Valve Springs

Printed From: Unofficial Allis

Category: Other Topics

Forum Name: Pulling Forum

Forum Description: Forum dedicated to Tractor and Garden Pulling

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=124681

Printed Date: 01 Feb 2026 at 6:09am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Valve Springs

Posted By: Ryan59

Subject: Valve Springs

Date Posted: 16 Jun 2016 at 8:43pm

http://s150.photobucket.com/user/rw68560/media/DSC_0066.jpg.html" rel="nofollow"> " border=""> " border="">Would there be any issues caused by doubling the stock valve spring pressure? I am considering installing stock Chevrolet valve springs in a 125ci engine. |

Replies:

Posted By: MACK

Date Posted: 16 Jun 2016 at 9:56pm

| As long as you don't use stock retainers and keepers. MACK |

Posted By: PaulB

Date Posted: 17 Jun 2016 at 6:38am

|

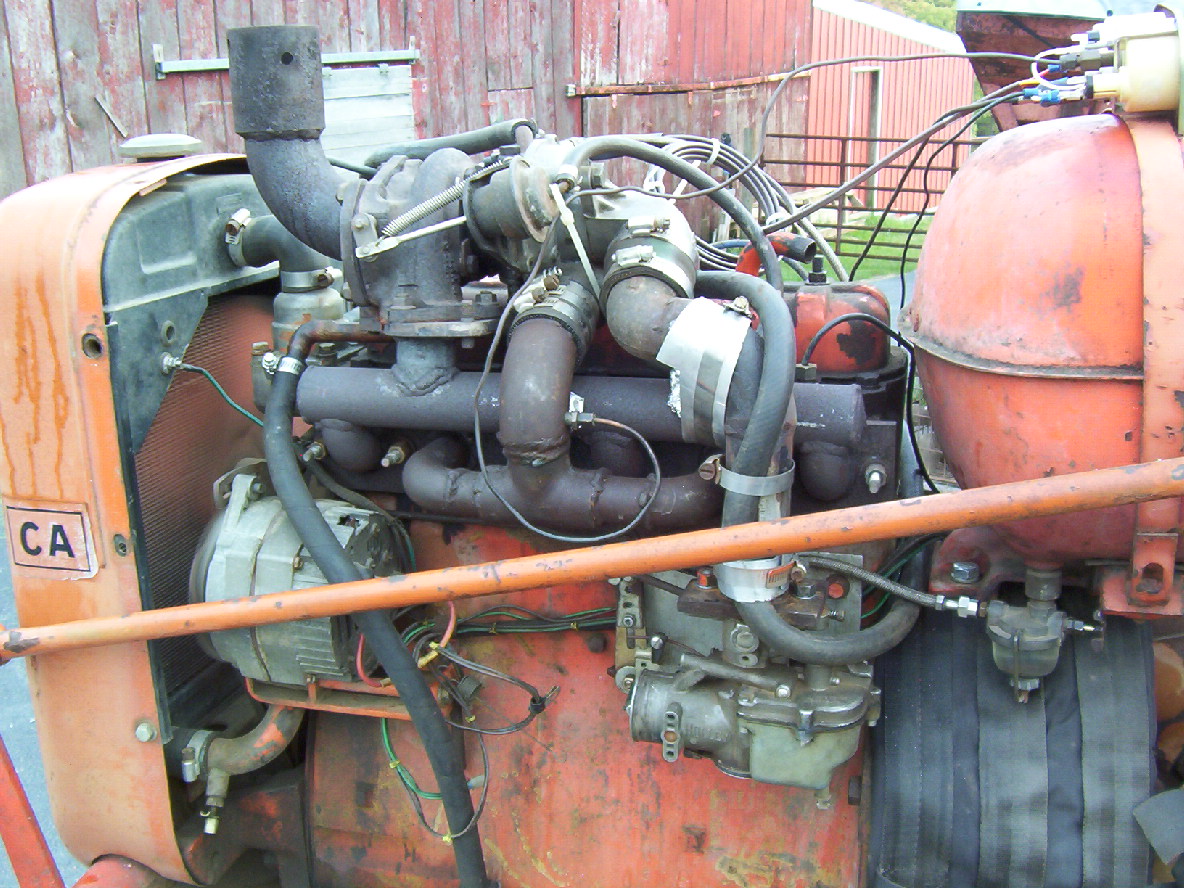

I can't remember exactly what the seat pressure ended up on the head of the 160 engine in my turbo CA. I kinda think it is near to 60 PSI seat pressure. Then again I run at near 15PSI boost and over 4000RPM. Now with the big two barrel it can breath like it should. I have not noticed any wear in the valve train. I used new OEM stock retainers and keepers. I do use Amziol 15/40 in both of the pulling CAs. This is when I still had the single barrel up draft on. to see how it runs now with the two barrel watch this. http://youtu.be/GXU6b43E6ro

------------- If it was fun to pull in LOW gear, I could have a John Deere. Real pullers don't have speed limits. If you can't make it GO... make it SHINY |

Posted By: CTuckerNWIL

Date Posted: 17 Jun 2016 at 7:36am

|

WHY? I know guys that run big cubes at or near stock rpm that go the other way drastically, to reduce pressure on the cam. ( cam has notches cut in it to clear the rods) With a good seat, higher spring pressure won't help with anything but wear, unless you are running 3 times the rated rpm or more.

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Ryan59

Date Posted: 17 Jun 2016 at 5:20pm

|

Thank you Paul for the useful information and posting a picture of your turbo set-up. I had been wanting to see how you plumbed the draw-through system, She sure walks that sled LOL. Well, parts came in yesterday so I made a trip into town to go over what I wanted done to the head. The exhaust seats were ate up a lot worse than pictures show. Before I bought it, it had set outside in the rain, probably for years. Although the exhaust was capped water runs in around the exhaust pipe adapter sleeve at the manifold. The shop where I took the head has a Serti machine, he showed me how deep he would have to cut the worse exhaust seat to clean up the pitting. So we stepped back in his air conditioned office where we could think a little clearer. He knows this tractor and has rebuilt dozens of these heads, he doesn't think I'm doing anything unusual or extreme. He made me a cash deal on hardened exhaust seats installed and 3-angle Serti cut. The intakes seats didn't need a lot of material removed to clean up like the exhausts. I did ask him about valve springs and showed him the stock and Chevrolet springs. He checked the rate of the chevy spring and said it was a 45lbs rate spring, wouldn't hurt the stock valve train at all. Didn't add anything more to his reply. All I can do is offer my opinion why I feel this engine would respond positively to higher rate valve springs. I wish Jerry had checked the rate of the new stock spring but it didn't seem important at the time. First I considered all the weight that the spring has to over-come. Valve, retainer, keeper, rocker arm, pushrod and lifter. The valve spring has to control the weight of those items to follow the cam lobe profile. I understand we are discussing a low rpm engine but those stock springs look marginal at best for maintaining valve-train control. I'm going to say that 45lbs of seat pressure should be required as an upgrade to seal the valve on the seat for reliable compression. That's not carved in granite though. There are some very knowledgeable engine builders on this forum that may be holding a different opinion. |

Posted By: DiyDave

Date Posted: 17 Jun 2016 at 5:34pm

| [TUBE]http://youtu.be/GXU6b43E6ro[/TUBE] |

Posted By: DrAllis

Date Posted: 17 Jun 2016 at 8:26pm

| Hundreds of thousands of those engines built and you think it needs more valve seat pressure???? |

Posted By: Ryan59

Date Posted: 17 Jun 2016 at 10:44pm

|

Yes. Manufactures build most things as cheaply as possible. Not everything of course. These tractors were designed to operate in a wide variety of elements across the nation. From Canadian and Alaskan winter cold to Arizona's dry 117 degree heat they expect this weekend. For the largest part of their design, engineers took into consideration farmers working on them out in the pasture or along the side of a country road in the middle of nowhere. I'm sure at some point over the many years that these tractors have been in service, a valve spring or two has broken and something other than the factory original valve spring(s) were put in and left in there for generations. I bet there are several members of this forum that have something other than the stock valve springs under their valve covers. I offer you this statement: If the factory built every engine for maximum power output. There would be no need for aftermarket parts. Even airplane engines are not developed for 100% work load. |

Posted By: DrAllis

Date Posted: 17 Jun 2016 at 11:27pm

| The Engineer(s) who designed the valve train on this engine series(which would include the valve springs) had to meet several criteria before settling in on the final design. Now, I wasn't there, but I imagine I can guess what some of those criteria were. #1. Performance #2. RELIABILITY #3. cost #4. Serviceability #5. service life. To just decide to increase spring pressures without proper testing of the rest of the components, would automatically create at least one negative...lack of performance. By that I mean, increasing spring pressure on all eight valve springs (when it isn't needed) would certainly not result in an engine HP increase. Quite the contrary...it would create more friction on all parts involved and quite possibly result is less HP/torque produced at the flywheel. How much?? Depends on the increase in spring pressure, but one thing for sure.....it wouldn't cause a gain in HP !! Then, there's the matter of service life. Cold starts with little oil to lube the camshaft lobes and lifter faces, etc, etc. Yes, all of those nasty little details that one change in design specs can come back and create unforeseen problems to the life span of other related parts. You go right on ahead and do what you want to do. But, always remember there were millions of those springs used over the last 70 years that have never caused one second of downtime over millions of hrs of service life AND were often reused time and time again at overhauls and placed back into service, and they still performed well not ever causing a problem.. |

Posted By: Ryan59

Date Posted: 18 Jun 2016 at 7:06pm

|

Posted By: DrAllis

Date Posted: 18 Jun 2016 at 10:18pm

| The valve spring p/n is 70206879 for the B-C or CA tractor engine. It also is used on the D-14 and D-17 engines. Those are 2,000 RPM factory speed engines. I have used stock valve springs at 3,000 RPM when tractor pulling and have never floated a valve or had a push rod jump out of place. I sure hope you find someone who is knowledgeable about these AC engines to help you figure out valve spring pressures are good enough as-is. |

Posted By: DSeries4

Date Posted: 18 Jun 2016 at 11:32pm

Ryan, I see you are new here. As Dr. Allis mentioned, you should be talking to someone who is very familiar with Allis Chalmers engines (not mini bike or DOHC engines - you are comparing apples and oranges). Dr. Allis IS one of the people who can tell you straight up what works for these engines. He has a lifetime of working on them and pulling with them. I would not question any of his thoughts. He is the resident expert on this forum. His opinions and knowledge should be appreciated and not criticized. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: Ryan59

Date Posted: 19 Jun 2016 at 12:29am

|

Posted By: LeonR2013

Date Posted: 01 Jul 2016 at 9:45am

| Ryan I like your forward thinking approach to things, and jumping out of the box to see what is going on. And Doc I appreciate your having confidence in what has worked successfully and sticking to your guns. But I do hope you two don't get to butting heads and the rest of us lose the competitive knowledge we get from these discussions. Sixty years ago now I helped Dad overhaul our little "C" and I guess that set the tome for a lifetime of fascination with mechanical things. At 75 the old body is losing ground with the attrition of old age, but doggone it I ain't giving up easy. I just takes longer. So let us old guys work along with the new and let's see what both of us can learn. |

Posted By: Ryan59

Date Posted: 02 Jul 2016 at 2:32pm

|

Posted By: bradley6874

Date Posted: 03 Jul 2016 at 10:46am

|

Okay Ryan I'll put in my two cents the spring pressures only function is to close the valve in according to the lifter profile on the cam. the valve seat is what seals the combustion chamberincreasing, spring pressure has absolutely nothing to do with sealing the combustion chamber. if valves are not floating or losing contact with the cam you'r just creating more wear as the doctor said!!! exaggeration here but if you put a thousand pounds spring on a seat that doesn't seal it's still never going to seal but now you have a thousand pound hammer hitting the rocker every time the valve opens hope this helps ------------- You can wash the dirt off the body but you can’t wash the farmer out of the heart and soul |

Posted By: Ryan59

Date Posted: 03 Jul 2016 at 6:04pm

|

Posted By: bradley6874

Date Posted: 03 Jul 2016 at 7:26pm

|

Alright Brian the one thing you have not shared is if you're changing anything else in the valve train . what would justify increasing the stock Springs if you're not changing anything else please explain how this will be a improvement ------------- You can wash the dirt off the body but you can’t wash the farmer out of the heart and soul |

Posted By: Big Orange

Date Posted: 03 Jul 2016 at 7:33pm

| Valve spring pressure increase has more to think about than RPMs, when you are dealing with turbo boost pressures. As the valves have to close against that flow pressures also. |

Posted By: Ryan59

Date Posted: 03 Jul 2016 at 8:08pm

|

Posted By: LeonR2013

Date Posted: 04 Jul 2016 at 12:47am

| Change of thought here Ryan, you said you worked at Boeing. Was that in St Louis? |

Posted By: Ryan59

Date Posted: 04 Jul 2016 at 6:22pm

|

No, and there can be no other reason for you to ask that question other than to be-little me. I do not care where you work, where you are from or what you did or do in life. It is obvious that we do not understand one another so I bid you a good day. |

Posted By: bradley6874

Date Posted: 04 Jul 2016 at 7:27pm

|

Ryan the way I see it you have made your mind up to do this regardless of what several people have tried to give you reasons not to ,you keep trying to justify this to us it's you tractor fix it the way you want and have a great day ------------- You can wash the dirt off the body but you can’t wash the farmer out of the heart and soul |

Posted By: mgburchard

Date Posted: 12 Jul 2016 at 7:18pm

| You will be fine as long as you don't go over 120 lbs on seat |

Posted By: DiyDave

Date Posted: 12 Jul 2016 at 7:27pm

| I see spanky series 2 has weighed in... Now you know... |

Ryan59 wrote:

Ryan59 wrote: