D17 ser. 4 diesel, left brake locked

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=134086

Printed Date: 01 Jan 2026 at 1:52am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D17 ser. 4 diesel, left brake locked

Posted By: Marble17

Subject: D17 ser. 4 diesel, left brake locked

Date Posted: 21 Jan 2017 at 11:26am

| Reaching out for some help. Last night while plowing my driveway the left brake "locked up" forward and reverse, happened going uphill, if I hold right brake it will unlock for a foot or two then lock right up again. Well being in the middle of my driveway and 5' banks on both sides, I did this forward reverse thing about a 100 times to get 200' where I could get it off the side. The small spring on the front of the axle is connected and has tension on it. Also the hydrologics are super slow when it's locked, 3 point and loader??? It was doing this occasionally in reverse only but as soon as I went forward it was fine, just chalked it up to sticking brake, but now she is really sticking. Please any help and hopefully good news, stranded at 8,000ft and 6' of snow! |

Replies:

Posted By: Dan73

Date Posted: 21 Jan 2017 at 11:42am

| I don't know the serries 4 but on the serries 1 there is a cover on the axel which gives you access to the brake pads and a bolt to adjust the brakes. My first thought would be to pull the cover on that side and see if you can back the brake off so it releases and then finish what you need without brakes. It can't hurt to try and back them off a little. |

Posted By: Eldon (WA)

Date Posted: 21 Jan 2017 at 11:49am

|

I would jack it up and try turning it back and forth by hand to get a better idea of what is happening. The brakes are an expanding drum with bands to actuate the drum...kind of a 2 way braking system. The two pieces of the drum are held together by 2 small spring and separated by 4 steel balls that run on ramps to spread the two halves. Possible a spring has broken and the balls have come out of the ramps causing the lockup. Also check the final drive oil level...it could be a dry bearing going bad if it has run without oil...had that happen last summer. Unfortunately the final drive has to be removed to service the brakes (fender removed, tranny oil drained, seat removed, hydraulic cylinder removed)...fortunately it is the left side, which is much easier than the right. Don't force anything, parts are not cheap! Good Luck. ------------- ALLIS EXPRESS! This year: |

Posted By: Eldon (WA)

Date Posted: 21 Jan 2017 at 11:51am

Series IV are totally different. ------------- ALLIS EXPRESS! This year: |

Posted By: Marble17

Date Posted: 21 Jan 2017 at 12:22pm

| Oil is good, the plate on the top, by looks seat comes off then you can get the plate off. Can you get to the brakes from there? I guess it could be anything but seems like the brake. |

Posted By: Eldon (WA)

Date Posted: 21 Jan 2017 at 12:34pm

|

You can't do much from on top but maybe see if something is out of place....you are going to have to pull the final to do anything. My first one took 10 hours as it was a rusted mess and I had trouble getting cylinder and brake pins out....last one took 1 1/2 hours (the 4th tractor that I did that year) Good luck, and I&T Manual would help as there is a spec than needs to be met by shimming. ------------- ALLIS EXPRESS! This year: |

Posted By: Marble17

Date Posted: 21 Jan 2017 at 1:22pm

| I have a manual, haven't dug into that yet, was hoping someone else might have gone down this road. Of course it's in the worst spot, at the bottom of my driveway in a snow bank. And the being gentle went out the window last night. I did want to clarify my brake theory. Last fall, occasionally if I was in reverse and applied that brake it would do the same thing locking up, then as soon as I went forward it was fine. Also looking were the brake rod goes into the axle there are what looks like brake filings around it, the other side has nothing like that. |

Posted By: Don(MO)

Date Posted: 21 Jan 2017 at 2:24pm

You will need to pull the axle off like Eldon said and it will look like, this tractor is a 185 but your D17 will be the same. this tractor was doing the same thing and I hope yours is not as bad as this one.      ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Marble17

Date Posted: 21 Jan 2017 at 2:30pm

| WOW, depressing, I want to puke! |

Posted By: LeonR2013

Date Posted: 21 Jan 2017 at 2:44pm

| A couple of friends and plenty of Black Label (or Coors) will make all the difference in the world.You'll either jump right in there or set by the stove and not give a flip. I've been where you're located many times and it's a bear in the winter. |

Posted By: Marble17

Date Posted: 21 Jan 2017 at 3:08pm

| No I'll do it, just not what I needed right now. It will not fit in my garage, so it's going to be a driveway job outside of the garage. Heck I can't even get it up to my house right now, it's going to have to be a heck of a lot warmer for this project.This Colorado winter has been kicking me in the family jewels pretty hard. |

Posted By: Stan R

Date Posted: 21 Jan 2017 at 3:09pm

| More intimidating than it actually is. Did our IV in about 6 to 8 hrs each side. 2 men, not that difficult technically. We just replaced the disc and drum pads and fixed the similar issue you have. Same type of wheel lock up as you describe. Best to try to go forward or reverse to unlock it (if possible) and get it into a garage to fix. Will need a chain fall or jib crane to pull off the final drive. |

Posted By: Marble17

Date Posted: 21 Jan 2017 at 3:31pm

|

Thanx for the info, I'll get it in the spring. By the way does the hydrologic thing make any sense? It acts like it is low in fluid (it's not), pull handle and nothing, then it slowly moves but jumps, just like it would if it was low. No looking forward to it, just such a handy tractor with the loader. My fenders are junk, so good time to get them off and replaced. Maybe I can even figure the power steering being on the soft side By the way, I'm a Crown man.... |

Posted By: darrel in ND

Date Posted: 21 Jan 2017 at 4:52pm

| Probably not this simple of a fix for you, but on my one ninety gasser, my brakes were locking up every time the humidity got high; mostly when raining. It got worse later on, and I had just relined em. Anyway, I went into the hole on the brake housing where one of the springs is anchored, and shot about a half a can of WD 40 into each housing, and so far, ,so good. I think series 4 D 17 brakes are similar to my one ninety brakes. Darrel |

Posted By: Marble17

Date Posted: 21 Jan 2017 at 8:04pm

| Oh, are the parts available? And ball park on the $ |

Posted By: Eldon (WA)

Date Posted: 21 Jan 2017 at 8:18pm

|

http://www.ebay.com/itm/Brake-Plate-Assembly-W-Lining-Allis-Chalmers- D17-170-70237208-/121886670187?hash=item1c6102fd6b:g:nkAAAOSwvUlWtQYK http://www.ebay.com/itm/70277327-70237208-New-Brake-Plate-Assembly-Made-to-Fit-Allis-Chalmers-D17-170-/321637263081?hash=item4ae31326e9:g:FkwAAOSwl9BWKjqo http://www.ebay.com/itm/Brand-New-Allis-Chalmers-Brake-Band-70277379/262791184540?_trksid=p2047675.c100005.m1851&_trkparms=aid%3D222007%26algo%3DSIC.MBE%26ao%3D2%26asc%3D40839%26meid%3D621a51fbc52742d7bb7e6fc3605d4e8c%26pid%3D100005%26rk%3D3%26rkt%3D6%26sd%3D172363933266 ------------- ALLIS EXPRESS! This year: |

Posted By: Eldon (WA)

Date Posted: 21 Jan 2017 at 8:22pm

|

http://www.ebay.com/itm/D17-170-Allis-Chambler-Tractor-Disc-Brake-Plate-Assembly-25-Spline/252194707811?_trksid=p2047675.c100005.m1851&_trkparms=aid%3D222007%26algo%3DSIC.MBE%26ao%3D2%26asc%3D40839%26meid%3D26325078c3754ce9bc28956333ac1d48%26pid%3D100005%26rk%3D2%26rkt%3D6%26sd%3D321637263081 Make sure you count the splines and the new parts match, there are both fine and course splines used. ------------- ALLIS EXPRESS! This year: |

Posted By: Stan R

Date Posted: 21 Jan 2017 at 8:27pm

|

I suggest you take the tractor apart before you order parts. We just bought the brake pads and rivets and re-padded the disc and drums ourselves. Probably under $100 total (did ours maybe 10 years ago and can't recall the price, but was relatively cheap). Sandy Lake Implement (advertiser on this site) probably can get them for you. |

Posted By: Marble17

Date Posted: 21 Jan 2017 at 8:41pm

|

Thanx guys, just wondering if it was going to break the bank. I will tear it down first and take some pictures so you can see the carnage and hopefully steer me in the right direction. I got this girl from my dad and brought it across county from Vermont in August, don't have the hart to tell him it's having issues. I'll bring her back to life! Hey off topic here, but I used to be on this site back in the early 2000's, didn't remember my login name but was sure of email address. Said it didn't remember me? Was it just to long ago? |

Posted By: SteveM C/IL

Date Posted: 21 Jan 2017 at 10:07pm

| This site is much changed since back then....when new format showed up I think you had to re-do everything.If so nothing carried over....that would explain "don't remember". My memory ain't great so I could be wrong. |

Posted By: Sugarmaker

Date Posted: 22 Jan 2017 at 9:20am

|

Yikes ! That type of problem in the middle of the winter is not a good thing! Looks like you have lots of folks on here that have done the brakes. Thats what i like about the site and folks have helped me a lot on my old WD's. Stay warm and plan your attack on the 17 brakes in warmer weather. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Don(MO)

Date Posted: 22 Jan 2017 at 10:50am

|

Don't let it scare you, just have some good heavy duty stands and a way to lift and hold the axle for removal, read the book two or three times before you start and it will save time. The left side will go faster than if you where doing the right side. It's like most jobs, just getting started is the hardest part of doing something. One bolt at a-time. The shots I posted above are of one of the worst you might run into. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: LeonR2013

Date Posted: 22 Jan 2017 at 1:18pm

| It looks like you've made the right decision. Sit by the fire with he beverage of choice. The next big decision to make is; how much is this going to interfere with my fishing? LOL |

Posted By: Marble17

Date Posted: 08 Jul 2017 at 10:04pm

|

Gentleman, just an up date, the F$&!@ing snow is finally gone!lol. Had to put the 17 on the back burner till today! Tire, loader arm, fender and must all final drive bolts, OFF. bringing my mini-ex up tomorrow and will pull final tomorrow. Been reading my book... I don't know if it's more confusing, just doesn't make sense. When I get the final pulled hopefully it will make more sense |

Posted By: Burgie

Date Posted: 09 Jul 2017 at 5:09am

|

It makes more sense than the book when you see it in there. The service manual is a good help. ------------- "Burgie" |

Posted By: Marble17

Date Posted: 09 Jul 2017 at 3:57pm

| Well got the final out and exposed all the carnage. I tried posting some pics. But says my file is to big. I did email Eldon all my pictures (thankfully he's been mentoring me) basically everything that holds the 4 balls together, is in about 20 different pieces all the way down to powder. The brake bands look to be intact and functional, not sure how think new ones are, but these are 1/8" thick. Shaft and splines look good on final. The rest of it is junk. |

Posted By: Eldon (WA)

Date Posted: 09 Jul 2017 at 6:12pm

|

The brake bands need to come out in order to check the 2.xxxx measurement to see if shims need to be changed. I would replace those linings as well as long as you are in it this deep. ------------- ALLIS EXPRESS! This year: |

Posted By: Eldon (WA)

Date Posted: 09 Jul 2017 at 6:17pm

------------- ALLIS EXPRESS! This year: |

Posted By: Marble17

Date Posted: 09 Jul 2017 at 6:27pm

| Thanx Don, yep I think mine is worse, at least there is more pieces. I see you had the bottom brake linkage out. Mine seems fines and even works fine. Can't I just take the pins out on both sides of the bans and leave the rest? Eldon says it's a bare to get the bottom pin out. It looks like I can just pull the pins on both sides |

Posted By: wekracer

Date Posted: 09 Jul 2017 at 6:36pm

| Find an A&I dealer. You can get the whole assembly for about $300. Did my buddies 180 a couple years ago. The ramps were worn badly. |

Posted By: wekracer

Date Posted: 09 Jul 2017 at 6:44pm

| Also I had to cut the pins on my buddies. I used a sawzall and cut near the outer housing then slide the band as far to the outside as possible then cut again leaving as much pin sticking out as possible from the inner housing. I then took a die and started cutting threads on the pin. Once the die hit the housing the pin came out easy. Good luck |

Posted By: Gatz in NE

Date Posted: 09 Jul 2017 at 7:22pm

|

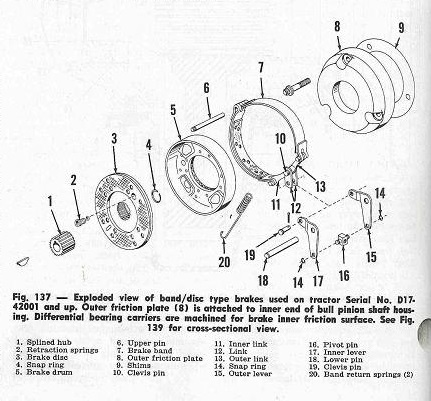

This from the I&T manual. Can't recall if the A-C manual even has this info for the SerIV Replace the retractor springs while you're in there.

|

Posted By: Gatz in NE

Date Posted: 09 Jul 2017 at 7:23pm

|

Posted By: Marble17

Date Posted: 18 Aug 2017 at 8:41am

|

Well, I just wanted to thanx everyone for advice and support. It's been up and running for a while now. So if it's any advice to anyone and I know I didn't do it the official correct way, but cheaper. So my drums were completely destroyed, springs, linings, the drum was broken in several places, the only thing that was salvageable was the 4 balls. Bands were in good condition and worked. Outer friction plate was badly scored from broken metal. (I know your all going to cringe here) I used a disk grinder, kept moving and took the scoring out, then 40, 80, 120 to 220 orbital sander and got it smooth. Had to buy 2 shim packs and Had a 1/8" plate cut to a shim, had to grind the three blot heads down a little also. I had to make up .185".... ya I know. So I did not pull lift arm bracket, took the two bolts off on low side of bands, top pin out, removed, a good shop vac session. Got lucky and brake rod was free and adjustable with some PB blaster. Bought both brake drums, springs, used the old balls, and put together, bought the two return springs for the bands and installed everything. I know this was not the correct way but was quicker and cheaper. Thanx again to all |

Posted By: SteveM C/IL

Date Posted: 18 Aug 2017 at 1:16pm

| At least now you know how to do it if you have to go back in... |

Dan73 wrote:

Dan73 wrote: