WELDING AND REPAIRING EXHAUST MANIFOLDS

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=150630

Printed Date: 07 Feb 2026 at 12:09pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: WELDING AND REPAIRING EXHAUST MANIFOLDS

Posted By: Tad Wicks

Subject: WELDING AND REPAIRING EXHAUST MANIFOLDS

Date Posted: 20 May 2018 at 11:14am

Hi guys, I thought I would show how I go about welding exhaust manifolds. The manifold I am working on is a Model M John Deere that I would guess filled with water and then froze, there were spider web cracks all over and quite a bit of damage. The first set of pictures shows the repair of the large hole and surrounding cracks. The welds can be ground and no one would ever know because the repair is made with cast iron rod and a torch but I have not done so yet, might not, it is under a hood and not visible. Now let me say on this particular manifold it is really silly to repair it, a new one can be bought for under $100, but this will show you what can be done if necessary. This will be the first part, I will do it in several posts     |

Replies:

Posted By: CTuckerNWIL

Date Posted: 20 May 2018 at 12:09pm

|

More power to ya if you can do that! I had one on the 45 with a small hole and a slight crack. A guy told me, " no problem, I can weld that." and I believed him for a second or 2. He no more than touched the rod to it and it turned to powder and crumbled away, making a bigger hole. Evidently , there are people that know how to do it, but he wasn't one of them. I found a new aftermarket manifold and haven't regretted it. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Ian Beale

Date Posted: 20 May 2018 at 4:49pm

|

Don't overlook Lincoln Ferroweld for repairing things like exhaust manifolds. There was an on-line dodger specifically on that which I can't see at the moment. Mentioned that Ferroweld would rust like the original whereas high nickel wouldn't if finish was important. Here in Oz you seem to have to rely on old supplies as it is about unobtainable. A neighbour has some and it worked very well on an exhaust on our Mitsubishi truck. I found this https://www.manualslib.com/manual/95363/Lincoln-Electric-Softweld-Ferroweld-Aluminweld-Cast-Iron-And-Aluminum-Arc-Welding-Electrodes.html" rel="nofollow - https://www.manualslib.com/manual/95363/Lincoln-Electric-Softweld-Ferroweld-Aluminweld-Cast-Iron-And-Aluminum-Arc-Welding-Electrodes.html |

Posted By: steve(ill)

Date Posted: 20 May 2018 at 5:32pm

|

Charlie, I think it depends on the manifold condition... The one in the photo as surface rust, and the hole was caused by freezing.. You can see the metal is in relatively good condition at the hole...... I have also taken an old "B" manifold from 1942 that was rotted out and tried to weld it up.. Paper thin and what is there is like carbon.. no metal to speak of.. Strike an arc and you got a hole the size of a dime.. I think TAD is talking about a manifold ( intake or exhaust) that is in good condition metal wise, just has a hole. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 20 May 2018 at 5:35pm

|

TAD, that weld don't look like a stick... you say torch -- accet weld ?? or are you using a TIG ?

------------- Like them all, but love the "B"s. |

Posted By: Tad Wicks

Date Posted: 20 May 2018 at 6:08pm

|

Hi guys, as exhaust manifolds age and are subjected to extreme heating cycles such as a gas engine produces, the cast iron does seem to erode into what I call ash metal,which can be tough to deal with, you can make brass look good and you can make nickle look good but as cast can turn a dull cherry red under load, that means it is reaching the melting point of both brass and nickle and eventually they will lift and separate from the base metal, the newer lean burn engines are the worst for this, in most cases brass and nickle won't stay for long. However, the older diesel engine manifolds seem to tolerate this better than most. One can not argue with someone who has had success doing things a certain way, everybody has their own way, I don't care to use an arc on manifolds, it is done with the square cast iron rods and put on with flame, that is what works for me, it gives a general heating and not a specific concentrated heat area. Sometimes when arc welding high carbon or cast the arc will make ferric carbide, that is an alloy that Rockwells about the equivalent to the hubs of Hades, now that is hard. In these pictures the base metal is actually melted, filler metal added to complete the repair and it can be done on ash metal as well. Thanks Tad |

Posted By: Tad Wicks

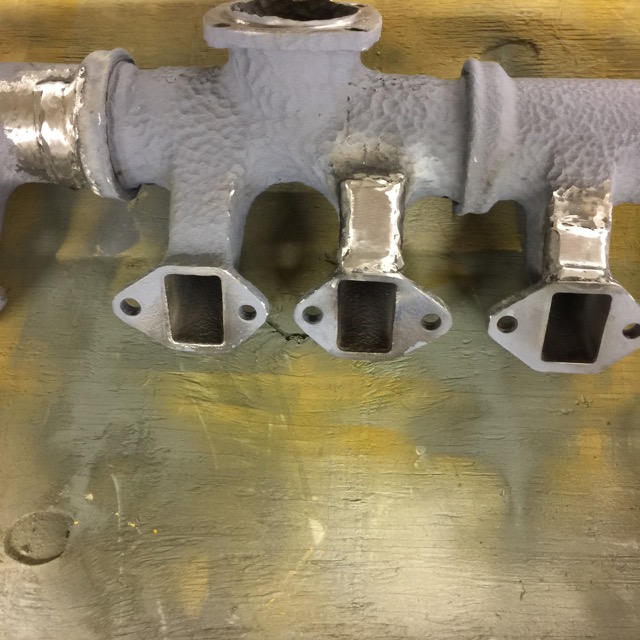

Date Posted: 20 May 2018 at 6:42pm

Not only was there a big hole but one bolt hole ear was completely broken away and the other was severely cracked, so the same process, add filler metal until there was more than enough, surface a bit, use the new gasket for a layout guide, grind to the line, drill the holes, turn over, blend, counter seat so the nuts are seated flat so as not to break the new ear, then final surface. It is not uncommon to get a bit of porosity next to the base metal Tad          |

Posted By: Sugarmaker

Date Posted: 20 May 2018 at 9:57pm

|

Very nice work! Thanks for posting. Looks like it could take some practice! Just replaced a cracked manifold on the WD45. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: jerbob

Date Posted: 23 May 2018 at 9:00am

Thank you Tad. Great pics and workmanship demonstrated. My HD16 exhaust manifold had 3 rust/age holes. 2 were the size of dimes and the 3rd was completely worn through and spanned the entire width of the one of the exhaust ports. I have a fabricating welding company that I have used and they were able to repair "PROVIDED THE CAST STILL HAD ENOUGH CARBON IN IT TO TAKE A WELD". I said HUH, and he explained that cast loses its carbon over years due to heating and cooling of the material. In my case, he was surprised how well it took a weld and was able to find good solid metal to weld on. Thanks for the great info.

|

Posted By: Tad Wicks

Date Posted: 23 May 2018 at 11:24am

|

Jerbob I am not a big fan of arc welding on cast especially MIG, but what ever works is considered successful. Is it just me or the camera, does number 4 port look a bit not quite right? cast usually does not move much so I must assume that it is the picture. Have you put a straight edge across the ports or test fit it to the head? You will be making diesel smoke in no time. Tad |

Posted By: jerbob

Date Posted: 23 May 2018 at 11:33am

|

Thank you Tad.. Just the pic angle. Ports are square and flat. Cost me $100.00 but a replacement manifold was over 500.00 plus shipping and no guarantee of what your getting. I should get a few more years out of it. |

Posted By: wfmurray

Date Posted: 24 May 2018 at 2:58pm

| Worked in textile mill about ten years . Done most of the welding.Welded hundred parts with torch.Bare cast rod (three sixtenth square x 15)cast iron flux and torch.Use blunt flame .When welded can grind down and look like orignal metal.If it is something like say bowl shaped it is hard to keep from cracking.Exhaust manifold that is burned up you will be wasting time. All carbon is gonne.PS I have also welded alum with torch. |

Posted By: Allis dave

Date Posted: 24 May 2018 at 3:08pm

| Looks great, I need to learn how to do that. Takes a lot of knowledge and practice I think. |

Posted By: Tad Wicks

Date Posted: 24 May 2018 at 9:29pm

|

WFMurray, that's the rod alright, boy some of the beautiful casting in those big looms and especially the lace weaving machines is almost unbelievable, very hard for me to conceive how they did it. Allis Dave grab a torch and go for it, it is a lot like brazing, if you get it to hot to quick it won't flow well, a very general flame not very close with a bit of blue tail and away you go, of course heat management is the key and the right flux as WF stated brazing flux does not work. Thanks Tad |

Posted By: HudCo

Date Posted: 29 May 2018 at 9:09am

| here s the thing about cast iron especaliy cast before wwii you just have to find the prosess that works for the cast that you are working on , newer cast seem to to be more consistant |

Posted By: jerbob

Date Posted: 29 May 2018 at 1:30pm

| You are right about that. Not a one size fits all for sure. |

Posted By: LeonR2013

Date Posted: 02 Jun 2018 at 4:43pm

| I did maintenance in a big sawmill back in the seventies and brazed several six tooth 30" cast wheels. Heated them in charcoal, raked it back and welded them up. They were so heavy that I had to turn them over and do both sides. They were easy to do, but hot as heck. They never gave any trouble. |

Tad Wicks wrote:

Tad Wicks wrote: