Piston scoring D-21/210/220/7030 engines

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=209128

Printed Date: 05 Mar 2026 at 5:28am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Piston scoring D-21/210/220/7030 engines

Posted By: DrAllis

Subject: Piston scoring D-21/210/220/7030 engines

Date Posted: 27 Nov 2025 at 9:09pm

| Trying to finish up this customers knocking 220 engine. I've experienced this problem for I'd say 30 years off and on. It's always the engines that don't have piston cooling spraying oil from underneath to keep piston temps down that seem to do this. Replacement pistons and sleeves are parts that work fine in 7040's and bigger because they do have piston cooling, but the newer design piston/sleeves do not like being used in the old non-piston cooled engines. Unfortunately, the old piston/sleeve parts have been discontinued for a very looong time. All you can purchase now is the newer designed tighter fitting parts. The older engines used to spec piston skirt to cylinder sleeve clearance at .007". All the newer piston/sleeve kits are .003". Sometimes they work for years and then, just like this engine, you've got a mess to deal with. I've got a jig made to take my sleeves to a favorite machine shop and have (new or old) sleeves power honed out an extra .004" to alleviate this problem. It's an unfortunate event with no warning whatsoever. My advice is if you are overhauling one of these older non-piston cooled engines, you'd better loosen it up a little or you might get to do it again someday down the road. Pictures on the way. |

Replies:

Posted By: Calvin Schmidt

Date Posted: 28 Nov 2025 at 4:40pm

|

Thanks DR. I've heard of this before. Had this happen about 20 years ago while breaking in a fresh rebuilt D21 engine on the dyno at a moderate load. ------------- Nothing is impossible if it is properly financed |

Posted By: coggonobrien

Date Posted: 28 Nov 2025 at 8:07pm

|

Posted By: DrAllis

Date Posted: 28 Nov 2025 at 11:39pm

| I got the 220 engine fired up today and it sounds fine, but was only ran for a couple of minutes as it was supper time. This engine has the later model crankshaft driven oil pump and deeper oil pan on it. The oil capacity should be 21 quarts. This tractor has passed thru how many owners and technicians over the years ?? Who knows ?? Anyway, there isn't a serial number tag on the engine block, so I'll have to try and determine by the chassis s/n if it had this newer oil pump or not from the factory. I did notice that the engine oil level dipstick had been modified by someone in the past. It has been made longer, which would cause you to NOT fill the engine to 21 quarts capacity. I think it's about an inch too long, so we've probably been maybe 2 gallons LOW on oil all these years?? So, I will be changing that for sure. It also (at some point) had new slotted -.010" rod bearing shells installed and they did not get the connecting rods turned around as was required with that change to updated parts. So, now that has been corrected. It now has the newest "ARP" brand connecting rod bolts installed and torqued to 85 ft lbs. All six new wrist pin bushings were needed as they should have been replaced when the engine was OH'd before sometime in its past. One more thing to be extremely careful of when installing sleeves in these engines. Obviously, you want to clean the block very well and dry fit the new sleeves without the Orings on them. They should go in easily and be able to rotate when installed fully in the block. Remove the sleeves, roll on the new Orings (two black on the top two grooves and orange in the bottom groove) and then with a pocket screwdriver go around each one to be sure nothing is rolled/twisted. Now, the next important part: wipe Mazola cooking oil lightly on each Oring with your finger. Also wipe the inside of the lower block bore too. Nothing excessive !! just a light coat on the rubber and in the block bore. Shove the sleeves in and bolt them down. Excessive lube between those Orings can cause things to squeeze the sleeve and when you've only got .003" skirt clearance, you cannot afford to have that happen. Maybe the snow storm won't be so bad tonite and I can get the front axle under it and get in a hr or so of run time tomorrow. We'll see !! |

Posted By: SteveM C/IL

Date Posted: 29 Nov 2025 at 12:08am

| I'm sure it wouldn't help if it was turned up some. Show me one that isn't. Mine got the mains jetted at OH with M&W's and turned to 170hp in early 2000's. Has around 1500hrs on it. So far so good. It's retired to batwing duty now. |

Posted By: DrAllis

Date Posted: 29 Nov 2025 at 12:47am

| I've thought of a couple of other things too that could contribute to this problem : A muffler versus a straight pipe. A straight pipe might be enough of a benefit (100 degrees pyro temp cooler ) to offset altering HP upwards a bit. The fan belts on the D-21/210/220 were those da** shoestring width sized belts that had to be kept very tight or there was a reduction in fan/water pump speed at full throttle, especially when the tin pulley on the fan got worn. It makes sense that 180 degree coolant temps would have to be better than running right on the edge of the red when it comes to piston skirt diameters. Lastly, your M & W's probably are a little looser fit than .003". For sure there's less blow-by with their top ring design and that would make for a cooler piston too, wouldn't ya think ?? |

Posted By: Mikez

Date Posted: 29 Nov 2025 at 7:34am

| This should be put in knowledge section |

Posted By: Lynn Marshall

Date Posted: 29 Nov 2025 at 10:32am

| Do you think that the scoring starts around the o-ring area? Our shop worked on an early 7030 one time that would score the pistons on a break in pull on the dyno. I didn't personally work on it and I remember that it was turned up to 180 horsepower. I think that it did that twice before we talked to someone higher up and they suggested removing the top o-ring on the sleeve. My memory fades, but I think that fixed it. Question, were the 426 engines always a three o-ring design or did the early ones just use two on the sleeves? |

Posted By: Michael V (NM)

Date Posted: 29 Nov 2025 at 11:14am

|

I'm for sure following this thread, because I have a 220 that needs a complete rebuild. needs an injection pump rebuild also,,planning on turning it +12-15%,, jus for playing mostly,, as long as I have it,, it will never see long days of hard work Hey DR.,, is there a way to get a sleeve/piston/overhaul set from you that has been honed the +.004??

|

Posted By: DrAllis

Date Posted: 29 Nov 2025 at 11:24am

| Old original Gen One 426's I know were only two Orings. One black on top and one orange on the bottom just like the 301. You find that out on the first OH. Personally, I've only ever seen three Oring replacement sleeves and I'm sure a 7030 probably was just that. Remember, the 7030 engine developed 12 to 15 more flywheel HP right off the bat compared to a 220 engine, because of chassis/hydraulic loads. I too know of a very early 7030 that went thru two OH's in the first 24 to 36 months of its life due to scored pistons. It had an intercooler installed and turned up a bit. I don't remember if the muffler was on it or not. I didn't work on it either time but was aware of its issues. |

Posted By: DrAllis

Date Posted: 29 Nov 2025 at 11:30am

| That could be done. Or you could get your own kit of choice and just send me six sleeves and one piston and I can have them oversized for you. I'd suggest checking the clearance first to verify they are in that .003" to .0035" range to warrant doing it. My guy charged me $50 bucks each I believe. |

Posted By: DrAllis

Date Posted: 15 Jan 2026 at 8:17am

| Update to this subject: This particular 220 tractor got finished and driven 30 miles home on a nice Saturday (I think) the week after Thanksgiving. All is well at this point. Ten days ago, I had another 220 brought to me with a slight knock in the engine and coolant in the oil. I feel pretty strongly that we have another scored piston scenario with it too. I don't know the history on the tractor or engine, but maybe in a couple of weeks I'll have a chance to get into it to verify my suspicions as to what's actually going on. Finally, on the same subject, last night a friend of mine called me and was telling me of a restored 220 in his neighborhood that has right at 500 hrs on an engine OH that was being used on a forage chopper and now suddenly has coolant in the oil. It has since been parked for some time because of this. The owner thinks that an Oring was cut when a new sleeve was installed. I am wagering, once again, tight skirt pistons and sleeves and maybe some warm operating temps and once again, a scored piston or maybe more than one. In 50 years, I've never seen a cut sleeve O-ring at OH time, as there are three Orings to cut. But I sure have seen scored pistons that fry the sleeve Orings and dump coolant in the oil. I don't know if I'll get that engine to repair or not, but we will see how things go. |

Posted By: SteveM C/IL

Date Posted: 15 Jan 2026 at 9:10am

| The guy who OH'd my 220 warned me to let engine get up to temp before loading it or it could experience "4 corner score". Have no idea what clearance the M&W's were made with. He worked at a Deere dealership in the early days and said they experienced this problem on new 4020's when dynoing them before delivery. Must be something to it..... |

Posted By: DrAllis

Date Posted: 15 Jan 2026 at 9:37am

| I suppose that could be the aluminum piston was growing fatter and faster than the sleeve was until up to full operating temps. |

Posted By: tbran

Date Posted: 15 Jan 2026 at 12:22pm

|

When we have them down we usually plug the oil squirter hole for the old cam driven oil pump gear that is not now used. In theory will up cold start oil pressure on the galley it feeds. Doc- as to those belts, I use a wrap idler bolted to the pump front cover off an F2 to push the belts in and wrap the water pump pulley more. EZ to install. 71178651 is the pulley needed. It is designed for matched belts, flat sided. Have done the ones I own. Doubles the belt life and don't have to run them as tight. Doesn't 100% cure the issue but really helps. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: DrAllis

Date Posted: 15 Jan 2026 at 12:35pm

| So, you're pushing in on the fan belts on the injection pump side ?? That would certainly help with belt pull power. I've got a couple that I have gone so far as to use two "B" width belts, especially for that worn tin water pump pulley. They stand up high, but when tensioned properly they do not slip. Same thing on any D-15 that I work on. A new 1/2" wide belt instead of the original 3/8" one. |

Posted By: tadams(OH)

Date Posted: 15 Jan 2026 at 2:13pm

| Used to have this trouble in semi with Cummins if you didn't leave them warm up before you headed down the road usaually happen in the winter |

Posted By: tbran

Date Posted: 15 Jan 2026 at 9:18pm

|

Yes, and would probably help if added a 1/2" longer belt and moved it in even more. Wrapping the worn water pump pulley helps, alternator still slips after long cold starts as it charges wide open. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: Mikez

Date Posted: 16 Jan 2026 at 12:45pm

| Tim. Where are you putting the pulley |

Posted By: tbran

Date Posted: 16 Jan 2026 at 4:58pm

|

Right on the front injection pump cover plate - use one of the bolts - longer of course - and shims. I will try to get a picture posted. EZ to do. I made a big mistake and put a 6 blade fan on one (210) - 2 shoestrings as Doc calls them just will not pull it at 2400 RPM for long. I got off the tractor after the first joy ride and was covered with belt chards. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: DrAllis

Date Posted: 07 Feb 2026 at 5:57pm

| I had a good day today at the shop. Got the front axle rolled out from underneath 220 #two and removed the pan. I can see coolant dripping from the #1 sleeve and the piston is scored too. I also see scoring on piston #5. So, I need to get some help hoisting that 200 lb hood up and off and begin the tear down to see how many more pistons are scored. This tractor has an incorrect radiator fan spacer about 2 inches thick, moving the fan forward into the shroud box, thus reducing the maximum possible air flow. The fan blades are dinged up and it has 1/2" AGCO fan belts that are bottomed out in the fan pulley and the alternator pulley. I'm thinking this one really got hot some time recently from poor fan placement and slipping fan belts at full throttle. Chassis s/n 220-1267 and engine 3D-10390. It has the old camshaft driven oil pump. |

Posted By: SteveM C/IL

Date Posted: 07 Feb 2026 at 11:47pm

| Them hoods are rediculus! Must be 11 ga. Appear as 1/8 in. Bad job with 2 people. |

Posted By: Calvin Schmidt

Date Posted: 08 Feb 2026 at 7:59am

|

Many years ago, I built a rolling "A" frame with a 1 ton electric hoist on the beam. Best shop tool ever. Works great lifting those 220 hoods and many more things. ------------- Nothing is impossible if it is properly financed |

Posted By: DanWi

Date Posted: 08 Feb 2026 at 9:33pm

| 30+ years ago I lifted the hoods off 190's by myself. Now I have used the cherry picker fully extended to lift them off from the front. It might work from the side if you have room and can negotiate the tires. Last couple times I drove in the machine shed under a truss and threw 2 ropes over the truss and hoist them off that way. Just need something to tie them off to to hold it up. |

Posted By: AC7060IL

Date Posted: 09 Feb 2026 at 7:29am

|

DrAllis when I view your 426 pistons photo(coggonobrien’s), my initial take is “Wow, those pistons have a long skirt!” Just a thought. Could the new pistons lower skirting be easily machined off (removed) to minimize the sleeve’s lower squeeze, especially during cold start warm ups, & still allow them to perform? During the 1960s, do think the AC engine engineers designed these piston skirts to assist higher diesel cylinder compression, better cylinder heat transfer to entire sleeve coolant jacket, etc,,,? |

Posted By: NEVER green

Date Posted: 09 Feb 2026 at 8:26am

I think the skirts are so long because the wrist pin height is so low, racing engine experts claim the pin should be 1 1/2 from top, looks to be twice that. ------------- 2-8050 1-7080 6080 D-19 modelE & A 7040 R50 |

Posted By: DrAllis

Date Posted: 09 Feb 2026 at 9:41am

| The 426 piston length/skirt design is so very similar in design to any DT466, Deere 466, Caterpillar, Cummins and etc,etc,etc. There's nothing different about it for a heavy-duty turbocharged diesel fueled engine. That's not the issue. The issue is not enough skirt clearance when there isn't piston cooling, tight fan belts, clean radiator, functioning thermostats, a muffler instead of a straight pipe and last of all OVER FUELING of the injection pump. Any extra and unwanted heat can swell those tight skirt pistons up too much and once it starts, it becomes a disaster. This kind of thing never happens on light loads. It's when the engine is loaded heavily and for a prolonged period of time. The coolant temp may never even have gotten to the "red" zone, but probably was high in the green. I've never been there when this happens. Just am trying to connect the dots after the fact. So, the moral of the story is, keep fan belts TIGHT and coolant temps COOL and probably nothing will ever happen. The slipping belt issue can be dealt with using "B" width belts in my experience. If you hear the radiator fan change speeds when running full throttle, the belts are slipping even if they are tight. We can't have that. Also, piston skirts are the tightest clearance down low and 90 degrees to the piston pin. The pistons (below the pin) are "cam ground" and not perfectly round like one might think. |

Posted By: AllisFreak MN

Date Posted: 09 Feb 2026 at 6:06pm

|

Doc, earlier you mentioned the worn tin water pump pulley. I replaced my worn tin pully with a new cast iron one and now my belts don't seem to slip because the grooves are narrower. The original tin one was badly worn and a little bent besides. This was on a 1975 7040. ------------- '49 A-C WD, '51 A-C WD, '63 A-C D17 Series III, 1968 A-C One-Seventy, '82 A-C 6060, '75 A-C 7040, A-C #3 sickle mower, 2 A-C 701 wagons, '78 Gleaner M2 |

Posted By: DrAllis

Date Posted: 10 Feb 2026 at 10:02am

| I just want to clear something up about this piston scoring post. I am in no way suggesting that owners of these particular models of tractors (non-piston cooled) be fearful of imminent engine failure. I'm not suggesting that everyone drop their oil pans and remove cylinder heads and check piston/sleeve skirt clearance either. I'm not trying to diminish confidence in the 426 engine family. What I am doing, is sounding the alarm bell to seriously maintain cooling systems and their components and do everything possible to keep engine coolant temps low. It's heat that makes the pistons get tight in their sleeve bores. Keeping exhaust temps low also contributes to cooler pistons as well. The "426" and these old tractors will continue to live on !! They just need some faithful attention to keep things from going awry. That's all this post was intended to do. I get pretty passionate about some things when I feel it could have been prevented. |

Posted By: coggonobrien

Date Posted: 14 Feb 2026 at 6:18am

|

Posted By: DrAllis

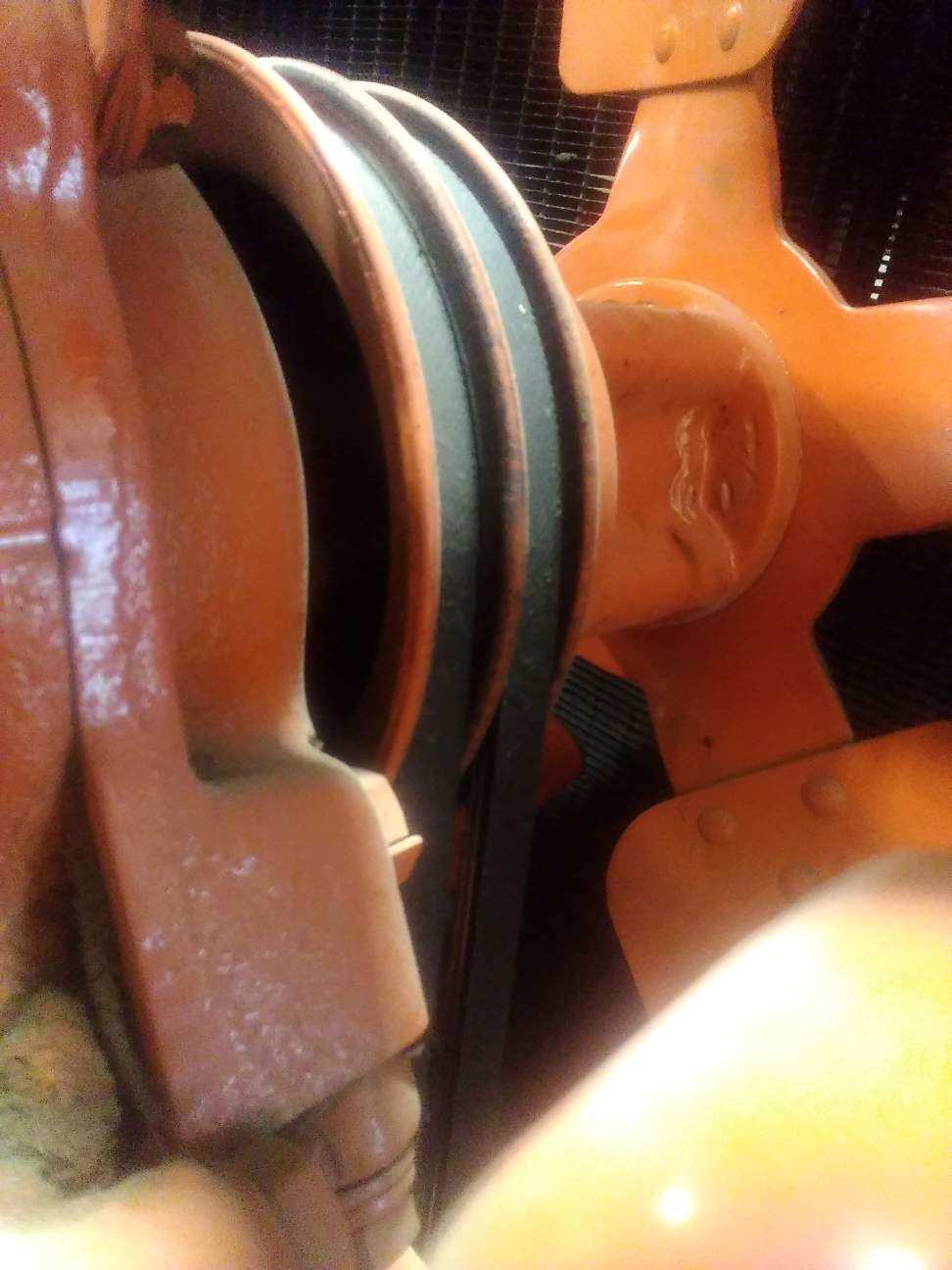

Date Posted: 14 Feb 2026 at 6:29am

| Thank you, David. Here are two pictures of the current 220 I'm working on. The 1/2" belts are bottomed in their grooves causing fan speed reduction and lower coolant flow which can lead to possible over heating on a warm day at 100% load. The alternator charging at 100% output can also have belt slipping issues. Changing to "B" width belts pretty much solves the slippage problem and especially on 50 year old pulleys. Another problem we have here is someone (not very knowledgeable) in the past has installed a fan spacer that moves the fan forward to within an inch of the radiator. This makes it impossible to work on and air flow is actually reduced, causing more potential engine over heating. This change may have been an effort to combat an over heating engine on a hot day?? One might think moving the fan closer to the radiator core would draw more air thru the radiator, but the reality is that's not the case. Max air flow is achieved when the tips of the fan blades are 50% in and 50% out of the shrouds edge. |

Posted By: AC7060IL

Date Posted: 14 Feb 2026 at 9:29pm

|

Yes DrAllis. One fan tip may even have a slight opposite bend to assist that science? A “Centrifugal effect” of airflow is created from rotating fan blades that forces air toward their fan blade tips, where air is then forced along 1” clearance of shroud which allows air to be pushed outward from shroud edges for a more rapid exit. It creates a good constant vacuum where minimal air has no/little chance to recirculate back inward. |

Posted By: Buddy2366

Date Posted: 19 Feb 2026 at 5:36pm

|

Been following this post and learning alot about the 220 tractor/3500 engine. Grew up farming on Allis Chalmers equipment in the 60's-80's. Used to dream as a boy sitting on a dealers lot wishing to someday run a 220. Thank you Dr Allis for your wealth of knowledge. Always wondered why the HP was set on 135, but yet some brochures I have show the 220 pulling an 8bottom on-land plow! With the piston cooling issue, I now understand more why the HP was kept at a minimum. My thoughts on this subject for what they are worth; what was the factory thermostat deg for these tractors? is it water getting too hot or Oil, or a combination of both? Would a more aggressive water pump move more water if one could be designed? How about an Oil pan such as what M & W designed for the JD 4020 with the cooling fins built in? How about a thicker radiator with an extra row of cores. I know a place in Arizona that custom builds about any radiator you can dream up. I know this is all very costly and maybe not even possible, but what does a fresh OH'd engine with minimum hrs cost to rebuild again. A robust 220 snorting 165-180hp with 6-16's would sure make some heads turn at Rantoul, IL in 27! Just my thoughts, so fire away.

|

Posted By: DrAllis

Date Posted: 19 Feb 2026 at 6:54pm

| I truly believe that if the piston skirt clearances were left as they were back when the tractor was new (.007" instead of today's .003" to .0035") there wouldn't be this problem. This didn't happen 50 years ago when these tractors were in their hey-day. So, what's changed??? Tighter clearances for number one. Worn out water pump/fan pulley's number two. And 1/2" fan belts that go to the bottom of the pulleys when the belts and pulleys are worn out. This requires constant belt re-tensioning to keep belt slippage from slowing down the fan and the water pump impeller speed. Any extra heat can cause this .003" skirt clearance to get tighter and then there's a problem. A cooler thermostat (180F standard) won't hurt but on a 90 degree day at 100% full load, the temps are still going to be closer to 200 degrees than 160 degrees. As far as the 135 PTO HP rating goes ?? That is what Milwaukee Sales personnel asked for. So, that's what they got. After the D-21 bull gear and axle bearing failures, they sure weren't going to set the new 220 at 160 HP. They hoped the problems at 135 HP would be zero and I think that's what happened. |

Posted By: Buddy2366

Date Posted: 19 Feb 2026 at 7:29pm

| Do you dare run fully synthetic engine oil in a 3500? How is the engine oil cooled in a 220? Is it possible to run an engine oil cooler in front of the radiator, with a larger radiator to boot? I stand corrected on the custom radiator manufacturing location. Its in Oregon instead of AZ. |

Posted By: DrAllis

Date Posted: 19 Feb 2026 at 7:32pm

| The engine already has an oil cooler on it. The engineering goal was to keep oil temps equal to coolant temps as it is a coolant operated type device. I see no problem with synthetic engine oil. |

Posted By: ranger43

Date Posted: 19 Feb 2026 at 8:18pm

| I have been following this post and I had a scoring issue on my 210 on an in-frame overhaul at around 100 hours. Never ran remotely hot. I did the overall, but spoke to several AC mechanics at the time.... 1997/98 timeframe and they were experiencing similar issues with some overhauls in both AC's and New Hollands. They conlcuded a clearance issue, but thought is was ring gap being too tight. I was/am a very amateur mechanic so I failed to measure ring gap, but never really determined the cause of my failure. I ended up putting in a reman shortblock and never had another issue to this day. |

Posted By: NEVER green

Date Posted: 20 Feb 2026 at 9:37am

|

I have brought block with sleeves still in it to a machine shop with computer run hone machine and remove a couple thousands, plus you get the high tech hone finish every one raves about now. ------------- 2-8050 1-7080 6080 D-19 modelE & A 7040 R50 |

AC7060IL wrote:

AC7060IL wrote: