D17 series iv 4 weak 3 point lift

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=141279

Printed Date: 01 Jan 2026 at 12:07am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D17 series iv 4 weak 3 point lift

Posted By: Tom_C

Subject: D17 series iv 4 weak 3 point lift

Date Posted: 09 Aug 2017 at 9:09pm

|

Hi everyone, My name is Tom and I am new here. I recently acquired a new to me d17 series 4. The factory 3 point goes up but is slow and will not lift me if I stand on the arms. I have freed all the linkage and spools. The striker is not pushing in the spool nearest the fender. Also I have good hydraulics at the remotes. The tractor had been sitting for a number of years. Oil is clean and at the right level. Any idea what it is? Thanks, Tom |

Replies:

Posted By: MACK

Date Posted: 09 Aug 2017 at 9:57pm

| The spool next to fender is traction booster. Pull the lever closest to fender next to remote levers. MACK |

Posted By: Tom_C

Date Posted: 09 Aug 2017 at 10:06pm

|

Hi, Yes that is the lever I am pulling to lift and lower the hitch. I mentioned the other spool near the fender because I believe if that one is partially depressed then lift will be affected as if a loss of traction were being sensed? |

Posted By: DrAllis

Date Posted: 10 Aug 2017 at 7:27am

| Plug a 3000 psi gauge into any remote outlet and activate the lever and HOLD it. You should have a steady 2,200 psi. Hard to imagine if that pressure is correct that the hitch would be weak in lifting power. Both remotes and hitch are on the same relief valve. Front lever next to fender is for the hitch. |

Posted By: Stan R

Date Posted: 10 Aug 2017 at 1:39pm

| Two oil fills- left is hydraulics, right is transmission. Checked left when you say it is full ?? |

Posted By: Tom_C

Date Posted: 10 Aug 2017 at 3:52pm

|

Yes, left side filler, the one with the hex nut and dipstick below. Also, I don't have a guage, But I hooked it up to my skidsteer auger drive and 12 inch bit. Drive was attached to skidsteer and hydraulics attached to tractor. At a dead idle it pulled the auger all the way down into hard soil and screwed it back up, lifting the front of the skidsteer off the ground. There is no problem with the pump. It must be in either the traction boost or 3 point spools that it is not allowing the full flow to the hitch lift cylinders. Even the engine doesn't bog down when you deadhead the lift, but it does when you pull the levers for the remotes. Thanks |

Posted By: DrAllis

Date Posted: 10 Aug 2017 at 3:56pm

| Hydraulic oil enters the valve stack on the left side and goes thru each remote valve and then the 3 point hitch valve. All three valves are protected by the same 2,200 psi relief valve. Are you sure the 3 point lever doesn't work backwards??? Someone could have connected the link rod on the top side instead of the bottom side and that would make the lever work in reverse. |

Posted By: Tom_C

Date Posted: 10 Aug 2017 at 4:05pm

| When I move the 3 point lever toward the front of the tractor the spool is depressed, when i move it toward the back of the tractor the spool is pulled. The hitch moves up when the lever is moved to the back of the tractor, it just doesn't have any power. |

Posted By: Tom_C

Date Posted: 10 Aug 2017 at 6:48pm

| Ok, the anemic lift is sorted. There is a screw on the end of the 3 point spool . I turned it in and now I have tons of lift. Also the position lever for depth seems to be working okay. The only thing I wonder about now is there doesn't seem to be much downforce. I can grab the arms and lift them by hand though with some effort. How solid should the arms be when in working position? |

Posted By: Dave H (NE)

Date Posted: 10 Aug 2017 at 6:58pm

|

the lift cylinders are one way. no down pressure. |

Posted By: Tom_C

Date Posted: 10 Aug 2017 at 7:06pm

| I think I misspoke. Down force no, but if the circuit is closed at the valve body, the lift arms should stay put until lever is moved to allow it to flow back to reservoir? |

Posted By: JC-WI

Date Posted: 10 Aug 2017 at 9:44pm

|

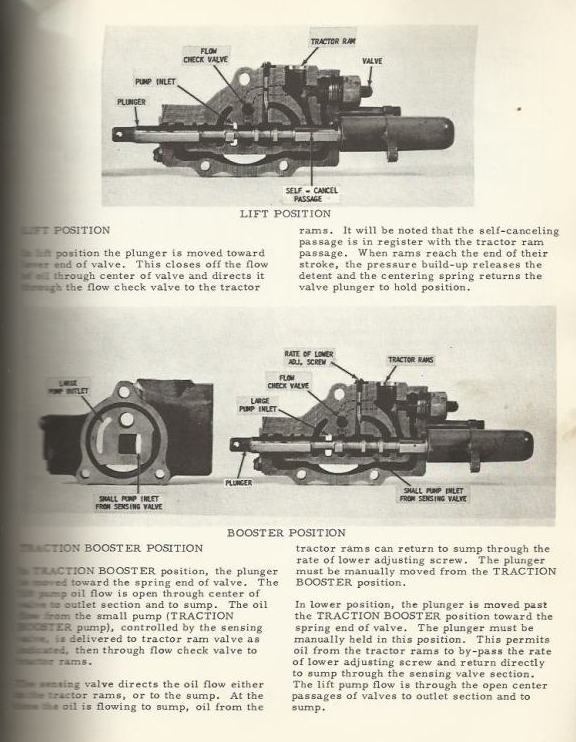

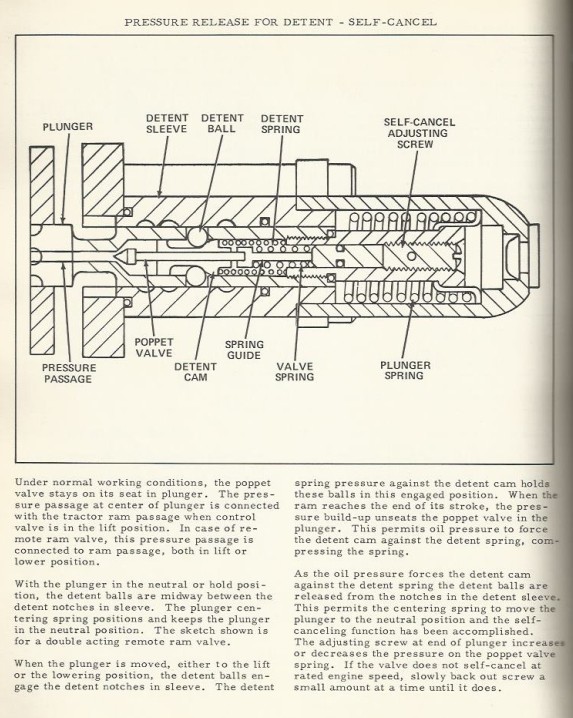

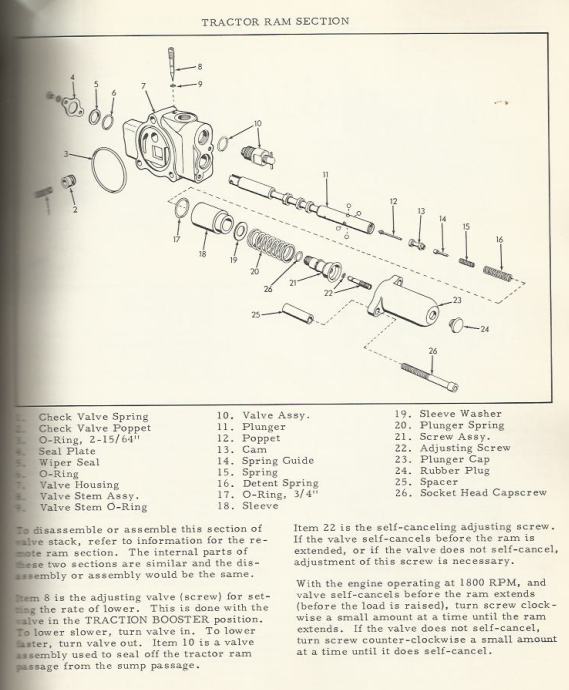

If it sinks in center position, Then there is something wrong... and being you had to screw the pressure detent in, something or some one messed with it I would bet. Remember that there is the lift position, a hold position, a float/traction booster position and a lower position... And when you press it down to lower, you have to pull up to the first detent to the hold position. Just some pics to look at...    ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: Tom_C

Date Posted: 11 Aug 2017 at 2:51pm

|

Hi, Thanks for posting the photos. Before I open the control I would like to check the linkages for the traction boost. Does anyone have information on setting and adjusting those? |

Posted By: JC-WI

Date Posted: 11 Aug 2017 at 10:23pm

|

Think you should First check to see if your 3pt lift lever is detenting in the hold position. Lift hold traction booster lower Usually if something is wrong in the TB section, it will be the linkage is stuck/froze/rusted, not the spool. got one tractor that a valve is not centering and keeps bleeding oil into the cylinder and keeps dropping the equipment... someday I need to see if that can be corrected. lol ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |