Blew the motor on an Allis D-14

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=144629

Printed Date: 21 Oct 2025 at 4:01pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Blew the motor on an Allis D-14

Posted By: squirt239

Subject: Blew the motor on an Allis D-14

Date Posted: 20 Nov 2017 at 1:26pm

|

Well...it was a good run. I rebuilt the D-14. Had it running great! Bush hogged my property twice this year. Moved stuff around the farm, etc. And then it happened.... Yesterday, I shot a deer back in the woods. Took the tractor down the hill to get it. When I got to the bottom of the hill, it sounded like it was "missing" out. Maybe a fouled plug, but then it quit. I had been having issues with the spark plug wire grounding out on the block, so I didn't think much about it. Loaded the deer on the back, and went back up the hill. Again, started sounding like it was missing, and quit running half way up the hill. Odd.... So I sat for a couple seconds, and started it again. It fired right up, only this time it belched out a HUGE cloud of white smoke out of the stack. Not good. I got it to the top of the hill (20 yards) and I shut it off. When I went to start it back up, it wouldn't even turn over. Almost like it's locked up. Fluids all checked good. It looks like another rebuild is in the books for the ole girl. Sure wish I knew where to start. That's my luck though.... |

Replies:

Posted By: jaybmiller

Date Posted: 20 Nov 2017 at 2:19pm

|

white smoke generally means some water in the cylinders...maybe a blown head gasket , busted sleeve ?? won't turn over , it could be 'hydraulic lock'. That's when water FILLS a cylinder and you cannot compress water(piston tries to get to top of cylinder with both valves closed and 'slug of water' stops it HARD. I'd pull all 4 plugs and blast some compressed air into each cylinder. I'm betting 1 or 2 will soak you....sorry. Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Ted J

Date Posted: 21 Nov 2017 at 8:10am

|

Yep, sounds like water in the cylinders. Did you re-torque the heads after it got warm after your rebuild? If not, that is your problem for sure! ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: LeonR2013

Date Posted: 21 Nov 2017 at 8:38am

| When torquing a head, instead of just pulling it up fairly quickly and quitting there, I like to pull it up slowly until it clicks. I'll do the whole head this way. I've never had one let go. But I agree with the other guys that after at least a couple of heat cycles, then completely retorque. Clean the holes and wash out the holes with solvent and blow out. Clean the head bolts real well, and I like to use Lubri-Plate on the threads, not a lot. Hope this helps. |

Posted By: squirt239

Date Posted: 21 Nov 2017 at 10:55am

|

Thanks guys. Guess it looks like a spring job. It's down at the farm (some 50 miles one way), so I don't think I will trailer it home any time soon. It's going to be hard to get the thing back over the rail tracks, up on a trailer, etc. So I might have to do all the work down there. Which means carrying all the tools needed to do so. Ugh... Not looking forward to all that. Think I could clean all the pistons out, retorque the head, and fire it up down there? Or do you think I'll need a new head gasket? |

Posted By: Gary Burnett

Date Posted: 21 Nov 2017 at 12:04pm

|

Well before during major work I'd check out a few things.Number one would be the possibility that when you started down the steep hill a slug of water that's been riding in your fuel tank or line may have entered into the fuel system and carb.That'll create havoc and white belching smoke not running right etc.Could have ruined a plug or two etc.Not saying for sure that's what happen but you need to check it out.When you go back to your tractor get it on the level drain the carb blow out the fuel line and let whatever is in the bottom of the tank out.The take out your plugs and take a look,spin the motor over with the starter while the plugs are out.Put in new plugs and try to fire it up.Good chance it may fire right up also if it does add Seafoam to the fuel and let it run awhile before moving the tractor. |

Posted By: squirt239

Date Posted: 21 Nov 2017 at 1:09pm

|

One can only hope it's that easy!!! You guys are awesome! |

Posted By: squirt239

Date Posted: 10 Dec 2017 at 3:13pm

|

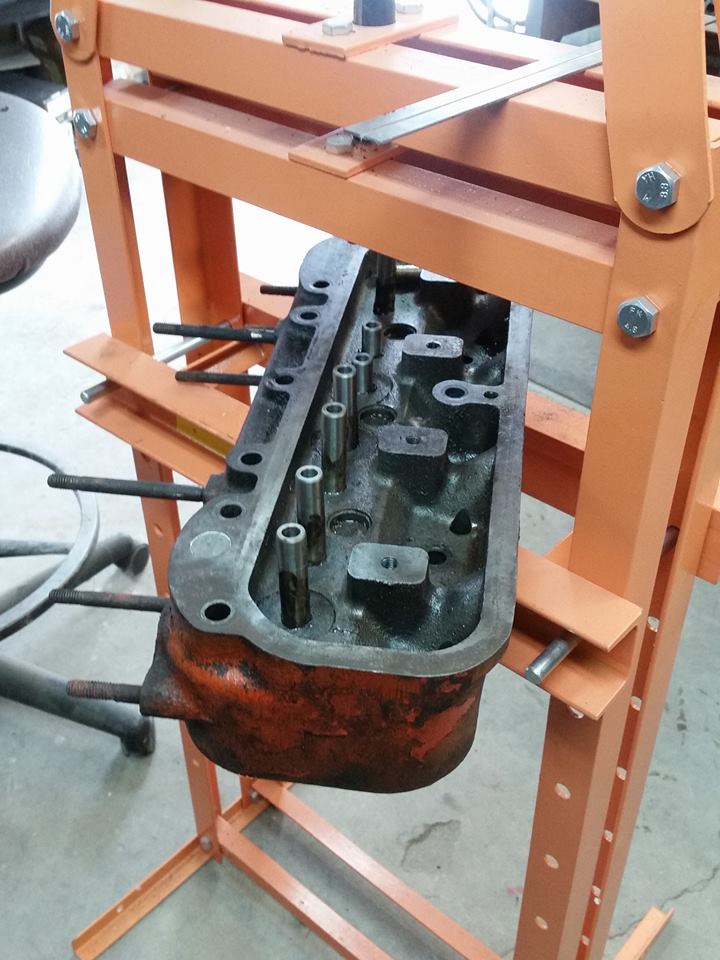

Well...it's a little worse than I thought.... |

Posted By: squirt239

Date Posted: 10 Dec 2017 at 3:29pm

|

Posted By: Mikez

Date Posted: 10 Dec 2017 at 6:07pm

| Wow that's not looking good |

Posted By: thendrix

Date Posted: 10 Dec 2017 at 6:56pm

|

Eewwwwww. ------------- "Farming is a business that makes a Las Vegas craps table look like a regular paycheck" Ronald Reagan |

Posted By: squirt239

Date Posted: 11 Dec 2017 at 11:24am

|

Posted By: squirt239

Date Posted: 11 Dec 2017 at 11:24am

|

Posted By: JohnCO

Date Posted: 11 Dec 2017 at 11:38pm

|

That piston looks a lot like the #i on my Ford 555 backhoe. Cracked cylinder (no sleeves), It now has a sleeve and a new piston. Haven't gotten around to getting it back together. Hopefully this next month or so. Your engine looks nasty but a couple hundred bucks of parts should make her good as new! ------------- "If at first you don't succeed, get a bigger hammer" Allis Express participant |

Posted By: dt1050

Date Posted: 12 Dec 2017 at 6:38am

|

ouch, that stinks. hope the blocks ok, but it looks like ya might have to rebuild that engine, stp aint gonna fix that.. ------------- Just cause it's orange don't make it a tractor, there's only one..Allis Chalmers |

Posted By: Bill Long

Date Posted: 12 Dec 2017 at 7:38am

|

GOOD GRIEF!!! I was hoping it would be water in the gas, condenser, or coil. Let us know how it goes. Wish you the very best. Good Luck! Bill Long PS: We have to realize these tractors are 60 years old. Hate to say it but as I am finding at my age that things just eventually wear out. Sorry |

Posted By: squirt239

Date Posted: 14 Dec 2017 at 8:36am

With this valve stuck sideways, it gouged the metal. Is this something that should be welded, then machined again, or should I be looking for a new head? With this valve stuck sideways, it gouged the metal. Is this something that should be welded, then machined again, or should I be looking for a new head? Is there anyone you would recommend to do the work? If I need to replace the head, where should I look? I've been looking online, and haven't found much... |

Posted By: CTuckerNWIL

Date Posted: 14 Dec 2017 at 9:04am

|

It appears to me , there is a hardened insert for the valve seat. They can be replaced if needed and done properly. Full engine kits come with all new valves. Probably be a good idea to replace them all with new springs. Maybe even new guides would be in order if the old ones are noticeably wore . ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Ted J

Date Posted: 14 Dec 2017 at 9:51am

|

1st question, did the broken valve cause this? or did the piston coming apart cause the valve to break? I've NEVER seen a piston come apart like that before! Maybe your best bet would be to contact Don(MO). He's our expert here on these old engines. He'll guide you down the path to having her up and running in no time. I'll PM you his phone number. He'd be the first place I'd start. Good LUCK!! ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: HoughMade

Date Posted: 14 Dec 2017 at 10:12am

|

I would guess the valve dropped (or broke, but likely dropped, then broken by the piston) and caused everything. Sorry, that looks like some work....but think how sweet it will run when done. ------------- 1951 B |

Posted By: squirt239

Date Posted: 18 Dec 2017 at 6:35am

|

Posted By: squirt239

Date Posted: 18 Dec 2017 at 6:38am

|

Posted By: Gary Burnett

Date Posted: 18 Dec 2017 at 2:21pm

|

Could always run it on 3 might miss a little but you'd have 1 more cylinder than the old John Deere tractors |

Posted By: B26240

Date Posted: 18 Dec 2017 at 3:58pm

| I'm guessing it over-reved going down the hill and the valve floated and was hit by the piston. Block, head and crank should all go to a good engine machine shop and be checked out. At least thats what I would do to start with. |

Posted By: Macon Rounds

Date Posted: 18 Dec 2017 at 4:57pm

|

IMPRESIVE !!!!!! I've seen many high performance engines come apart and not do that kinda damage. I believe rod bolt may have came loose and started the chain reaction. Dropped valve usually just beats the crap out of piston and head. Never seen dropped valve cause rod bolts to break and or bend the rod sideways. Was the rod still in tact on the crank or are my assumption correct ?????

------------- The Allis "D" Series Tractors, Gravely Walk behind Tractors, Cowboy Action Shooting !!!!!!! And Checkmate |

Posted By: orangeman

Date Posted: 18 Dec 2017 at 5:10pm

|

Based on the damage to the top of the piston - it looks like the valve danced on top of the piston for a while. Time to start the overhaul process! Of course wish you all the best - lots of excellent knowledge and talent here to walk you through the repair.

|

Posted By: Hubnut

Date Posted: 18 Dec 2017 at 5:50pm

|

Sorry for the loss--but thanks for the pictures. They are indeed impressive. Could the sleeve have been shattered by the dropped valve? ------------- 1940 B "Lucy" 1941 B w/ Woods L59 "Flavia" 1942 B w/ finish mower "Dick" 1941 C w/ 3-point "Maggie" 1947 C SFW w/ L306 "Trixie" 1972 314H |

Posted By: DiyDave

Date Posted: 18 Dec 2017 at 6:08pm

|

Head don't look too bad, I'd take the valves outa that cyl, and grind the dents til the surface us relatively flat (4" hand grinder). Then take it to be magnafluxed and pressure tested, if its OK, there, then have the head rebuilt, or DIY, if you feel equipped and experienced enough to take it on... Good luck

|

Posted By: jaybmiller

Date Posted: 18 Dec 2017 at 6:10pm

|

I keep shaking my head when I see the pictures...then I ask myself would you be better buying another complete running D-14 VS the cost of all the bits and pieces and shoptime to fix this engine? Pad of paper and sharp pencil time ?? I KNOW I can't afford or justify rebuilding the Buda diesel when it croaks in the forklift. Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Steve in NJ

Date Posted: 18 Dec 2017 at 6:17pm

|

Wow! Nothin' worst than an oil pan full o' parts. Looks like the valve broke, beating the piston to death, breaking the sleeve and allowing the rush of coolant into the cylinder. Hence the bent rod. Coolant doesn't compress well. I would have that block magged to make sure its not cracked. Might have cracked the block with all that damage... Steve@B&B ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: GreenMule

Date Posted: 18 Dec 2017 at 7:50pm

| I second what Steve said, sure hate that happen |

Posted By: DSeries4

Date Posted: 18 Dec 2017 at 8:52pm

If the block and head check out ok, rebuild both - then you will know what you have. Getting a second hand engine is a crapshoot. Could be as good as what you already have. Parts are readily available for these engine. When built properly, you would not have to touch it again. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: Don(MO)

Date Posted: 19 Dec 2017 at 7:48am

X2

------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Steve in NJ

Date Posted: 19 Dec 2017 at 9:37am

|

Bring it to ma' man Don. He'll do ya up a nice motor providing the parts check out okay... Steve@B&B ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: squirt239

Date Posted: 19 Dec 2017 at 11:44am

|

Thanks for all the advice guys! I'm a gunsmith by trade, and tinker with other stuff on the side. I have a vertical mill and lathe in the shop, and my wife's uncle owns a machine shop. He and I have discussed what to do. So here's where I am headed...you tell me if you think I'm crazy.... I've ordered and received a new piston, connecting rod, and sleeve, along with gaskets. I also ordered a valve train overhaul kit. Currently the head is on the mill. I'm going to go ahead and "face" the head. This "should" help find any visible cracks. Next, it will be off to his shop to check for cracks in the head. All in all, the head doesn't look THAT bad. Is there damage, yes. But I think the fact that I didn't keep forcing the motor, it prevented a lot of further damage. I've pulled the caps off the other connecting rods, and all the bearings look perfect. There's really no other metal pieces from the sleeve in the motor. I'm going to soak it with oil, and let it drain again through a coffee filter, just to be sure. I think I can salvage this. Maybe I'm being optimistic, but it's not as bad as what I originally thought. Just going to cost me money and time! Thanks again for all your input! This is a great forum to belong to...everyone has been very kind and very helpful! Brett Havlin Brownsburg, Indiana |

Posted By: DaveKamp

Date Posted: 24 Dec 2017 at 5:48pm

|

I'll second Steve's description of the failure... with one exception: The valve broke, and bounced around in the chamber... piston found it several times, and bent the rod. THEN... the bent rod, with piston cock-eyed in the bore, shattered the sleeve, which then ventilated the coolant. With a broken sleeve and a missing valve, no substantial hydrostatic locking would occur, but it'd make quite a white cloud overhead. If it were me, I'd check the crank for damage (cracks and twist), then the block in every area near the sleeve for damage in webbing and seal faces. If it looks clean, put the lower end back together with a replacement piston and sleeve, rod, wrist pin, and rings. Milling the head... yeah, if there's a crack, that might help discover it... Fortunately, that's really good malleable iron, so it's not gonna shatter like a lesser grade casting would. It's a no-worries job... don't overthink it, don't sweat it, just dig in, make somethin' happen, and have faith and fun. For what it's worth, I've got one engine that when I was lookin' in, I noticed it had one sleeve and piston that were smaller than the rest... it obviously had a problem, and someone substituted with whatever they had from some other wreck... and it ran wonderfully, so I left it alone.  ------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: SteveM C/IL

Date Posted: 24 Dec 2017 at 7:26pm

| I got a con rod outta a 283 Chevy that looks like that. Broke ex valve @5800rpm one night.Destroyed piston and busted cyl wall. Valve head was stuck in piston head sideways. Made me believe in always replacing ex valves on rebuilds. |

Posted By: DrAllis

Date Posted: 24 Dec 2017 at 8:04pm

| Do not worry about any spark plug hole cracks. They don't hurt anything. Also, if the head surface isn't quite perfect, it too won't hurt a thing. You're the only one that will ever know. |

Posted By: squirt239

Date Posted: 22 Jan 2018 at 7:15am

Getting some work done! All new valve guides!

|

Posted By: squirt239

Date Posted: 22 Jan 2018 at 7:15am

|

Posted By: squirt239

Date Posted: 22 Jan 2018 at 7:21am

|

Couldn't find my valve spring compressor, so I improvised.... $4000 piece of machinery to save buying a $20 tool.  |

Posted By: squirt239

Date Posted: 28 Jan 2018 at 12:41pm

|

Weather is nice here in Indiana. Has been in the upper 40s, low 50s...in January! Has given me the opportunity to get back to work on the D14! Today I got the block all cleaned out and up. Got all the metal out of it from the sleeve that let go. Installed the new sleeve, and new piston. Got the connecting rod on the crank and everything torqued down. I'm hoping (fingers crossed, rabbits foot in my pocket, four leaf clover in my wallet) I'll have this back up and running this week! |

Posted By: BenGiBoy

Date Posted: 28 Jan 2018 at 1:53pm

|

Hope it goes well for you! ------------- '39 Model B Tractors are cheaper than girls, remember that! |

Posted By: Dave(inMA)

Date Posted: 28 Jan 2018 at 4:21pm

|

Brett, thanks for posting this story. It's good to see your progress, and I really appreciate the pictures. Sounds like you're getting close to giving it a whirl.....looking forward to hearing about that! Good luck. Dave ------------- WC, CA, D14, WD45 |

Posted By: Hubnut

Date Posted: 28 Jan 2018 at 4:23pm

|

Great post. While I hate this happened, I've enjoyed the information and rebuild. ------------- 1940 B "Lucy" 1941 B w/ Woods L59 "Flavia" 1942 B w/ finish mower "Dick" 1941 C w/ 3-point "Maggie" 1947 C SFW w/ L306 "Trixie" 1972 314H |

Posted By: squirt239

Date Posted: 30 Jan 2018 at 6:23am

|

Head is back on! I'm going to try and get the push rods and rocker on. Hopefully set the valves today as well. Question, though, how does one hand crank a d14? There's really no spot to put a wrench to turn it. Am I missing something? |

Posted By: jaybmiller

Date Posted: 30 Jan 2018 at 6:40am

|

engage PTO, put pipe wrench on PTO shaft REMOVE pipe wrench BEFORE starting !!! do NOT ask WHY I KNOW this.... other option is to put a big ,bent screwdriver in the timing hole and move the ringgear,just be careful.... this is closer and since no plugs in holes is easy enough to do. Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Lonn

Date Posted: 30 Jan 2018 at 6:52am

|

Isn't there a hole under front grill screen for a crank to slip in? If so, and the crank pulley is right then a C Allis crank should grab the crank pulley to turn it over. ------------- -- --- .... .- -- -- .- -.. / .-- .- ... / .- / -- ..- .-. -.. . .-. .. -. --. / -.-. .... .. .-.. -.. / .-. .- .--. .. ... - Wink I am a Russian Bot |

Posted By: squirt239

Date Posted: 30 Jan 2018 at 8:45am

HAHAHA!!! We've all had those moments. Trust me, I have had more than my fair share... Great idea! Thanks! |

Posted By: squirt239

Date Posted: 30 Jan 2018 at 8:46am

There is, but I don't want to chance buying a tool that may or may not work. I think the pto trick is the way to go!!! Thanks guys! |

Posted By: BenGiBoy

Date Posted: 30 Jan 2018 at 9:20am

Just take your key out and tie it to the pipe wrench.  (Assuming you have a key, that is... (Assuming you have a key, that is...  ) )------------- '39 Model B Tractors are cheaper than girls, remember that! |

Posted By: squirt239

Date Posted: 30 Jan 2018 at 10:19am

|

Posted By: squirt239

Date Posted: 30 Jan 2018 at 10:20am

Because I have been known to be a bonehead at times....

|

Posted By: squirt239

Date Posted: 30 Jan 2018 at 10:30am

|

Another question.... What tools have you used to get the two bolts on the oil pan, closest to the bell housing? I've used a wrench, but I can only move it a smidgeon each time before resetting. Tite reach? Some tool I've never heard of? |

Posted By: chaskaduo

Date Posted: 30 Jan 2018 at 10:40am

|

Patience ------------- 1938 B, 79 Dynamark 11/36 6spd, 95 Weed-Eater 16hp, 2010 Bolens 14hp |

Posted By: BenGiBoy

Date Posted: 30 Jan 2018 at 12:08pm

There ya' go!!! LOL...    ------------- '39 Model B Tractors are cheaper than girls, remember that! |

Posted By: squirt239

Date Posted: 30 Jan 2018 at 12:44pm

Ain't that the truth!!! |

Posted By: JohnCO

Date Posted: 30 Jan 2018 at 12:54pm

|

Using the machine tool to install the valve springs seems like a logical thing to do. I once used a jack used to lift war heads onto air defense missiles to install an engine in my VW bus. Inspector later asked the crew where the dirty engine oil on the jack came from....... ------------- "If at first you don't succeed, get a bigger hammer" Allis Express participant |

Posted By: corbinstein

Date Posted: 31 Jan 2018 at 6:41am

| Which Missile System John? Sounds like old Hawk Stuff. LOL |

Posted By: squirt239

Date Posted: 18 Feb 2018 at 3:33pm

|

Today I had my 9 year old son in the garage helping me put the D14 back together. We got the push rods, rocker arms, valve cover, and thermostat and housing all back on. He was excited to help, and was awesome at helping set the initial tappet gap. Next on the agenda is the pick up, oil pan, and putting fluids back in. To say I'm nervous, is an under statement. But, that's we learn, right? Spending time with the oldest boy, and teaching him a little something is worth it. |

Posted By: jaybmiller

Date Posted: 18 Feb 2018 at 4:09pm

|

progress !! Great !! hope you're taking pictures especially get your 'helper' in them...later on you'll both enjoy going down 'memory lane'... ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: DaveKamp

Date Posted: 19 Feb 2018 at 12:49pm

|

Being nervous is natural... all part of the process. I don't know why, but I'm always nervous when I go to start an engine that I've built fully... but if I only give it a partial... like just a top end, or bottom end, etc., I'm not nervous at all. Perhaps it's because they're all unproven at the same time... I dunno. But you've done a good, thorough job of everything here so far, and keep in mind that between technology, tools (Bridgeport made a high-quality Precision Valve Spring compressor!!!), and and resources (books, materials, and an army of old farts with computers willing to share their mistakes... "REMOVE pipe wrench BEFORE starting !!! do NOT ask WHY I KNOW this...." Owch! Yep... and the chuck-key from the drill press... and the can from the exhaust stack of the oilfield engine parked directly underneath the big merc-vapor low-bay lamp... ...You'll do just fine. Realize, farmers did this on rainy days, and if they were lucky, the dirt-floor shed was high enough to stay dry... so you're gonna be fine. Double check all your fasteners around the front of the engine, and make sure it won't jump into gear and drive over you or your pit crew when it lights up.  ------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: DaveKamp

Date Posted: 19 Feb 2018 at 12:54pm

|

Also remember- if something goes wrong, it's not a failure in your ability to perform, it's a success in your ability to learn... and your assistant NEEDS to see you do both. Why? Because our children need to see that we're super-heroes. That doesn't mean we're perfect at everything... it means we're human, subject to mistakes and pitfalls... and strong enough that when we stumble, we get back up and do it again. The best lesson for our kids, is to see us at both our best, and worst, and see that patience and persistent dedication is what we're made of.  Oh, and when you start it... stand alongside, with your hand on the kill switch, listen for 'bad' sounds. If you hear any, shut it down... and if after a minute or two it settles in, sounds good, etc., then let your kids watch you jump up and down and celebrate like a little kid!!! ------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: Jim Hancock

Date Posted: 19 Feb 2018 at 2:50pm

|

Well said, Dave! I've experienced it- still am. My 10 yr old daughter still hugs me when I fix or do something for her that she can't do - yet. But, I'm teaching her about things along the way and she's seen me get ecstatic over things and she's seen me when I've come slightly unglued, too. But, that's been few and very far between as I have a whole lot of patience to see some things and engage my brain before opening my mouth. ------------- How blessed we are by HIS GRACE! |

Posted By: HudCo

Date Posted: 19 Feb 2018 at 3:35pm

| lot of shrapnall i hope you got every oil passage brushed and cleaned good so it does not run a tiny little grain of sand size piece through a bearing. sad to see that happen and also screw up a good deer hunt. cylinder heads sure are the heart beat of an engine |

Posted By: LeonR2013

Date Posted: 19 Feb 2018 at 7:37pm

| Before you put the plugs in, roll the engine over several times. If there are any tight spots in it have a can setting close by and kick it as far as you can, or you can set on it and cry for a while. If you didn't have the crank checked for bend or check the other rods for bends. Have it done. That means a tear down, and take crank and rods to an engine shop and have them checked. If they're not OK the best you can expect is a heck of a vibration when you start it up and it will not get better. They both can be straightened and reused if you want to. |

Posted By: squirt239

Date Posted: 20 Feb 2018 at 6:48pm

|

Got her started today! Got everything together including fluids. She fired up the second try. I didn't let her run long as there was a little blue smoke coming out. So I let her rest and fired her up again. Blue smoke gone! Runs smoother and cleaner than before! Downside. Found there is a small leak from the oil pump. No big deal. It's a split tube. Easy fix. I can thank you all enough for your advice and help. Any time any of you are in the Indianapolis area, supper is on me. |

Posted By: Allis dave

Date Posted: 21 Feb 2018 at 7:00am

| Great news. That's the best feeling ever isn't it? |

Posted By: squirt239

Date Posted: 21 Feb 2018 at 10:33am

Yes SIR!!!!!!! |

Posted By: Dave(inMA)

Date Posted: 21 Feb 2018 at 10:57am

|

Excellent news! Congratulations - must feel great!!!! How about a video of her starting and running? Please? ------------- WC, CA, D14, WD45 |

Posted By: squirt239

Date Posted: 21 Feb 2018 at 12:29pm

I have video. Just need to get it uploaded! Only down side is that one oil line. It looks like it has been replaced prior to my acquisition, as it is a steel line, unpainted, looks like new, about the size of my pinky. It runs from the oil pump down, around the front of the oil pan and into a brass fitting at the front of the tractor. I'll take some pictures and show you all. I think, I THINK, it's leaking from the brass fitting itself, not the line. However, I'm doing it, I am doing it right! I'm at the firehouse today, so I'll have tomorrow and Friday to tinker some more with it. As a side note, my oldest boy was grinning ear to ear. My wife's comment was, "I didn't doubt you could do it. I mean...you did it once already..." Thanks Hunny...rub some salt in that wound ;-) She's a great woman...I love her dearly, and she's been understanding and supportive with this venture. |

Posted By: squirt239

Date Posted: 25 Feb 2018 at 11:29am

|

New problem. I'm burning oil around the muffler. Yep...that's what I said. I don't see any leaks, pulled the intake/exhaust manifold off and had some black, burnt oil on the ports. Cleaned it up, but can not for the life of me see where it's coming from. So I took some pics. See below... |

Posted By: squirt239

Date Posted: 25 Feb 2018 at 11:39am

|

Posted By: Lynn Marshall

Date Posted: 25 Feb 2018 at 12:40pm

| The last picture looks like it may be antifreeze. |

Posted By: jaybmiller

Date Posted: 25 Feb 2018 at 1:53pm

|

Maybe do the yuck, taste test. If it's 'sweet' it's antifreeze... though you should do a 'reference' test to be sure. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: JohnCO

Date Posted: 25 Feb 2018 at 9:34pm

|

Oh, OH, hope it's something simple to fix! "REMOVE pipe wrench BEFORE starting !!! do NOT ask WHY I KNOW this...." I put an interesting dent in my 4 year old Ford Courier front fender that way while working on a n MF 65 about 40 years ago... ------------- "If at first you don't succeed, get a bigger hammer" Allis Express participant |

Posted By: ryanschott

Date Posted: 25 Feb 2018 at 9:58pm

| Maybe condensation or antifreeze that was blown inside the muffler from the accident and now back together and heating up the muffler that antifreeze and carbon goo melting and coming out |

jaybmiller wrote:

jaybmiller wrote: