How not to die under an HD6G loader

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=156792

Printed Date: 06 Feb 2026 at 3:08pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: How not to die under an HD6G loader

Posted By: Leop

Subject: How not to die under an HD6G loader

Date Posted: 29 Dec 2018 at 8:06pm

|

Hi gals & guys, I have noticed that working on the motor of my HD6G is a huge pain with the loader in the resting position. I have also noted that the bucket can be raised and will hold itself up for several days. Nevertheless, I simply dont trust it to stay up, or someone to not come bump the hydraulic control. If it came down with my head under the hood in would easily chop me in two. So, is there a pin someone can insert somwhere. That mechanicaly keeps it suspended. I assume that OSHA did't regulate such things back then, but i doubt there were many mechanics that would trust it even when it was knew! Ideas appreciated. Sincerely, Leo New HD6G owner. |

Replies:

Posted By: DiyDave

Date Posted: 29 Dec 2018 at 8:24pm

You can make up a piece of angle iron, that is the extended length of the lift cylinder(s), and clamp, or trap, or wrap with chains, or wire, to keep the cyl from coming down. Same principal, as a dump truck anti-colapse safety system...

|

Posted By: Leop

Date Posted: 29 Dec 2018 at 8:44pm

| I assume you mean to clamp it around the cylinder shaft, with ends resting against the clevis on one end and the body end cap on the other? |

Posted By: DiyDave

Date Posted: 29 Dec 2018 at 8:47pm

And if you can trap it, on the top of the cyl rod, that is even better, as it won't fall off, should the clamps fail...

|

Posted By: Leop

Date Posted: 29 Dec 2018 at 8:55pm

|

Something like this i assume http://www.emersonjacks.com/products/safety-equipment/cl-30-safety-cylinder-locks" rel="nofollow - http://www.emersonjacks.com/products/safety-equipment/cl-30-safety-cylinder-locks |

Posted By: Eric B

Date Posted: 29 Dec 2018 at 9:05pm

|

I'm glad you're thinking... we all wish to assume the best and not to expect the worst. I've owned and operated equipment for nearly 40 years especially loaders. We have probably all walked under a raised loader attachment at some time... thinking it's not coming down. That angle iron Dave mentioned is the way to go. Within the last two years it happened on my Cat 935 track loader. Loader was raised to the top engine shut off, while I was busy with something else not many feet away a hose burst and down came the loader attachment... the unthinkable does happen, thankfully I was not in the way. I would have made a bet it would never happen to one of my machines while not running - wrong! ------------- Currently- WD,WC,3WF's,2 D14's B. Previously- I 600,TL745,200,FL9,FR12,H3,816 LBH. Earth has no sorrow that Heaven cannot heal! |

Posted By: Leop

Date Posted: 29 Dec 2018 at 9:25pm

|

Thanks Eric, It seams as if I take a lot less chances sice the birth of my son. He has probably saved my life at least a half dozen times when I would have otherwise thought to take a short cut "because it will never happen to me". At most I have probably lost an hour or three cumulative by skiping those half dozen short cuts. |

Posted By: Jim.ME

Date Posted: 29 Dec 2018 at 9:27pm

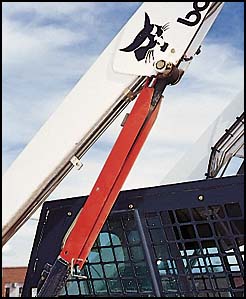

This is a support on a Bobcat. You would want to make similar, but heavier. The "U" shape is good and is easy to set in place. Angle iron with flat bar welded to it is one way you can make them. |

Posted By: Leop

Date Posted: 29 Dec 2018 at 10:25pm

|

I have a piece of box tube that would work if i cut off one side. Walls look to be 1/4" thick. I was thinking a couple of grade eight bolts maybe at each end and one in the middle should do the job. What do you guys think? Should i make one or two? Leo |

Posted By: desertjoe

Date Posted: 29 Dec 2018 at 10:27pm

|

Very interesting thread and some great ideas for Not taking any chances. When I removed the Backhoe off my D14 for cleaning and rebuilding,, The outrigger cylinders were holding it up right nicely and it was level to make the re-assembly easier. I kept worrying bout my young Grandson always wantin to help Grandpa,,,,,,,It finally bothered me to the point I cut 4 pieces of 2"X2" X 1/4" angle iron to fit snugly at both ends of the cylinders and welded them together . Never was bothered again it would come down because of the cylinders bleeding off. Way better safe than sorry.

|

Posted By: Jim.ME

Date Posted: 30 Dec 2018 at 5:37am

| The box tube would work good to make a support from. One is common, but having two may give you more piece of mind if you were going to be under it for extended projects or if kids are around. Look at where the end sets on the cylinder gland when you build them. I don't know what the glands of your cylinders look like and this may not be an issue. Make sure they set flat when loaded and don't crush any raised areas of the gland, you might have to make a custom foot to fit the gland. |

Posted By: Randaleky

Date Posted: 30 Dec 2018 at 10:58am

| I worked in underground coal mines all my life. the booms and cutter heads came with load locks which required hyd. pressure to release them. we always used crib blocks to block them up as required by MSHA law. Always better safe that sorry . |

Posted By: Leop

Date Posted: 30 Dec 2018 at 6:24pm

|

New Idea, What does everyone think of mounting some high pressure valves on the drain side of the cylinders right at the cylinders. Better yet mount them on both sides. Then when you lift the bucket simply shut off the valves. The only way the bucket could come down is if both the cylinder valve and the hydraulic controll failed on both sides. I suppose the seals on the piston could also fail, but you would still have the added displacement of the rod going back into the cylinder to hold it back unless the rod seals also failed. Thats a lot of stuff to fail before the bucket could accidentally come down on you. |

Posted By: NomoreJohnDeere

Date Posted: 30 Dec 2018 at 6:51pm

|

exactly more stuff to fail ------------- HD3 |

Posted By: DougG

Date Posted: 30 Dec 2018 at 8:04pm

| Just now thinking of this, it could be a big issue glad taking the safe route |

Posted By: HD6GTOM

Date Posted: 30 Dec 2018 at 8:36pm

| I simply chaned mine to the brush cab. |

Posted By: truckerfarmer

Date Posted: 30 Dec 2018 at 9:16pm

|

Use the KISS acronym. Keep It Simple Stupid! Don't add a bunch of valves. That will give you at least 8 more connections that could leak. A simple cylinder stop made out of a u channel is more than sufficient. I run heavy equipment for a living. Most of the ones that come with our equipment is a simple u channel with one pin in the middle. The pin is just to hold it in place. If the cylinder settles or a seal fails, all stress will be longitudinal trying to compress the channel from the ends. No actual leverage trying to pull it out of place to warrant anymore than one pin in the middle or one at each end, if the ends of the channel sit squarely on the cylinder housing and the clevis end. ------------- Looking at the past to see the future. '53 WD, '53 WD45, WD snap coupler field cultivator, #53 plow,'53 HD5B dozer Duct tape.... Can't fix stupidity. But will muffle the sound of it! |

Posted By: DMiller

Date Posted: 31 Dec 2018 at 6:17am

| If going to work under the lift arms for extended periods of time besides the cylinder brace remove the bucket from the arms, reduce the weight hanging out in space pulling those arms down. |

Posted By: jerbob

Date Posted: 31 Dec 2018 at 6:38am

|

Great advise everyone and much valued. I worked construction back in the 70’s and surrounded be heavy equipment daily. I was a pipe layer on crew working on underground projects. Have seen many short cuts made and safety overlooked. These comments are critical in a literal way. ------------- HD16DC, Bobcat 863 Turbo, Oliver 1855, John Deere 855, |

Posted By: exSW

Date Posted: 31 Dec 2018 at 8:33am

My round baler has that for the end gate. I still don't much like it. Couple pieces of angle and some hose clamps to hold in place. |

Posted By: Lee Bradley

Date Posted: 31 Dec 2018 at 1:20pm

| Check out the photos on 'Recovering HD-21G for collection' on this page for angle iron supports. |

Posted By: Ron Eggen

Date Posted: 06 Jan 2019 at 9:40pm

| Our local retired Ford tractor dealer was working on his Bobcat with the bucket up and it came down on his head, three days later he was laid to rest. |

Posted By: michale34

Date Posted: 07 Jan 2019 at 7:48pm

| My uncle had a john deere 400 backhoe. The deere mechanic was working on the wabble stick and decided to pull on the leavers while standing on the ground . He was crushed between the boom and out rigger . He was layed to rest a few days latter. |

Posted By: michale34

Date Posted: 07 Jan 2019 at 7:52pm

| My dad use tell some eue opening stories about the dragline days. He talked about cables breaking and booms falling . Guys getting there fingers cut off and guys getting drug under the counter weight while oiling |

Posted By: truckerfarmer

Date Posted: 12 Jan 2019 at 9:48pm

Here's a picture of a cylinder support that is on one of our loaders at work. The black part is the bolt that holds it in place. Kinda hard to see, but if you can see the but welded on the top left, that is what holds it in place when in use. Hmmm, for some reason pic is turned. Left is top. ------------- Looking at the past to see the future. '53 WD, '53 WD45, WD snap coupler field cultivator, #53 plow,'53 HD5B dozer Duct tape.... Can't fix stupidity. But will muffle the sound of it! |

Posted By: Leop

Date Posted: 26 Jan 2019 at 3:12pm

|

Thanks everyone. We had a string of storms out here that have had me cooked up inside, so not much to post. I do have some pictures finally since 100% of my questions have multiple request for them. Just warning you, she ain't pretty. Now i just need to find a place to host them. Leo |

Posted By: dozerdan

Date Posted: 03 Feb 2019 at 11:20am

| I think it is like mentioned in my ford 8n tractor manual .it states always lower the draw bars when done because some one or by it self can come down un anounced and take some one out. they also say there are only two safty features the ign key and your brain . |

Posted By: Leop

Date Posted: 03 Feb 2019 at 7:06pm

|

Thanks Dozer Dan. Yup the loader gets put down every night, especially after that time i left it suspended above the deck and deck rail. My bigger concern is what to do while im working on her. So far my brain says "forget it "WE ain't gona go under that thing ever. However, it shure would be nice to be able to work on her without having to be a contortionist to get around the loader arms when the bucket is down. At least half your suggestion is working though. Now all I need to do is add an ignition switch to her, and i should be super safe

|

Leop wrote:

Leop wrote: