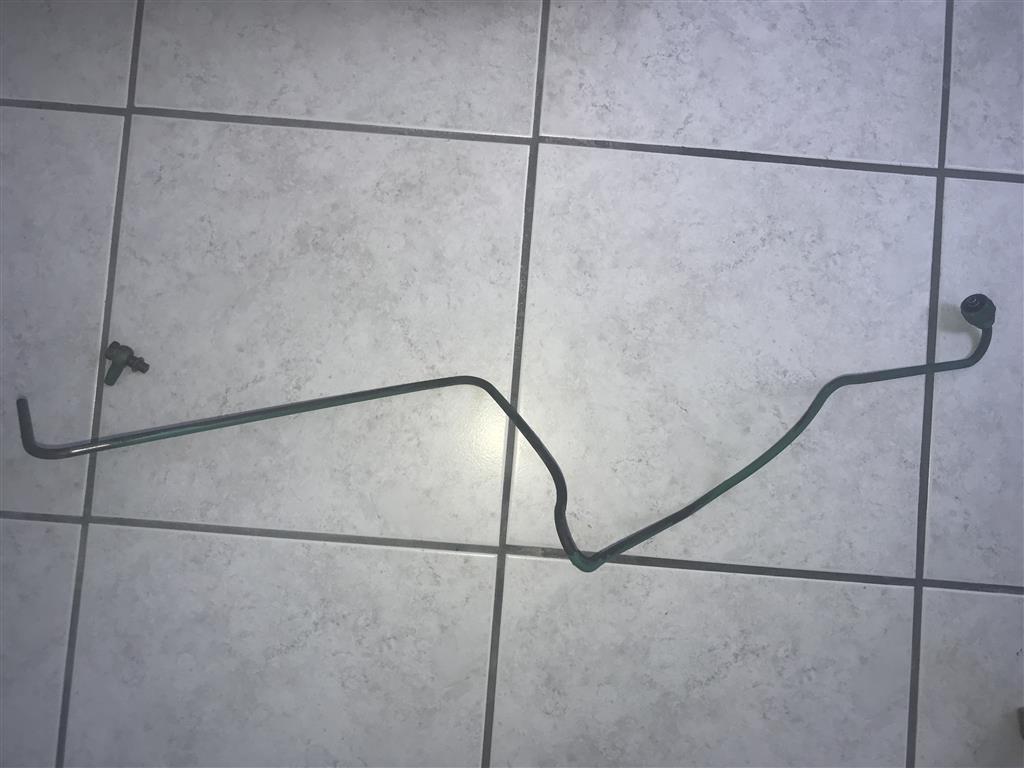

Fuel line with banjo bolt end

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=151786

Printed Date: 07 Feb 2026 at 8:25am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Fuel line with banjo bolt end

Posted By: OMBAK

Subject: Fuel line with banjo bolt end

Date Posted: 04 Jul 2018 at 11:50am

Have an older Onan generator with an Allis Chalmers engine. It has an old Roosa Master pump (Model #DCGFC631-2MK). One fuel line had the banjo bolt end connecting to the Roosa Master pump break off. I need a replacement. Any ideas where to find one?

|

Replies:

Posted By: Jim.ME

Date Posted: 04 Jul 2018 at 2:10pm

|

Welcome to the site. Some shops that service injectors and pumps can make lines, using your old one as a pattern. The lines are all supposed to be equal length. InjpumpED, who posts on here, may be able to help you with info if not the line itself. For starters you will need to supply the engine model, engine serial number, and which cylinder this line goes to, if you want to consider getting one through AGCO, or a used one from someone. If you have a manual it may have at least some of the info you need. If you weren't aware; Onan is a part of Cummins now and their site has some downloadable manuals. |

Posted By: Coke-in-MN

Date Posted: 04 Jul 2018 at 10:43pm

|

Hmm - I think I would put the banjo in drill press vice and drill it out to OD ofthe line - then silver solder the line into it - probably would be 1/4" shorter but should work . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: jaybmiller

Date Posted: 05 Jul 2018 at 6:34am

|

I was wondering what kind of pressure the line has on it...then looked at his location.. Virgin Islands ! yeesh, bet there ain't too many options for scrap yard. so query.. could he put a 'sleeve ' of say 2 inches long on the two pieces and braze/silver solder them ?? Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: DiyDave

Date Posted: 05 Jul 2018 at 5:56pm

Or, make a sleeve, that fits ID of hole drilled into banjo, and fits the OD of the line, and solder in place, might change the line to a little longer, but you can always bend one of the bends a little tighter, IMHO...

|

Posted By: steve(ill)

Date Posted: 05 Jul 2018 at 6:02pm

|

When the first FIAT machines were imported by Fiat Allis, they all had this type of failure. NO SPARE PARTS. We use to have a GOOD welder just braze the ends back together.. Making a sleeve to go 1/2 inch over each end and socket brazing would be even better.. If the length is off a little, the line can be rebent to align at both ends. ------------- Like them all, but love the "B"s. |