. FIRST thing though... disconnect and remove battery from tractor !! Yeah, kinda obvious but I know someone who put a big wrech down on the MISSING battery box cover one day.. When you get the nut and bolt off, file any ridges on the tapers of the bolt. Also remove any paint,rust where the jam nut and the starter meet the cast iron. Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: B26240

Date Posted: 27 Apr 2019 at 6:32am

| I think the nut takes a 1 1/16 socket. After removing tapered bolt and jam nut use a small pry bar to remove starter. |

Posted By: jaybmiller

Date Posted: 27 Apr 2019 at 6:43am

|

yeah, 1 1/16.. I have two BIG combo wrenches, one's always 'hiding'... needed to TAP the wrench with 4" hammer to free one of the bolts. That I remember, thinking ,yeesh what if the bolt breaks? They must be made outta REAL steel cause once free it was easy. Will need to 'wiggle' starter as it's a tight fit... Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Sugarmaker

Date Posted: 27 Apr 2019 at 7:55am

|

Slow, Your doing good! If you have never seen one of these tapered, sq head, screw with the large jam nut, well welcome to the WD world of Allis. This was a favorite locking method for them. A little off topic but this is a partial list the places on a WD series that they exist: - Starter - crank pulley - belt pulley - I think there is a small one in the PTO box - small one in the hand clutch compartment Others? Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: ACinSC

Date Posted: 28 Apr 2019 at 11:59am

| On my old D 15 starter the 11/16 lock bolt was rounded off . Using a 6 point socket is very good advice . Also I was told this bolt and locknut are not available new . Thanks |

Posted By: AaronSEIA

Date Posted: 28 Apr 2019 at 2:25pm

|

I'm pretty sure I've seen them reproduced in the DJS catalog. AaronSEIA |

Posted By: ACinSC

Date Posted: 28 Apr 2019 at 3:09pm

| Haven't seen any in a catalog , but the good guy at Sandy Lake found a good used one for me . Thanks |

Posted By: Slowmotion

Date Posted: 28 Apr 2019 at 5:43pm

| Surprise, surprise! Everything came out easily. I bought a used starter from Sandy Lake and I'm wondering if there's anything I should know or do before installing it, such as lubricating it? |

Posted By: CTuckerNWIL

Date Posted: 28 Apr 2019 at 5:58pm

Clean any rust or paint from the hole that the starter fits into, and clean the outside diameter of the starter itself, where it contacts the housing. Then clean and polish up the stud making sure the tapered part is bare metal. Those points are where the starter grounds to the rest of the tractor, and paint or rust will only cause a slow crank situation by adding resistance. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: jaybmiller

Date Posted: 28 Apr 2019 at 6:49pm

|

Assuming it's 6 volts.... use BIG,FAT, welder cable sized premade cables and NOT small,skinny 'car duty' battery cables... Be sure EVERY connection is clean ! Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Michael V (NM)

Date Posted: 28 Apr 2019 at 7:56pm

|

sugarmaker clutch petal length adjustment...

|

Slowmotion wrote:

Slowmotion wrote: