Question for overhauling c engine

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=156245

Printed Date: 15 Dec 2025 at 10:45pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Question for overhauling c engine

Posted By: Krazy Karl

Subject: Question for overhauling c engine

Date Posted: 08 Dec 2018 at 11:57am

|

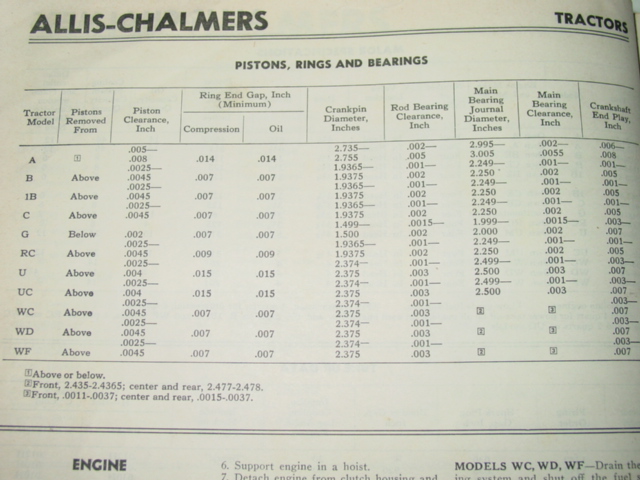

Im sure i second guessing myself here. But planning on doing an in-frame OH on this engine. I measured the rod journals and I got 1.912 I have an IT manual that gives spec of 1.937 so now to my questions So by that when i order the kit to get the .020 oversized kit Second question is what do you guys think if the A&I kits. I can get one through a local store thats why i ask |

Replies:

Posted By: steve(ill)

Date Posted: 08 Dec 2018 at 12:20pm

|

the first thing I would suggest is pull the motor so you can flip it over and work right side up. In 2 hours you will have it out and mounted in a stand and ready to go.. The liners are WET sleeves so you will want to pound them out, clean the block and reinstall with new O-rings.. Lot easier working when your standing up. ------------- Like them all, but love the "B"s. |

Posted By: Sugarmaker

Date Posted: 08 Dec 2018 at 1:02pm

|

Karl, That would be .020 under bearings for the rods. But the mains may be different. Pulling the engine is probably the right thing to do. May be other things you need to work on too?? Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Gerald J.

Date Posted: 08 Dec 2018 at 3:21pm

|

The AC shop manual has far more details than the I&T manual. http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf" rel="nofollow - http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf Gerald J. |

Posted By: Dick L

Date Posted: 08 Dec 2018 at 4:45pm

I have never seen rod journals with that much wear and still be round enough to keep from taking out the new bearing in a short time. I would guess they were ground under size at one time or you would not have any bearings in the rods at this time. A good crankshaft grinder will stamp the crankshaft the size when done. You measurement might be off some also. You need to measure all the journals in four equal places around the journal for an out of round condition. I personally would never use a crankshaft that the journals were out of round more than .0015. If you find your crankshaft is round within spec. you will have to file new bearings to fit with the proper .001 to .002 clearance. I have pictures of how I measure and file bearing shells to fit.

|

Posted By: B26240

Date Posted: 08 Dec 2018 at 4:46pm

| I'm with the guys that say "pull the engine" cam bearings are real important on this engine for good oil pressure and they are cheep and easy to change with engine out and front cover off. |

Posted By: Boss Man

Date Posted: 08 Dec 2018 at 4:58pm

|

the back of the bearings are stamped with the size a lot of times. When I wrenched full time it wasn't uncommon to find rods a different size than mains. Especially gas engines. The cranks aren't real hard so if they spun a bearing they'll turn the rank to what ever it takes to get all the rods one size and the mains one size. |

Posted By: Dick L

Date Posted: 08 Dec 2018 at 5:51pm

For information only: In the B, C, and CA engines the bearings have nothing to do with oil pressure. The bearings are not connected to the bearings with passages. Oil is sprayed on the rods from the holes in the spinning camshaft onto the rods and forced into the bearings thru little funnels in the rods by the spinning rods. |

Posted By: CrestonM

Date Posted: 08 Dec 2018 at 6:15pm

|

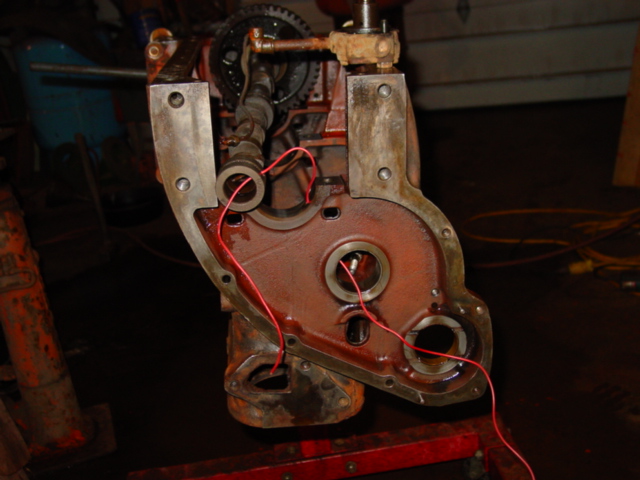

You've got pretty good photos showing the routing of the oil in a B/C/CA engine on your photo website, don't you, Dick? Seems I remember it showed a red wire snaked through the oil passages. I believe the oil filter media is the only thing that builds pressure at the gauge on these engines, right? And sometimes guys will push the narrow tube on the oil filter base down into the base too far, cutting off oil to the filter, which helps build pressure some at the gauge. |

Posted By: KerryM

Date Posted: 08 Dec 2018 at 6:22pm

|

Dick, I have to tell you, I learn something new every day by reading your posts. I hope you are around a good long time to share that wisdom with the rest of us. I take your word and experience as gospel  Someday (hopefully soon) when I'm able to finally get into my CA, I'm going to refer back to everything you have written and quiz you if I still can't figure it out ------------- 1950 C, 1952 CA, 1961 D17 (Dads last tractor) 1944 Farmall B, 1947 Farmall B, Bobcat 610 |

Posted By: Dick L

Date Posted: 08 Dec 2018 at 6:31pm

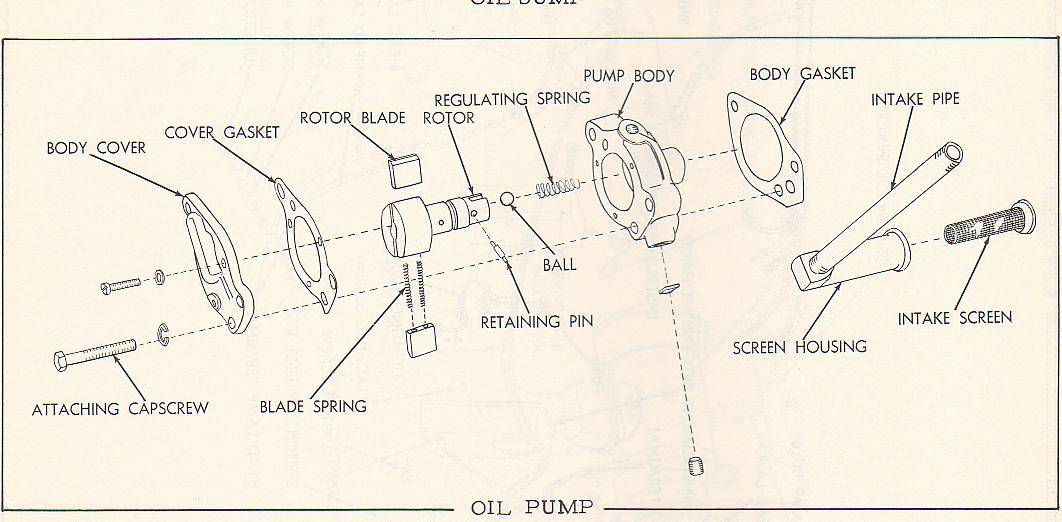

The oil pump for these engines has a spring and ball that builds pressure along with the oil filter to build pressure.  The oil is pumped into the center of the camshaft and flows to the main bearings thru the holes the red wire is threaded thru. Each camshaft bearing has holes that lead to a main bearing.

|

Posted By: Dick L

Date Posted: 08 Dec 2018 at 6:42pm

I aim to help where I can. I am unable to do much engine work anymore but as long as my pictures and memory holds out I will help where I can. |

Posted By: B26240

Date Posted: 09 Dec 2018 at 6:52am

| Dick , I respect your years of experience but I still think changing camshaft bushings/cam bearings is a good idea. |

Posted By: Dick L

Date Posted: 09 Dec 2018 at 8:10am

Sure enough! I was only addressing that bad bearings will not effect the oil pressure on these engines. No oil pump pressure on the bearings. My three 1920's Chevy's have little dippers on the bottom of the rods to oil the rod bearings from standing oil in the pan with no pump pressure to the bearings. If and when the bearings go bad it is only detected by the knock/noise. To the left is a rod that shows the hole that catches oil for the rod bearings when the engine is running. To the left is a rod from a D 15 that has the full pressure system. The D 15/ D 14's camshaft is also where the oil is pumped under pressure by placing the relief ball and spring at the front of the camshaft rather in the oil pump stem. The camshaft in them does not have the spray holes like the C. It has the crankshaft drilled from the mains to the rods.  In addition to your thought, if the camshaft bearings are bad in this system it can blead off oil the needs to be going to the main bearings which could cause the main bearings to go bad. It just has no effect on the oil pressure gauge. I hope I have covered it well enough. This oil system is different than most modern engine oil systems. |

Posted By: Lon(MN)

Date Posted: 09 Dec 2018 at 8:45am

| I have tried the minimum fix to save $$, but have not been happy with the way it turned out. Now I am back in these engines to fix them right. I have rebuilt three this year. I have new parts on the shelf. Rebuilt crankshaft, new piston and liner kit, gaskets, rebuilt governors, and many other parts on the shelf. I am a collector, not a retail store. I am willing to help you. These are fun engines to rebuild. I see you are 175 miles away. Might be a nice road trip. |

Posted By: DSeries4

Date Posted: 09 Dec 2018 at 9:03am

|

I am another one who is in favor of pulling the engine. If you are going to do it, do it right. As mentioned above, cam bearings are very important too. Just talking to my mechanic yesterday, he did not have good things to say about A&I kits, says their gaskets are terrible. I have used Reliance kits in all of my rebuilds and have been very happy. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: Krazy Karl

Date Posted: 10 Dec 2018 at 11:48am

| Its an inlaws tractor and the story gets complicated from there i only know part of it. Tractor been overhauled maybe 20 years ago and been sitting 15 years outside without rain Cap. And inlaw got it few years ago with engine locked up. And we got it in shed and started soaking it.Way it sounds was completely done. Cant ask the one guy in family that know what was all done because of some bad feud. But have piston sleeves out 2 were stuck bad. And liners are rusted that why thinking doing inframe OH. Lonn might have to see if can swing in a friend and i are planning on making are way to st. Cloud between Christmas and new years. If weather is nice to get some stuff he is after |

Posted By: Dick L

Date Posted: 10 Dec 2018 at 12:04pm

| Not to start another feud but I bought a 310 case dozer with a fresh overhaul that only had new bearings on a bad crankshaft. When I got into it I had to buy and new crankshaft, camshaft, lifters, sleeves and pistons along with new bearings for all. I also bought an engine taken from a gravel truck that was sold as having a fresh overhaul. I sent out the block, crankshaft, and camshaft to NAPA where they bored the block, reground the crankshaft and camshaft. Bearings and pistons were all new. I was able to get financial help from the sellers in both cases. Some people throw out the word (overhaul) without knowing the actual meaning. |

Posted By: Krazy Karl

Date Posted: 10 Dec 2018 at 7:52pm

| I know what you are saying on what some call an overhaul. Its a family tractor on wifes side. Father in law seen it completely apart. He said he remember them sending parts away. But not exactly what. He says it budget project. So just going off what he says. |

Posted By: Lon(MN)

Date Posted: 10 Dec 2018 at 8:41pm

| I am with Dick L. One of the engines I did this summer sounds like the one you are working on. Sat for 18 years. New rings on old pistons. reground crank with new bearings. No antifreeze. broke the block, wrecked the crank, rings were rusted to the pistons. But he fixed it. The right way. |

Posted By: Dick L

Date Posted: 11 Dec 2018 at 7:03am

All I am really saying is measure, measure and remeasure checking against the engine spec sheet.

|

Krazy Karl wrote:

Krazy Karl wrote: