D17 S1 running cold

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=137043

Printed Date: 24 Dec 2025 at 10:45am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D17 S1 running cold

Posted By: Creek Jenkins

Subject: D17 S1 running cold

Date Posted: 05 Apr 2017 at 8:55am

|

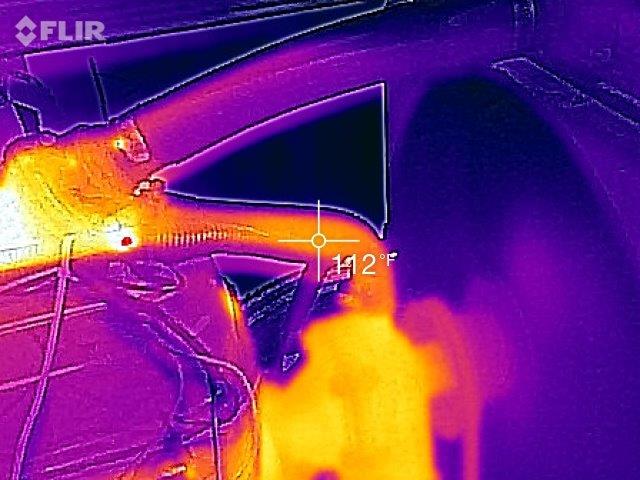

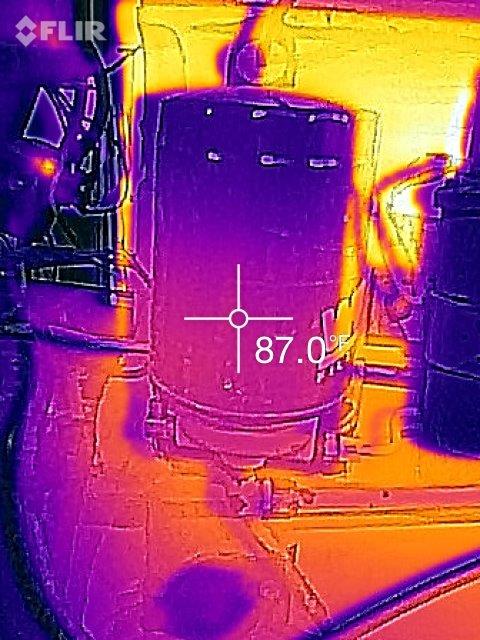

My D17 S1 always ran cold. When I first got the tractor I discovered the thermostat was more or less rotted away and the temp gage didn't work. I bought a new thermostat and new temp gage, but the engine would never heat up unless I covered the rad. Plowing in the summer on a 80F day would be the only time it would get warm with no cover. In the winter I had to completely cover the rad just to get the temp gage to move off of 130F. Last summer the engine spun a cam bearing so thanks to a fellow forum member I put in a gleaner engine. Works great, but still ran cold. The rad was rotten and more of a antifreeze sprinkler system than a rad so thanks to another forum member I found a replacement (I work for a large radiator manufacturer, but we serve the mining industry and our rads usually start at 1000+hp, and business has been pretty awful lately so home projects are tough to get done). So with my new engine in I was determined to get it to run at the proper temp. Here is the existing tstat housing:  I tested the new thermostat:  I found that the thermostat was not completely sealing against the rad side of the housing. There is a rubber ring, but it looked like there was an 1/8" or so gap between the tstat and the rubber ring. Fellow forum member Carbonite and I looked around the shop and found a piece of exhaust pipe the right size, so we cut a ring and after some experimenting on height, we seemed to hit on the correct size:  So installed it and tightened everything down filled up the system. There was a bit of an interval (2 months) before I could check it out as work and other things got in the way. So last weekend I got the IR camera and fired up the engine. Here it is cold:  The engine is warming up, but no flow is going to the rad. Mission accomplished? I rad it for a few minutes until the temp gage hit 180F, you could see the stat open up and vent water to the rad, then close, open and close until it reached an opening that held the engine at about 175F. Haven't put it to work yet, but will try it this weekend. here is the engine hot:  One thing I noticed that even though the oil pan read 80 - 90f, the oil filter was only getting flow in the bottom section. This new engine is the full flow style, so it looks like the cold oil in the top of the filter is not moving. I imagine if I ran it for more than 20 minutes the oil would eventually warm and flow through the entire filter. I'll have to check that when I start plowing later this month I hope. cheers, Creek ------------- Have spacesuit, will travel |

Replies:

Posted By: IBWD MIke

Date Posted: 05 Apr 2017 at 10:27am

| Those IR pictures are really cool. |

Posted By: ACjack

Date Posted: 06 Apr 2017 at 9:49am

| IR photography is the "hot" ticket. |

Posted By: Stan R

Date Posted: 06 Apr 2017 at 2:40pm

| Oil flows thru the path of least resistance. As the lower section of the filter accumulates "debris", flow (temperature) will move upward. Also, their is some level of cooling on the upper section of the filter (but "cooler" oil flows). |

Posted By: CrestonM

Date Posted: 06 Apr 2017 at 3:00pm

x2!

|

Posted By: Ted J

Date Posted: 06 Apr 2017 at 6:23pm

|

x3! Great pics and an even better idea!! Where there's a will......... NOW, if I can only remember it....Thanks Creek!

------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: captaindana

Date Posted: 07 Apr 2017 at 5:10am

| Creek the whole post is exciting,mthanks!! To be continued can hardly wait for more IR pics while plowing! |

Posted By: B26240

Date Posted: 07 Apr 2017 at 6:17am

| WOW !! Those IR pictures sure take the guess work out of the problem. Thanks so much for sharing with us. Mark |

Posted By: allisrutledge

Date Posted: 07 Apr 2017 at 6:45am

|

I love the IR cameras. I a wanted one until I quoted one. Thanks for the pictures Creek ------------- Allis Chalmers still exist in my mind and barns |

Posted By: Allis dave

Date Posted: 07 Apr 2017 at 7:18am

| Thanks for the topic. Looks like you made a good fix. Very cool pictures. You can see exactly what happening inside! |

Posted By: Creek Jenkins

Date Posted: 07 Apr 2017 at 1:42pm

|

The camera is surprisingly inexpensive, it attaches to an iPhone and costs $250, made by Flir. I borrowed it from work, we use it for cooling tests. I'm hoping to borrow it again during haying season to look for warm bearings on the mower, rake, and balers. Here is a shot of the oil filter when the engine was warm:  Appears that the top is not getting much flow yet. cheers, Creek ------------- Have spacesuit, will travel |

Posted By: Allis dave

Date Posted: 07 Apr 2017 at 2:27pm

| Well, you're pictures kind of prove Doc and I's idea. When I converted my WD45 to full flow oiling, I used a shorter version of the oil filter so help with dry starts. Same filter as on my Dodge RAM. Same micron, flow, and burst rating. This proves to me that the tall filter isn't needed. You can see it's not all being used. |

IBWD MIke wrote:

IBWD MIke wrote: