Valve spring inserts

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=132007

Printed Date: 15 Dec 2025 at 3:17am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Valve spring inserts

Posted By: alan-nj

Subject: Valve spring inserts

Date Posted: 30 Nov 2016 at 6:59am

|

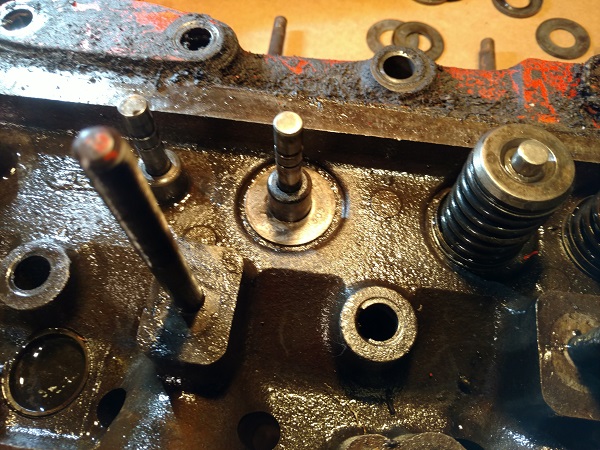

Was taking apart a WD45 head last night and saw something I hadn't seen before. This head had been assembled with valve spring inserts under the spring seats. i researched them on the web a bit, and it seems that they are primarily recommended for high rpm use, aluminum heads, and weak springs. I'm re-doing the head and not putting them back, but was wondering how often these were used in tractor rebuilds....seems to me that if the springs were weak, it wouldn't cost that much more to just use new springs....or were they thinking something else at the time......   ------------- If ignorance is bliss, than happy days are here again. |

Replies:

Posted By: DrAllis

Date Posted: 30 Nov 2016 at 7:06am

| When valve faces and seats are reconditioned, the compressed spring length/height increases. Those are to place the spring back into a proper height spec. |

Posted By: Fred in Pa

Date Posted: 30 Nov 2016 at 7:07am

|

When u cut-resurface vales and seats valve goes in head ,shims make up spring compression. If installing new seats and valves u would most likely not need them .Shop done the head that understands how to do job correct. Not just grind everything and put back together ------------- He who dies with the most toys is, nonetheless ,still dead. If all else fails ,Read all that is PRINTED. |

Posted By: Steve in NJ

Date Posted: 30 Nov 2016 at 7:13am

|

When I used to do a lot of cylinder head work, if the springs were just a tic under the seat poundage rate, a shim would bring the rate back into spec depending on the shim size. For just stock applications, it was faster to do that practice than to wait for new springs to come in which was more down time, and also more cost to the customer. On high performance applications, I would just go with a heavier/larger spring depending on the application. Most of the head work I did in my earlier years was Automotive. (Ford, Chev, Chrysler etc.) ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: alan-nj

Date Posted: 30 Nov 2016 at 7:26am

|

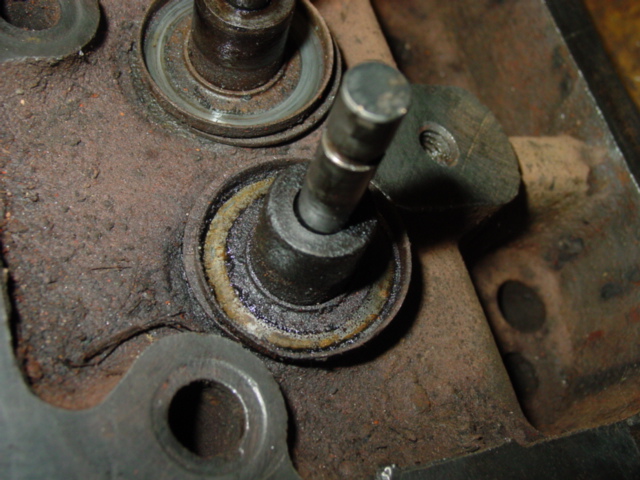

ok, thanks....head also had rubber umbrella seals. tractor smoked quite a bit on start-up, then exhaust cleared up after running a bit. tractor ran a bit rough and engine wouldn't accelerate smoothly and would bog down under load.....after determining that it wasn't electrical or fuel, figured it was in the valves....clearances were ok, so pulled head and found some pitted valve seats. Also noticed that the radius on the rocker arms is worn quite a bit. Surprisingly though, while the valve guides are worn, the valves themselves don't appear to be real old or worn badly. ------------- If ignorance is bliss, than happy days are here again. |

Posted By: Butch(OH)

Date Posted: 30 Nov 2016 at 7:46am

Alan, next time dont guess about the smoke, look When you pull the manifold look at the valve stems through the ports , if wet with oil that is your smoke problem. Use the old valves if decent because they are better quality than the new aftermarket ones. I use the aftermarket guides but look them over carefully as they sometimes get carried away with the radius on top and that is bad. I face them in the lathe before installing and give them a light turn with the deburr tool, that's it. With everything up to snuff leave the umbrellas out when you assemble as they are not needed. When you pull the manifold look at the valve stems through the ports , if wet with oil that is your smoke problem. Use the old valves if decent because they are better quality than the new aftermarket ones. I use the aftermarket guides but look them over carefully as they sometimes get carried away with the radius on top and that is bad. I face them in the lathe before installing and give them a light turn with the deburr tool, that's it. With everything up to snuff leave the umbrellas out when you assemble as they are not needed. |

Posted By: alan-nj

Date Posted: 30 Nov 2016 at 7:55am

|

Butch....thanks....i did actually look ...and didn't like what i saw....i think the valves are already aftermarket....i'm thinking they did this without replacing the guides or having the seats checked out....put new valves, umbrellas, and inserts and hoped for the best. I'm going to have my local machine shop press the guides in when they look at the seats for me.....i don't have the tool and i'd probably booger them up..!! ------------- If ignorance is bliss, than happy days are here again. |

Posted By: Allis dave

Date Posted: 30 Nov 2016 at 10:35am

| Oops. I had new valves seats put in my 45. Each of my valves had a little flat bottomed bowl (for lack of better term) with one of those shims in it. I just put it all back together how it was when I took it apart. |

Posted By: DrAllis

Date Posted: 30 Nov 2016 at 10:48am

| Valve stem umbrellas do not belong on a WD-45. |

Posted By: 79fordblake

Date Posted: 30 Nov 2016 at 12:23pm

| I have 512 bucks in my WD45 head. All surfaces machined to be flat. All new springs, valves, seats, guides, freeze plugs. |

Posted By: Gerald J.

Date Posted: 30 Nov 2016 at 12:36pm

|

A running engine test for intake valve stem oil leakage exists. Run the engine fast, close the throttle all the way to create maximum intake manifold vacuum. When the engine gets down to idle speed increase the speed gently. If that maximum intake manifold vacuum pulled oil around the valve stems there will be some blue oil smoke. While valve stem oil seals weren't original they probably won't hurt anything and could give extended valve guide life. Gerald J. |

Posted By: Allis dave

Date Posted: 30 Nov 2016 at 1:08pm

| I would think the oil seals could shorten life because as a little oil leaks past it's lubricating the valve guide?? |

Posted By: 79fordblake

Date Posted: 30 Nov 2016 at 7:44pm

| I've always heard guides will wear more with added seals. |

Posted By: Dick L

Date Posted: 01 Dec 2016 at 6:52am

|

The only Allis B valve guides I have ever seen this sloppy had stem seals on them. I have no idea of the history of the engine but they had two seals on each valve stem. A head scratcher for sure.

|