3D printed sealed beam light adapters WC,WD

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=141329

Printed Date: 01 Jan 2026 at 1:51am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 3D printed sealed beam light adapters WC,WD

Posted By: jbirnsch

Subject: 3D printed sealed beam light adapters WC,WD

Date Posted: 10 Aug 2017 at 10:15pm

|

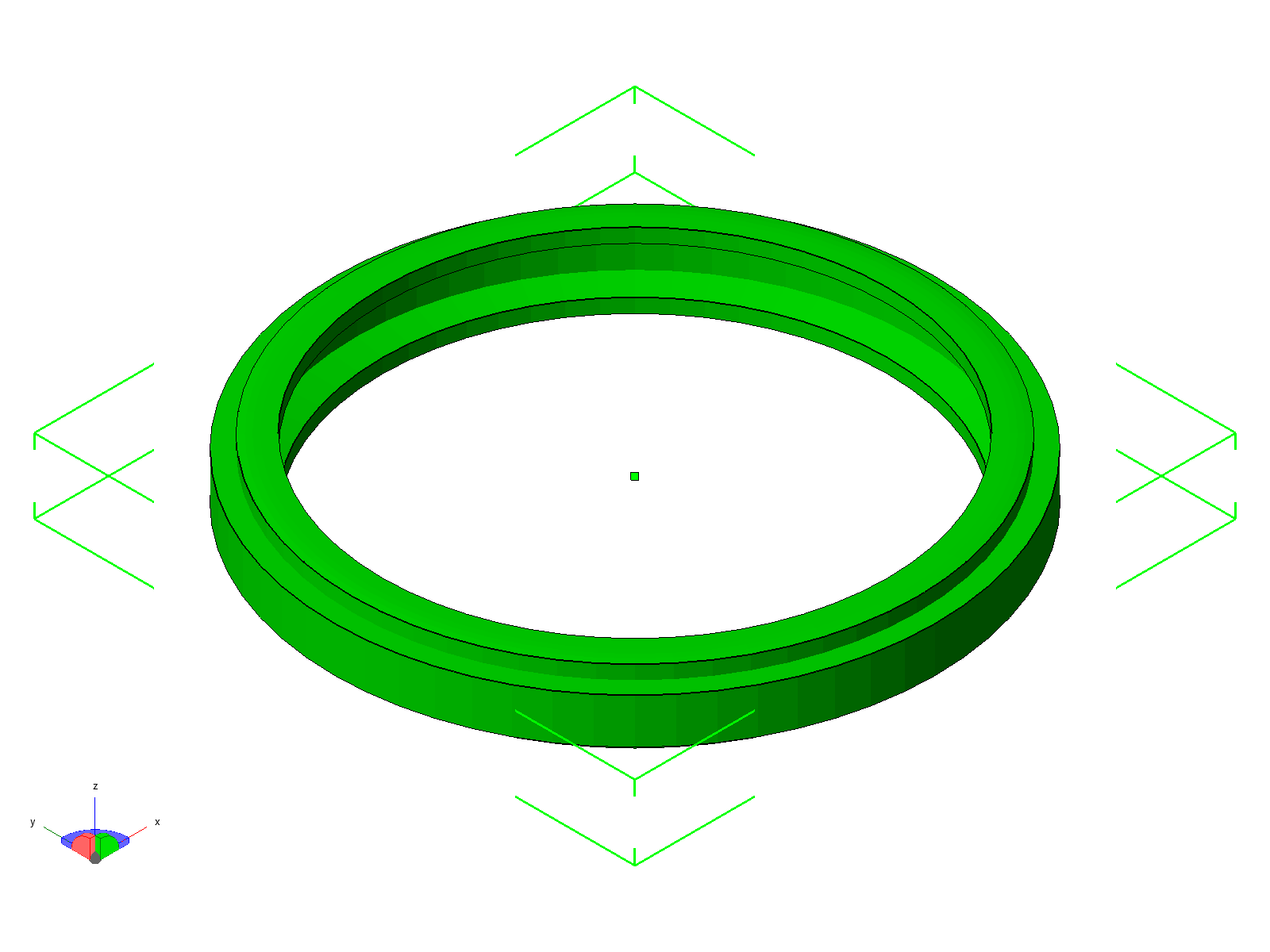

Have an abundant supply of sealed beam bulbs and need new lights on the WC I'm getting running. Nobody makes direct replacement sealed beams for the original housings. I have seen hose wrapped around sealed beams to take up the gap. A little time on tinkercad and I drew up this adapter. I am 3D printing it now out of flexible black TPU filament. Will know Saturday if they fit when I'm back at the tractor.  |

Replies:

Posted By: CrestonM

Date Posted: 10 Aug 2017 at 11:07pm

|

Awesome! Pretty soon we'll probably all be making our own parts if parts supply is discontinued. Maybe the Minneapolis Moline guys will be the first ones to try that. Lol

|

Posted By: jbirnsch

Date Posted: 11 Aug 2017 at 10:59am

|

Here it is installed on the sealed beam. Took 4.5 hours to print it. |

Posted By: Kenny L.

Date Posted: 11 Aug 2017 at 2:09pm

|

Posted By: Allis dave

Date Posted: 11 Aug 2017 at 3:24pm

| Looks really good to me. Great solution. It's industries work like this that will help keep Allis alive well into the future. |

Posted By: Ted J

Date Posted: 12 Aug 2017 at 9:18am

|

Why does it take so long to print? Are you going to sell them? Price? ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: jbirnsch

Date Posted: 13 Aug 2017 at 1:51am

|

TPU needs to print at slower speeds. Also support material is needed to create the inside channel. All this takes added time. I need to make a tweak to the model so it fits tighter when clamped. I didn't plan to go to production with these. Do you think there would be a market for them? What would someone be willing to pay? The lens, gasket, and reflector aren't that cheap if they are missing or damaged. |

Posted By: jaybmiller

Date Posted: 13 Aug 2017 at 6:22am

|

What the 'media' never report is how LONG(zzzzzzzzzzzzzzzzzzzzzzzzz) 3D printers take to make 'stuff'. The 'computer' program is fast, it's the actual oozing out of plastic that takes time. They are good at prototype, one-of-a-kind or 'proof of concept' parts NOT mass production. As for the 'adapter ring', I'd look into a turret style CNC machine and use metal or plastic for the rings. You start out with a 'rod' or 'cylinder' then carve the inner grooves,outer, then part(cut off) the piece. Less than a minute per piece ONCE it's all set up. It is nice to see something USEFUL made from a home 3d printer ! Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Ted J

Date Posted: 15 Aug 2017 at 6:09am

|

I think there'd be a market for them. Guys who have working tractors would like to have sealed beams for seeing better when working at night. But then sealed beams aren't cheap either..... There should be a market from guys with show tractors also if you couldn't see that gasket. But then there are the nit pickers........... ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: DanC911

Date Posted: 15 Aug 2017 at 8:39pm

|

I would take a set. I want to change to LED bulbs but the sealed beam style doesn't fit like you said. ------------- 1950 WD, 1955 B, 66 Jacobsen Chief-O-Matic, 68 Simplicity 2110, 77 IH Cub Cadet 1450 w/front loader |

Posted By: jbirnsch

Date Posted: 17 Aug 2017 at 5:38pm

|

One more final tweak and I should have it. Need to fill in a slight gap on the clamp on the front of the ring. I am making it slightly thicker to take this gap up. |

Posted By: jbirnsch

Date Posted: 17 Aug 2017 at 9:09pm

|

Just started the print. Here is a short video from the first few layers. https://youtu.be/RE1WiSLRC8Y" rel="nofollow - Printing the sealed beam adapter video |

Posted By: jbirnsch

Date Posted: 18 Aug 2017 at 5:39pm

|

Final version complete. This version took 6 hours to print with the support material needed to create the inside groove. I lowered the print temp and increased the top am bottom layers to 3 to fill any holes that were showing on the first version. |