XT 190 INJECTOR PUMP TIMING

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=135374

Printed Date: 05 Nov 2025 at 9:16pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: XT 190 INJECTOR PUMP TIMING

Posted By: dishtech43

Subject: XT 190 INJECTOR PUMP TIMING

Date Posted: 22 Feb 2017 at 8:43am

Ok..I have an XT 190 Diesel.That I rebuilt motor 7 years ago.after 2nd year,had to rebuild injector pump.I think the guy who rebuilt it got it out of timing.I messed with it last year.and though it was of by one tooth.but still wont run..Can someone tell me how to time this motor to the injector pump.someone said pull #1 injector,and put welding rod in it to find tdc..but how would I know this in on the right place for firing?It might be for Exhaust,since its a 4 stroke motor..I do have the front gear plate off ,and see the marks and in the little window on the injector pump. last time I tryed to start.I only had 3 injectors little wet with Diesel after loosing nut.. Any Ideal..this Tractor has been setting in my shed for 4 years now not running.thanks |

Replies:

Posted By: tbran

Date Posted: 22 Feb 2017 at 9:14am

|

you can pull the injector and turn the engine in direction of normal rotation and feel or listen for the whoosh of air - or one can remove the tappet cover and see the intake close knowing you are coming up on compression. After sitting for this long your metering valve or rollers can be stuck in the pump. We normally remove the lines squirt some diesel in the holes, pressurize an outlet where the banjo bolt goes with air from a rubber tip blow gun and spin the engine to try to force out the rollers and then if that doesn't work pull the top off the pump and wiggle the metering vavle. IF that doesn't work call in the Calvary... Time the pump per the # on the pump - different pumps time differently.

------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: DrAllis

Date Posted: 22 Feb 2017 at 9:15am

| Like so many posts here, the info is somewhat lacking. Did the tractor ever run after your buddy rebuilt the pump?????????? if so, it couldn't have been 180 degrees off. Remove #1 injector. Find a plastic cap that fits the injector hole tight and install it. Rotate the engine by hand until it just blows out the cap and proceed a little more from there until timing marks are 24 or 26 degrees BTDC, whatever your engine should be. THERE'S MORE THAN ONE PUMP DEGREE SETTING DEPENDING ON PUMP S/N. |

Posted By: dishtech43

Date Posted: 22 Feb 2017 at 12:03pm

|

First off thanks Guys.. and yes the Tractor ran great,after I over hauled it.but one day while discing ,it started cutting out and missing..I took off pump,and Local here,who has worked on AC all his live..(Benny Mckinnon) rebuilt it for me..and said it had alot of junk in it..I since then cleaned out tank lines,ect.and new filters..and it would run if used ether,but ran like it was surging.I loosened up the two advanced bolts on the pump and pushed it up as far as permitted..and it was running alot better..that is when i took off front plate,and seen it was one tooth off,best I could tell..So I pulled gear out some to make it right.but hasnt run since then...and only puts out fuel to a couple of injectors..Benny said he had another rebuilt pump he would trade me.but I want to make sure its all timed this time.thanks ------------- Enjoying saving old Tractor setting or about to go to the Salvage yard.Its such a shame.I have saved in last 4 years over 25 Tractors...now I cant seem to find any cheap enough to buy. |

Posted By: lowell66dart

Date Posted: 22 Feb 2017 at 12:21pm

|

I would start over and pull the valve cover and get it at top dead center on the compression stroke with the timing pointer lined up where it needs to be based on your pump as was suggested above. Then see if your pump is in/timed right. Dot to dot on the shaft and timing marks aligned. I did all of the above to my 200 (never touched an injection pump in my life) after someone before me messed things up. ------------- AC 6080 (8030,7060,200,175,D-17HC, 6040,160,6140 all gone) Farmall 1066 & 656 Hi-Clear (for sale), White 2-62 High Clearance, JD 4255 Hi Clear. |

Posted By: injpumpEd

Date Posted: 22 Feb 2017 at 1:24pm

|

It really isn't as complicated as you think it is. Even though there's different timing specs for XT's based on if the pump has or doesn't have timing advance. Either way, you're looking at 26* for non advance pumps, compared to 24* for pumps with advance. 2* won't make it run as poor as you're saying. Something was put together wrong in the pump I'd guess cam ring is in backward. Good luck! ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: Digit

Date Posted: 23 Feb 2017 at 4:17pm

| Ok thanks guy...I agree..I think something was put together wrong..Benny was Good Mechanic..but he is also up in his years now...and even I forget things alot at times. Ill let you know what I come up with as soon as I can.thanks again. |

Posted By: Digit

Date Posted: 29 Mar 2022 at 2:18pm

|

Posted By: injpumpEd

Date Posted: 29 Mar 2022 at 5:45pm

|

seized pump is never good. But that didn't have anything to do with it being out of time lol! ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: John m

Date Posted: 30 Mar 2022 at 11:11am

| So what would have caused this. |

Posted By: DrAllis

Date Posted: 30 Mar 2022 at 11:13am

| The hydraulic "head" on the pump has seized/welded itself together. The drive shaft is designed to shear off like it did to protect the timing gears of the engine. A plugged injector or a big loader hanging on the side frames are the two most common reasons for seizure. |

Posted By: John m

Date Posted: 30 Mar 2022 at 4:54pm

| Well that's interesting. But better and cheaper fix than tearing the gears out of it I guess. Hopefully replacement parts are plentiful. John m |

Posted By: DougG

Date Posted: 30 Mar 2022 at 5:16pm

| Depends, one of those shafts are common - the other one not, just my experience with these pumps as they are great on farm tractors and real easy to get awesome horsepower- was pulling my One Eighty one night with the Roosa 450 pump head at 200 lbs fuel pressure, high rpm,s - seen the pressure gauge go to 280- POP there went the pump head - injector stuck and then it was $ 2500 that pull,, only money ! |

Posted By: Leon B MO

Date Posted: 30 Mar 2022 at 5:19pm

|

So Doc, we've had 2 XT's with 500 loaders for years with no complications, so I have to ask. You said a "big loader hanging in the side frames" could have caused this. Is it something to do with the front plate twisting or stress? Or just to much weight? Thanks Leon B Mo ------------- Uncle always said "Fill the back of the shovel and the front will take care of itself". |

Posted By: DrAllis

Date Posted: 30 Mar 2022 at 5:33pm

| Never seen a 500 loader do it. It yanks on the side frames and flexes the front engine plate. I saw a 220 many decades ado with loaded saddle tanks cross a rough waterway in the field and that's right where the pump seized. Seen a 7000 do it twice (10 yrs apart) with a Du-Al brand loader almost double the size of a 500. Loader was removed after the second time. |

Posted By: injpumpEd

Date Posted: 30 Mar 2022 at 5:58pm

|

This one's failure is obviously crappy old fuel. Look how nasty the fuel side of the shaft is. Now, imagine pump parts with millionths of an inch of clearance are supposed to function properly in that environment, this is typically the result. People just continue to try and start them when it obviously doesn't want to pump fuel. If it is properly torn down and cleaned up before starting it, you can usually save them. The head and rotors for these are in stock, at 1300 just for the new head & rotor. I've used up many of my good used ones! ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: MACK

Date Posted: 30 Mar 2022 at 9:01pm

| Crossing ditches and terrises at angel when axel bottoms out against stops will also cause the problem. Worst is front dozer blade. MACK |

Posted By: Digit

Date Posted: 25 May 2022 at 10:14pm

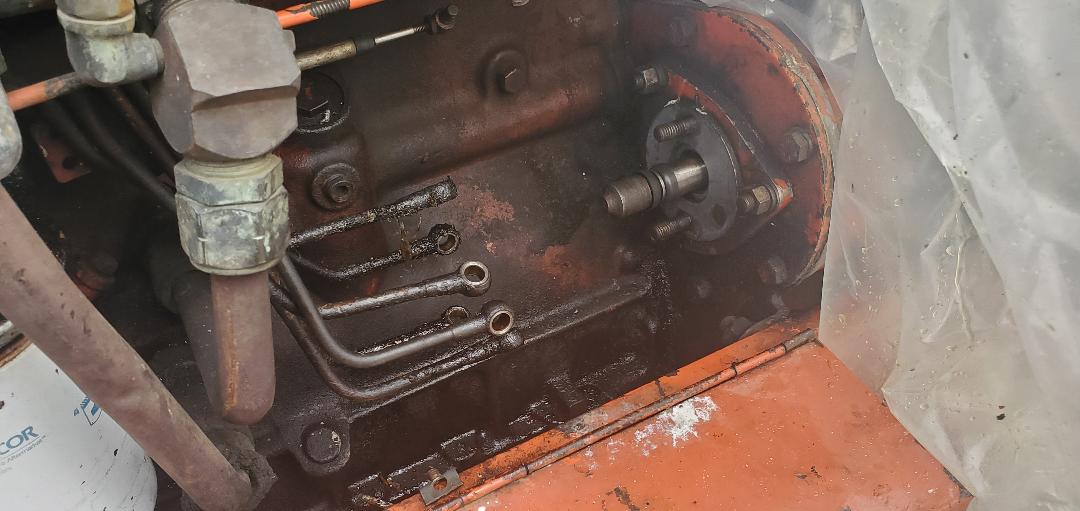

uploads/15343/XT_190_new_pump.jpg" rel="nofollow"> Yea, I sent the pump in to be rebuilt and bought a Pump Shaft. but after a couple weeks waiting. was told pump head was froze up. and would need a new one at $1200.00.... I said no way.. keep the junk pump. Ill find one somewhere. Any way I got one from Willard on AC.com I had him rebuild it. just got today ! It looks like a new one ! $990.00 to my door, and it came with a shaft and new seals already on the shaft and installed in pump. I didnt have a core. Thats a hell of a price. I took valve cover off. and valves closed on #1 piston and have set around 26 degrees. But not sure if that is right. This tractor is like a 67 model I think. How do I tell advanced pump from one that is not ? I need to know for sure what degree before top dead center it should be. Going to take cover off of pump to allign lines. and put gear on pump and make sure gear aligns with the other crank gear dots. That should be right ? Thanks Yea, I sent the pump in to be rebuilt and bought a Pump Shaft. but after a couple weeks waiting. was told pump head was froze up. and would need a new one at $1200.00.... I said no way.. keep the junk pump. Ill find one somewhere. Any way I got one from Willard on AC.com I had him rebuild it. just got today ! It looks like a new one ! $990.00 to my door, and it came with a shaft and new seals already on the shaft and installed in pump. I didnt have a core. Thats a hell of a price. I took valve cover off. and valves closed on #1 piston and have set around 26 degrees. But not sure if that is right. This tractor is like a 67 model I think. How do I tell advanced pump from one that is not ? I need to know for sure what degree before top dead center it should be. Going to take cover off of pump to allign lines. and put gear on pump and make sure gear aligns with the other crank gear dots. That should be right ? Thanks

|