D17 brakes

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=152709

Printed Date: 24 Oct 2025 at 4:06pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D17 brakes

Posted By: Hockeygoon

Subject: D17 brakes

Date Posted: 03 Aug 2018 at 11:50am

|

The brakes on my D17 Series IV are crap. The left one has had the brake rod cut and welded shorter once already so I am assuming there is no adjustment left. The right one has the adjustment rod frozen and very little braking left. Anyone have a good video on how to rebuild the brakes on a D17? I've only seen one on YouTube and they skipped a lot (the job sounded like a nightmare). I need to get one working brake if my 8 year old is going to drive this tractor next year while we pick up hay.

|

Replies:

Posted By: DougS

Date Posted: 03 Aug 2018 at 11:58am

|

The job is a nightmare. You need to pull the axles. You'll have good brakes once you're done, though. There's a complete thread on this topic somewhere here. Do not attempt without a service manual. Why anyone would need to cut the brake rod is beyond me. Expect to find that someone in past years screwed it up by doing it wrong and tried to compensate by cutting the rod. |

Posted By: DrAllis

Date Posted: 03 Aug 2018 at 12:20pm

| 8 hr job. Always anti-sieze the brake rods while doing this. Hydraulic console does NOT have to be removed. Remove lower traction booster linkages and lift console up and inch or so and prop it with a stick to the platform. Lift arm cylinders are in the way and if you can't remove the lower pin, remove the upper arm pin and the 90 degree fitting from the cylinder instead. Grease or anti-seize the ball pockets inside the drum and light lube on the axle splines. Brake rods go in the lower holes on the brake pedals. |

Posted By: Stan R

Date Posted: 03 Aug 2018 at 12:21pm

| We did our IV about 10 years ago and did not consider it a nightmare. Took my brother and I to do one side in about 5 hours (including refreshment breaks). Just need a chain fall though. |

Posted By: Hockeygoon

Date Posted: 03 Aug 2018 at 1:34pm

At the local dealership (KanEquip) there are 5-6 D17s lined up - all have the brake rods cut and welded shorter. The rods "seize" and you can't adjust them to compensate for wear. The local FFA took a tour of the dealership and museum and my older son spotted it - he thought it was just another half arsed repair done by his grandpa - turns out it was pretty common.

|

Posted By: DrAllis

Date Posted: 03 Aug 2018 at 2:02pm

| Whenever I had one seized like that ( no anti-seize) I cut off the "L" at the front and threaded the rod to 3/8" NF in chassis. Then, I installed a yoke from the left brake rod on a 180 or 185. It was now adjustable with the yoke. |

Posted By: Gatz in NE

Date Posted: 03 Aug 2018 at 2:10pm

|

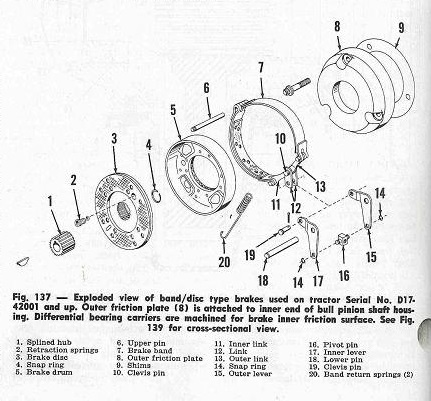

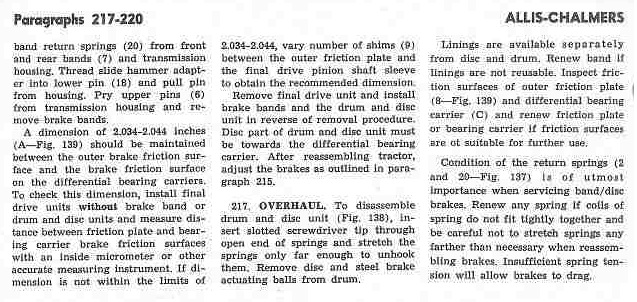

Here's where some people who dis the I&T manual need to read up on how to service the SerIV brakes. The A-C manual doesn't address the issue and how to make certain the gap between the brake disc and the housing is correct. This is important for performance and will prevent the band/disc brakes from locking up if done properly.   Replace the Retracting Springs, item 2 Fig 137, while things are apart. |

Posted By: BrianC

Date Posted: 03 Aug 2018 at 7:25pm

|

I see bands and disks, did they get the best or worst of both worlds? |

Posted By: DrAllis

Date Posted: 03 Aug 2018 at 7:38pm

| They were advertised as "combination band and disc" brakes. No hydraulic lines or valves to fail. If you drove an older D-17 ( especially with duals) the newer brakes were a huge improvement in turning power. |

Posted By: DougS

Date Posted: 04 Aug 2018 at 8:01am

|

Wasn't it a problem finding shims? If you can't find a shim set you'll need to buy some sheets of shim stock and make your own. If the rod is seized at #16 now is the time to remove it. You'll need less blue language if done when it is apart. Taking a shortcut may save time now but will cost you in the future. |

Posted By: Clay

Date Posted: 04 Aug 2018 at 2:18pm

|

DO NOT forget to make sure the return springs on the brake bands are in place. I should have double checked. I knew better. Did it anyway. The rear spring was OFF. OFF has new (blue) meaning when it is discovered after assembly! Shims are available in 0.005" and 0.007" from Agco. My local dealer has them in stock. I just finished the left brake on my 180. |

Posted By: Travis(NE)

Date Posted: 05 Aug 2018 at 12:56am

| I believe the shims are the same as any WD/D17 differential bearing shim. I save them out any tractor that I’ve parted out... |

Posted By: WF owner

Date Posted: 05 Aug 2018 at 5:19am

Great idea !!! Than you ! |

DougS wrote:

DougS wrote: